Composite aramid paper with high dielectric property

A kind of aramid paper, high dielectric technology, used in special paper, non-polymer adhesive additives, synthetic cellulose/non-cellulose material pulp/paper, etc., can solve the problems of easy loss of chemical additives and environmental pollution. , to achieve the effect of easy mass production, high breakdown strength, and reduced movement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

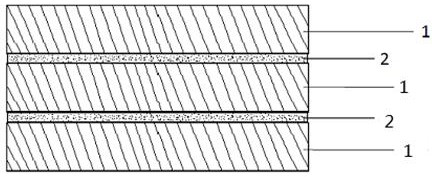

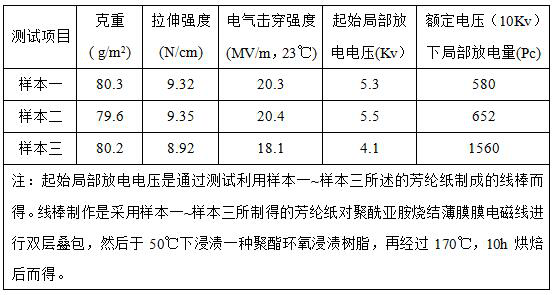

[0047] In this embodiment, comparative experiments have been carried out, such as figure 1 As shown, the composite aramid paper includes three layers of single-layer aramid paper, and each adjacent two layers of single-layer aramid paper are bonded by a high-temperature-resistant adhesive layer 2 . Among them, the single-layer aramid paper has a grammage of 20g / m 2 meta-aramid base paper, in which fibrids account for 51 parts, chopped fibers account for 49 parts, and the tightness is 0.36g / cm 3 , the high temperature resistant adhesive layer 2 is made by the following two methods respectively:

[0048] 1. Blend 100 parts of high-temperature resistant epoxy adhesive, 10 parts of nano-alumina filler, 50 parts of toluene and 0.2 part of titanate, stir at high speed and disperse evenly to make a mixed solution of high-temperature resistant adhesive;

[0049] 2. Blend 100 parts of high-temperature resistant epoxyimide adhesive, 10 parts of nano-silica filler, 50 parts of toluene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com