Patents

Literature

62results about How to "Promote desulfurization reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

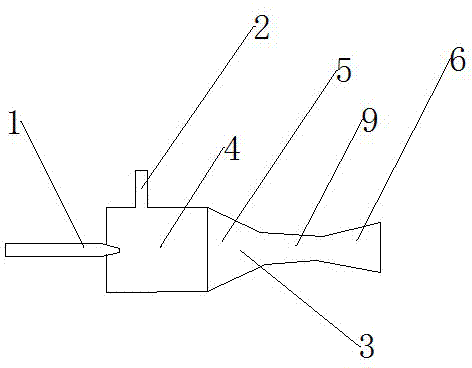

KR stirring paddle and manufacture method thereof

ActiveCN103014218APromote desulfurization reactionTo achieve the purpose of deep desulfurizationStirring devicesEngineeringHot melt

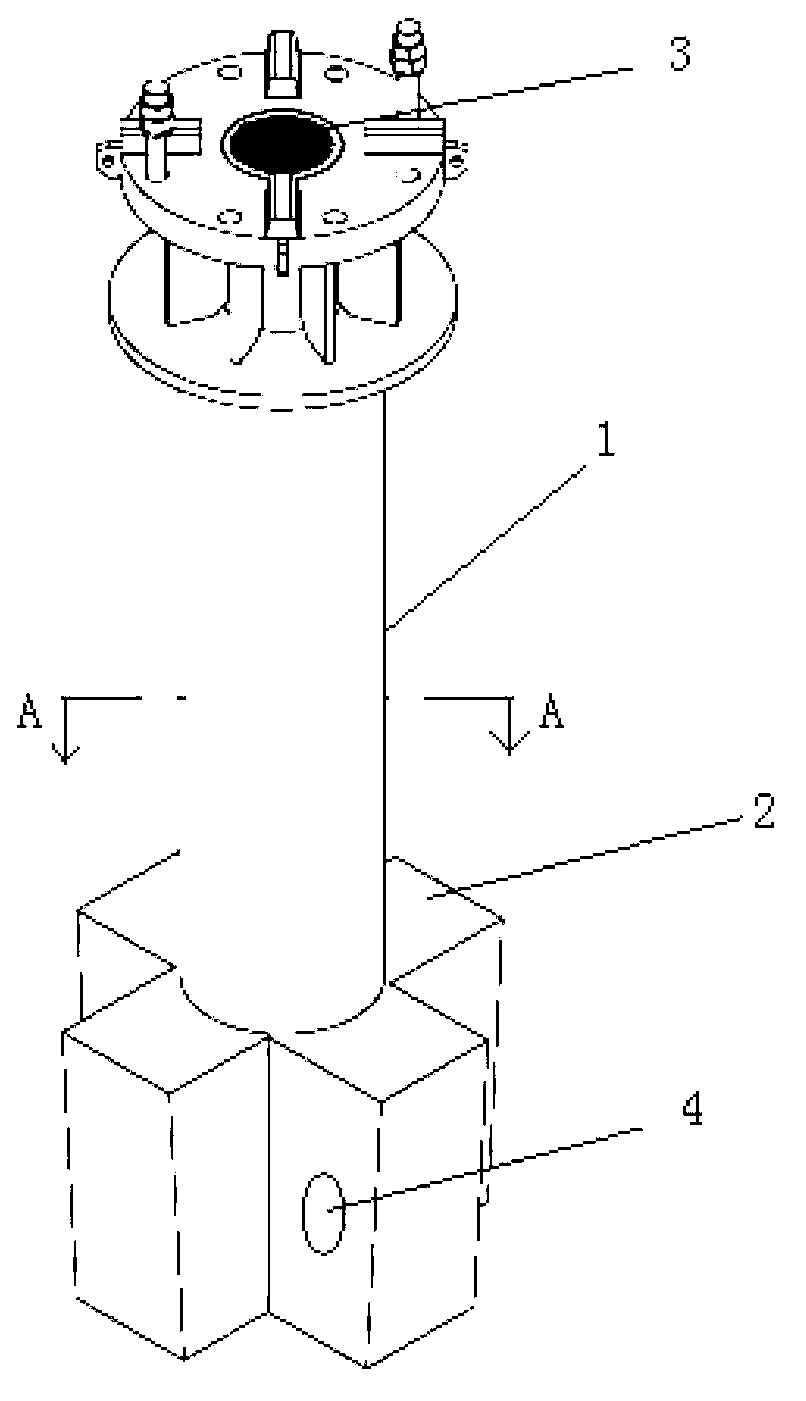

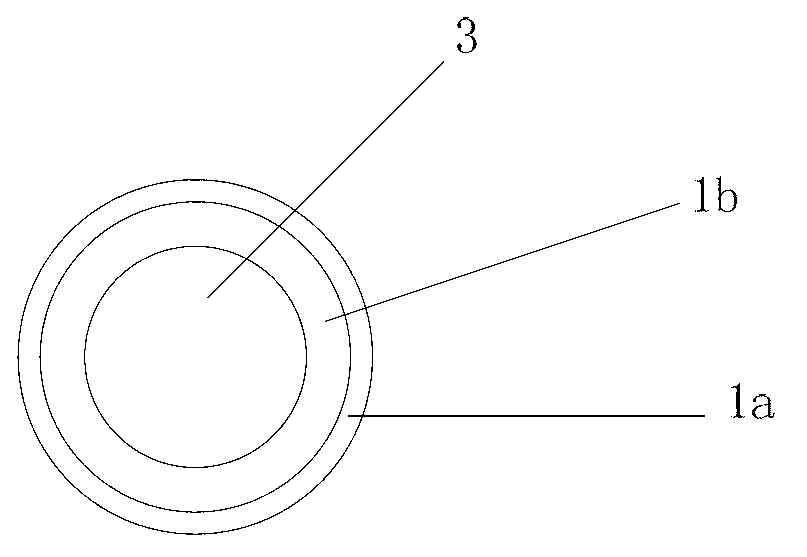

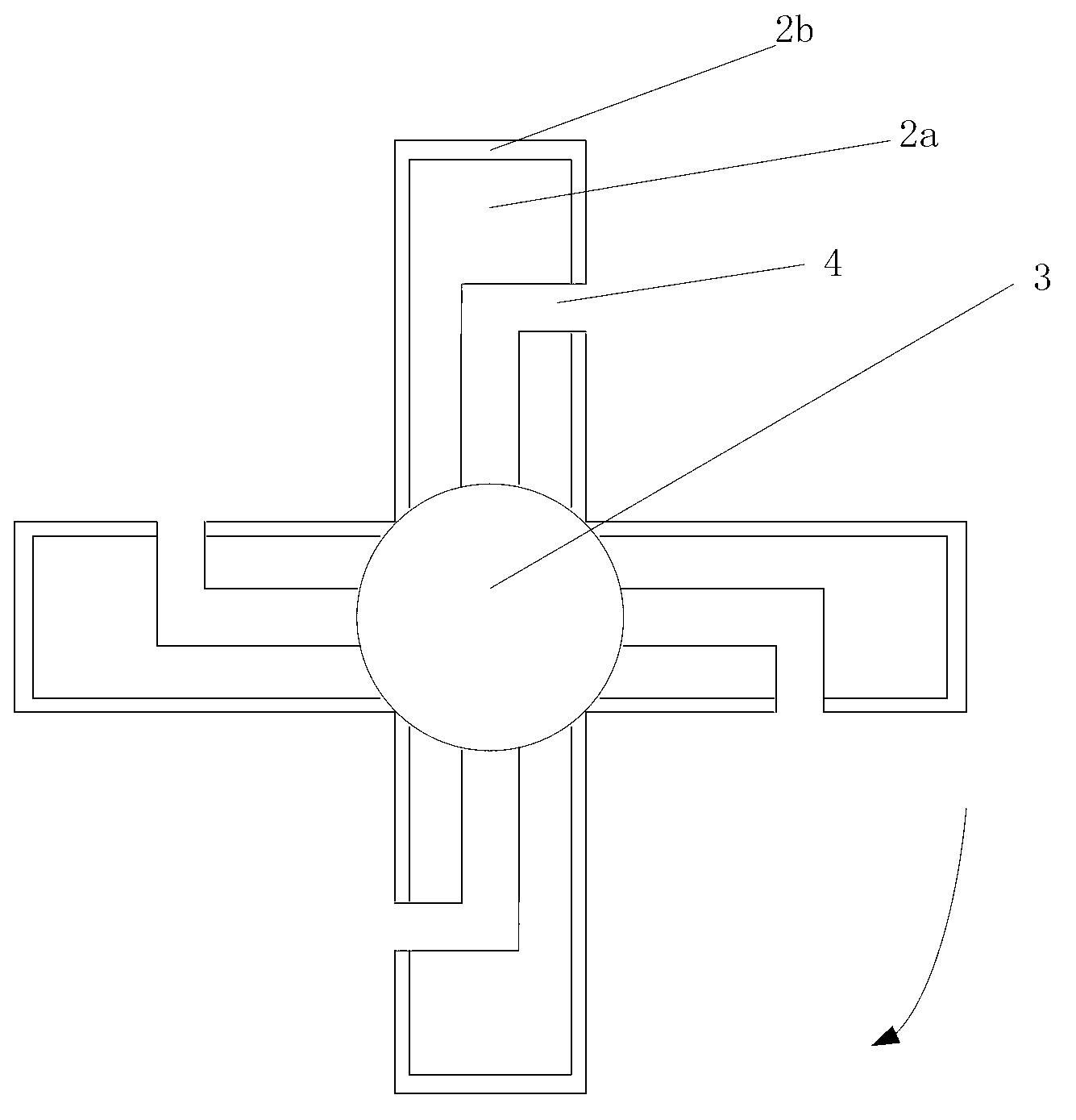

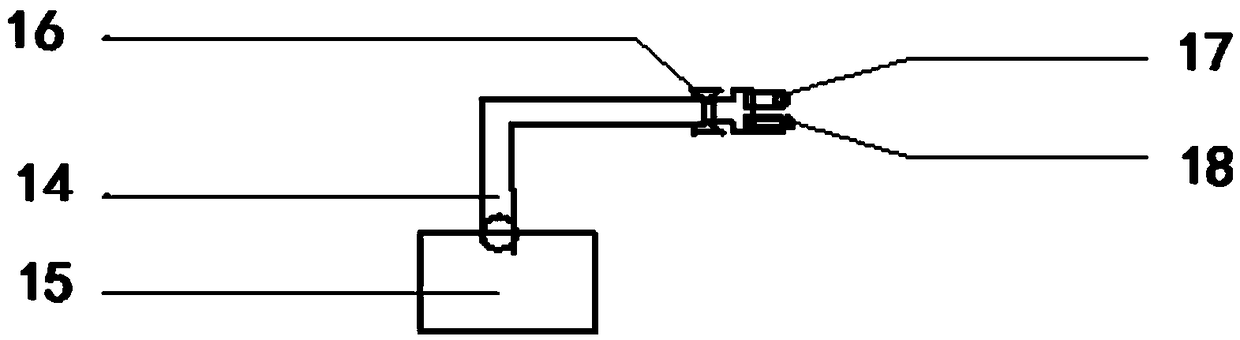

The invention discloses a KR stirring paddle and a manufacture method thereof. The KR stirring paddle is used in a hot-melt ladle desulfuration process and comprises a stirring shaft, paddles, a ventilating pipeline and ventilating holes, wherein the paddles are arranged on one end of the bottom of the stirring shaft, the core part of the stirring shaft is hollow and is used as the ventilating pipeline, the ventilating holes are formed in the paddles, one ends of the ventilating holes are communicated with the ventilating pipeline, the other ends of the ventilating holes are opened in the surfaces of the paddles, and one end of the top of the stirring shaft is connected with a gas supply device for supplying gas to the ventilating pipe. According to the invention, through the KR stirring paddle, the gas is introduced from the ventilating pipeline and is discharged from the ventilating holes, the discharged gas plays a role of reinforcing the stirring of molten ion to ensure that the molten iron is in well contact with a desulfurizing agent for reaction, therefore the desulfurization of the molten iron is accelerated, and the purpose of deep desulfurization of the molten iron is reached.

