Biological multienzyme cleaning agent and preparation method thereof

A cleaning agent and biological technology, applied in the direction of detergent compounding agent, chemical equipment and method, detergent composition, etc., can solve the problems of easy inactivation and hydrolysis of enzymes, achieve less residue, good compatibility, and uniform texture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

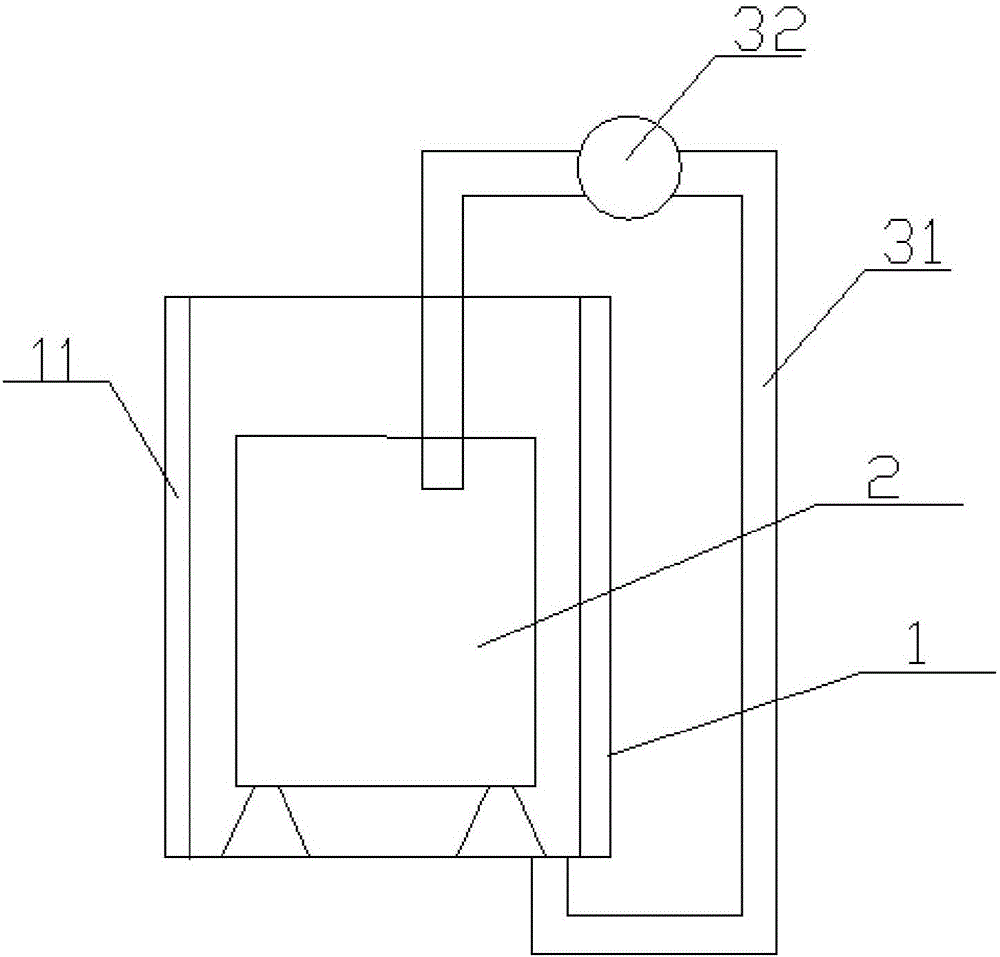

Method used

Image

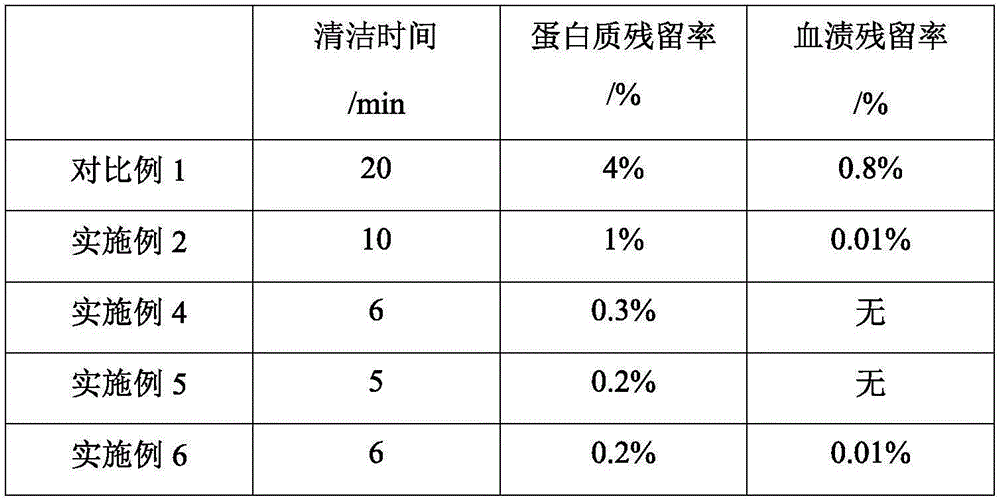

Examples

Embodiment 1

[0034] A biological multi-enzyme cleaning agent, comprising the following raw materials in parts by weight: 15.5 parts of deionized water, 10 parts of citric acid, 20 parts of propylene glycol, 10 parts of sodium hydroxide, 10 parts of protease, 6 parts of amylase, 4 parts of lipase part and 4 parts of cellulase, 20 parts of nonionic surfactants and 0.5 part of preservative, and said preservative is Kethon.

[0035] The present invention also provides a technical solution:

[0036] A preparation method of biological multi-enzyme cleaning agent, in parts by weight, comprises the following steps:

[0037] Step 1. Pump 15.5 parts of deionized water into the stirring pot, then add 10 parts of citric acid, 20 parts of propylene glycol, 10 parts of sodium hydroxide and 20 parts of non-ionic surfactant in turn, and heat the stirring pot to 70 °C to Stir at a speed of 50r / min for 25min;

[0038] Step 2, then lower the temperature of the stirring pot to 45°C, add 10 parts of protease...

Embodiment 2

[0040] A biological multi-enzyme cleaning agent, comprising the following raw materials in parts by weight: 94 parts of deionized water, 1 part of citric acid, 1 part of propylene glycol, 1 part of sodium hydroxide, 1 part of protease, 0.1 part of amylase, 0.1 part of lipase part and 0.1 part of cellulase, 2 parts of nonionic surfactant and 0.05 part of preservative, and the preservative is chitosan.

