Patents

Literature

33results about How to "Improve desulfurization reaction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for composite desulfurization of molten iron

The invention relates to desulfurizing process of molten iron, which belongs to metallurgy area of iron and steel. The invention molten iron double desulfurization method adopts rotary-type sprayer with agitator on the nozzle. Rotating spray of nozzle cooperates with agitation of agitator to desulfurize molten iron, in which rotary-type sprayer jets desulfurizer into the molten iron while agitator stirs the molten iron. Meanwhile, another desulfurizer CaO is released to molten iron from the top of hot-metal bottle or sack. CaO has the function of desulfurizating and thickening desulfurizing slag, which saves densifier compared with present technology. When sprayer jets desulfurizer, nitrogen is adopted as carrier gas and dense-phase is adopted to transport desulfurizer, which comprises anyone or combination of more than two of Na2O, CaO, CaC2 and Mg and takes the formation of powder. This invention has the following properties: perfect effect of desulfurizating (sulfur content of molten iron can drop to <=0.005% after desulfurizing process), low temperature drop (approaching <=1 DEG C / min), low cost of desulfurizer (0.2-0.5kg / tmolten iron) and good comprehensive economic effect (especially adapting to molten iron desulfurizating in mini-steel plant).

Owner:CENT IRON & STEEL RES INST

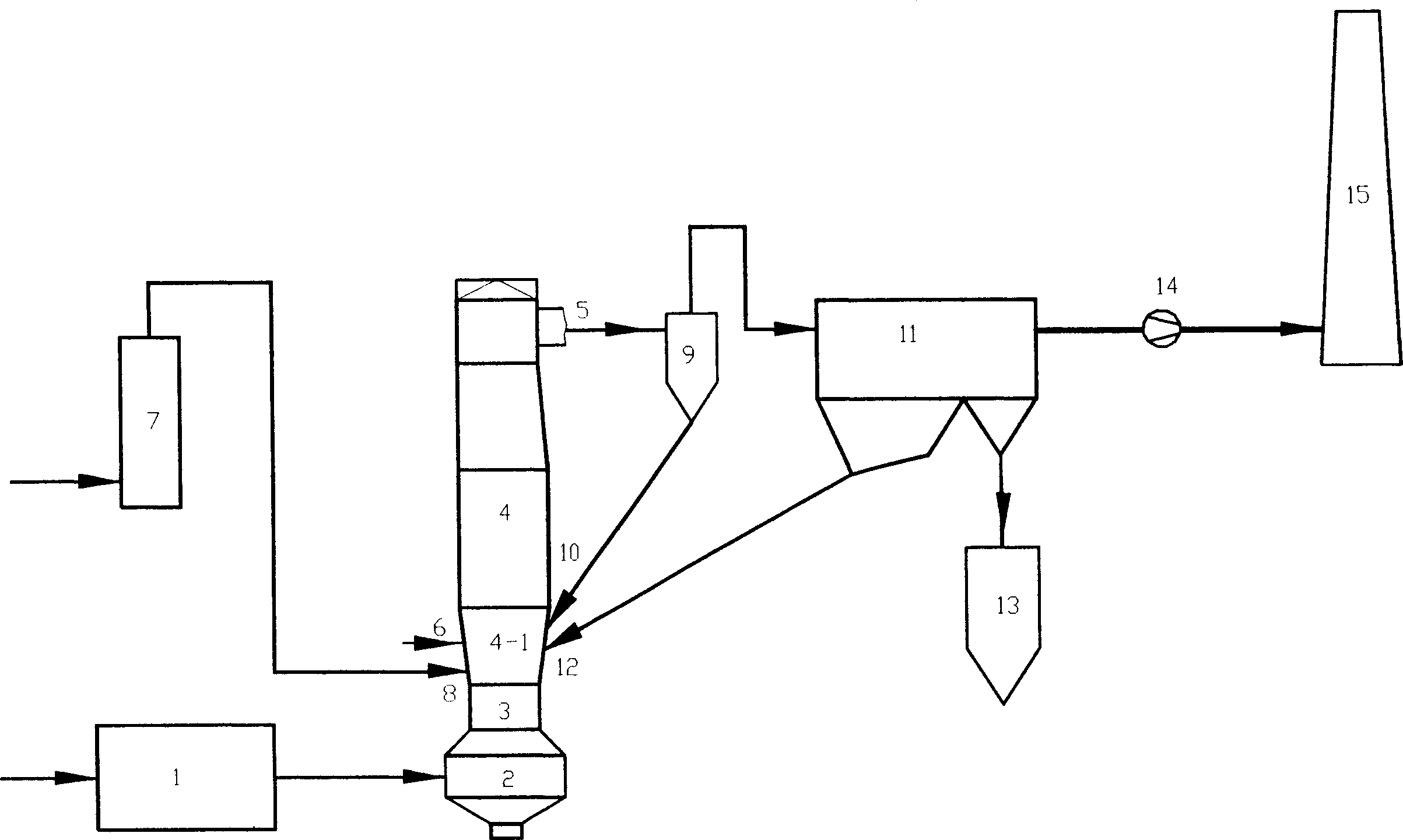

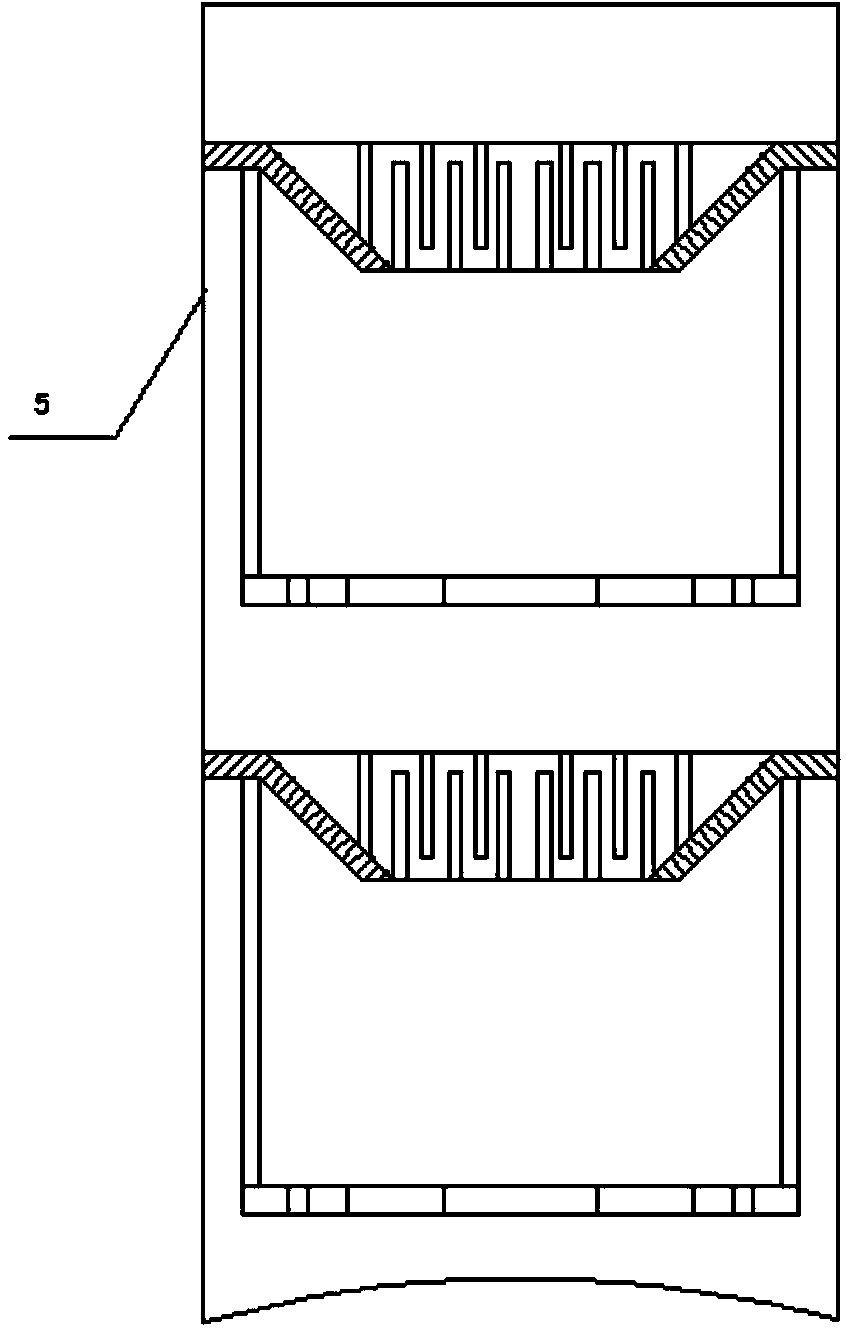

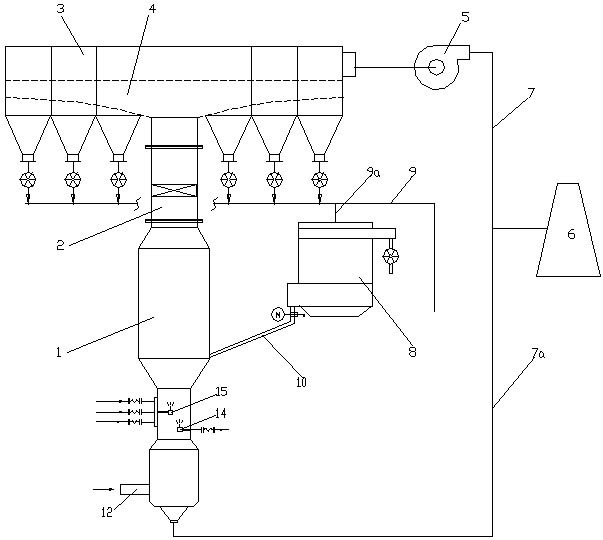