Owner:DAYE SPECIAL STEEL CO LTD

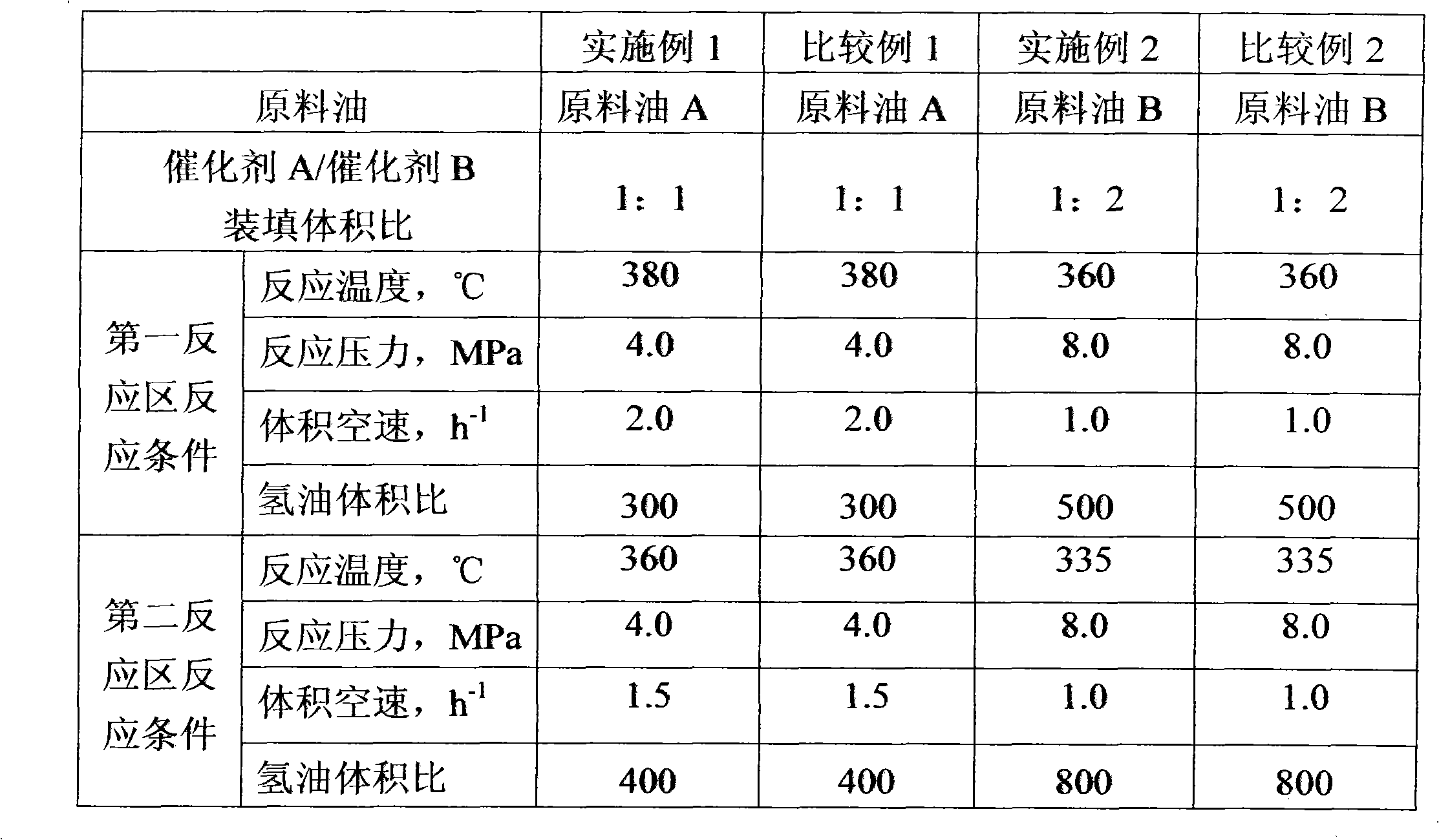

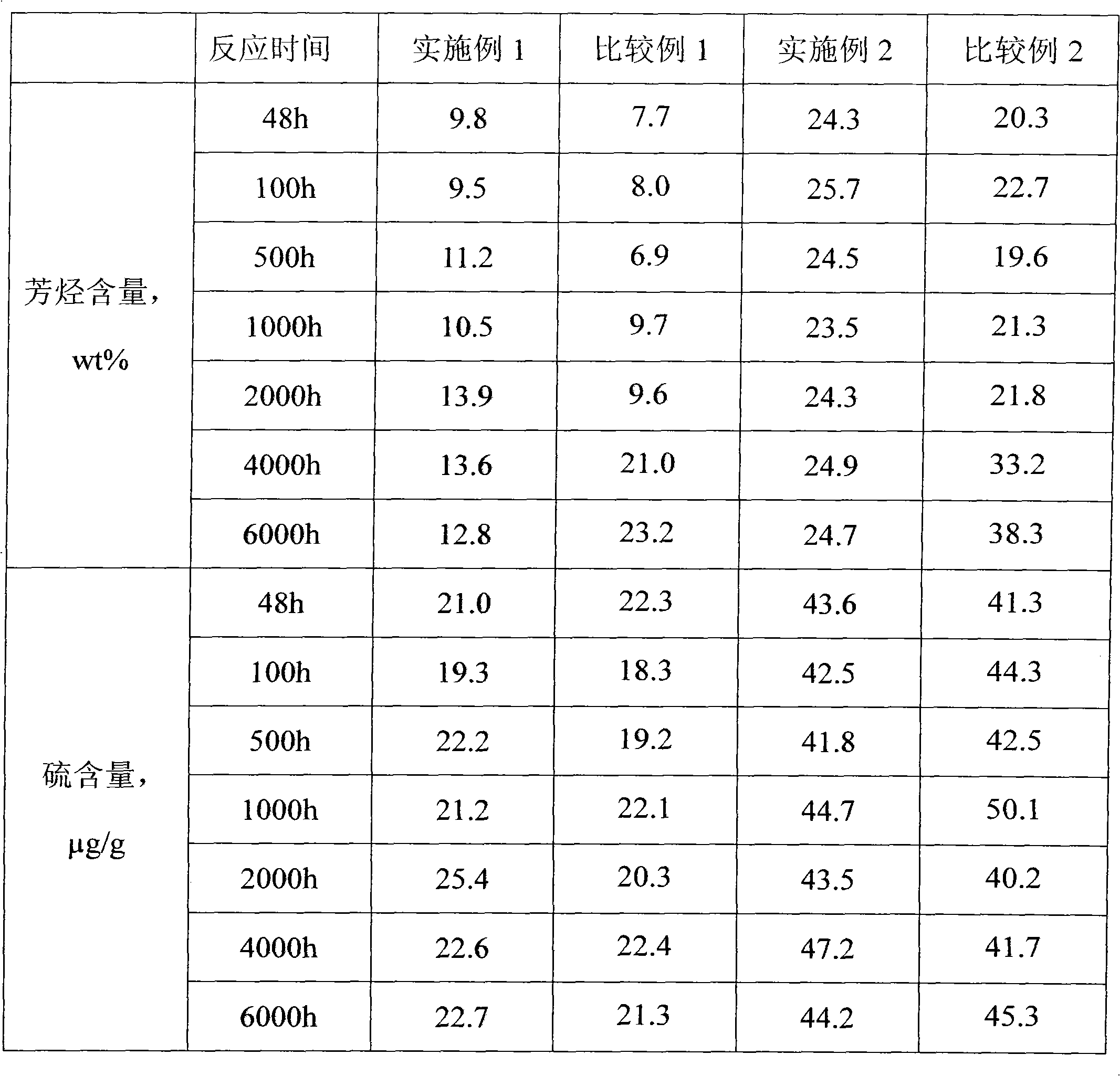

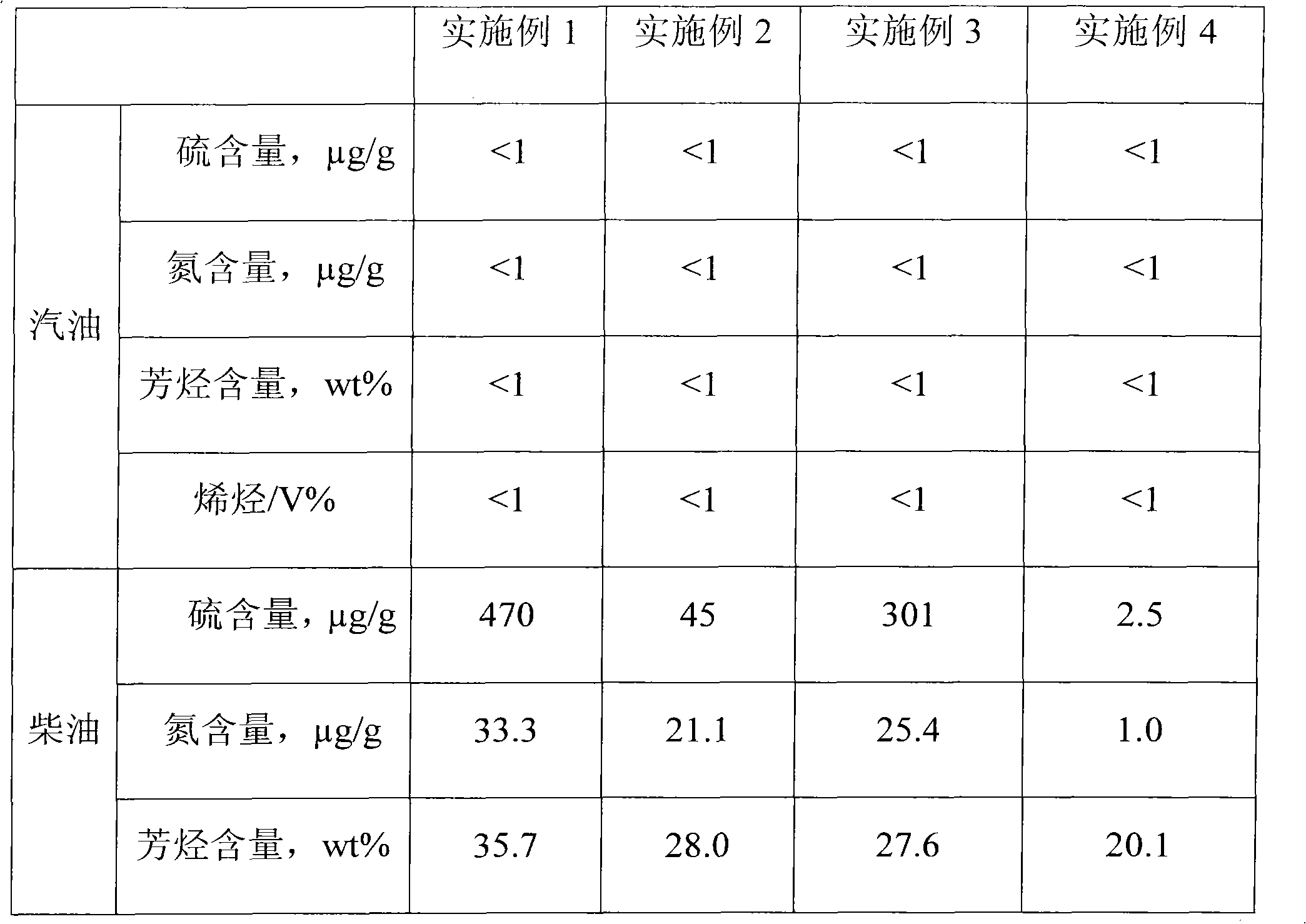

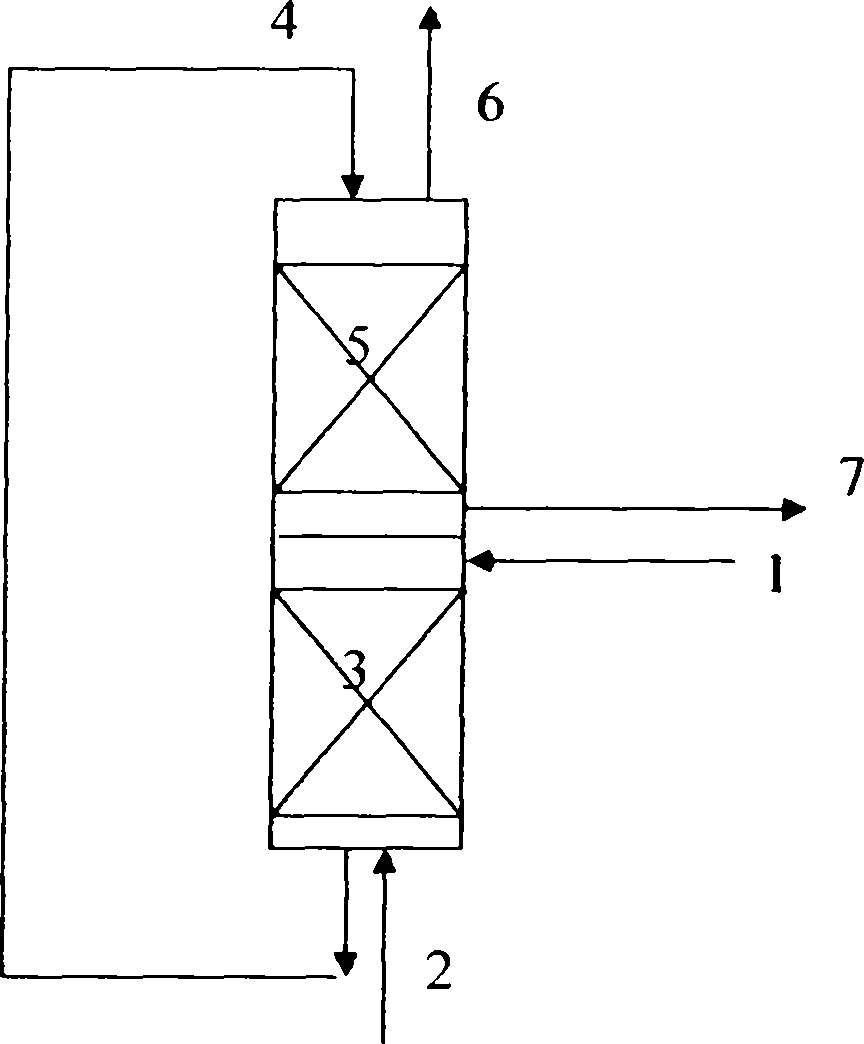

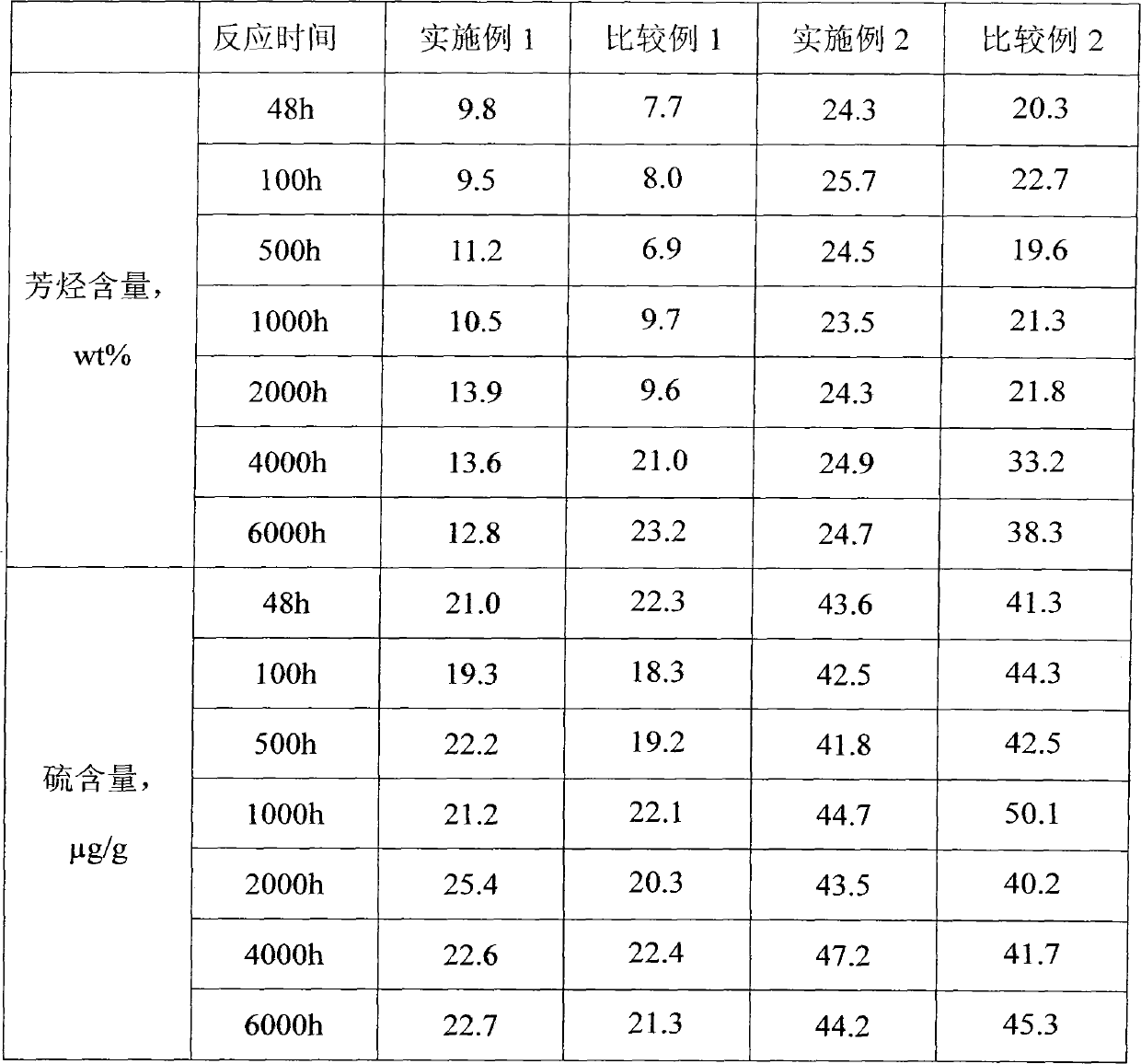

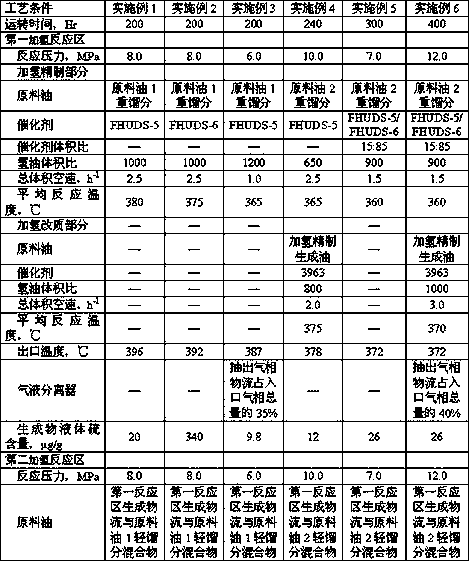

Method for deep hydrogenation, sulfur removal and aromatics removal of diesel oil

ActiveCN101942330APromote desulfurization reactionSave resourcesTreatment with hydrotreatment processesLiquid productPtru catalyst

