Multifunctional valve and multifunctional valve combination valve

A multi-functional valve and combined valve technology, applied in multi-way valves, valve details, valve devices, etc., can solve the problems of piston and cylinder end cover wear, piston and cylinder end cover damage, piston cylinder short service life, etc. , to avoid collision wear, increase resistance and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

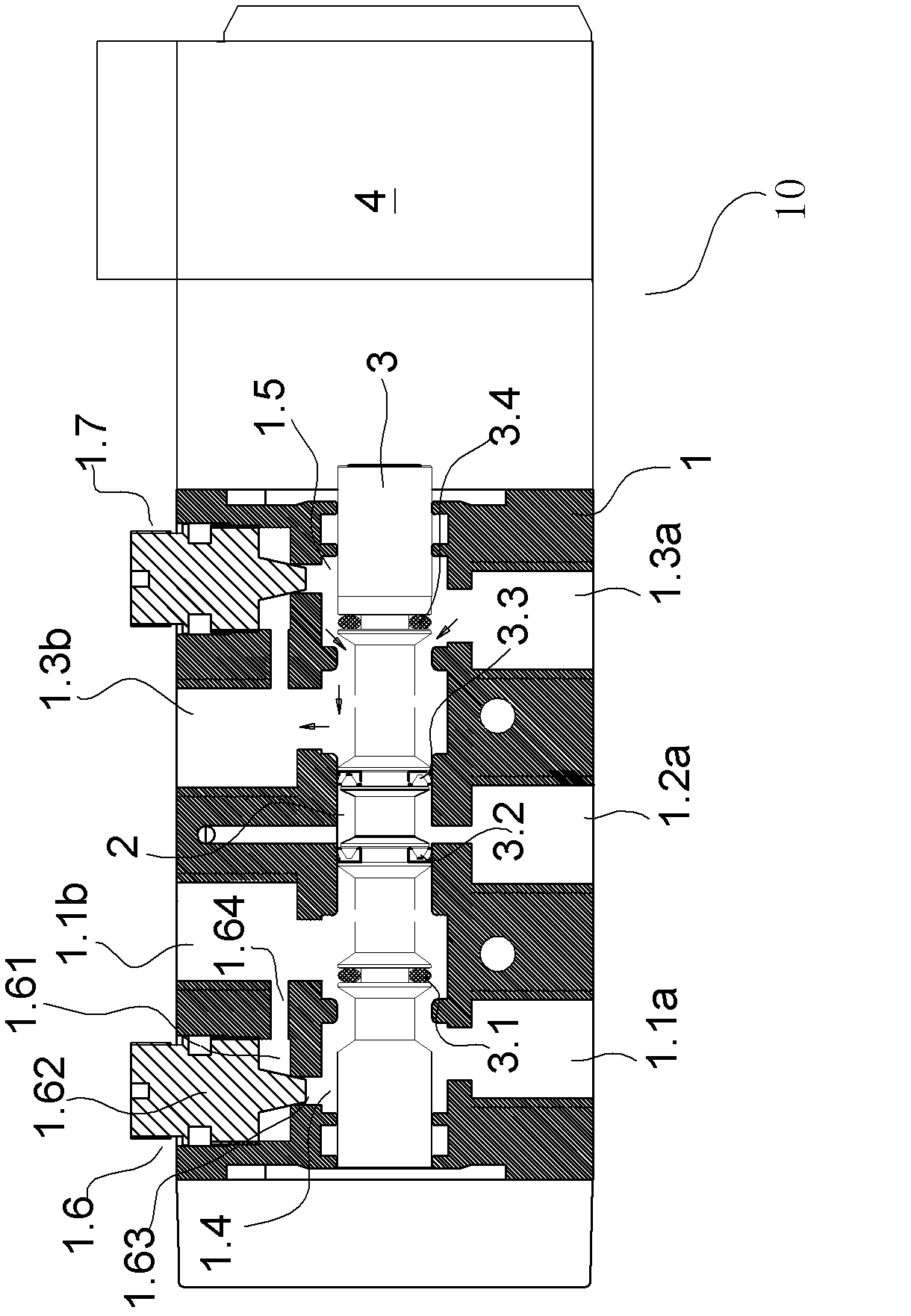

[0025] Such as figure 1 As shown, the multifunctional valve 10 includes a valve body 1 with a valve cavity 2 inside the valve body, and a valve stem 3 installed in the valve cavity 2, so that the valve body 1 is provided with an intermediate inlet 1.2 for the pressure medium to enter. a and the left inlet 1.1a and right inlet 1.3a for the pressure medium to enter, the other side of the valve body 1 is provided with the left outlet 1.1b and the right outlet 1.3b for the pressure medium to discharge: the left inlet 1.1a and the valve cavity The left sub-chamber 1.4 in 2 is connected, the right inlet 1.3a is connected with the right sub-chamber 1.5 in the valve chamber 2, the left sub-chamber 1.4 is connected with the left outlet 1.1b through the throttle valve 1.6, and the right sub-chamber 1.5 is connected through the throttle valve 1.7 It communicates with the right exit 1.3b.