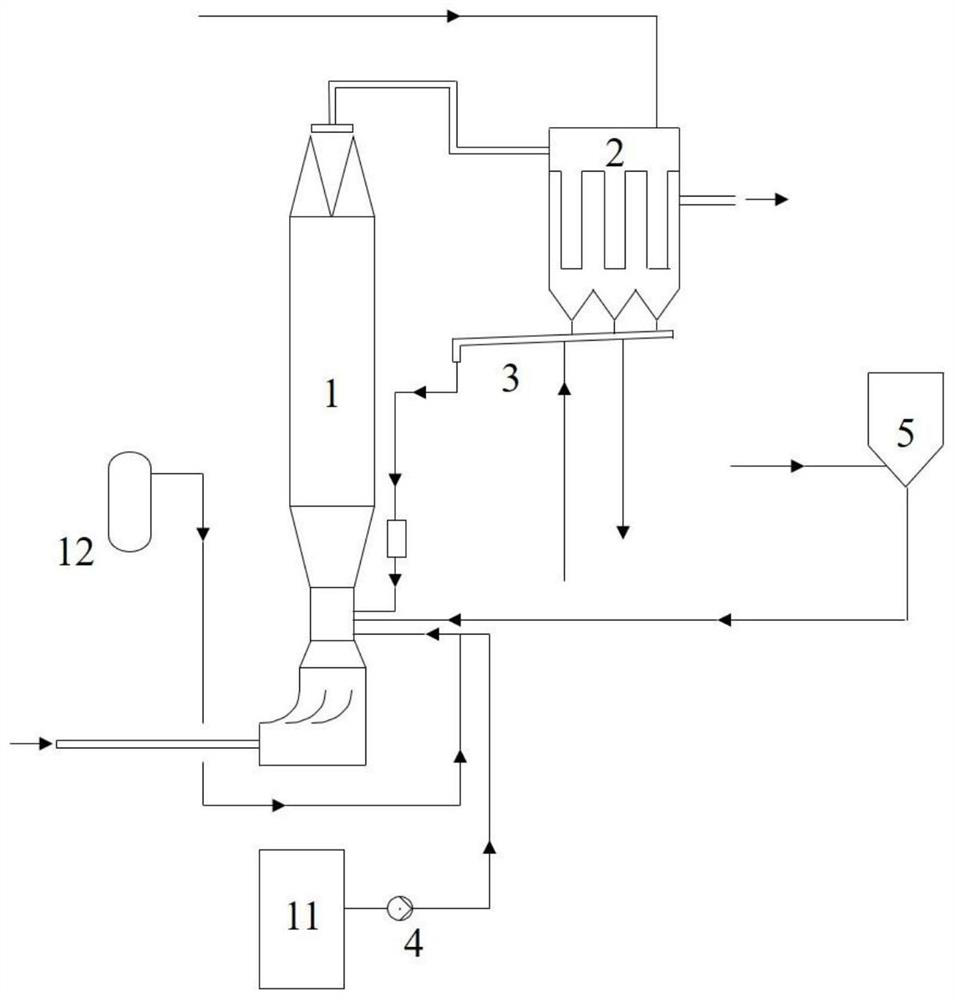

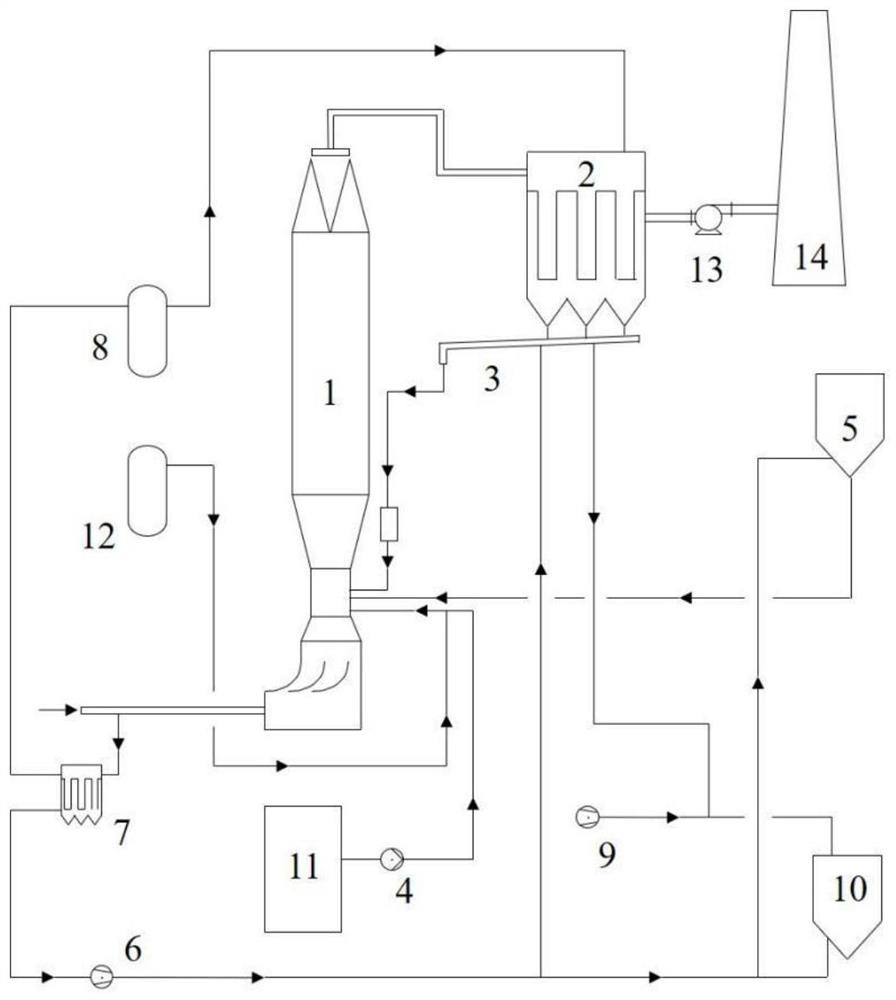

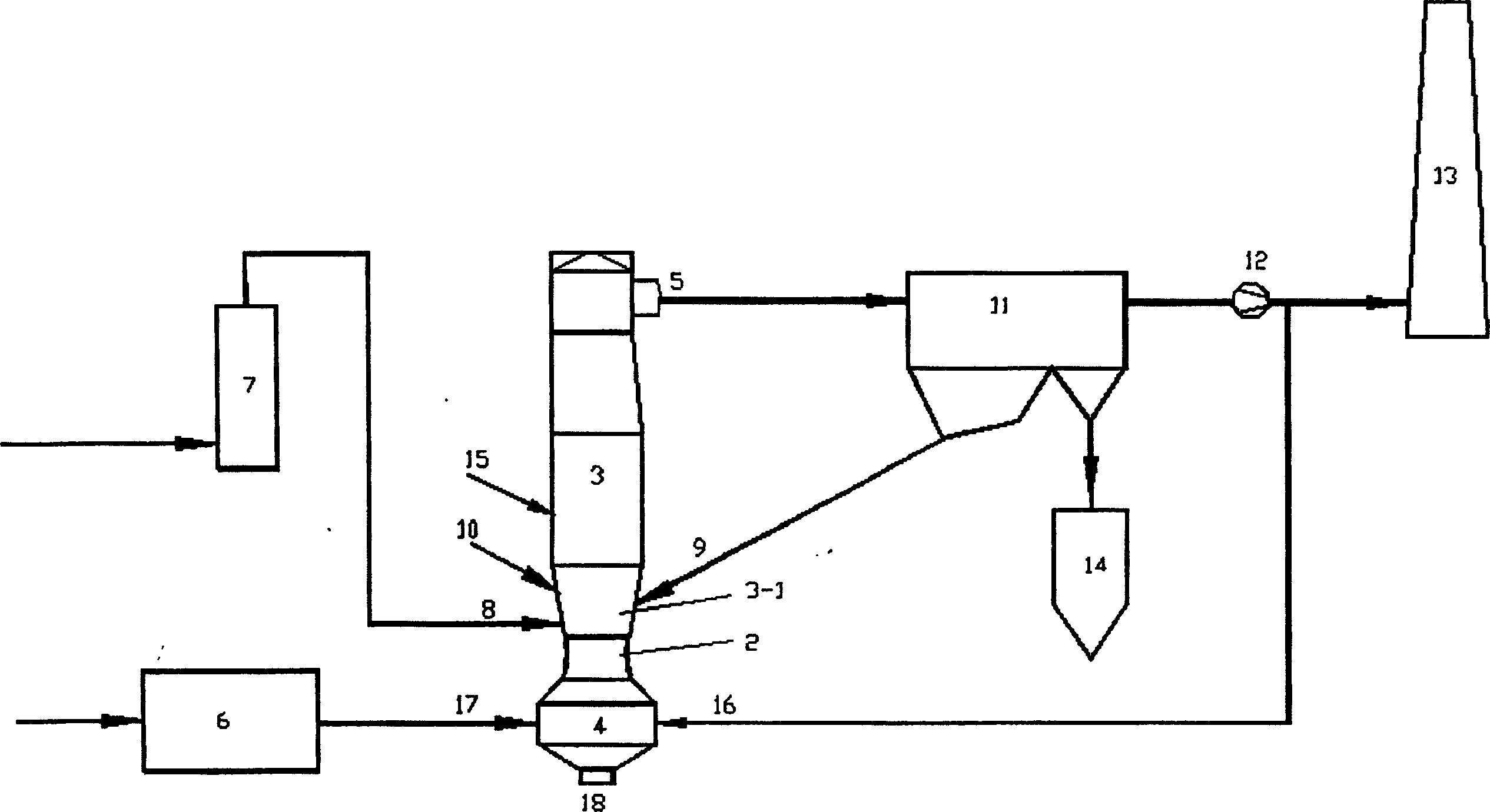

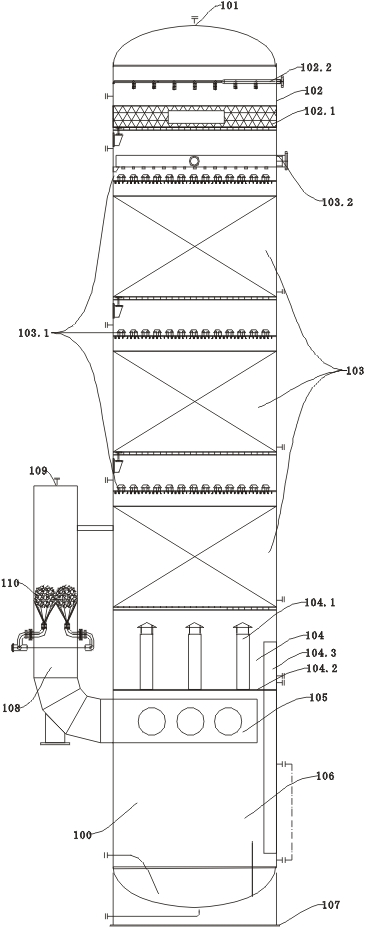

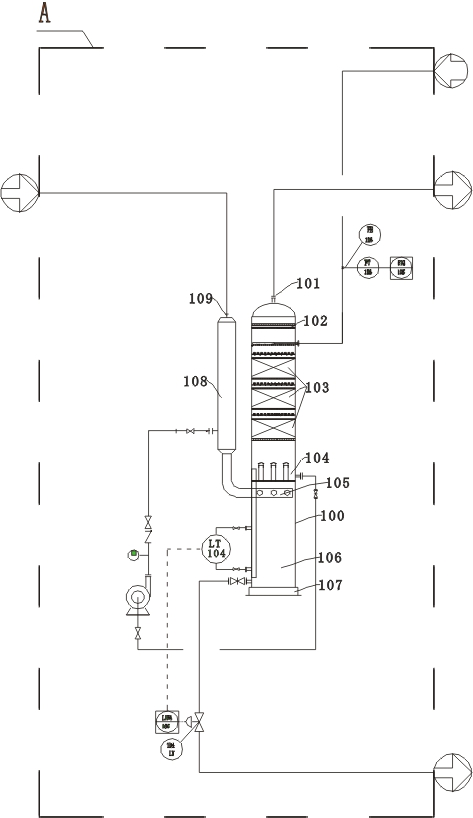

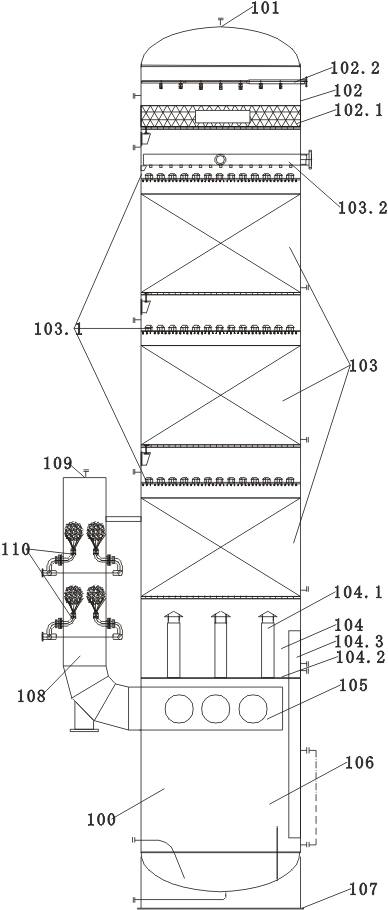

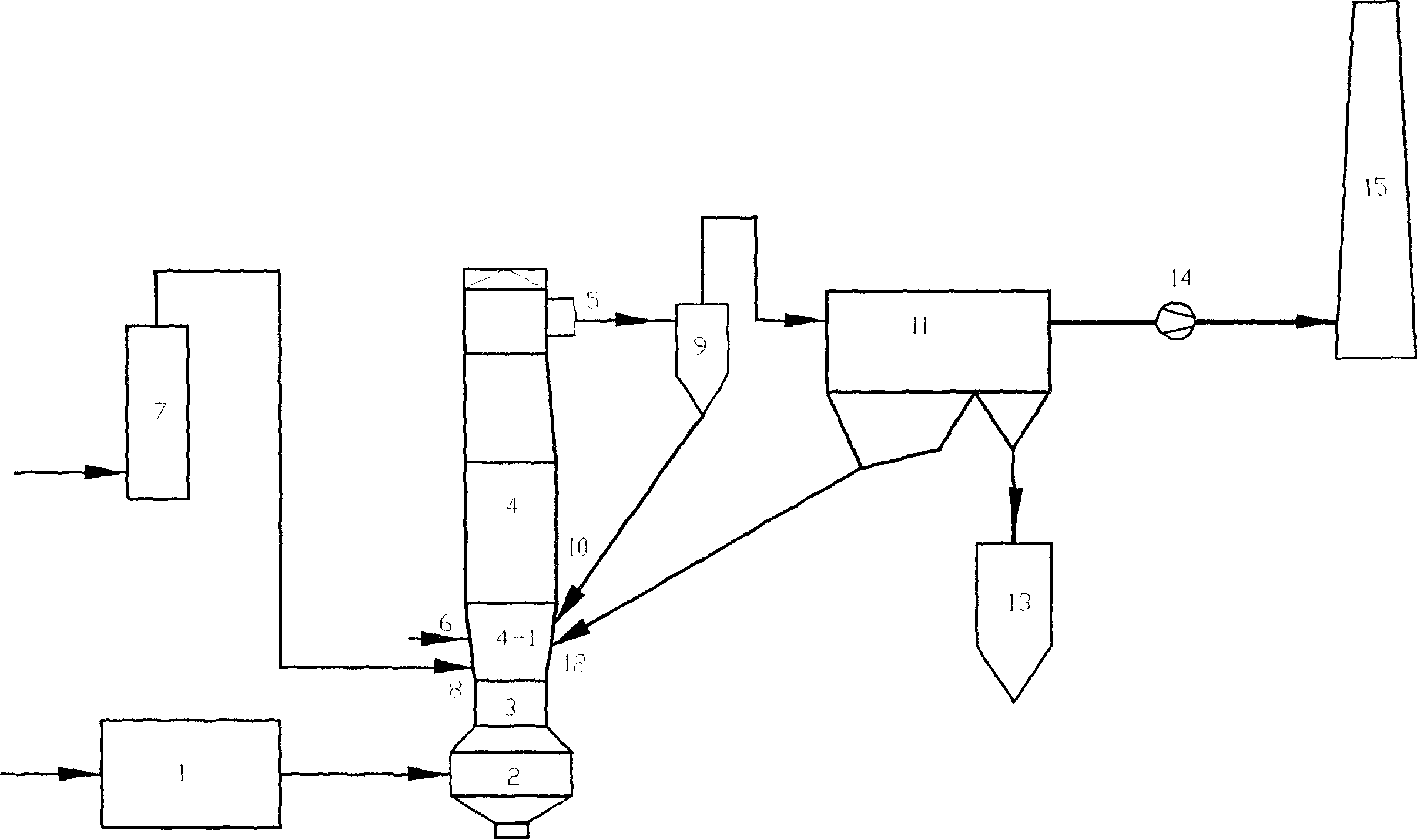

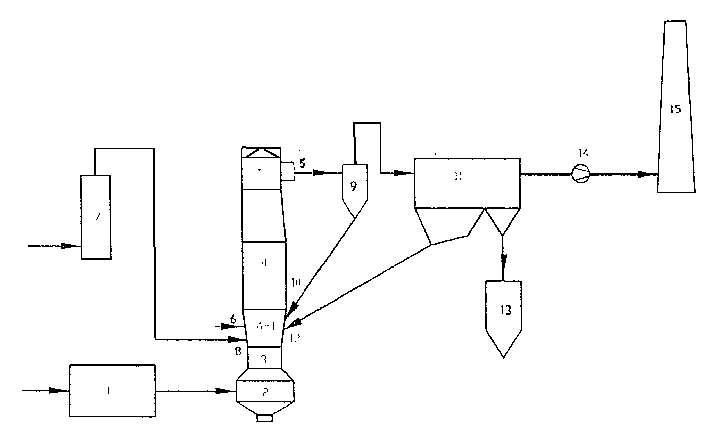

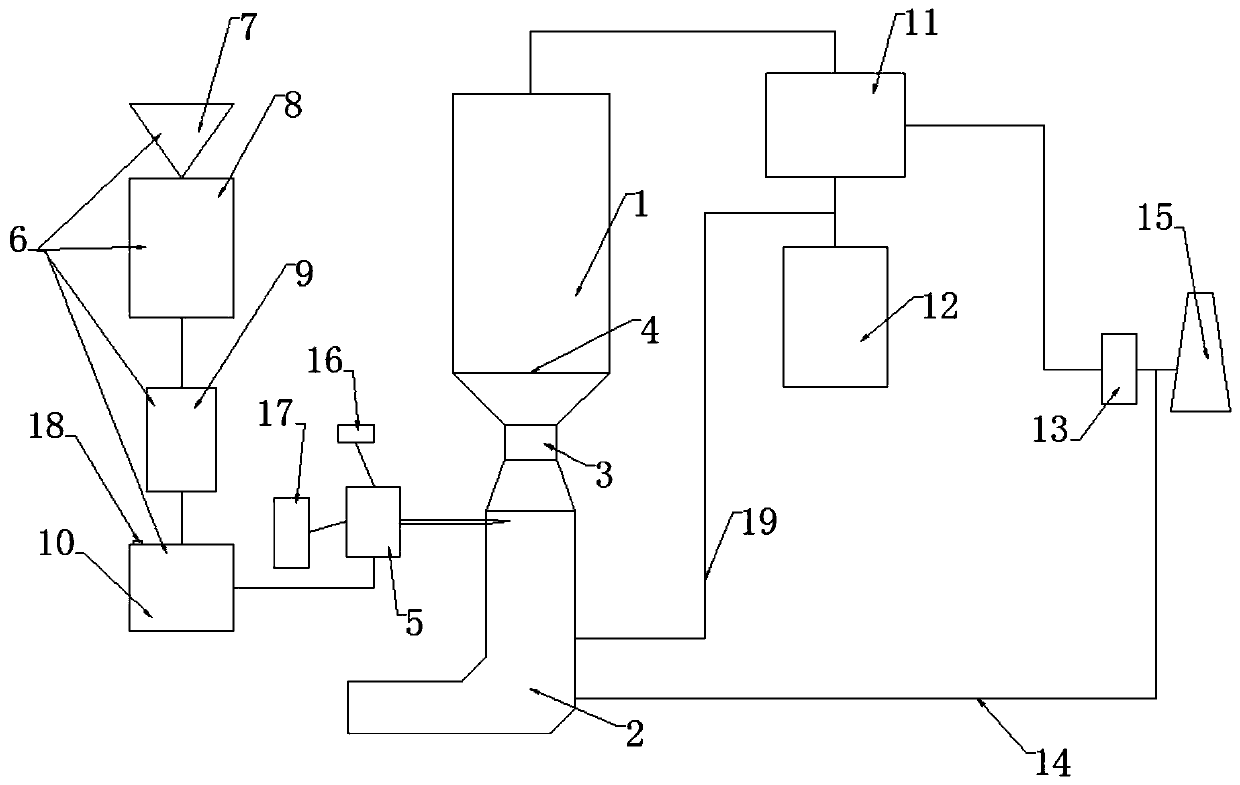

Smoke desulfurizing process by circulation fluid state dry method of layered feed back

The present invention relates to external grain re-circulating technology in large circular fluidizing dry fume desulfurizing system. The desulfurizing process includes preparing desulfurizing agent, desulfurizing reaction inside the desulfurizing reaction tower and external desulfurizing agent grain separation and re-circulation. In the external grain re-circulation, the returned material is two-stage separated and re-circulated, the grains separated by the first stage and the second stage desulfurizing agent grain separator are fed to the fluidizing region in the lower part of the desulfurizing reaction tower separately through different re-circulation inlets, resulting in raised desulfurizing agent grain utilization and desulfurizing reaction efficiency. Compared with available technology, the present invention has much higher fume dedusting efficiency, high desulfurizing efficiency up to 92 % at Ca / S of 1.1-1.3, less adhesion and blocking in the lower desulfurizing tower part and lowered load of the desulfurizing agent grain separator.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