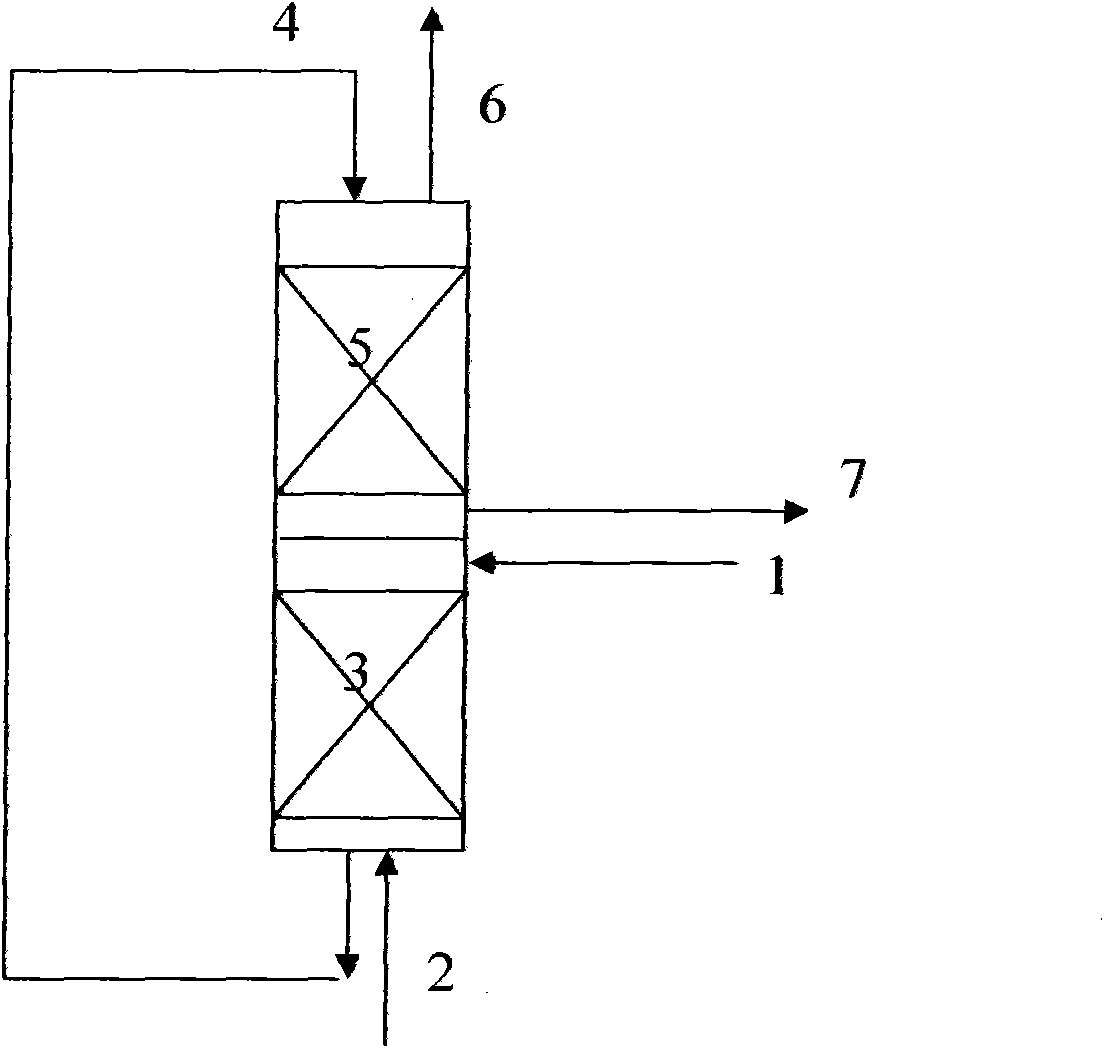

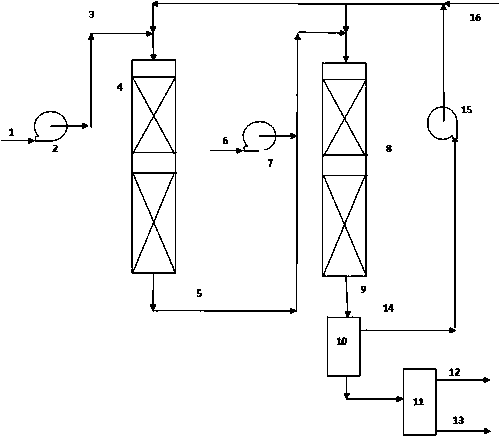

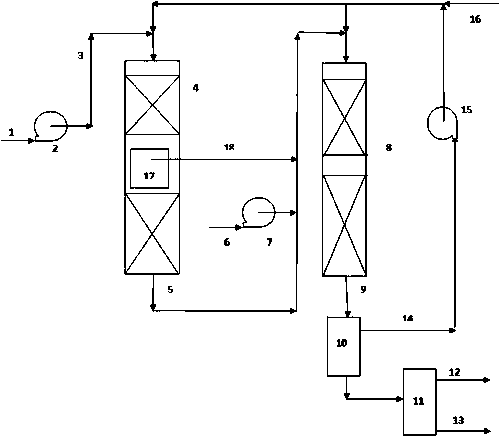

The invention discloses a method for deep hydrogenation, sulfur removal and aromatics removal of diesel oil. In the method, two reaction areas are included, wherein diesel oil raw materials and hydrogen gas counter pass the second reaction area, the reaction products out of the second reaction area are charged from the upper part of the first reaction area and in counter current contact with the hydrogen gas from the second reaction area, the obtained gas products are discharged from the top part of the first reaction area, and the liquid products are discharged from the lower part of the first reaction area. In the method, sulfide catalysts in the first reaction area and the second reaction area are not desulfurized, and simultaneously properties such as hydrogenation and sulfur removal of hydrogenation catalysts and aromatics saturation are ensured to be fully shown, so that the service life of the catalyst is prolonged and the production cost is lowered. The method has the advantages of fully utilizing the reaction heat in the second reaction area, saving heat collection or cooling treatment by adding cold medium, saving resources and lowering cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

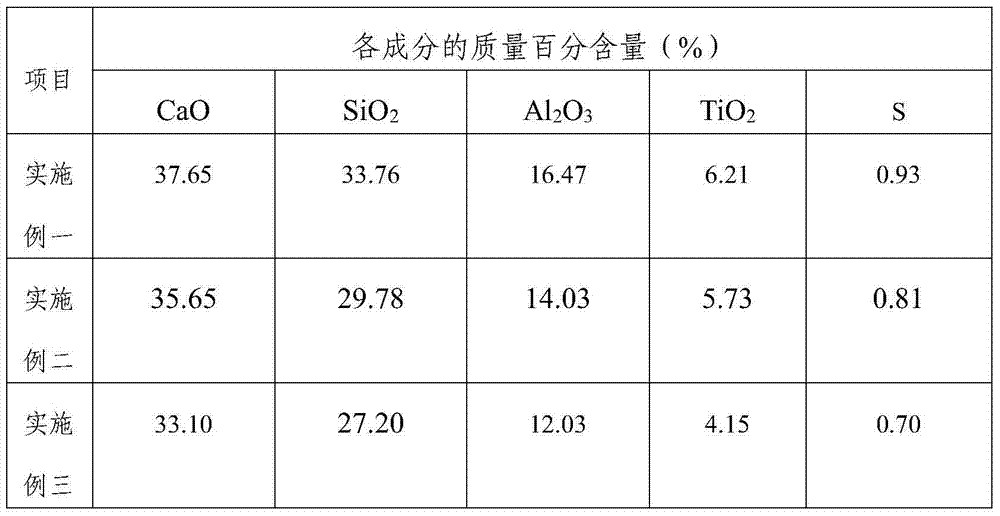

Efficient composite desulfurizer

The invention discloses a high-efficiency compound desulfurizing agent, relating to the ladle desulphurization accessory field. In the existing ladle desulphurization, the uniserial desulfurizing agent is uniformly adopted, with narrower function, and non-agreeable desulphurization effect. Aiming at the condition that small and medium-sized steel mills do not have liquid iron pretreatment systems or desulphurization stations, and do not have powder spraying desulphurization devices, the desulfurizing agent of the invention adopts ingredient with multi-components, namely, the compound desulfurizing agent consisting of limestone, calcined soda, fluorite, calcium carbide, magnesium powder and caustic-calcined magnesite, with the weight proportion of 40 to 50, 10 to 20, 5 to 15, 10 to 20, 4 to 6 and 5 to 15 sequentially. The desulfurizing agent has the following advantages that: 1. the integral desulphurization capability is strong, and the sulfur content can be reduced to 20ppm; 2. sulfur substance can be contained, and resulfurization phenomenon can not be generated; 3. the desulfurizing agent can be directly poured, and equipment and investment are not needed to be increased; and 4. the desulphurization speed is high.