[0026] The throttle valve 1.6 is an adjustable throttle valve that can adjust the flow rate. The v...

Embodiment 2

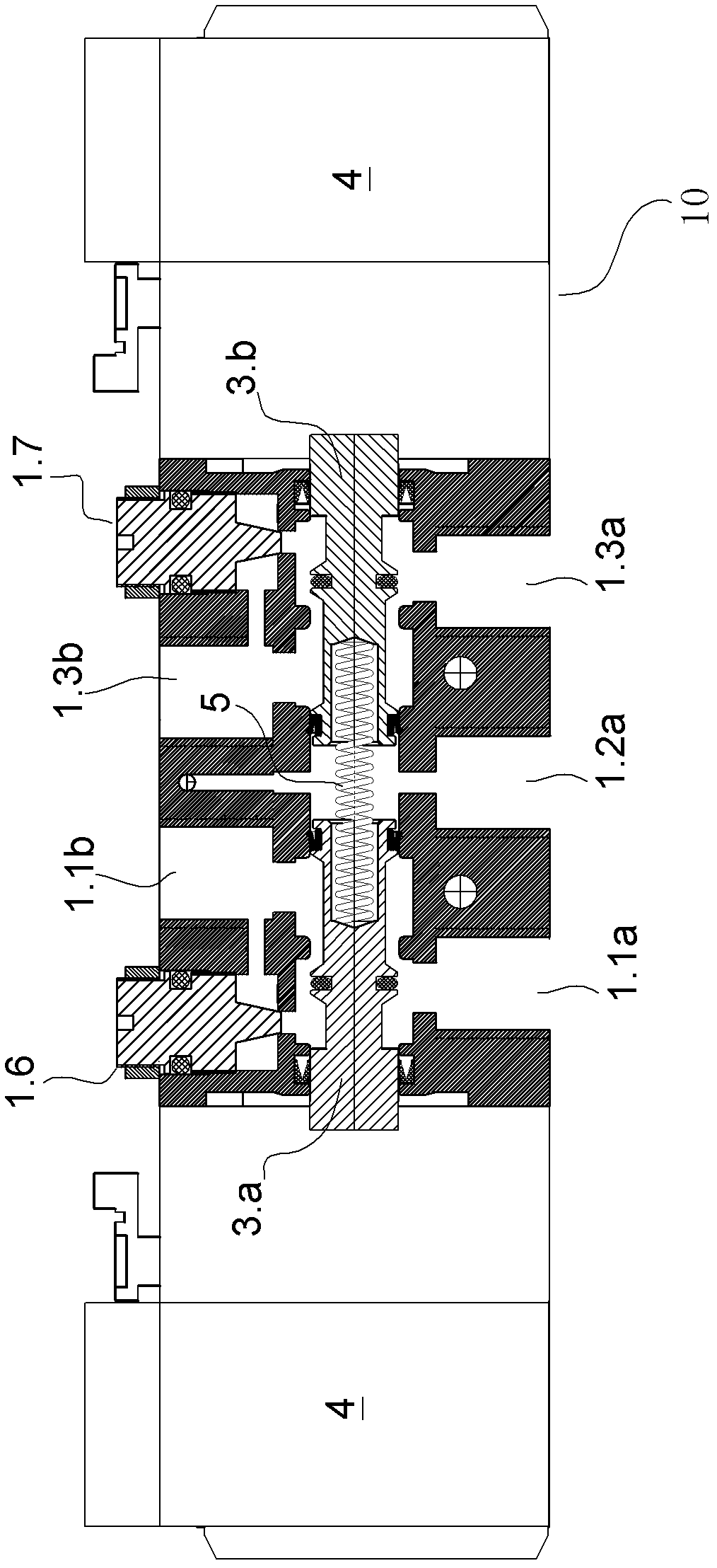

[0030] Such as figure 2 As shown, in this implementation example, the valve stem 3 is divided into a left valve stem 3.a and a right valve stem 3.b, and a left and right valve stem is arranged between the left valve stem 3.a and the right valve stem 3.b. The elastic part 5 of motion, others are similar to embodiment example the same.