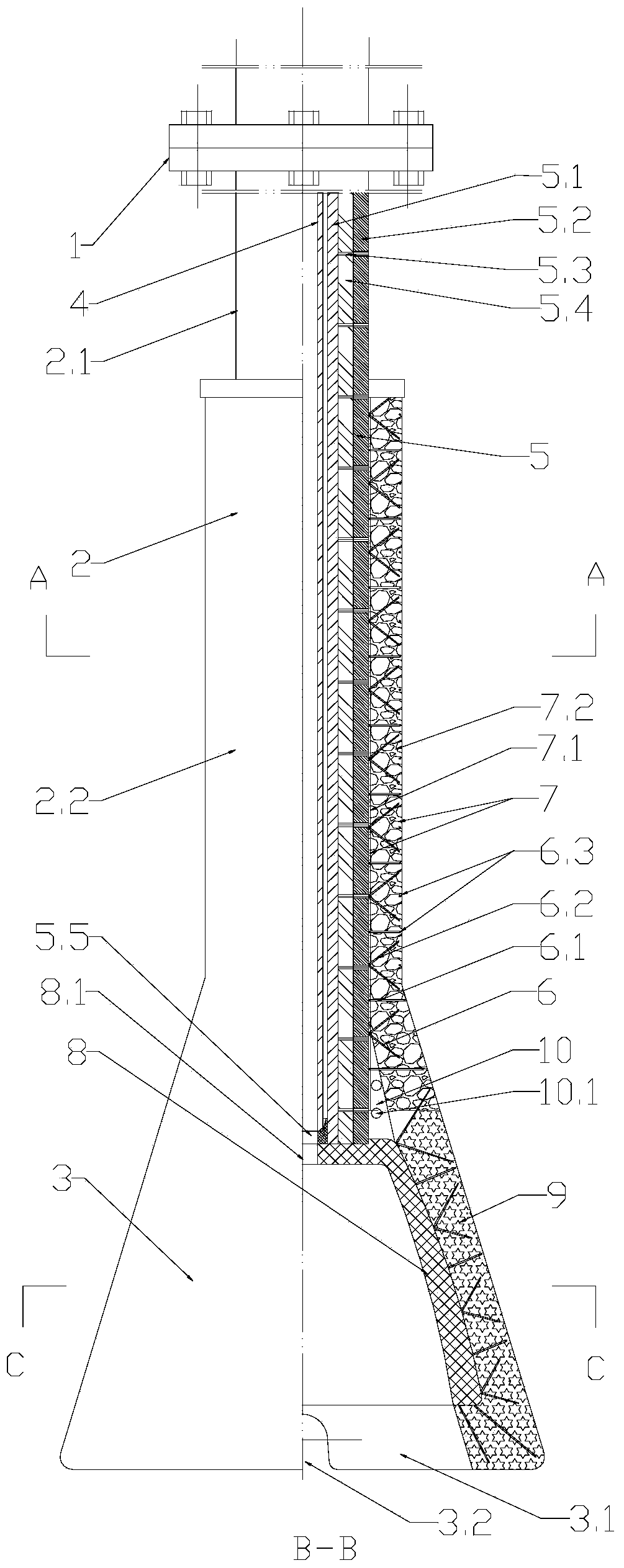

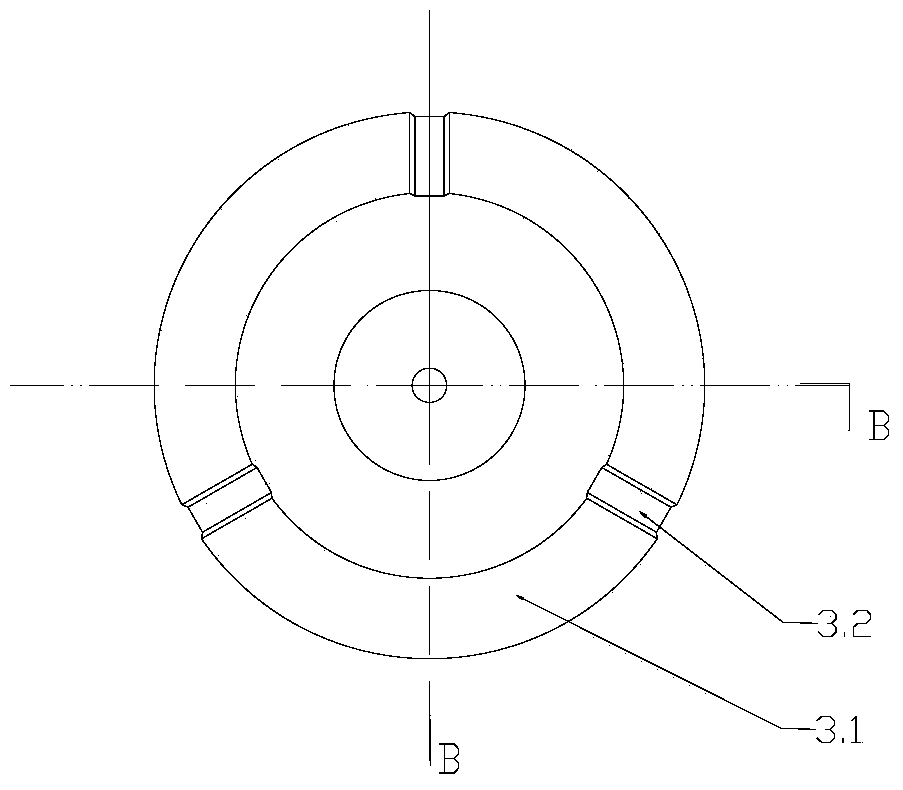

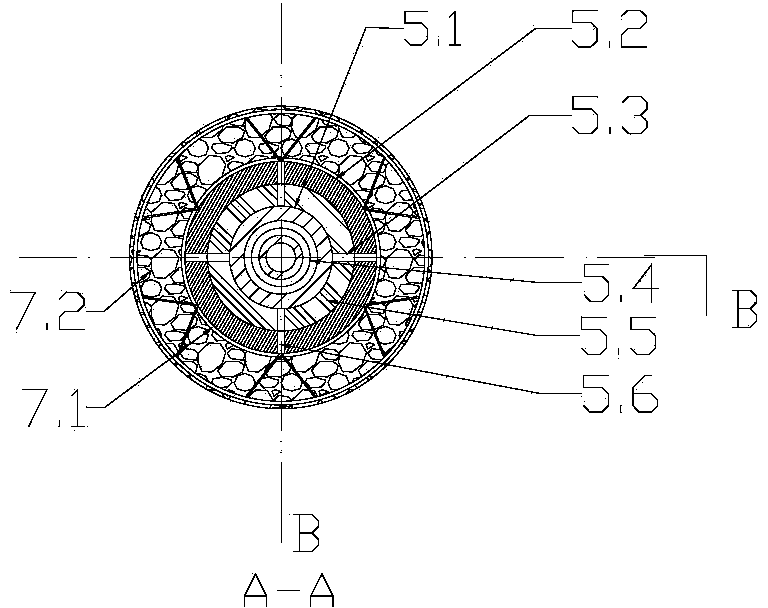

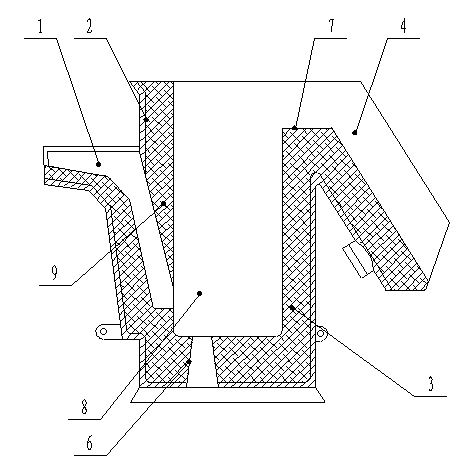

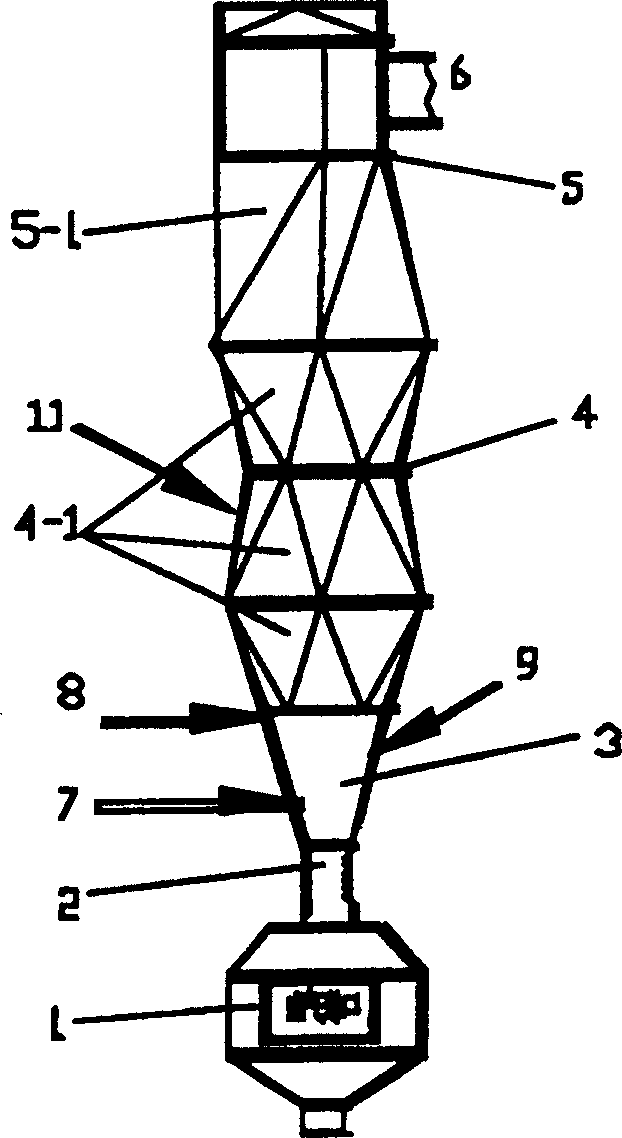

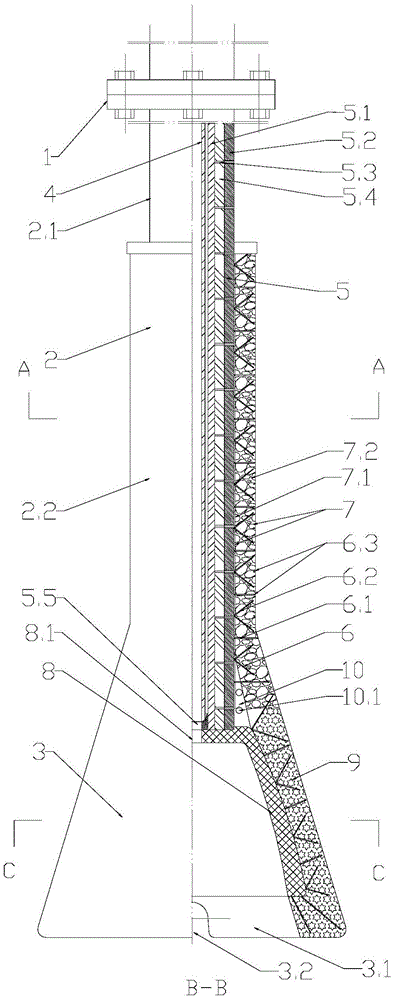

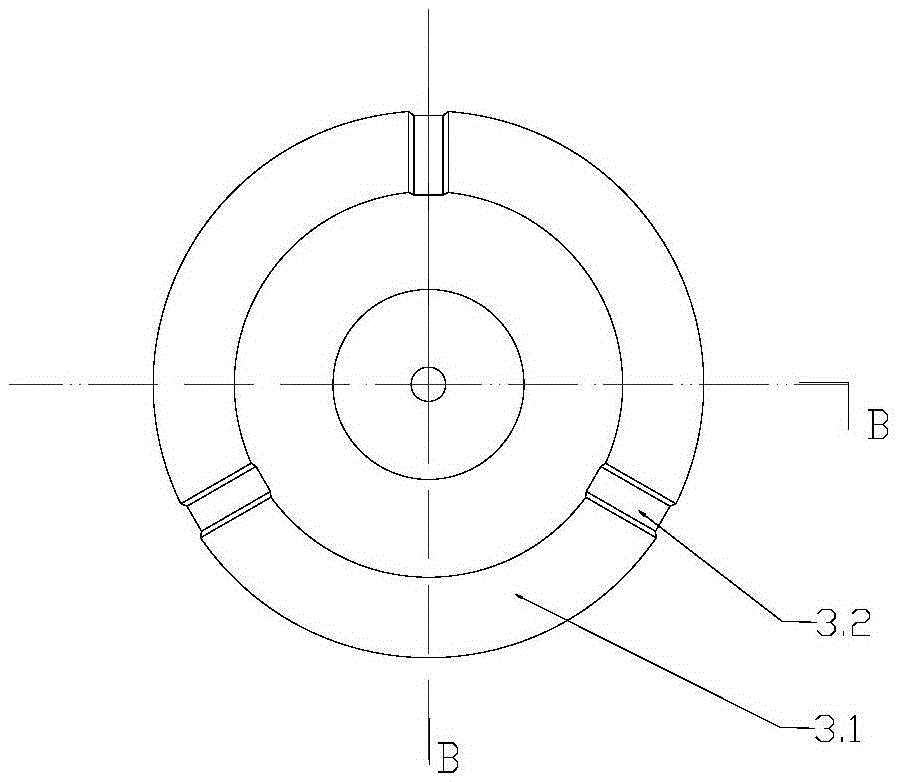

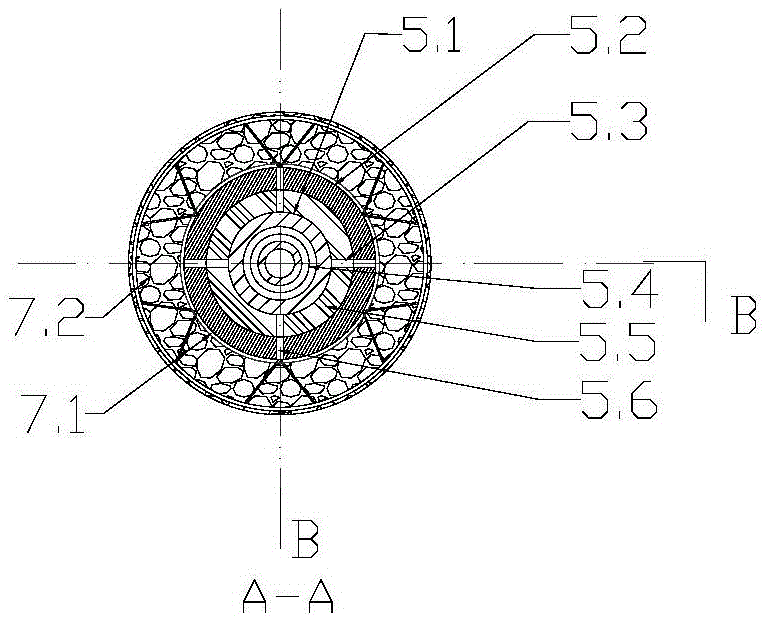

Molten iron pure spray particle magnesium desulfurization spray gun with vaporizing chamber in spearhead and preparation method of molten iron pure spray particle magnesium desulfurization spray gun

The invention discloses a molten iron pure spray particle magnesium desulfurization spray gun with a vaporizing chamber in a spearhead. The molten iron pure spray particle magnesium desulfurization spray gun comprises a connecting flange, a gun-barrel and a spearhead blowing vaporizing chamber, which are sequentially connected and communicated with each other, wherein the spearhead blowing vaporizing chamber is sequentially composed of a vaporizing chamber bell jar, an anchoring part group and a refractory castable lining from inside to outside; a bottom skirt is arranged at the lower end of the vaporizing chamber bell jar; and a plurality of air outlets are evenly formed in the bottom skirt in an emission shape. The method comprises the following steps: selecting a metal material to process and fabricate each component of the spray gun and removing rust for later use according to structural parameters of the spray gun; sequentially preparing a gun core and the vaporizing chamber bell jar; connecting the gun core and the vaporizing chamber bell jar by welding; and welding a reinforcing rib plate in a gap among the lower end of the gun core, the top of the vaporizing chamber bell jar and the refractory castable lining; and finally welding the anchoring part group, and pouring to obtain the spray gun. Compared with a conventional vaporizing chamber spray gun, the molten iron pure spray particle magnesium desulfurization spray gun disclosed by the invention has the advantages of being simple in structure, stable to blow, low in cost, efficient in desulfurization, long in service life and the like.

Owner:武汉钢铁有限公司

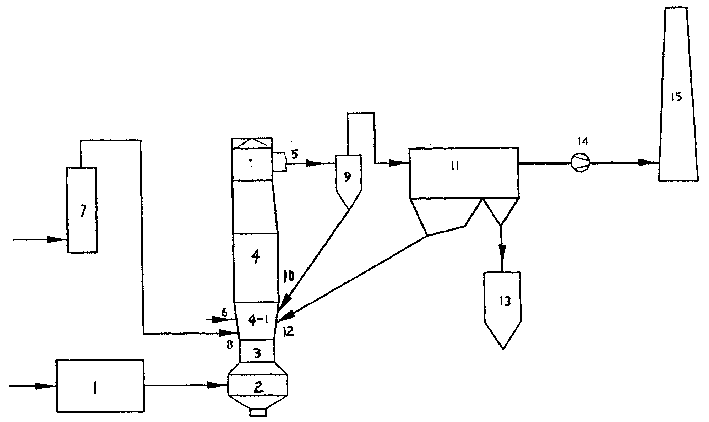

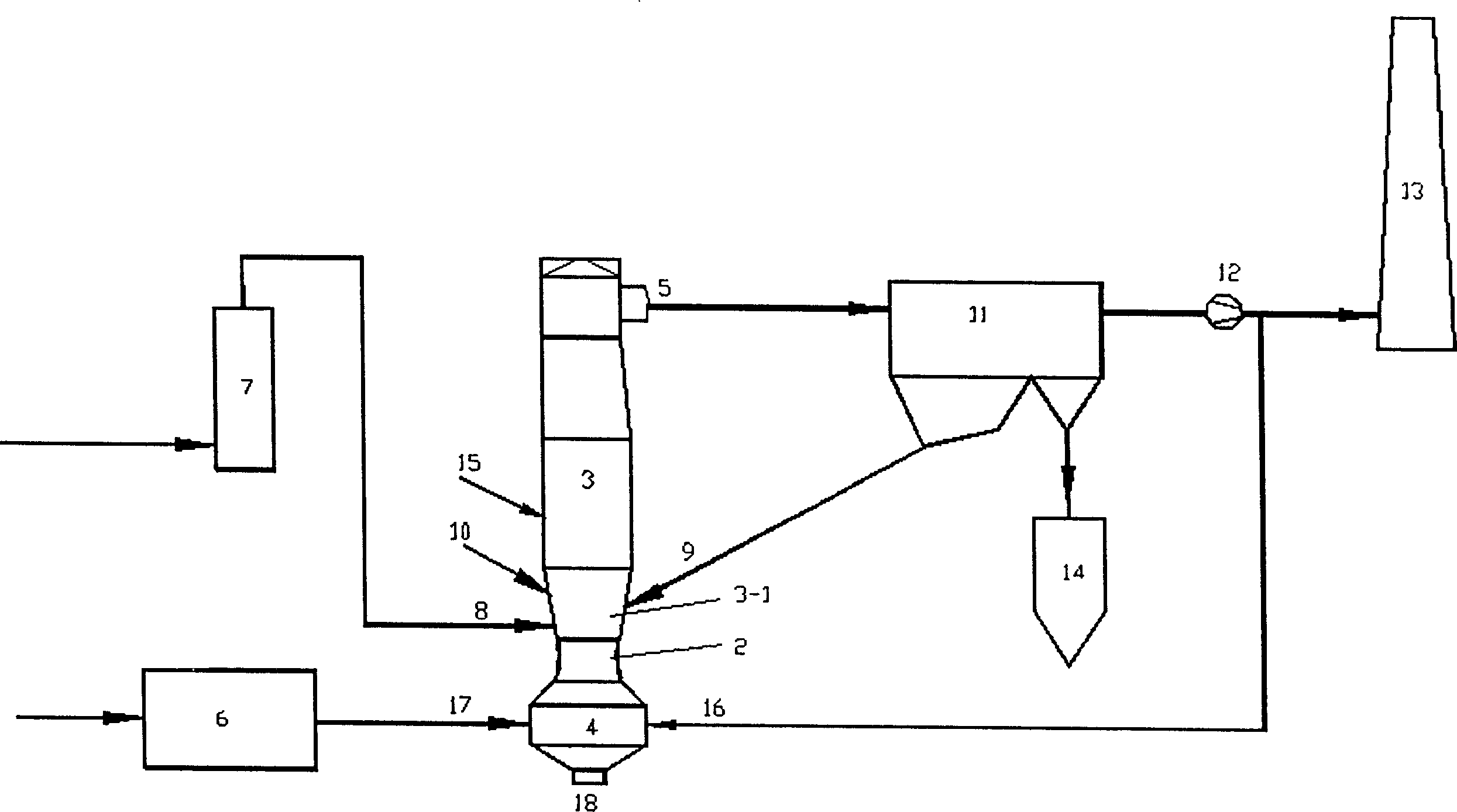

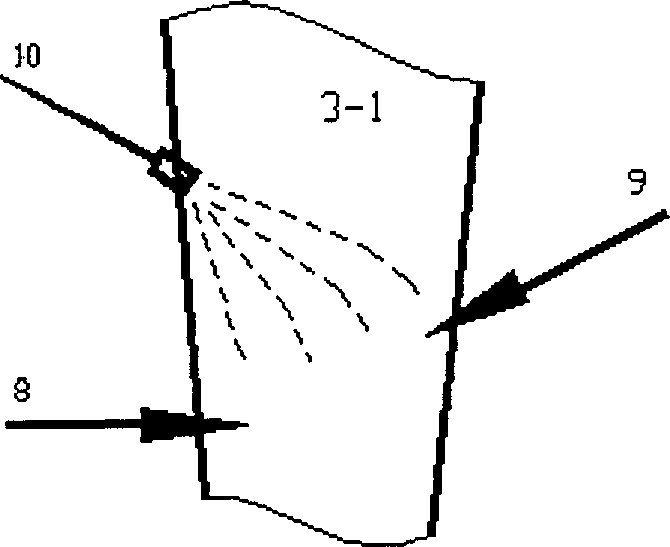

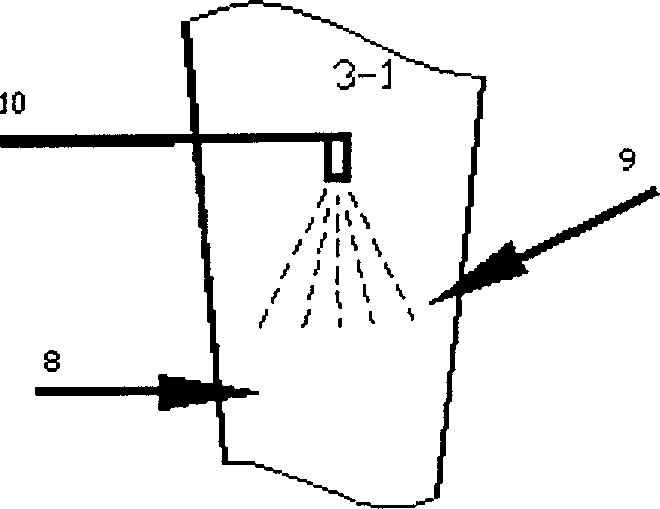

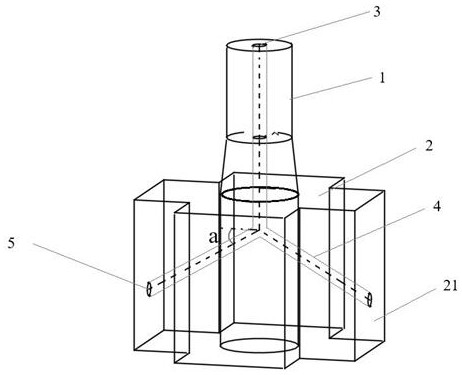

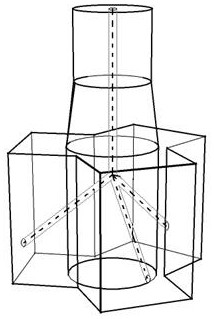

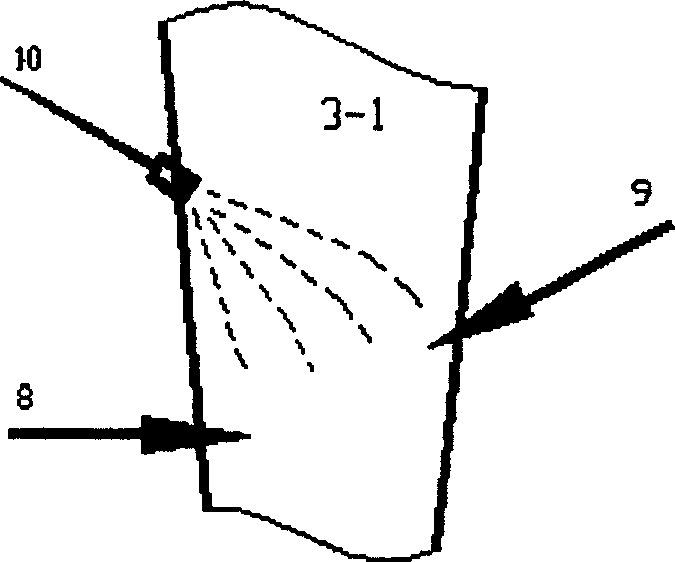

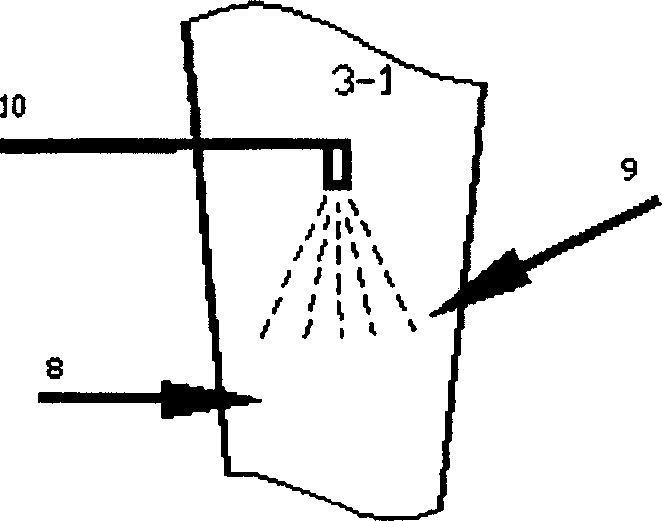

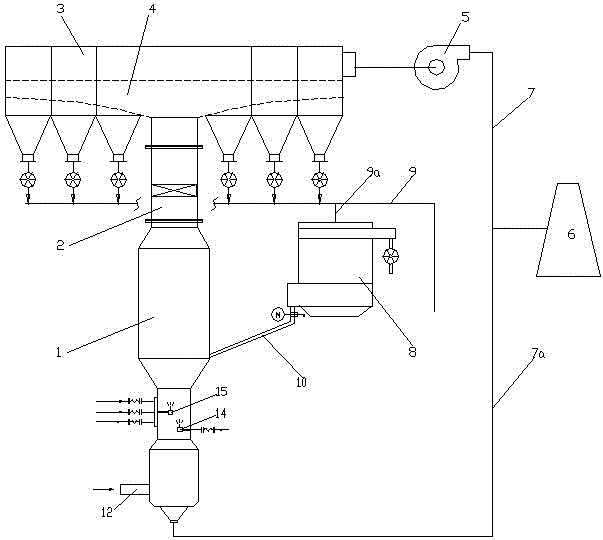

Dry flue gas desulfurizing process with independent feeding, back-returning and water-spraying devices

InactiveCN1515349AImprove desulfurization reaction efficiencyReduce back flowDispersed particle separationProcess engineeringDigestion

The present invention provides a dry flue gas desulfurizing process with independent feeding, feeding back and water-spraying device. It includes desulfurizing agent preparation digestion system, desulfurizing reaction tower and desulfurizing reaction system and exterior desulfurizing granules separation and recirculating system. The water-spraying atomization device of desulfurizing reaction tower, desulfurizing agent feeding device and granules recirculating feed back device are independently placed, and the different heights of the desulfurizing reaction tower are equipped with respective nozzles, so that the structure can raise the utilization rate of the desulfurizing agent and can raise the desulfurizing effect.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