Owner:西峡县福盈冶金材料有限公司

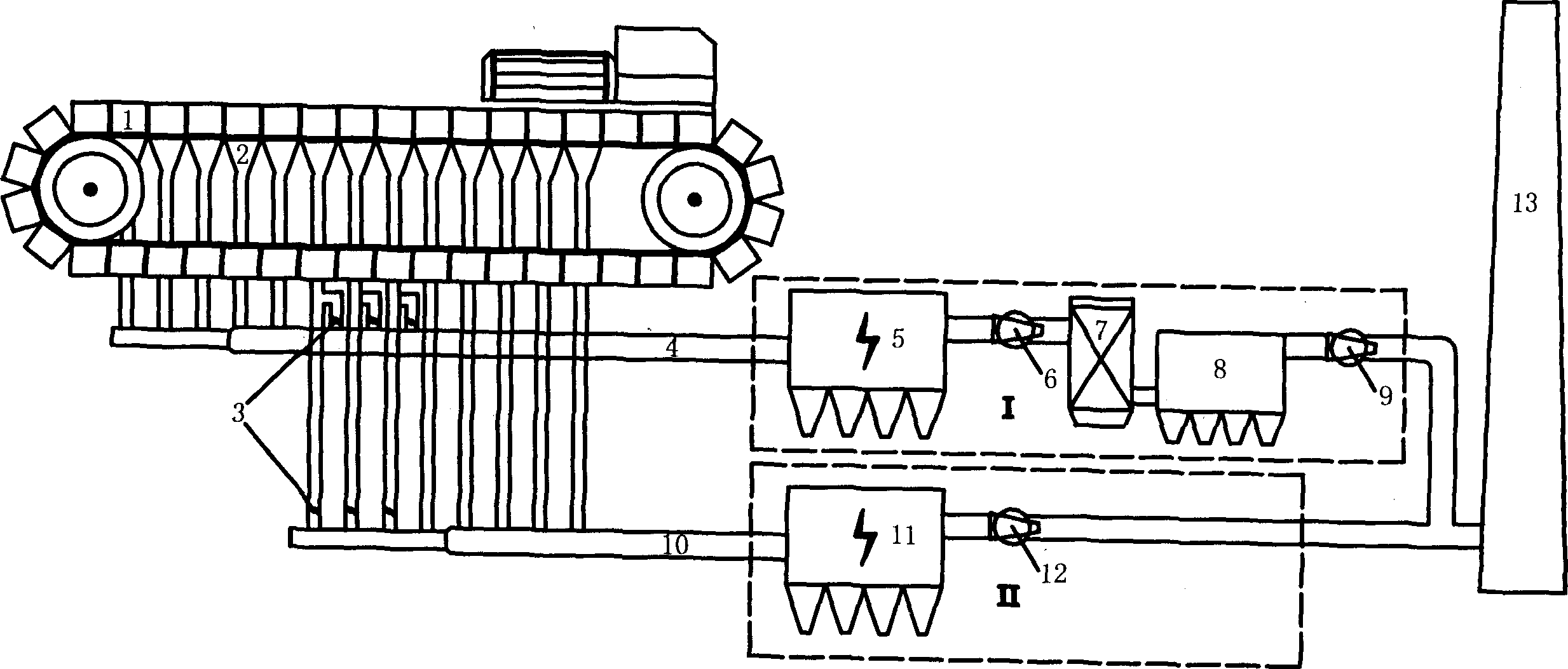

Selectivelly-desulfurized dense-phase tower drier

A closely coherent tower system for selective desulfurizing is composed of a desulfurizing system A and a non-desulfurizing system B, which serve a single sintering motion at same time. Said desulfurizing system A consists of wind gathering hopper, flue valve, flue, electric duster, exhaust blower, closely coherent tower, cloth-bag duster and boosting blower. Said non-desulfurizing system B comprises flue, electric duster and exhaust blower.

Owner:UNIV OF SCI & TECH BEIJING +1

Gasoline and diesel oil combined hydrogenation method

ActiveCN101942331AExtended service lifeRelaxed reaction conditionsTreatment with hydrotreatment processesHydrogenHydrodesulfurization