Embodiment 3

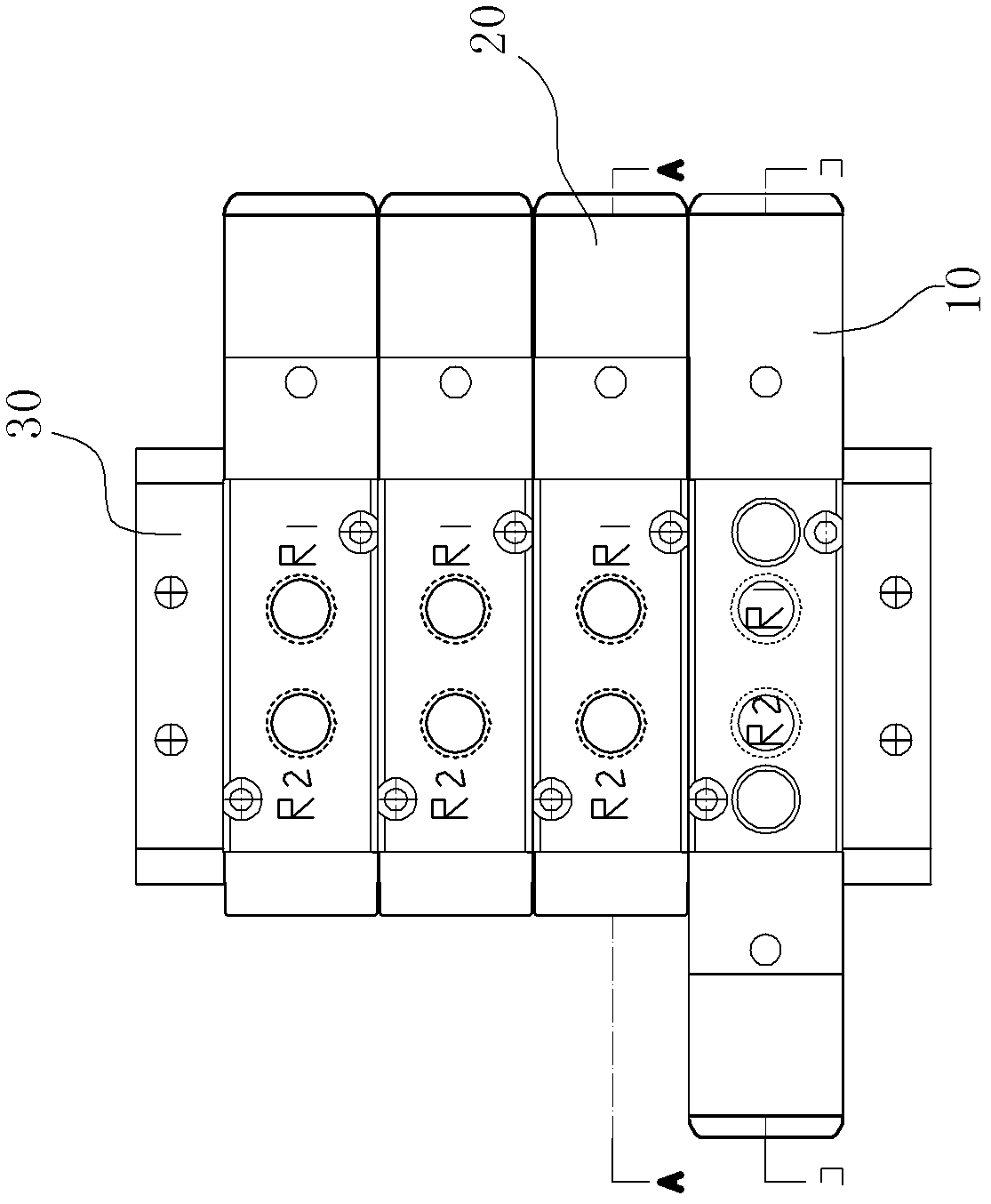

[0032] Such as image 3 As shown, a combined valve or valve island, which includes a multifunctional valve 10 in Embodiment 1 or 2, the specific structure is described in Embodiment 1, and will not be repeated here;

[0033] Three control valves 20;

[0034] and a manifold 30;

[0035] The left port 20.1b and the right port 20.3b on one side of the steering reversing valve 20 are respectively connected to the left chamber 40.1 and the right chamber 40.2 of the piston cylinder 40, while the left return port 20.1a and the middle inlet on the other side of the steering reversing valve 20 20.2a and the right return port 20.3a are respectively connected to the left flow channel 30.1, the middle flow channel 30.2 and the right flow channel 30.3 of the manifold 30;

[0036] The left inlet 1.1a, the middle inlet 1.2a and the right inlet 1.3a of the multi-function valve 10 are respectively connected to the left flow channel 30.1, the middle flow channel 30.2 and the right flow channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com