[0041] The present invention also provides a technical solution:

[0042] A preparation method of biological multi-enzyme cleaning agent, in parts by weight, comprises the following steps:

[0043] Step 1. Pump 94 parts of deionized water into the stirring pot, then add 1 part of citric acid, 1 part of propylene glycol, 1 part of sodium hydroxide and 2 parts of non-ionic surfactant in sequence, and heat the stirring pot to 50 °C to Stir at a speed of 35r / min for 15min;

[0044]Step 2, then lower the temperature of the stirring pot to 35°C, add 1 part of protease, 0.1 part of a...

Embodiment 3

[0046] A biological multi-enzyme cleaning agent, comprising the following raw materials in parts by weight: 65 parts of deionized water, 4 parts of citric acid, 10 parts of propylene glycol, 4 parts of sodium hydroxide, 5 parts of protease, 3 parts of amylase, 2 parts of lipase 2 parts and 2 parts of cellulase, 12 parts of nonionic surfactants and 2 parts of preservatives, and described preservatives are Kethon.

[0047] The present invention also provides a technical solution:

[0048] A preparation method of biological multi-enzyme cleaning agent, in parts by weight, comprises the following steps:

[0049] Step 1. Pump 65 parts of deionized water into the stirring pot, then add 4 parts of citric acid, 10 parts of propylene glycol, 4 parts of sodium hydroxide and 12 parts of non-ionic surfactant in turn, and heat the stirring pot to 60 °C to Stir at a speed of 40r / min for 20min;

[0050] Step 2, then lower the temperature of the stirring pot to 40°C, add 5 parts of protease...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com