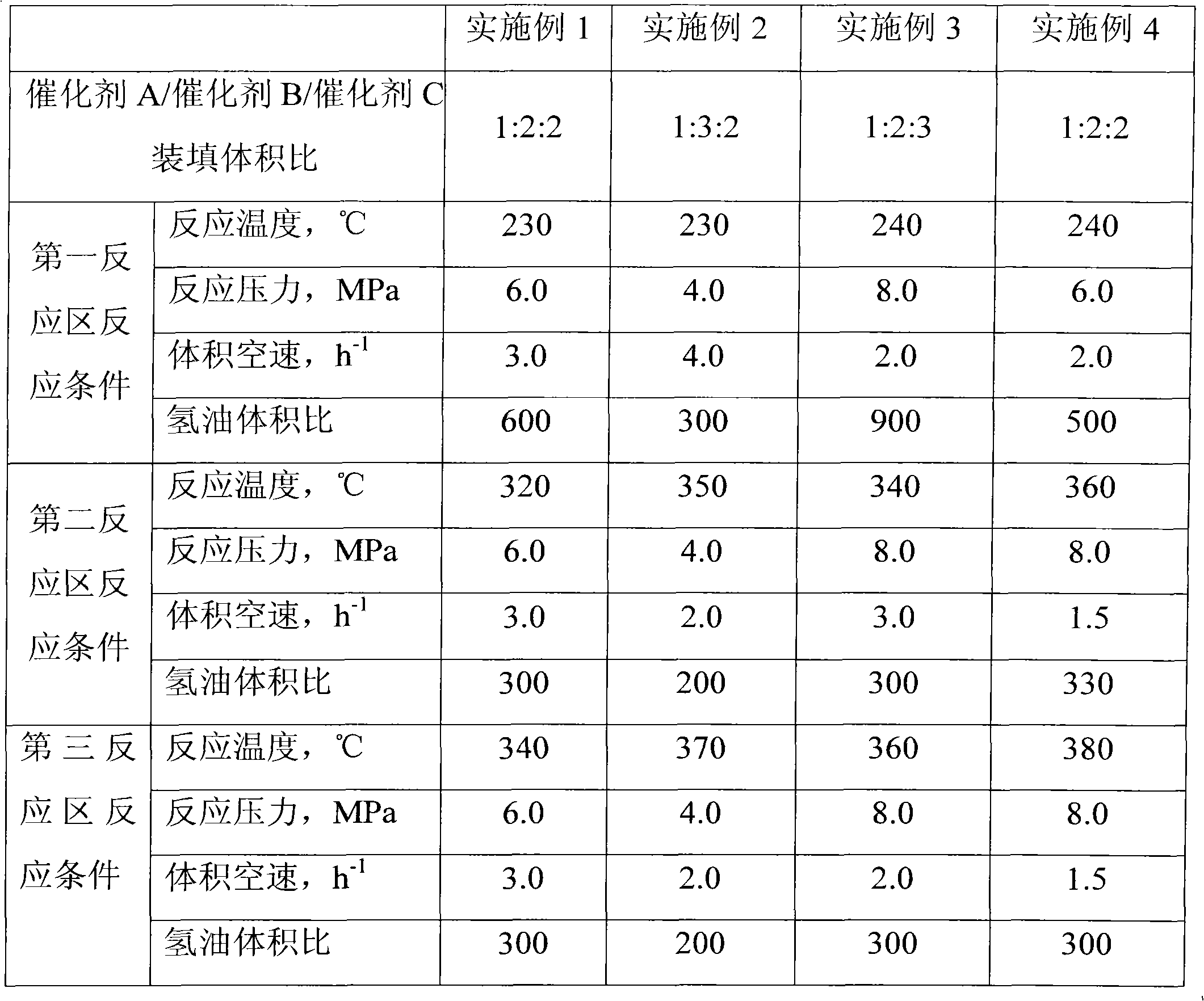

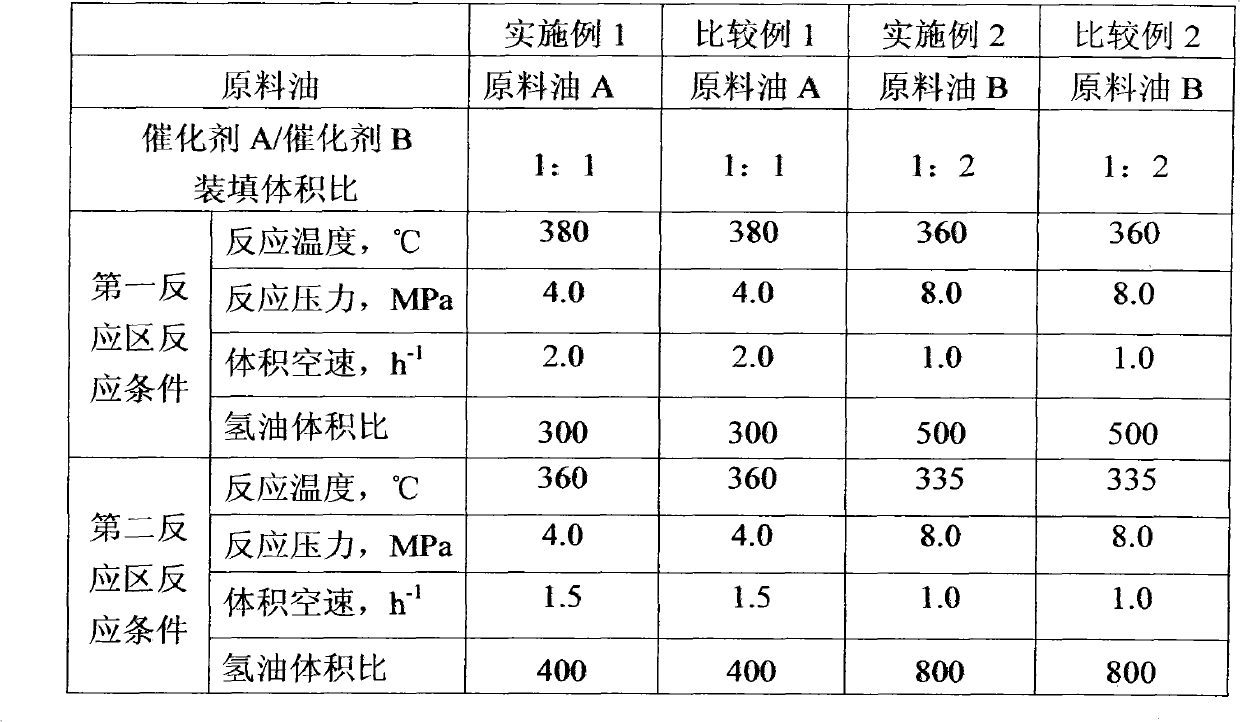

The invention discloses a gasoline and diesel oil combined hydrogenation method, comprising the following steps: the raw gasoline is mixed with hydrogen, the mixture passes through a first reaction zone under the condition of gasoline hydrofining, a hydrofining catalyst is used in the first reaction zone and the raw gasoline is coker gasoline and / or fluid catalytic cracking gasoline; the reactor effluent from the first reaction zone is mixed with the raw diesel oil, the mixture passes through a second reaction zone under the condition of diesel oil hydrodearomatization, a hydrofining catalystis used in the second reaction zone and the raw diesel oil is one or more of straight-run diesel oil, coker diesel oil or fluid catalytic cracking diesel oil; and the reactor effluent from the secondreaction zone passes through a third reaction zone under the condition of diesel oil hydrodesulfurization and a hydrodesulfurization catalyst is used in the third reaction zone. The method effectively utilizes the heat emitted during secondary processing gasoline hydrogenation, is simple in process and low in energy consumption and can obtain high-quality gasoline and diesel oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for deep hydrogenation, sulfur removal and aromatics removal of diesel oil

ActiveCN101942330BPromote desulfurization reactionSave resourcesTreatment with hydrotreatment processesLiquid productHydrogen

