Multi-stage spray treatment device for waste gas of printing and dyeing setting machine

The technology of a treatment device and a sizing machine is applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, etc., which can solve problems such as potential safety hazards of tail gas treatment equipment, and achieve the effect of reducing production costs and improving dust collection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

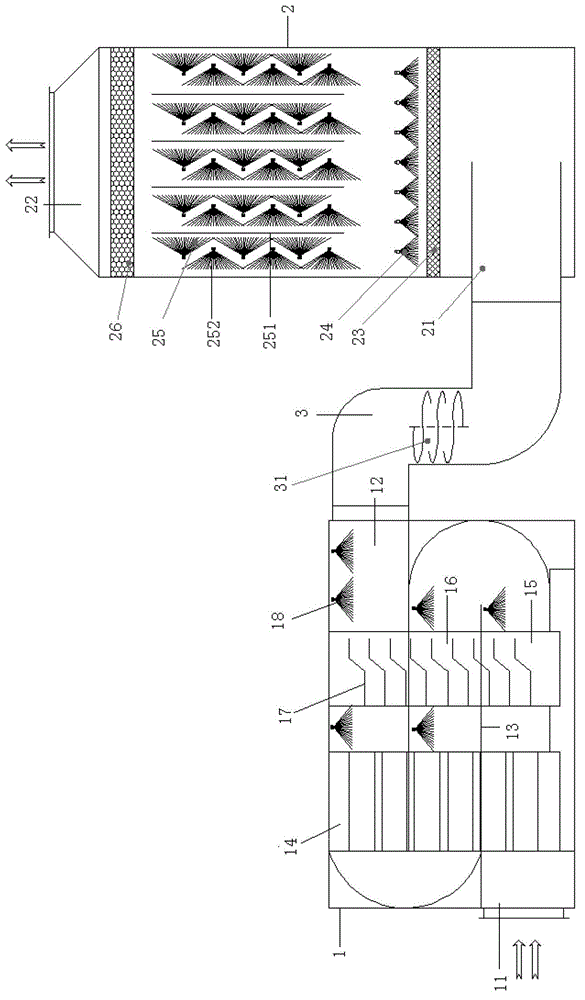

[0023] refer to figure 1 , printing and dyeing setting machine exhaust gas multi-stage spraying treatment device, including a clean room, the clean room is composed of a primary clean room 1 and a secondary clean room 2, one side of the lower end of the first clean room 1 is provided with a second An air inlet 11, the upper end of the other side is provided with a first air outlet 12; the bottom side of the secondary purification room 2 is provided with a second air inlet 21, and the top is provided with a second air outlet 22, the first air outlet 22 is provided An air outlet 12 is connected to the second air inlet 21 through a pipe 3;

[0024] The first-stage clean room 1 is divided into multi-layer clean areas by partitions 13, the partitions 13 are arranged in parallel and staggered up and down, and the positions where the upper and lower partitions are staggered are provided with outlets between adjacent clean areas. Air port 15 and air inlet 16, the left side of each de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com