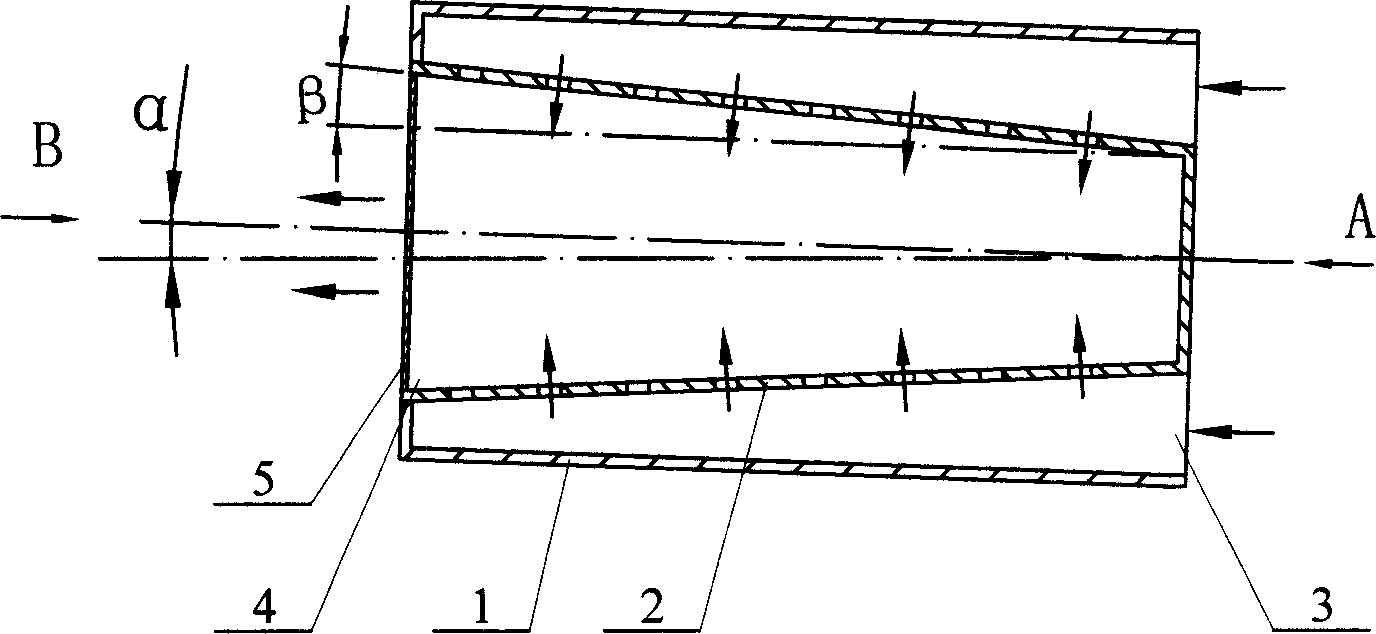

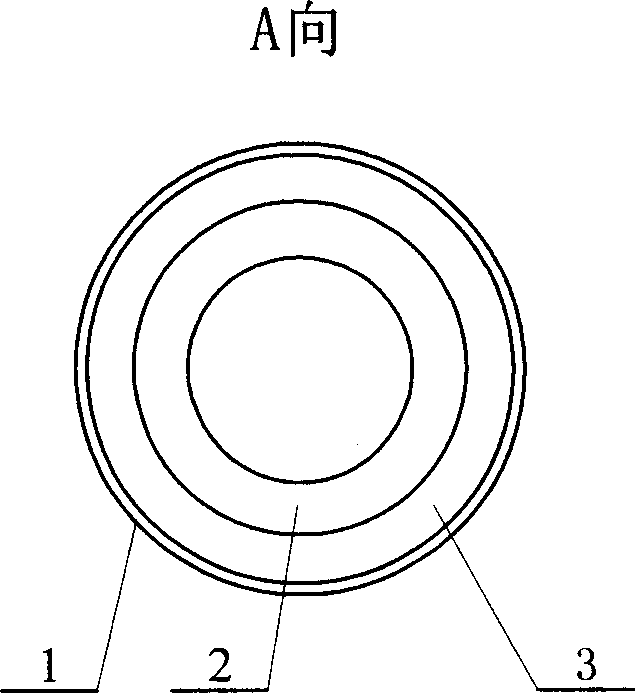

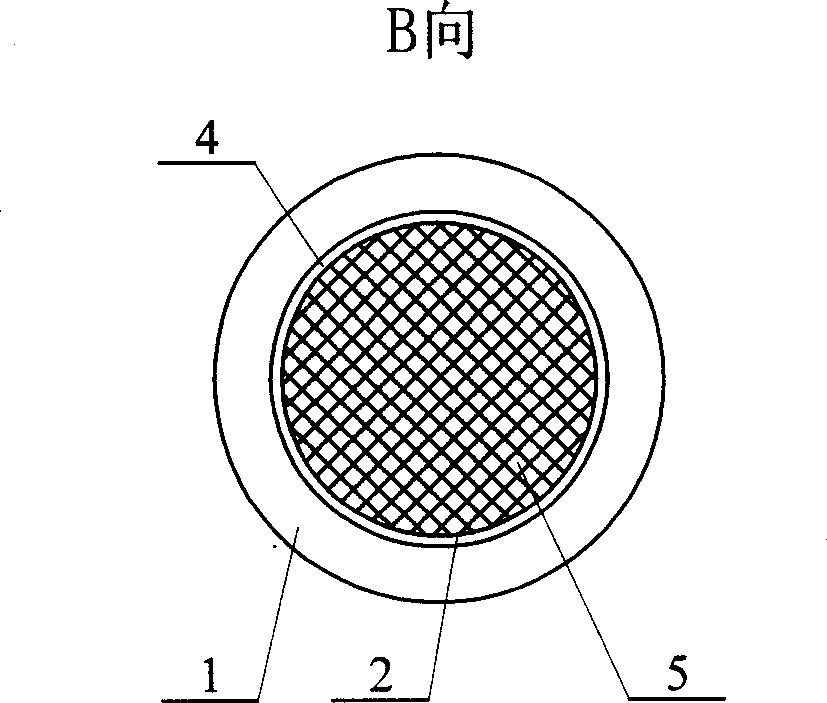

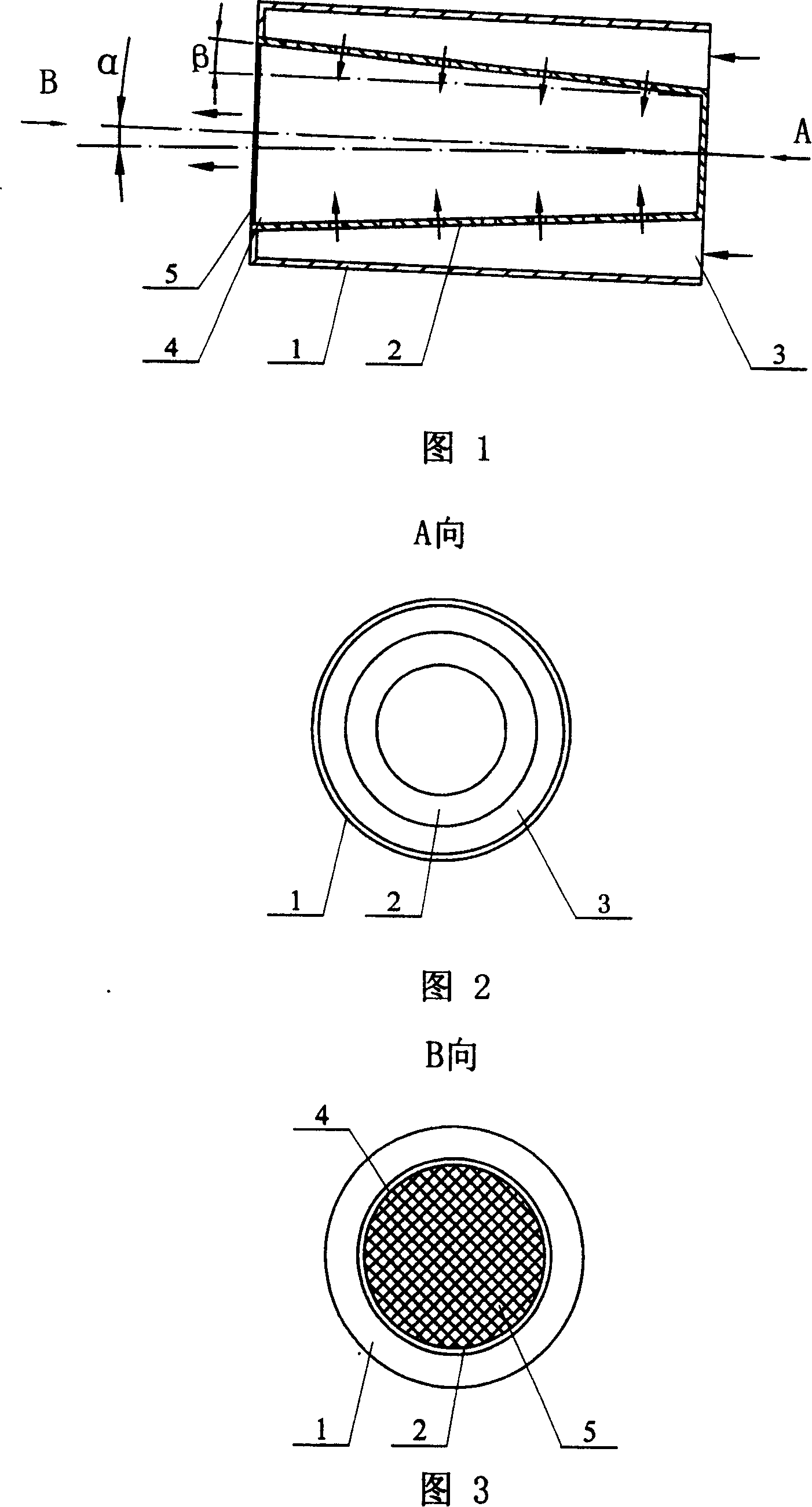

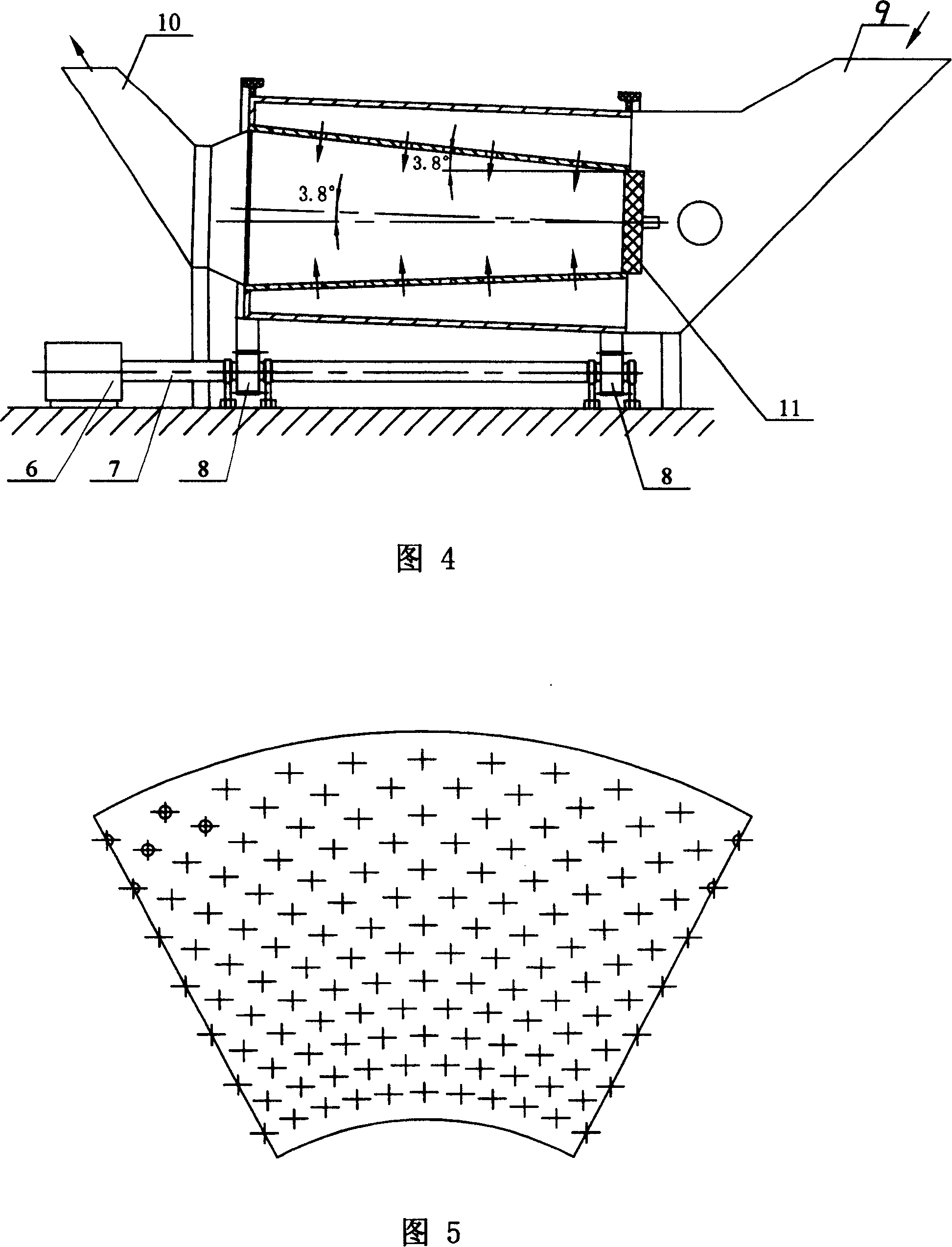

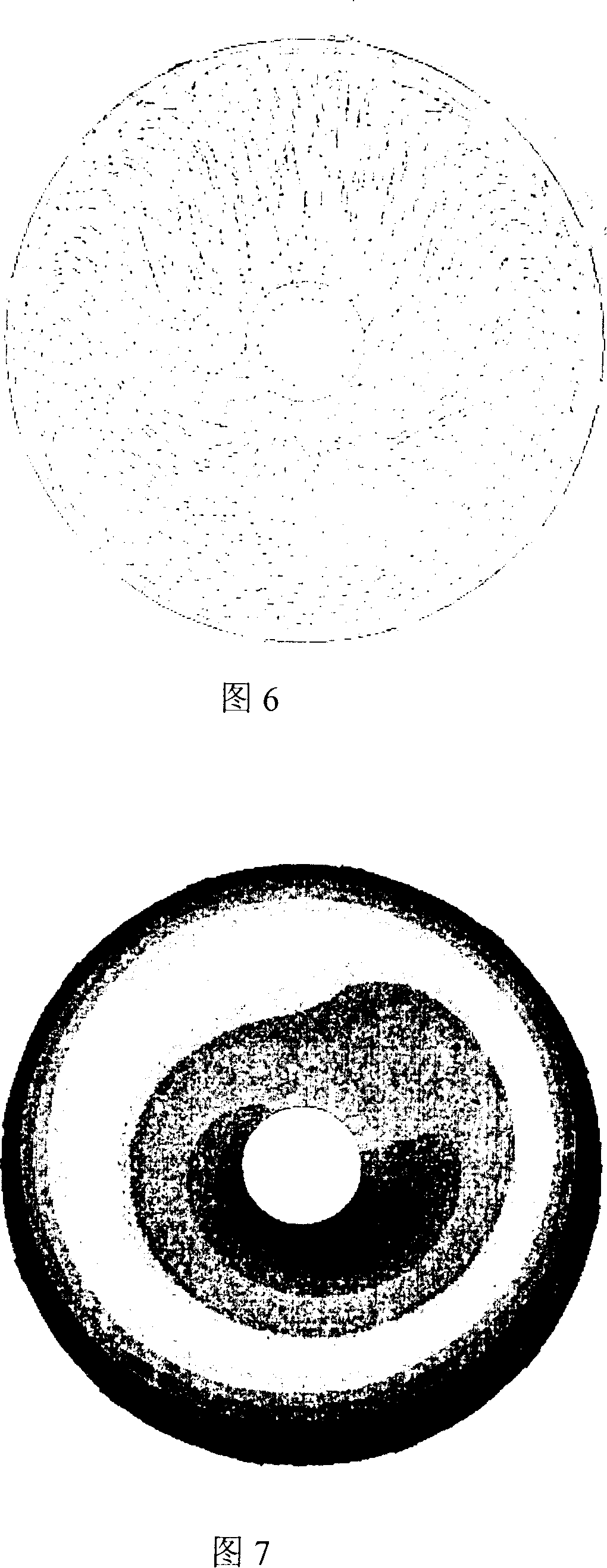

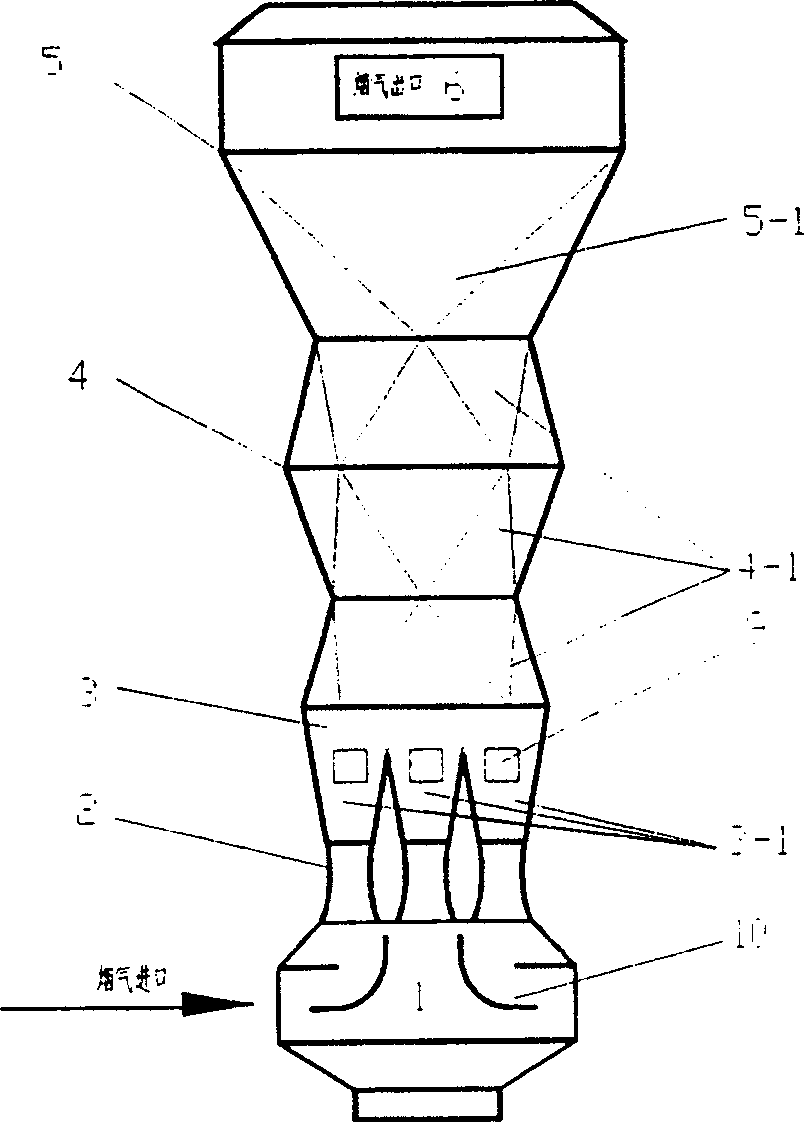

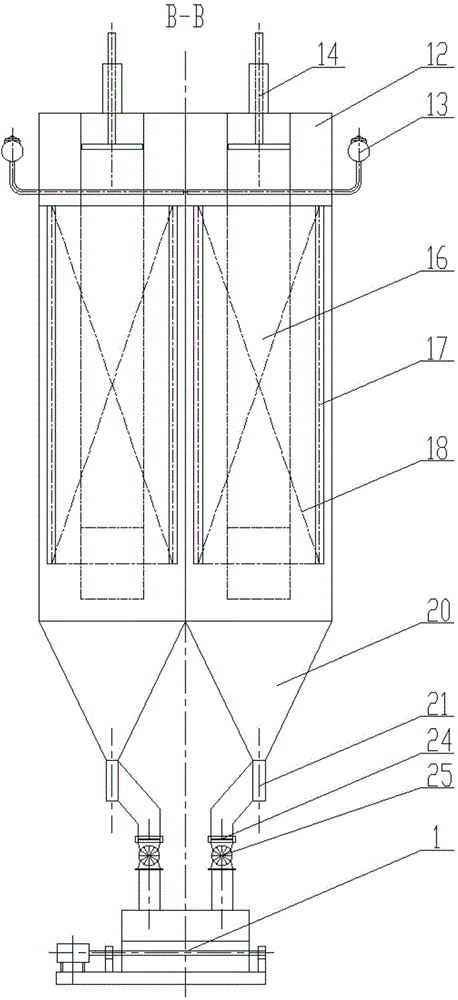

Horizontal inclined rotary fluidized bed desulfurizing reactor

InactiveCN1820827AUniform responseSolve the problem of low desulfurization reaction efficiencyDispersed particle separationChemical/physical processesInlet channelFluidized bed

The present invention provides one kind of horizontal inclined rotary fluidized bed desulfurizing reactor. The desulfurizing reactor is one double-layer structure including a truncated cone inner barrel with grid plate structure in the side wall, closed small caliber end and great caliber end as the gas outlet; and an outer barrel. There is a ring inlet channel formed between the small caliber end of the inner barrel and the outer barrel, the outer wall of great caliber end of the inner barrel is connected to the outer barrel, and the inclined reactor has outlet end higher than the inlet end. The present invention combines the fluidizing pneumatic force and the rotary centrifugal force well to realize the full reaction between SO2 and the desulfurizing agent grains, and has long reaction gas remaining period, high utilization rate one desulfurizing agent, and high desulfurizing efficiency up to 90-97 %.