The invention discloses a method for deep hydrogenation, sulfur removal and aromatics removal of diesel oil. In the method, two reaction areas are included, wherein diesel oil raw materials and hydrogen gas counter pass the second reaction area, the reaction products out of the second reaction area are charged from the upper part of the first reaction area and in counter current contact with the hydrogen gas from the second reaction area, the obtained gas products are discharged from the top part of the first reaction area, and the liquid products are discharged from the lower part of the first reaction area. In the method, sulfide catalysts in the first reaction area and the second reaction area are not desulfurized, and simultaneously properties such as hydrogenation and sulfur removal of hydrogenation catalysts and aromatics saturation are ensured to be fully shown, so that the service life of the catalyst is prolonged and the production cost is lowered. The method has the advantages of fully utilizing the reaction heat in the second reaction area, saving heat collection or cooling treatment by adding cold medium, saving resources and lowering cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

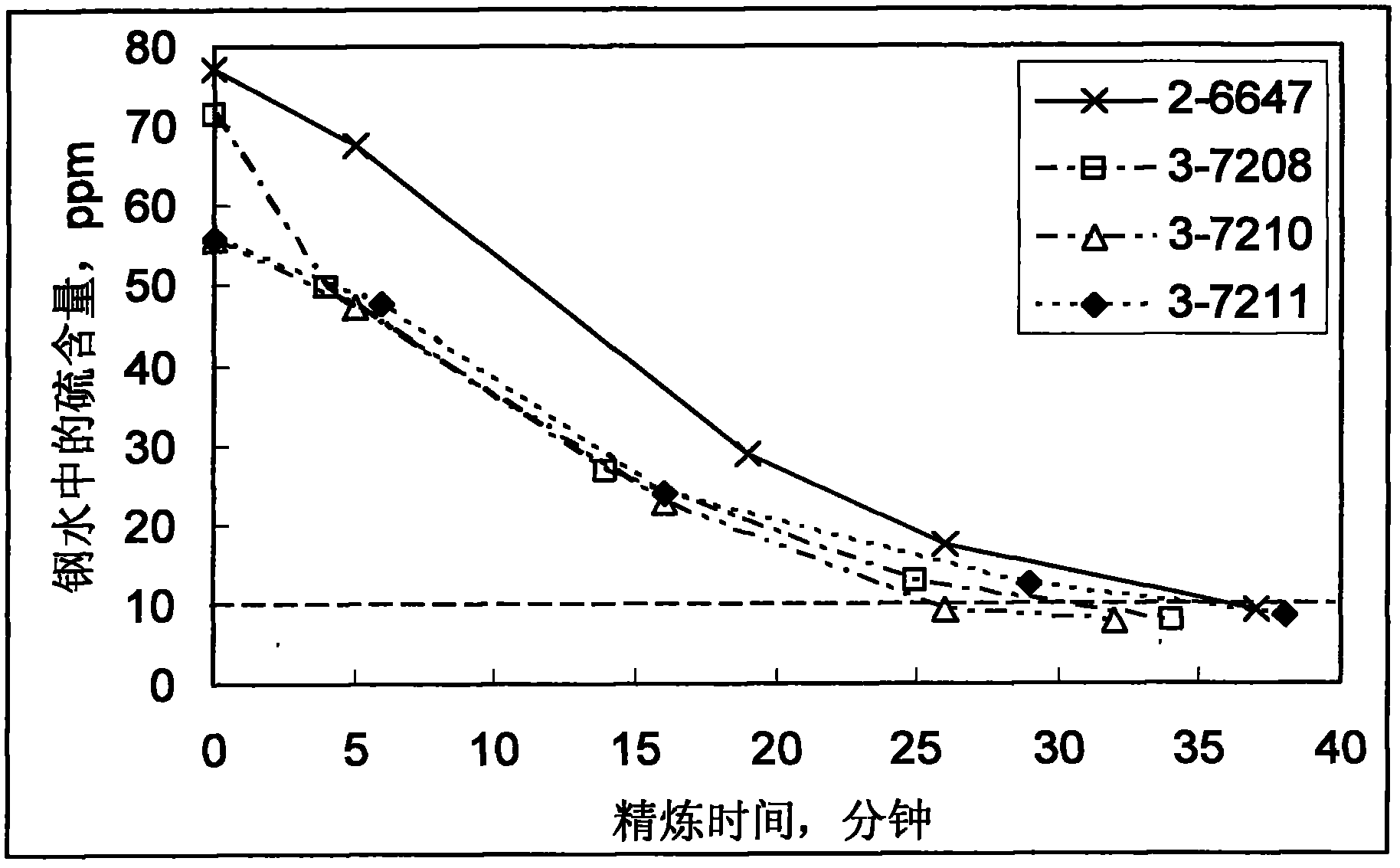

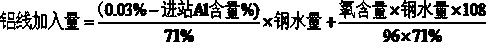

Ladle refining deep desulphurization method for low-carbon aluminum killed steel

ActiveCN102517420AReduce usageMeet the requirements of deep desulfurizationProcess efficiency improvementSlagMaterials science