Owner:HARBIN INST OF TECH

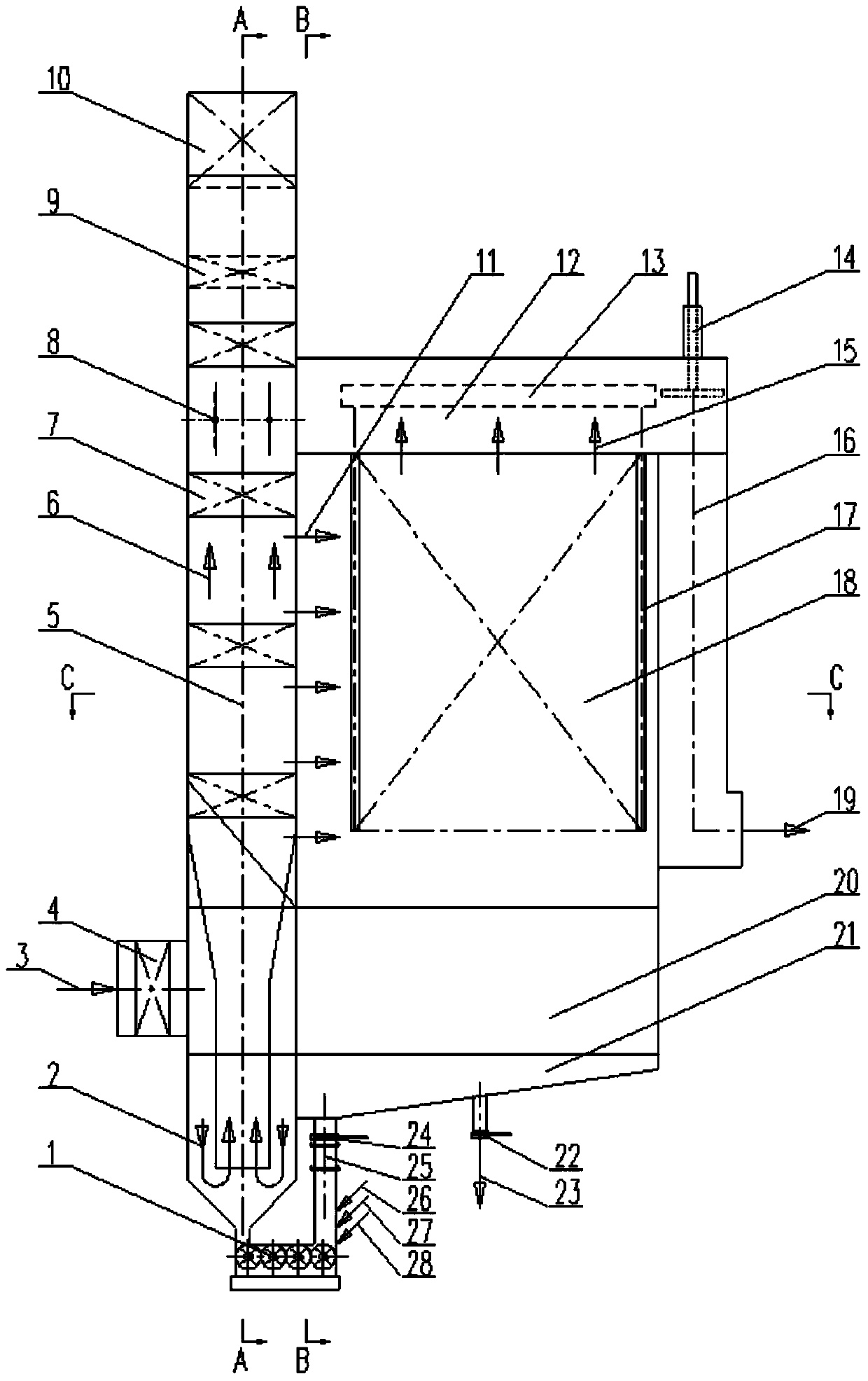

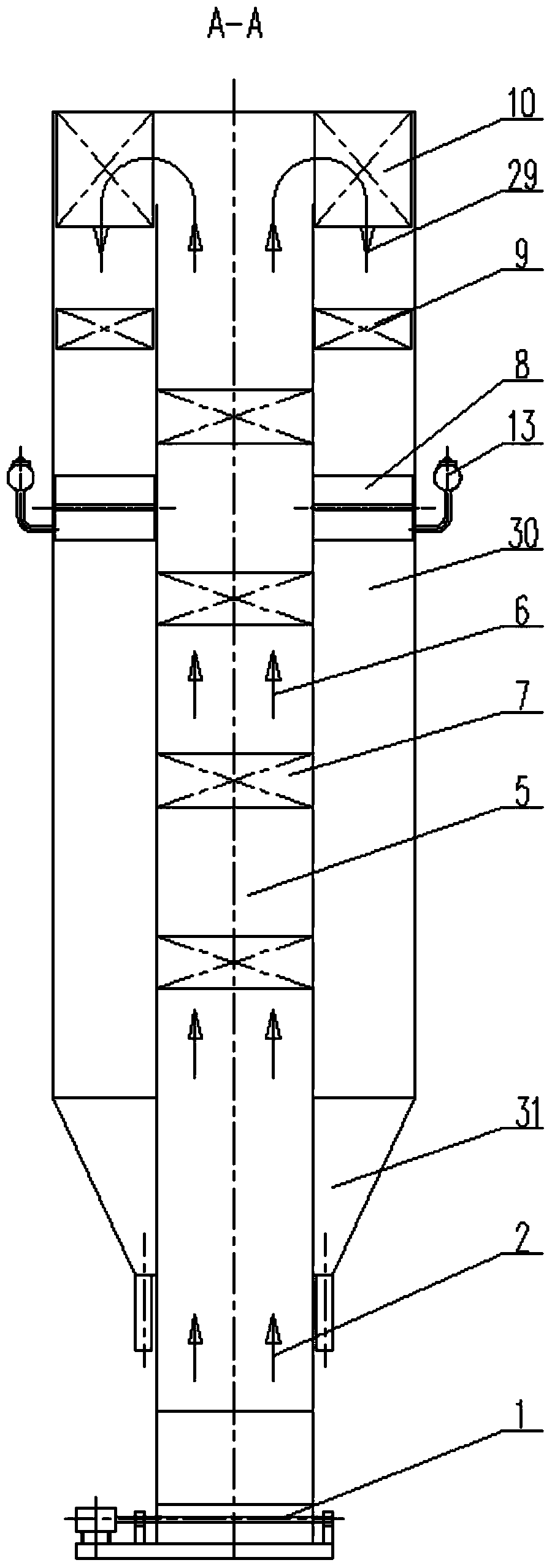

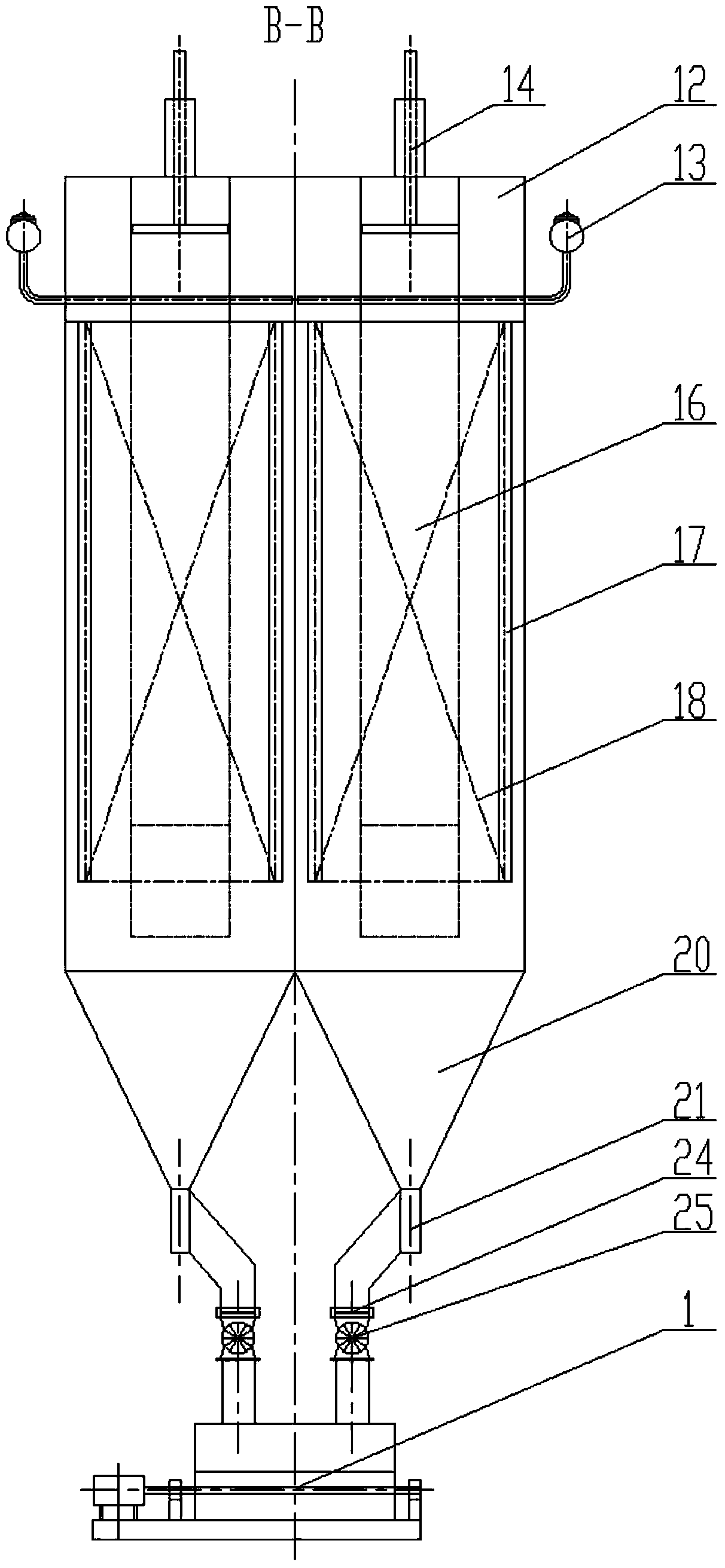

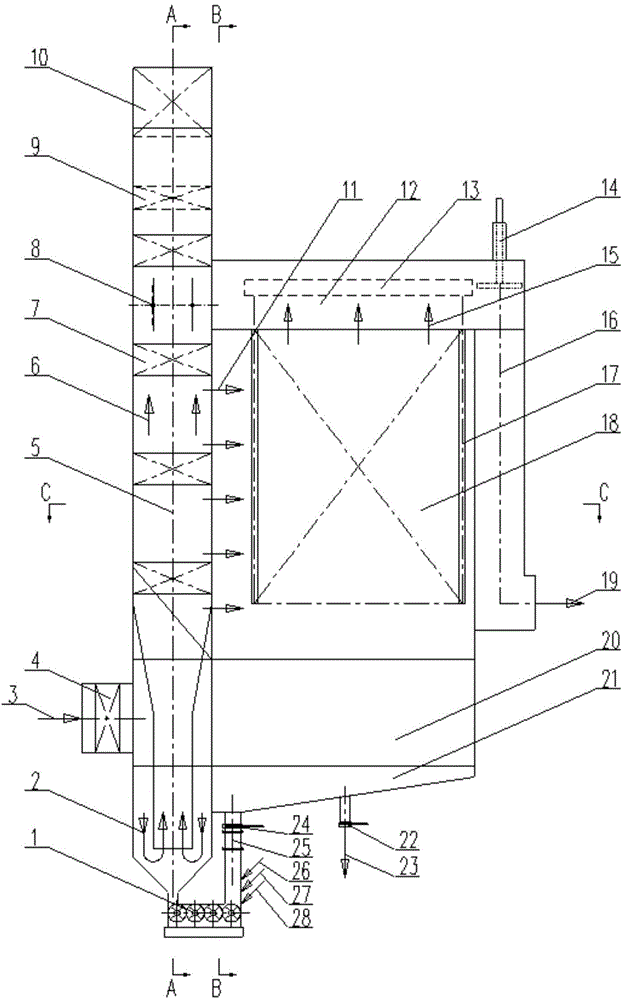

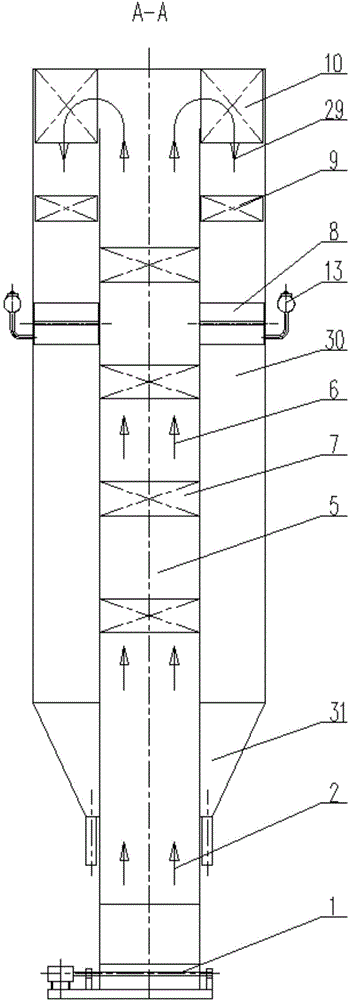

Flue gas desulfurization and dust removal equipment of low-temperature circulating fluidized bed

ActiveCN103463965AGuarantee working reliabilityEliminate worriesDispersed particle filtrationMoisture condensationFluidized bed

The invention discloses flue gas desulfurization and dust removal equipment of a low-temperature circulating fluidized bed. The equipment comprises a desulfurization reaction tower, a dedusting unit and a material returning unit, the equipment is internally provided with a heat exchange module, wherein the heat exchange module comprises a hot wall device; the hot wall device comprises at least one group of heating screens and at least one group of heat preservation layers, the heating screens comprise channels the ports of which are open for assisting a heating medium in circulating, the hot wall device is covered on heat dissipation wall surfaces of the desulfurization reaction tower and the dedusting unit, and the heating screens are positioned among the heat preservation layers and heat dissipation wall surfaces covered on the hot wall device. The flue gas desulfurization and dust removal equipment provided by the invention has the advantages that the worries of moisture condensation, scale formation and pasting bag of the desulfurization reaction tower and the dedusting unit are eliminated, the desulfurization adiabatic saturation temperature difference is controlled within 15 DEG C-5 DEG C, the desulfurization reaction efficiency is higher than 95% or even 99% under the condition that the molar ratio (Ca / S) of a calcium element and a sulfur element is less than 1.3, and the operational reliability of the equipment is still guaranteed.

Owner:SHANGHAI XIAOQING ENVIRONMENTAL PROTECTION TECH

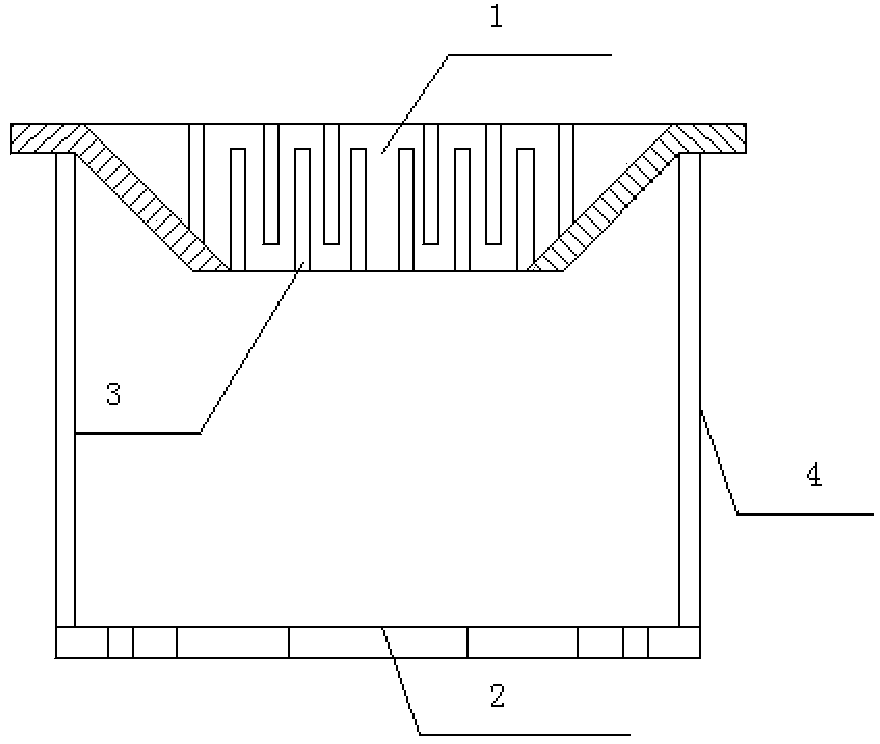

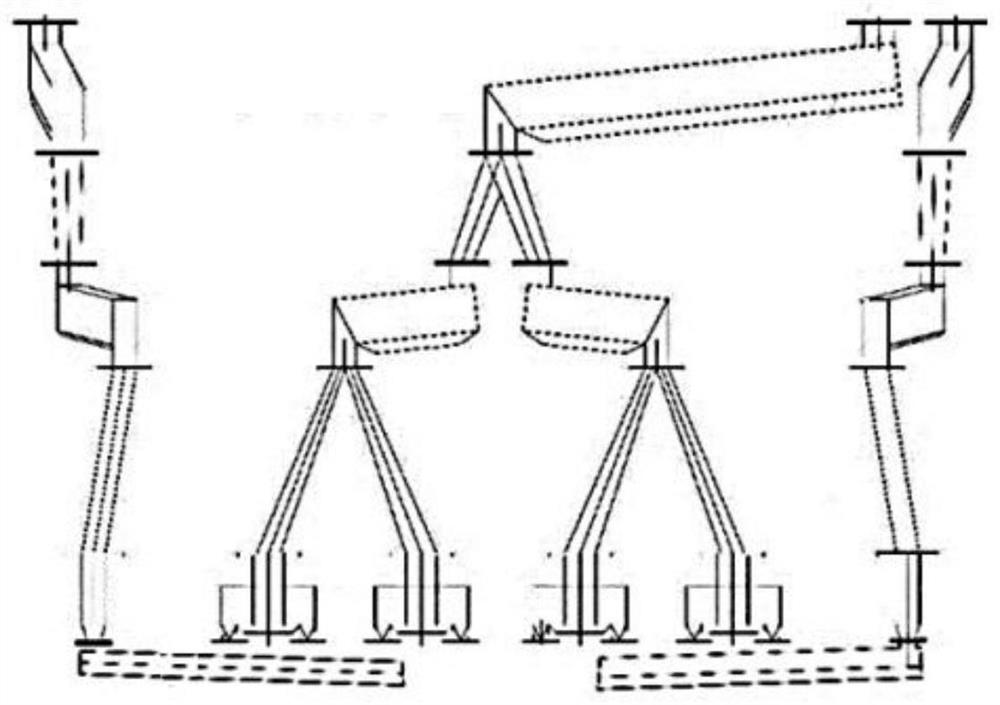

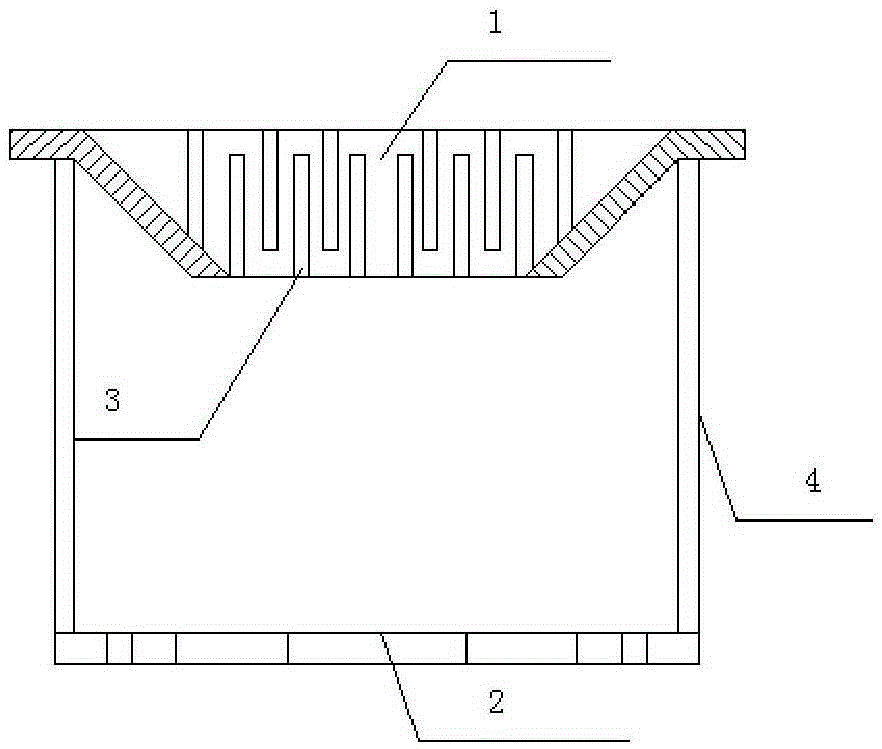

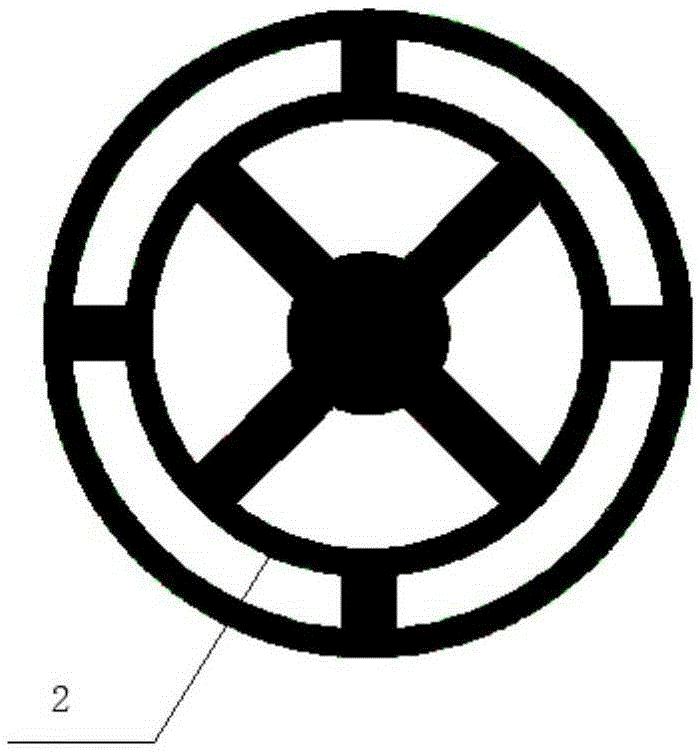

Compound internal member applied to circulating fluidized bed desulfuration reactor

InactiveCN103877848AIncrease backmixImprove the flow fieldDispersed particle separationChemical/physical processesEngineeringRadial distribution

The invention relates to a compound internal member applied to a circulating fluidized bed desulfuration reactor. The compound internal member comprises at least one internal member unit, wherein the internal member unit comprises an opening type funnel and an air distribution plate, a plurality of bar-shaped holes are formed in the side wall of the opening type funnel and are alternatively arranged in an upper row and a lower row, the air distribution plate is provided with at least two rows of fan-shaped holes along the radial direction, two adjacent rows of fan-shaped holes are arranged in a staggered manner, and the opening type funnel and the air distribution plate are connected through a support column. The compound internal member is capable of improving axial and radial distribution of a granular speed, increasing the granule backmixing and improving the fluidization quality of a fluidized bed, thereby increasing the utilization rate of a desulfurizing agent and the desulfuration reaction efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

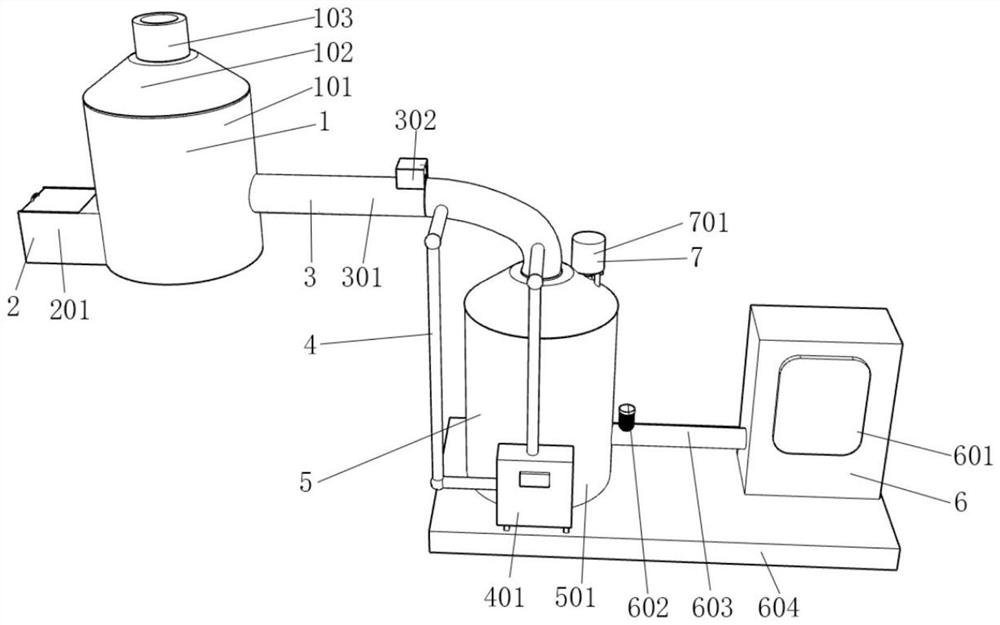

Lime slurry jetting circulating fluid bed semi-dry process desulfurizer

ActiveCN102000492AReduce workloadPromote desulfurization reactionDispersed particle separationSlurryEngineering

The invention discloses a lime slurry jetting circulating fluid bed semi-dry process desulfurizer which comprises a desulfurization reaction column, a gas-solid separator and a draught fan, wherein the lower part of the desulfurization reaction column is provided with a lime slurry nozzle and a fume inlet; an after-reaction gas outlet of the desulfurization reaction column is communicated with the gas-solid separator through a spoiler; and the spoiler is positioned on the upper part of the after-reaction gas outlet of the desulfurization reaction column. In the invention, the upper part of the gas outlet of the desulfurization reaction column is provided with the spoiler which can forcibly mix the gas-solid mixture discharged by the desulfurization reaction into a turbulent condition, thereby strengthening the desulfurization reaction of the mixture; and meanwhile, part of unreacted slurry particles return to the desulfurization reaction column for reaction after colliding with each other in the spoiler, thereby enhancing the desulfurization efficiency. The desulfurizer can reduce the working load of the gas-solid separator under the condition of high fume flow on the premise of ensuring the separating effect, and is applicable to high-flow fume desulfurization. When the fume flow is low, the turbulence is strengthened by the spoiler, thereby prolonging the contact reaction time and enhancing the desulfurization efficiency.

Owner:CISDI ENG CO LTD

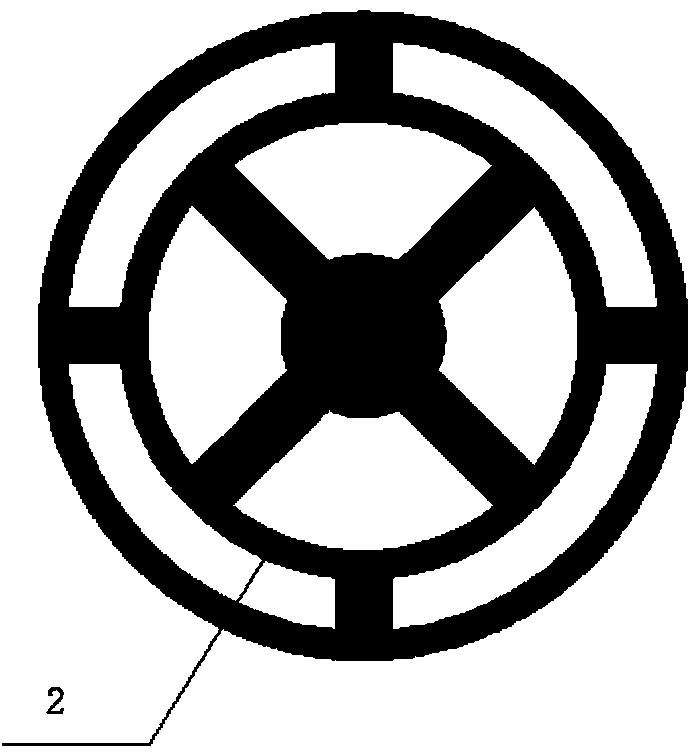

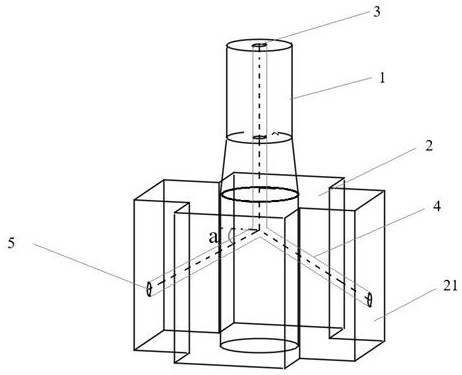

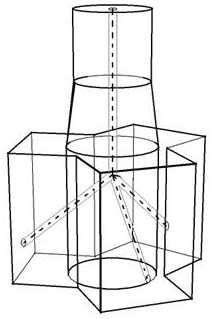

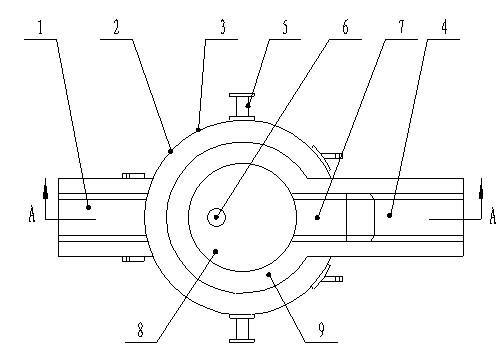

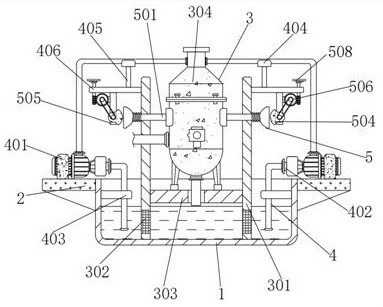

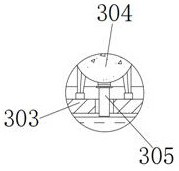

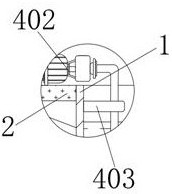

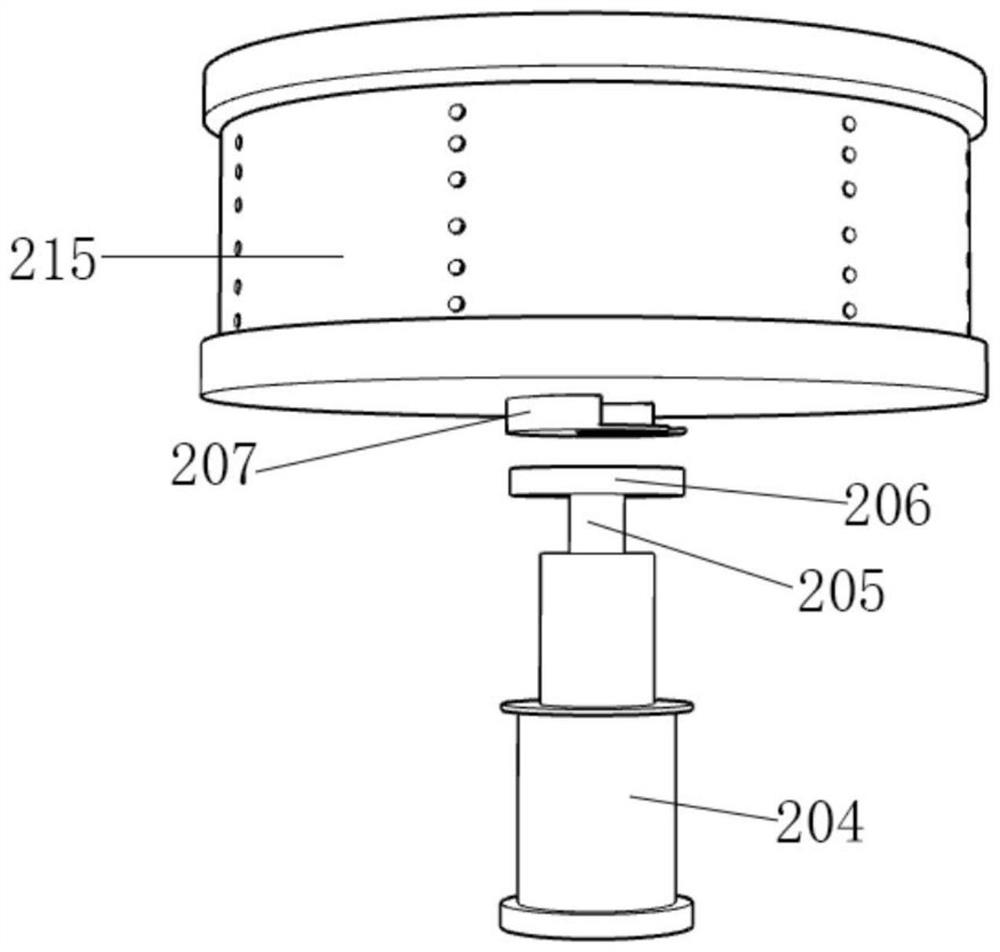

Mechanical stirring, blowing and desulfurizing stirrer for metallurgy

ActiveCN113846203ASlow downReduce aggregationStirring devicesProcess engineeringMechanical engineering

The invention relates to a mechanical stirring, blowing and desulfurizing stirrer for metallurgy. The mechanical stirring, blowing and desulfurizing stirrer comprises a stirring shaft and a stirring head connected to the lower portion of the stirring shaft, wherein a plurality of stirring blades are arranged on the outer side of the stirring head in the circumferential direction, and the included angles between the adjacent stirring blades are the same; a straight-through air blowing channel is formed in the stirring shaft, obliquely downward flow dividing pipelines are arranged in part of or all the stirring blades, and each flow dividing pipeline communicates with the straight-through air blowing channel to form an air blowing channel; and a blowing opening is formed at the tail of each flow dividing pipeline. Desulfurizing agent blowing holes are formed in the outermost edge wall surfaces of the symmetrical stirring blades, and a certain distance is formed between a bubble generation position and a central vortex region, so that the bubble aggregation of a desulfurizing agent can be reduced, the bubble growth probability can be reduced, the gas-liquid reaction area can be increased, the gas-liquid reaction time can be prolonged, and the desulfurization reaction efficiency can be improved.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD +1

Semi-dry desulfurization system suitable for low-sulfur flue gas

PendingCN113304585AReduce operating energy consumptionReduce concentrationGas treatmentDispersed particle filtrationWater storageFlue gas

The invention discloses a semi-dry desulfurization system suitable for low-sulfur flue gas. The system comprises a desulfurization absorption tower, a pulse-jet bag-type dust collector, a process water storage and conveying device, a desulfurizer storage and conveying device, a desulfurization circulating ash conveying device and a compressed air device. The desulfurization absorption tower is not internally provided with a circulating fluidized bed, but is provided with a Venturi structure, and the Venturi structure is also provided with a desulfurization circulating ash multi-point distribution device. The process water storage and conveying device, the desulfurizer storage and conveying device and the desulfurization circulating ash conveying device are respectively connected with the Venturi structure of the desulfurizing absorption tower, and the compressed air device is connected with the process water storage and conveying device. The system further comprises a desulfurization tail ash conveying and storing device and a flue gas pipeline. By adopting the system, the purification requirement of ultralow emission of low-sulfur flue gas can be met, meanwhile, the system configuration is simplified, the operation energy consumption of the desulfurization system is reduced, and the stability and the reliability of the desulfurization system are improved.

Owner:北京铝能清新环境技术有限公司

A metallurgical mechanical stirring jet desulfurization agitator

The invention relates to a mechanical stirring and spraying desulfurization stirrer for metallurgy, which comprises a stirring shaft and a stirring head connected under the stirring shaft; The included angles are the same; a straight-through air blowing channel is arranged on the stirring shaft, and some or all of the stirring blades are provided with a slanted downward shunt pipe, and each shunt pipe is connected with the straight-through air blowing channel to form a blowing gas channel; each The end of the shunt pipe forms a blowing port. In the present invention, the desulfurizing agent injection hole is arranged on the outermost wall of the symmetrical stirring blade, and the bubble generating position has a certain distance from the central vortex area, which can reduce the desulfurizing agent bubble aggregation and reduce the probability of bubble growth, so as to increase the gas-liquid The reaction area is increased, the gas-liquid reaction time is prolonged, and the efficiency of the desulfurization reaction is increased.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD +1

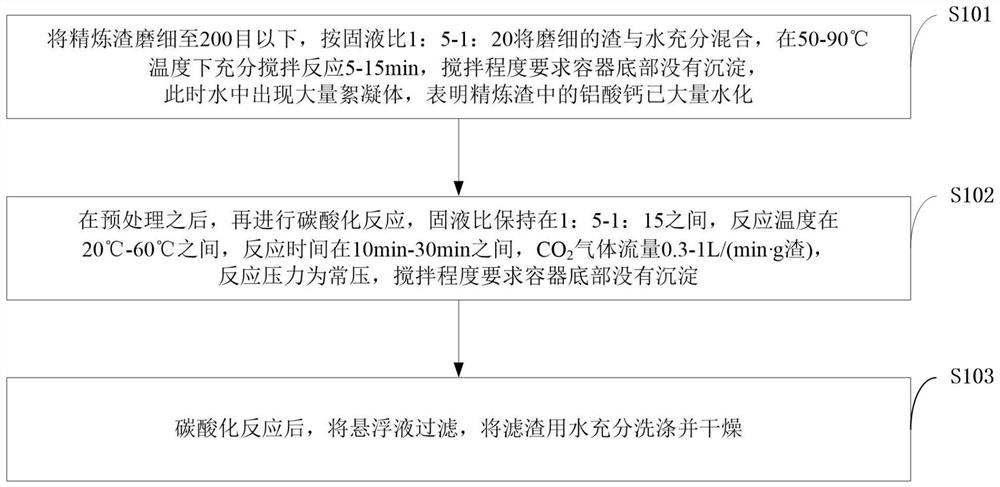

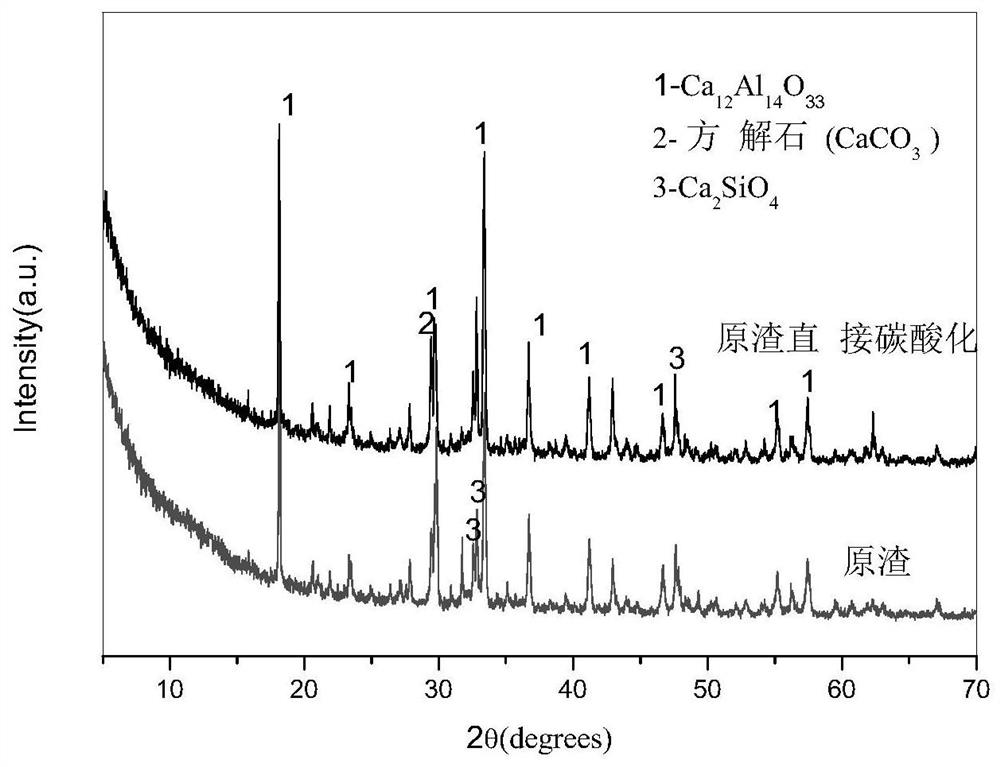

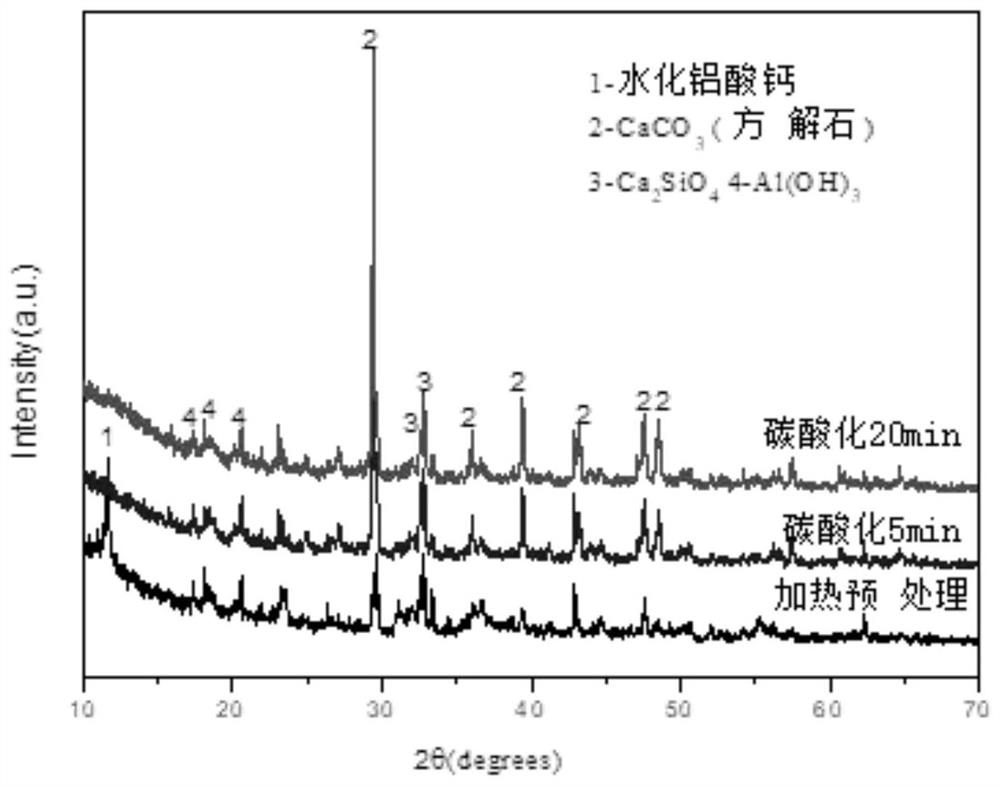

A treatment method for carbonation and desulfurization of steelmaking refining slag

ActiveCN110527758BIncrease the reaction areaAvoid formingRecycling and recovery technologiesProcess efficiency improvementCalcium silicateSteelmaking

The invention belongs to the technical field of smelting slag treatment and disposal, and discloses a treatment method for carbonation and desulfurization of steelmaking refining slag. The invention accelerates hydration before refining slag carbonation through hydrothermal pretreatment or ultrasonic pretreatment, so that alumina Calcium becomes flaky calcium aluminate hydrate, increasing the calcium aluminate and CO 2 The reaction area avoids the formation of calcium carbonate or hydrated calcium aluminocarbonate film, which improves the reaction rate. In addition, the activity of calcium silicate is stimulated by ultrasonic treatment, and the interaction between calcium silicate and CO is improved. 2 reaction speed. The invention uses hydrothermal pretreatment for carbonation, and the desulfurization efficiency is increased by more than 20% compared with direct carbonation without pretreatment, and the desulfurization efficiency is increased by more than 30% with ultrasonic pretreatment than direct carbonation without pretreatment. The invention can significantly improve the efficiency of the carbonation desulfurization reaction, speed up the reaction speed, and has a relatively simple process, which can be directly carried out at normal temperature and pressure.

Owner:HUNAN CITY UNIV

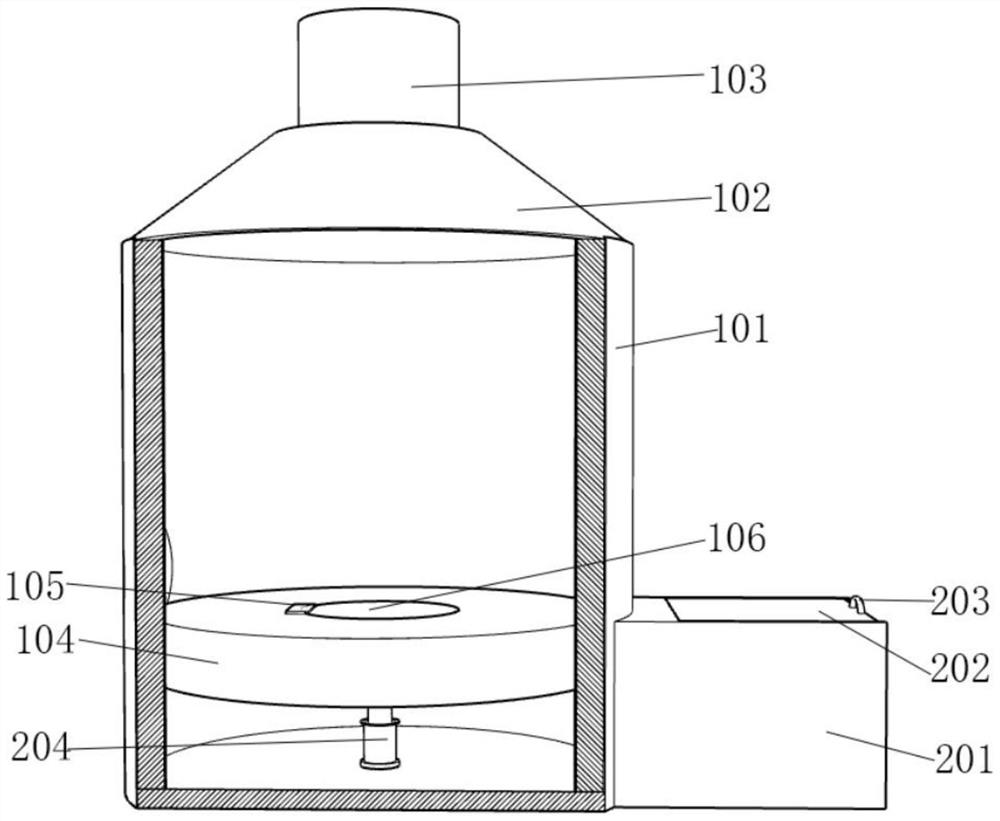

Molten iron desulfurizing method and desulfurizing device thereof

The invention relates to a molten iron desulfurizing method and a desulfurizing device thereof. The molten iron desulfurizing method includes pouring processing molten iron into an inner cavity of a desulfurizing device; adding a lime and fluorite compound desulfurizer constantly; blowing argon to stir the molten iron through an air inlet of the desulfurizing device, and removing sulfur in the molten iron; and discharging desulfurizing slag constantly from a slag discharging groove, and discharging the desulfurized molten iron through an iron discharging nozzle, wherein the S content in the desulfurized molten iron is 0.041 to 0.057. The desulfurizing device is provided with a tank casing with trunnion iron, and is characterized in that the iron discharging nozzle which inclines upward is arranged on the tank casing, the slag discharging groove which inclines from top to down is arranged at a position opposite to the iron discharging nozzle, fireproofing linings are arranged in the tank casing, the iron discharging nozzle and the slag discharging groove, an air inlet is arranged at the bottom, and the slag discharging groove at the upper end of the slag discharging groove is higher or 20cm higher than the front end of the iron discharging nozzle. According to the molten iron desulfurizing method and the desulfurizing device thereof, molten iron desulfurizing efficiency is improved, and the amount of the desulfurized molten iron can reach 15-25t / h.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

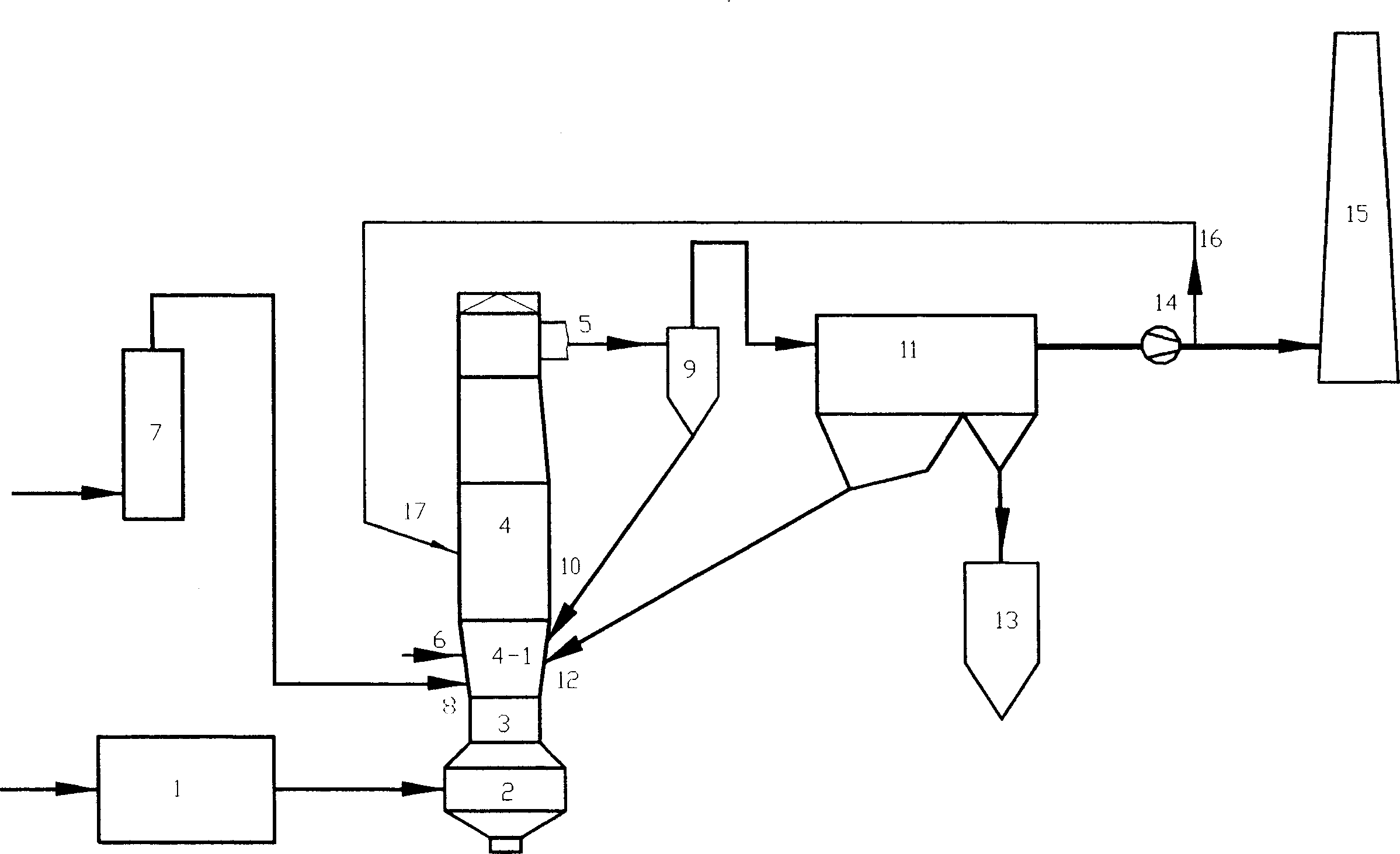

Dry flue gas desulfurizing process with independent feeding, back-returning and water-spraying devices

InactiveCN1226073CImprove reaction efficiencyImprove desulfurization reaction efficiencyDispersed particle separationFlue gasProcess engineering

The present invention provides a dry flue gas desulfurizing process with independent feeding, feeding back and water-spraying device. It includes desulfurizing agent preparation digestion system, desulfurizing reaction tower and desulfurizing reaction system and exterior desulfurizing granules separation and recirculating system. The water-spraying atomization device of desulfurizing reaction tower, desulfurizing agent feeding device and granules recirculating feed back device are independently placed, and the different heights of the desulfurizing reaction tower are equipped with respective nozzles, so that the structure can raise the utilization rate of the desulfurizing agent and can raise the desulfurizing effect.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

A Composite Internal Member Applied to Circulating Fluidized Bed Desulfurization Reactor

InactiveCN103877848BIncrease backmixImprove the flow fieldDispersed particle separationChemical/physical processesEngineeringRadial distribution

The invention relates to a compound internal member applied to a circulating fluidized bed desulfuration reactor. The compound internal member comprises at least one internal member unit, wherein the internal member unit comprises an opening type funnel and an air distribution plate, a plurality of bar-shaped holes are formed in the side wall of the opening type funnel and are alternatively arranged in an upper row and a lower row, the air distribution plate is provided with at least two rows of fan-shaped holes along the radial direction, two adjacent rows of fan-shaped holes are arranged in a staggered manner, and the opening type funnel and the air distribution plate are connected through a support column. The compound internal member is capable of improving axial and radial distribution of a granular speed, increasing the granule backmixing and improving the fluidization quality of a fluidized bed, thereby increasing the utilization rate of a desulfurizing agent and the desulfuration reaction efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

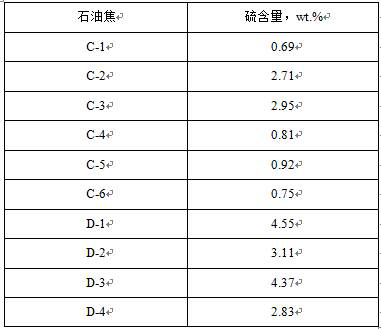

Petroleum coke desulfurization method

PendingCN114763263AReduce hydrogen bondingEasy to removeCarbon compoundsNitrogen oxidesMass transfer resistance

The invention discloses a petroleum coke desulfurization method which comprises the following steps: firstly, mixing a petroleum coke raw material with an alkali metal compound, and carrying out heat treatment to obtain pretreated petroleum coke A; further treating with a solvent to obtain pretreated petroleum coke B; treating the pretreated petroleum coke B and nitrogen oxide-containing gas to obtain pretreated petroleum coke C; and separating, washing and drying a pyrolysis material obtained by pyrolyzing the pretreated petroleum coke C to obtain a petroleum coke product. The petroleum coke desulfurization method provided by the invention can effectively reduce the mass transfer resistance of the reaction and improve the efficiency of the desulfurization reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Horizontal inclined rotary fluidized bed desulfurizing reactor

InactiveCN100369657CUniform responseSolve the problem of low desulfurization reaction efficiencyDispersed particle separationChemical/physical processesInlet channelFluidized bed

The present invention provides one kind of horizontal inclined rotary fluidized bed desulfurizing reactor. The desulfurizing reactor is one double-layer structure including a truncated cone inner barrel with grid plate structure in the side wall, closed small caliber end and great caliber end as the gas outlet; and an outer barrel. There is a ring inlet channel formed between the small caliber end of the inner barrel and the outer barrel, the outer wall of great caliber end of the inner barrel is connected to the outer barrel, and the inclined reactor has outlet end higher than the inlet end. The present invention combines the fluidizing pneumatic force and the rotary centrifugal force well to realize the full reaction between SO2 and the desulfurizing agent grains, and has long reaction gas remaining period, high utilization rate one desulfurizing agent, and high desulfurizing efficiency up to 90-97 %.

Owner:HARBIN INST OF TECH

Wet desulphurization device and process for sulfur-containing process gas

PendingCN111773895ASolve the low utilizationCompact structureDispersed particle separationProcess engineeringSulfur containing

The invention belongs to the technical field of chemical engineering, and discloses a wet desulphurization device for sulfur-containing process gas, which is first desulphurization equipment, comprises a desulphurization tower assembly and a first efficient reactor (GXR type reactor) fixedly arranged on the outer side of the tower wall of the desulphurization tower assembly. The device can furthercomprise second desulfurization equipment and / or third desulfurization equipment and / or fourth desulfurization equipment, desulfurization of process gas with different loads or sulfur contents is achieved through combination of multiple stages of desulfurization equipment, it is guaranteed that the overall desulfurization efficiency of the device is larger than or equal to 99.9%, the overall structure of the desulfurization device is compact, and the occupied area is greatly reduced; airflow flows smoothly, resistance drop is small, energy is saved, consumption is reduced, the common rate ofall parts is high, a large amount of materials are saved, and equipment investment is saved.

Owner:四川省达科特能源科技股份有限公司

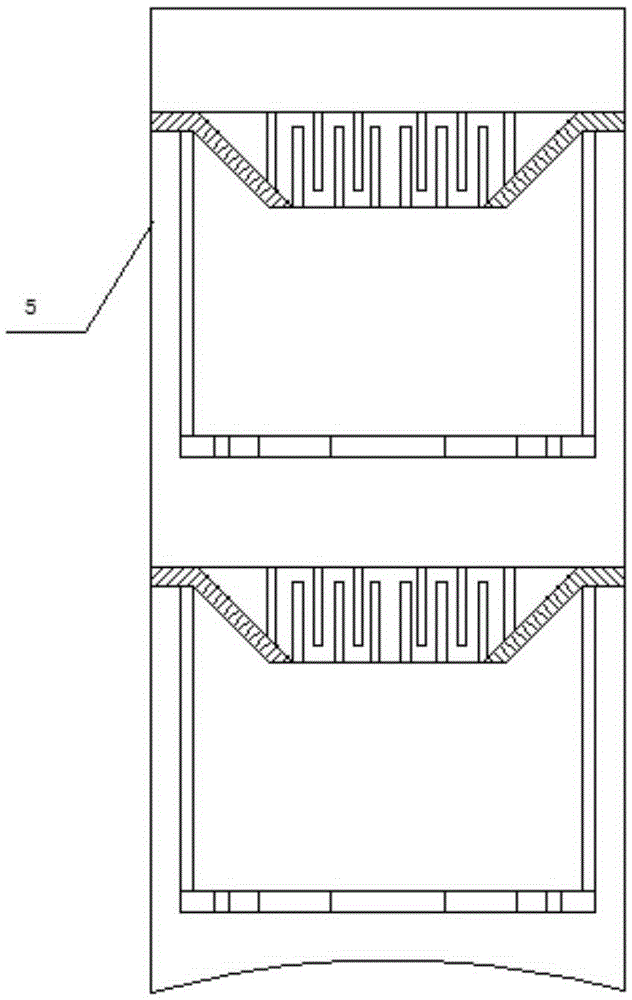

Dry process stack gas desulfur reaction tower with variation structure

InactiveCN1281297CSolve the fluidization problemLow flow resistanceDispersed particle separationSorbentFlue gas

The invention proposes a dry flue gas desulfurization reaction tower with a variable structure, which includes a flue gas mixing chamber at the bottom of the desulfurization tower, a flue gas injection device, a fluidization section in the lower part of the desulfurization tower, a main reaction section in the middle of the desulfurization tower, and a desulfurization tower. The upper section of the upper section and the inlet of fresh desulfurizer particles on the tower body, the inlet of external recirculating particles, the atomized water nozzle, and the flue gas outlet, the main reaction section in the middle of the desulfurization tower and / or the upper section of the desulfurization tower adopts a variant structure. The main reaction zone in the middle of the desulfurization tower is composed of several sub-sections of the desulfurization tower with variable structures. The shape of the outlet section of each subsection of the desulfurization tower is different from the shape of the inlet section, and the outlet of the next section is the inlet of the previous section; the main reaction zone in the middle of the desulfurization tower The outlet cross-sectional area of each desulfurization tower subsection is 1.1 to 1.5 times the inlet cross-sectional area.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

Polytropic-process desulfurization device

InactiveCN112023669AImprove desulfurization reaction efficiencyShorten the timeDispersed particle separationEngineeringCam

The invention discloses a polytropic-process desulfurization device. The device comprises a box body and inclined plates, wherein the inclined plates are fixedly connected to the outer walls of the upper portions of the left side and the right side of the box body, and a desulfurization device is installed in the box body. According to the polytropic-process desulfurization device, through mutualcooperation of structures such as the inclined plates, water pumps, a second vertical plate, a desulfurization tower and a discharging pipe, a solvent can be discharged into the desulfurization towerthrough the left water pump and the right water pump, so desulfurization reaction efficiency is improved, and time is saved; and through mutual cooperation of a rotary disc, a worm wheel, a worm, a cam, and arc-shaped block and other structures, the worm can be driven by the rotary disc to rotate, the worm drives the worm wheel to rotate, and the worm wheel drives the cam to rotate through the belt, so the cam drives the baffle to move through the arc-shaped block, and the device is more convenient and simpler to operate.

Owner:朱加招

Addition method and application of desulfurizer in blast furnace ironmaking process

The invention discloses an adding method of a desulfurizer in a blast furnace ironmaking process and application, and the method is as follows: adding the desulfurizer into pulverized coal before coal grinding to make the desulfurizer and the pulverized coal evenly mixed and dried, spraying a mixture of the dried desulfurizer and the pulverized coal into a blast furnace by a blast furnace wind mouth. The invention also discloses application of the adding method of the desulfurizer in the blast furnace ironmaking process. According to the adding method of the desulfurizer, no corrosion to spraying equipment and pipelines and no blockage of the pipelines may be produced, the desulfurization efficiency of the blast furnace can be increased, the blast furnace ironmaking cost and (S) content in pig iron can be reduced, and the quality of the pig iron can be improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

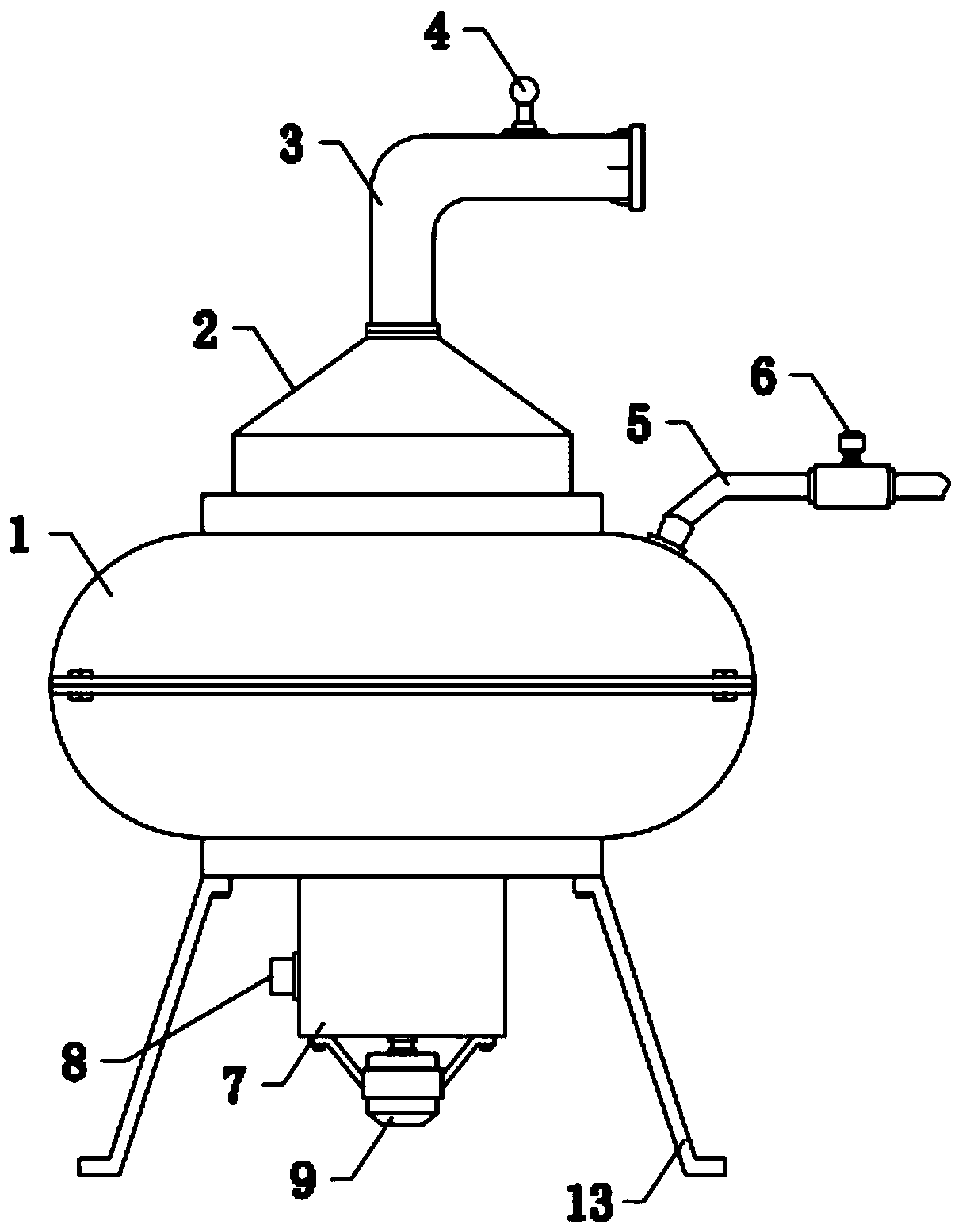

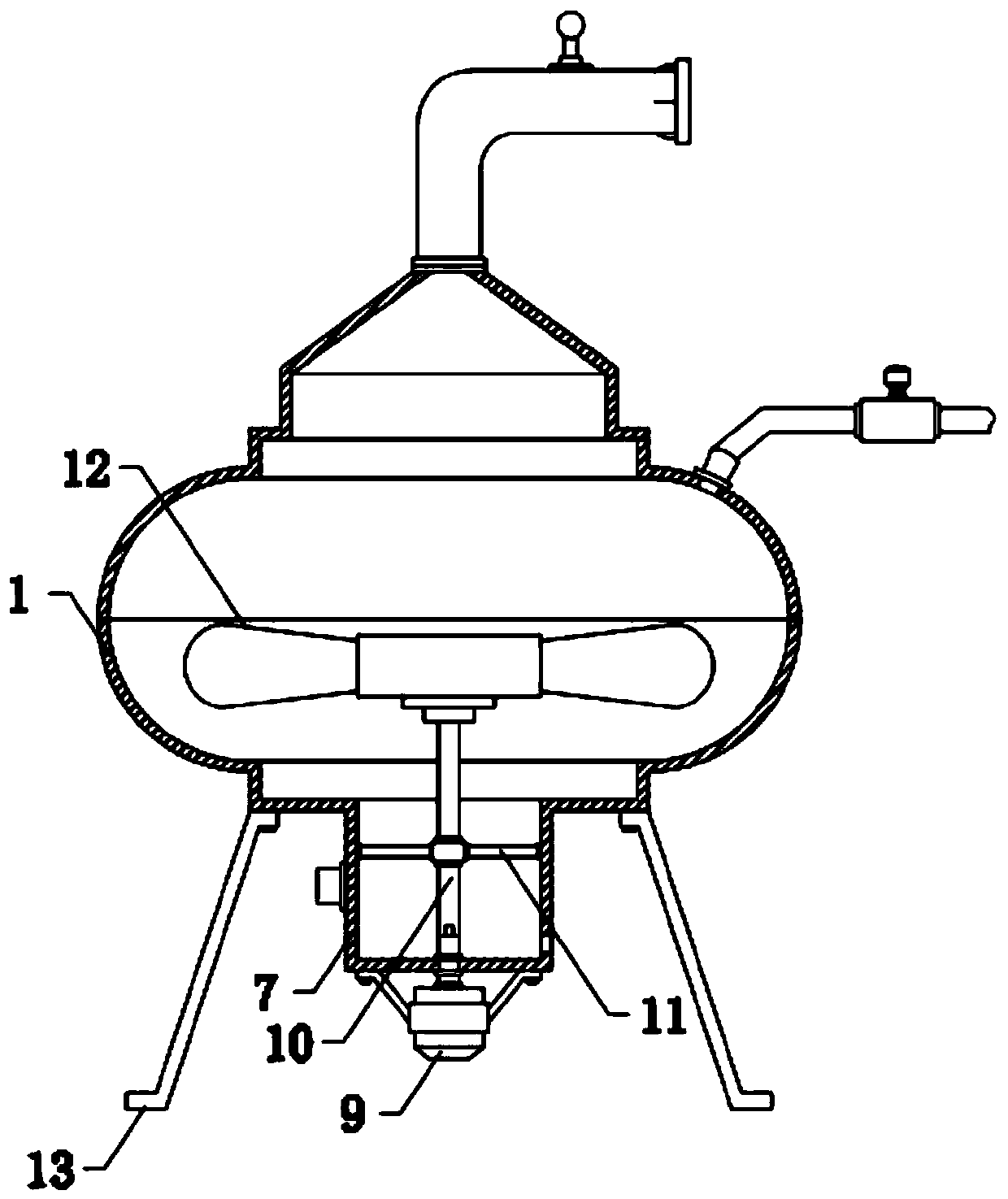

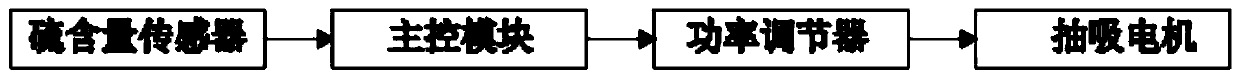

High-efficiency ship seawater desulfurization device

InactiveCN110721583AIncrease in sizeFast desulfurizationGas treatmentDispersed particle separationImpellerElectric machinery

The invention belongs to the field of seawater desulfurization technologies and particularly discloses a high-efficiency ship seawater desulfurization device. The device comprises a reaction tower, anexhaust pipe, a water inlet pipe, a smoke inlet and a drainage port, wherein through grooves are formed in the upper surface and the lower surface of the reaction tower respectively, the through groove at the upper side is connected with a gas collection cover through screws, the volume of the reaction tower is expanded, a larger reaction space is provided, the desulfurization reaction efficiencyof smoke and seawater is improved, and therefore smoke desulfurization can be quickly performed; through cooperation of a driving rotary shaft, a strut and a mixing impeller, the seawater and the smoke can be quickly stirred and mixed to be in full contact under the action of the rotating mixing impeller, and therefore the desulfurization effect is improved; and through an intelligent working mode of a sulfur content sensor, a main control module, a power regulator and a suction motor, the amount of entering seawater can be controlled in a feedback control mode, and therefore the functions ofguaranteeing the desulfurization effect and lowering energy consumption can be achieved.

Owner:上海蓝魂环保科技有限公司

Smoke desulfurizing process by circulation fluid state dry method of layered feed back

The present invention relates to external grain re-circulating technology in large circular fluidizing dry fume desulfurizing system. The desulfurizing process includes preparing desulfurizing agent, desulfurizing reaction inside the desulfurizing reaction tower and external desulfurizing agent grain separation and re-circulation. In the external grain re-circulation, the returned material is two-stage separated and re-circulated, the grains separated by the first stage and the second stage desulfurizing agent grain separator are fed to the fluidizing region in the lower part of the desulfurizing reaction tower separately through different re-circulation inlets, resulting in raised desulfurizing agent grain utilization and desulfurizing reaction efficiency. Compared with available technology, the present invention has much higher fume dedusting efficiency, high desulfurizing efficiency up to 92 % at Ca / S of 1.1-1.3, less adhesion and blocking in the lower desulfurizing tower part and lowered load of the desulfurizing agent grain separator.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

Desulfurization equipment for industrial sewage treatment and desulfurization method thereof

InactiveCN114656089AImprove efficiencyProtection replacement deviceSpecific water treatment objectivesWater contaminantsMotor protectionMicro motor

The invention relates to the technical field of sewage treatment, and discloses desulfurization equipment for industrial sewage treatment and a desulfurization method.The conveying mechanism comprises a conveying pipeline, a threaded groove is formed in the inner wall of the conveying pipeline, and a motor protection cabin is fixedly connected to the outer wall of one end of the conveying pipeline; the conveying mechanism comprises a motor protection cabin, a micro motor is fixedly connected into the motor protection cabin, a rotating gear is fixedly connected to one end of the micro motor, a gear ring body is movably connected to the rotating gear, and a conveying shaft is fixedly connected to the inner wall of the gear ring body. According to the sewage treatment device, a motor protection cabin is arranged, so that a power supply device is protected, a micro motor is arranged, so that rotating force is supplied, a rotating gear and a gear ring body are arranged, so that the rotating force is transmitted, and a transmission shaft and a transmission threaded block are arranged, so that sewage is transmitted.

Owner:河南省中创建筑工程有限公司

Molten iron desulphurization gun

The invention relates to a molten iron desulphurization gun, and belongs to the field of desulphurization pretreatment. The molten iron desulphurization gun comprises a desulfurization gun body, a spray gun gas outlet is formed in the side surface of the bottom of the desulfurization gun body, the side wall of the desulfurization gun body is fixedly provided with a paddle, and the paddle is arranged above the spray gun gas outlet. According to the molten iron desulphurization gun, on the basis of a rotary spraying blowingdesulphurization technology, on the basis of rotary spraying blowing, the paddle is installed on the desulfurization gun, the interaction between a desulfurizing agent andmolten iron is increased through stirring of the paddle, the traveling route of the desulfurizing agent floating is increased by realizing vertical movement of the molten iron, the standing time of the desulfurizing agent in the molten iron is prolonged, the desulfurization reaction efficiency of the desulfurizing agent is improved, and the effect of improving desulphurization of the molten iron is achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

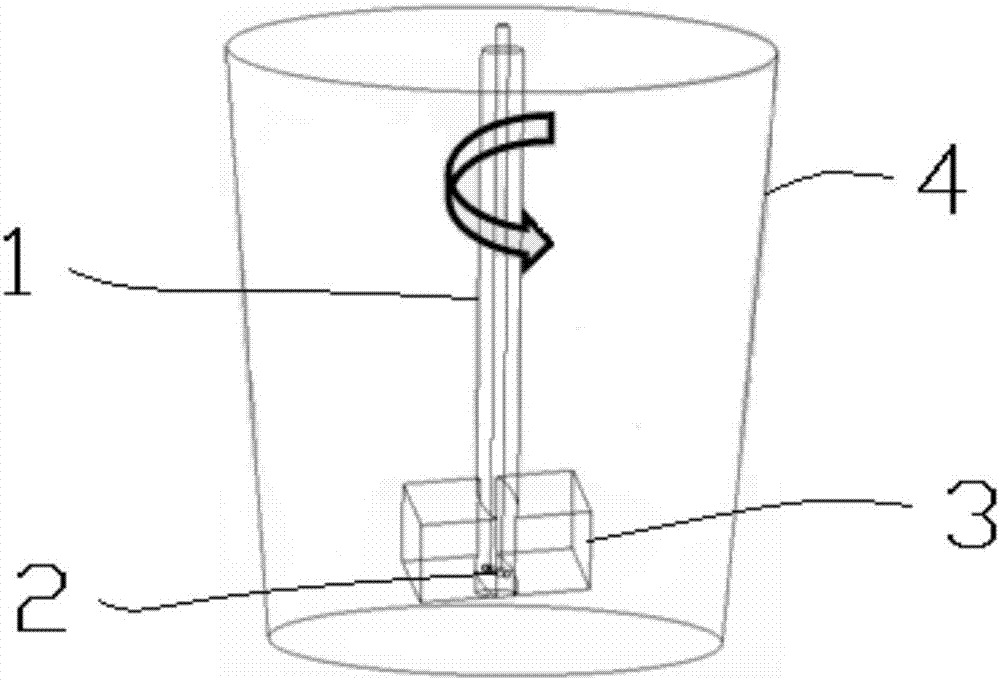

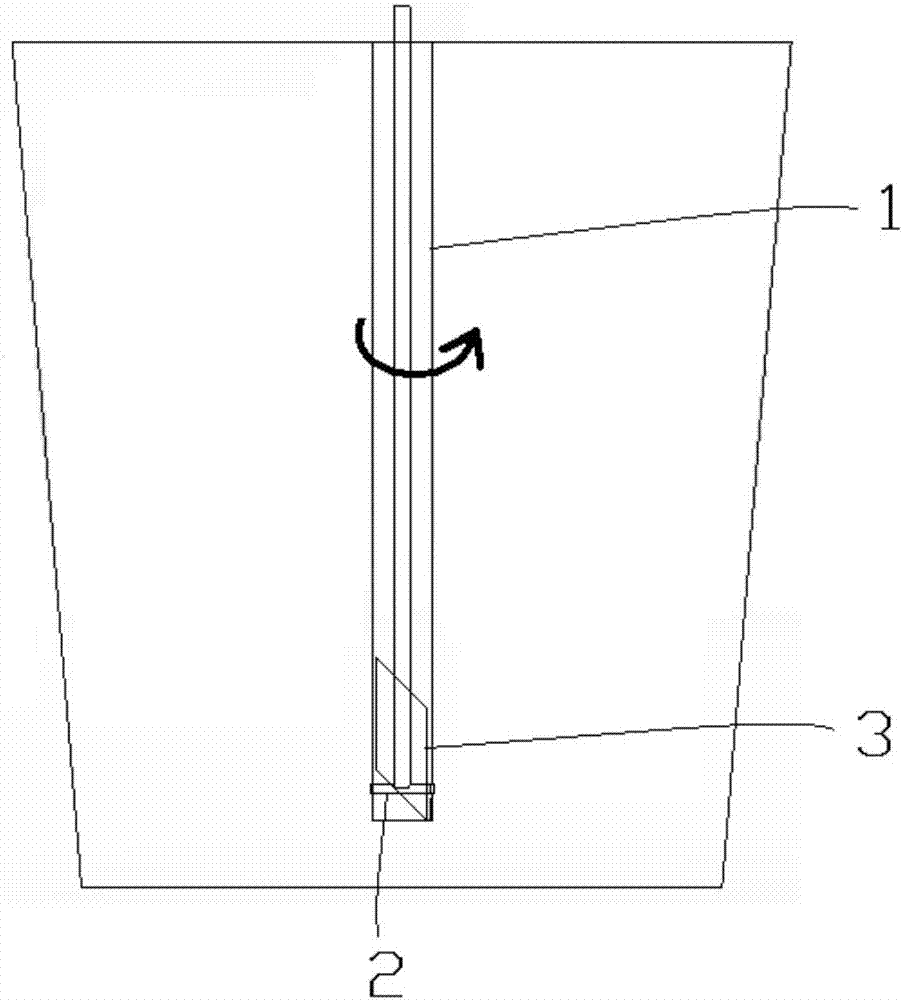

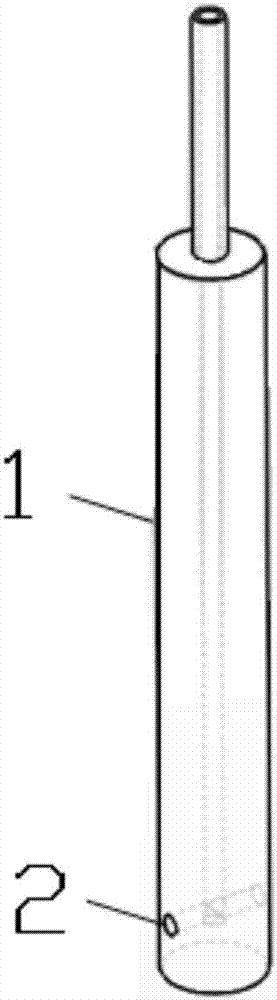

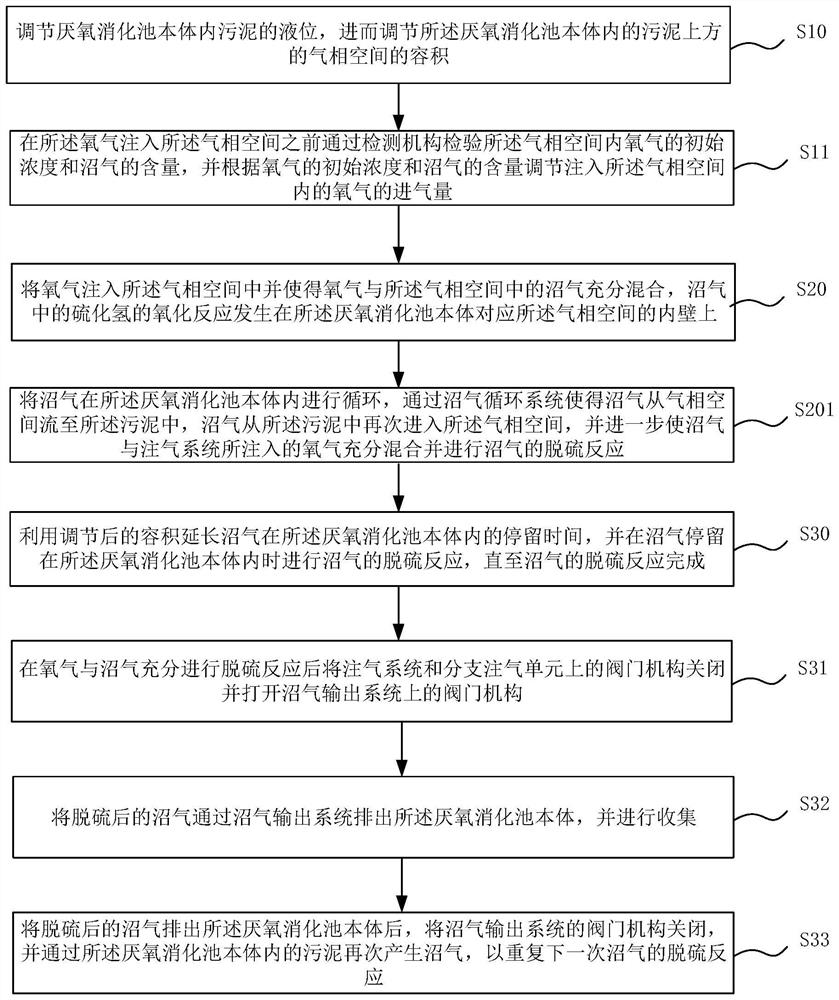

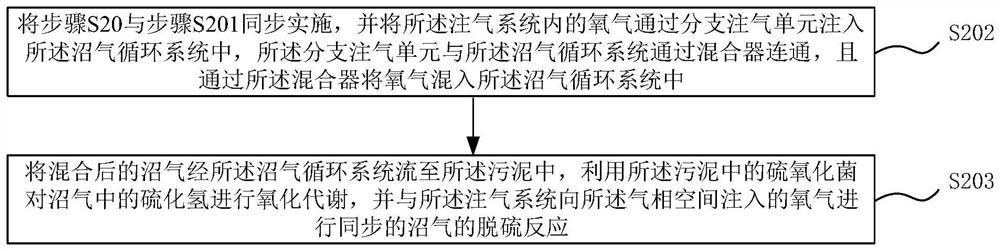

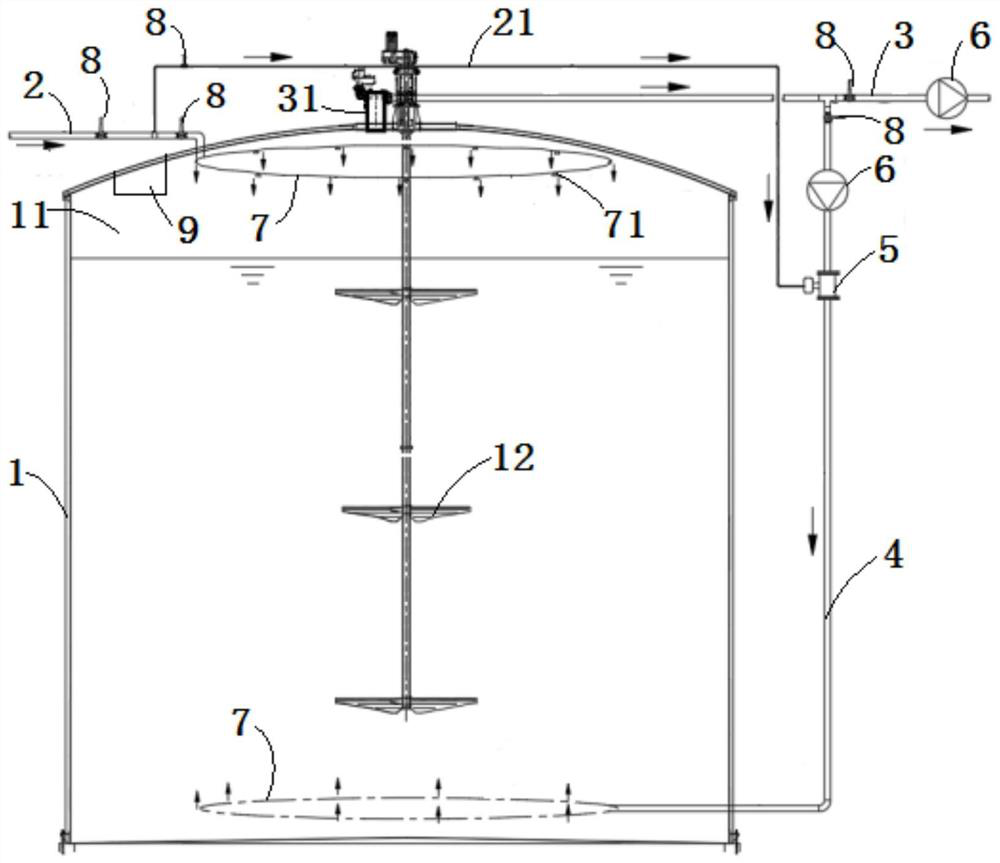

Oxygen injection desulfurization sludge treatment method and anaerobic digester

ActiveCN114853300AQuality improvementShort reaction timeGaseous fuelsWaste based fuelProcess engineeringAnaerobic digestion

The invention discloses an oxygen injection desulfurization sludge treatment method and an anaerobic digester, and the sludge treatment method comprises the following steps: S10, adjusting the sludge liquid level in an anaerobic digester body, and further adjusting the volume of a gas phase space above the sludge in the anaerobic digester body; s20, oxygen is injected into the gas-phase space, and the oxygen and the biogas in the gas-phase space are fully mixed; and S30, prolonging the residence time of the biogas in the anaerobic digester body by using the adjusted volume, and performing a desulfurization reaction of the biogas when the biogas stays in the anaerobic digester body until the desulfurization reaction of the biogas is completed. By adjusting the volume of the gas phase space, the volume meets the size required by the desulfurization reaction of the biogas, and oxygen is injected, so that the quality of the biogas after the desulfurization reaction of the biogas is improved, and the investment cost and the operation cost of other equipment such as an anaerobic digester during the desulfurization of the biogas are reduced.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Sintering flue gas desulfurization system and sintering flue gas desulfurization method

PendingCN111214933AImprove reaction efficiencyReduce the temperatureGas treatmentDispersed particle filtrationWater storage tankFlue gas

The invention provides a sintering flue gas desulfurization system and a sintering flue gas desulfurization method. The system comprises a slaked lime slurry supply device, an air supply device, a water storage tank, a three-fluid spray gun, a desulfurization tower, a dust removal device and a flue inlet pipeline, wherein the slaked lime slurry supply device is communicated with the three-fluid spray gun, the air supply device is communicated with the three-fluid spray gun, the water storage tank is communicated with the three-fluid spray gun through a liquid conveying pump, a flue gas inlet and a flue gas outlet are formed in the bottom of the desulfurization tower, a venturi tube is communicated below the flue gas inlet of the desulfurization tower, and is communicated with the flue inlet pipeline, and the nozzle of the three-fluid spray gun is arranged on the flue inlet pipeline below the venturi tube. According to the invention, the sintering flue gas desulfurization method appliesthe sintering flue gas desulfurization system, the sintering flue gas desulfurization system combines the advantages of a wet desulfurization method and a semi-dry desulfurization method, operation is flexible and reliable, the flue gas load application range is wide, corrosion and white smoke are avoided, and the desulfurization efficiency can reach 95-99%.

Owner:XIAN XIKUANG ENVIRONMENTAL PROTECTION

Lime slurry jetting circulating fluid bed semi-dry process desulfurizer

ActiveCN102000492BReduce workloadPromote desulfurization reactionDispersed particle separationEngineeringSlurry

The invention discloses a lime slurry jetting circulating fluid bed semi-dry process desulfurizer which comprises a desulfurization reaction column, a gas-solid separator and a draught fan, wherein the lower part of the desulfurization reaction column is provided with a lime slurry nozzle and a fume inlet; an after-reaction gas outlet of the desulfurization reaction column is communicated with the gas-solid separator through a spoiler; and the spoiler is positioned on the upper part of the after-reaction gas outlet of the desulfurization reaction column. In the invention, the upper part of the gas outlet of the desulfurization reaction column is provided with the spoiler which can forcibly mix the gas-solid mixture discharged by the desulfurization reaction into a turbulent condition, thereby strengthening the desulfurization reaction of the mixture; and meanwhile, part of unreacted slurry particles return to the desulfurization reaction column for reaction after colliding with each other in the spoiler, thereby enhancing the desulfurization efficiency. The desulfurizer can reduce the working load of the gas-solid separator under the condition of high fume flow on the premise of ensuring the separating effect, and is applicable to high-flow fume desulfurization. When the fume flow is low, the turbulence is strengthened by the spoiler, thereby prolonging the contact reaction time and enhancing the desulfurization efficiency.

Owner:CISDI ENG CO LTD

A low-temperature circulating fluidized bed flue gas desulfurization and dust removal equipment

ActiveCN103463965BGuarantee working reliabilityEliminate worriesDispersed particle filtrationMoisture condensationFluidized bed

The invention discloses flue gas desulfurization and dust removal equipment of a low-temperature circulating fluidized bed. The equipment comprises a desulfurization reaction tower, a dedusting unit and a material returning unit, the equipment is internally provided with a heat exchange module, wherein the heat exchange module comprises a hot wall device; the hot wall device comprises at least one group of heating screens and at least one group of heat preservation layers, the heating screens comprise channels the ports of which are open for assisting a heating medium in circulating, the hot wall device is covered on heat dissipation wall surfaces of the desulfurization reaction tower and the dedusting unit, and the heating screens are positioned among the heat preservation layers and heat dissipation wall surfaces covered on the hot wall device. The flue gas desulfurization and dust removal equipment provided by the invention has the advantages that the worries of moisture condensation, scale formation and pasting bag of the desulfurization reaction tower and the dedusting unit are eliminated, the desulfurization adiabatic saturation temperature difference is controlled within 15 DEG C-5 DEG C, the desulfurization reaction efficiency is higher than 95% or even 99% under the condition that the molar ratio (Ca / S) of a calcium element and a sulfur element is less than 1.3, and the operational reliability of the equipment is still guaranteed.

Owner:SHANGHAI XIAOQING ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com