The invention discloses a ladle refining deep desulphurization method for low-carbon aluminum killed steel. The method comprises: adding 1.2-2.8kg / t of aluminum and 1-5kg / t of lime in a converter tapping process, finish adding all slag materials about 1-2min before the end of tapping, and adding 0-0.2kg / t of aluminum to the slag surface for rapid deoxidation of ladle top slag when the tapping is over; then, after the ladle arrives an LF (ladle furnace) refining station, adding 1-5kg / t of lime into the ladle, and conducting energizing for slag melting, in the refining process, controlling the total flow of bottom blowing gas of the ladle at 1-9NL / min.t and the content of acid-soluble aluminum in molten steel at 0,02-0.08wt%, and controlling the molten steel temperature at 1600-1640DEG C atthe terminal point of refining. Compared with prior art, the method of the invention needs no CaF2 that is unfavorable to human bodies and the environment, relatively expensive premelting slag and the like. And under the premise of not increasing the operation time, the sulfur content of the molten steel can be controlled below 0.001wt% within 40min, and the desulfurization rate can reach more than 80%. The method provided in the invention has the advantages of simple process, strong operability and low cost.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

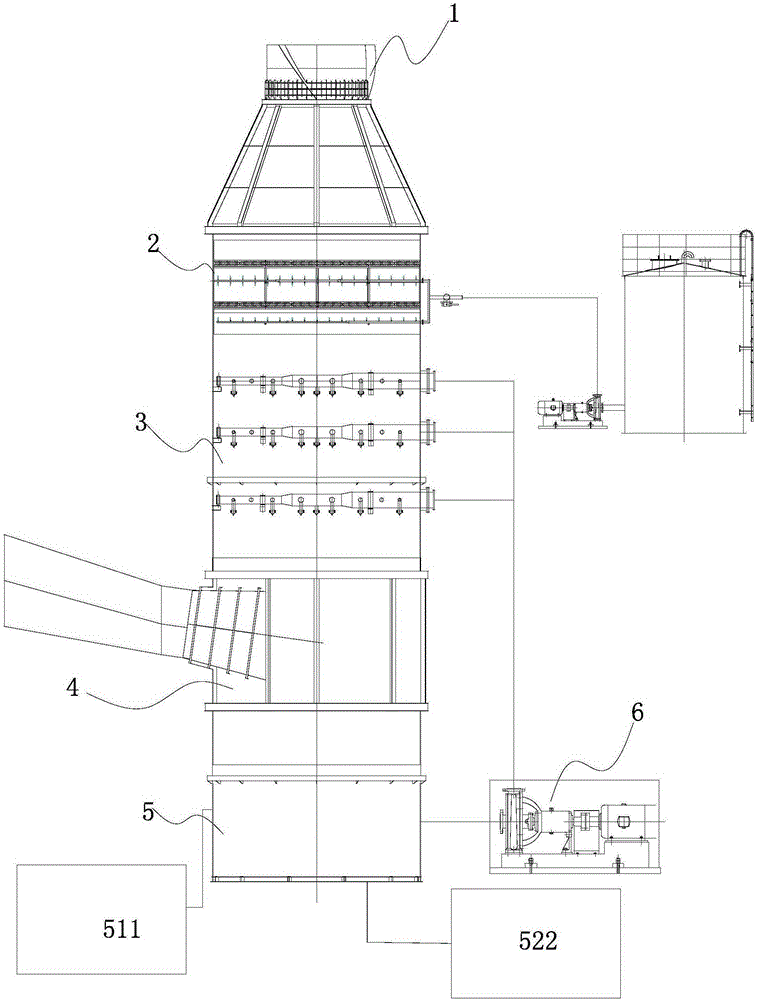

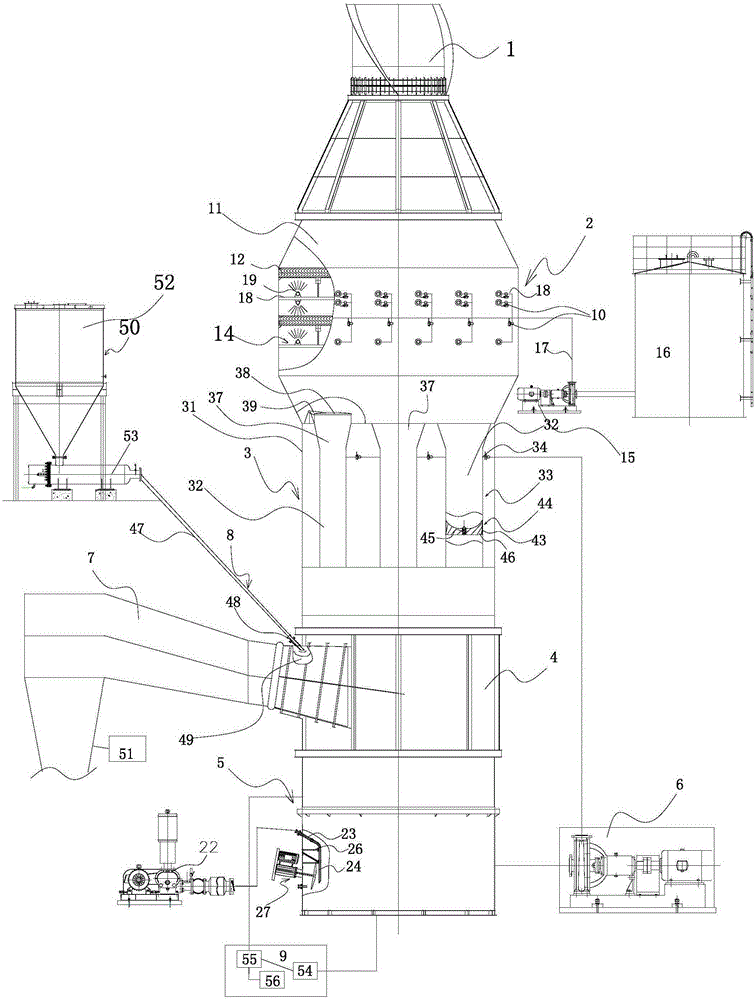

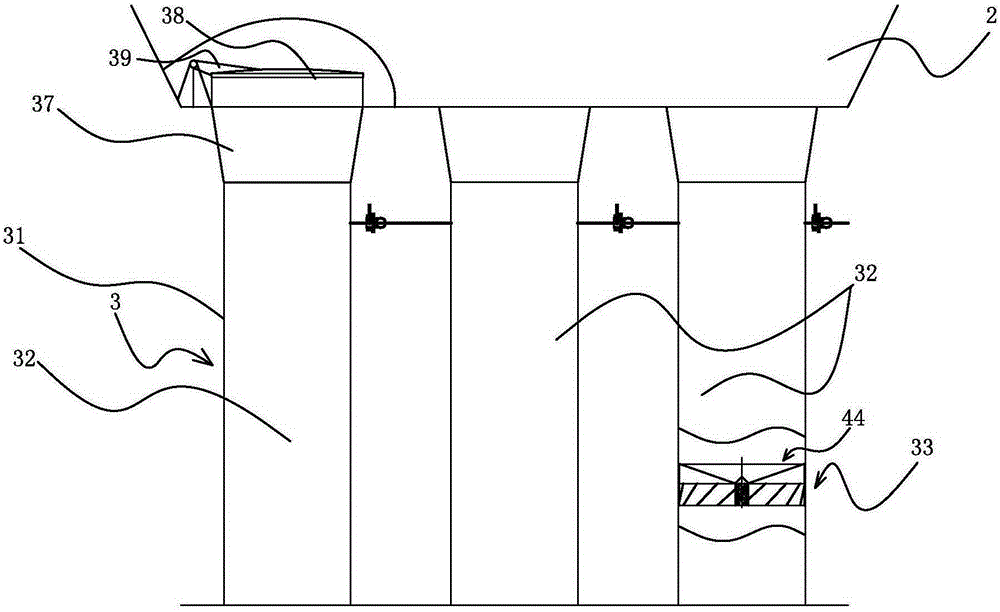

Flue gas desulphurization system and method for flue gas desulfurization by means of same

ActiveCN105169926APromote desulfurization reactionImprove desulfurization efficiencyDispersed particle separationImpellerFlue gas

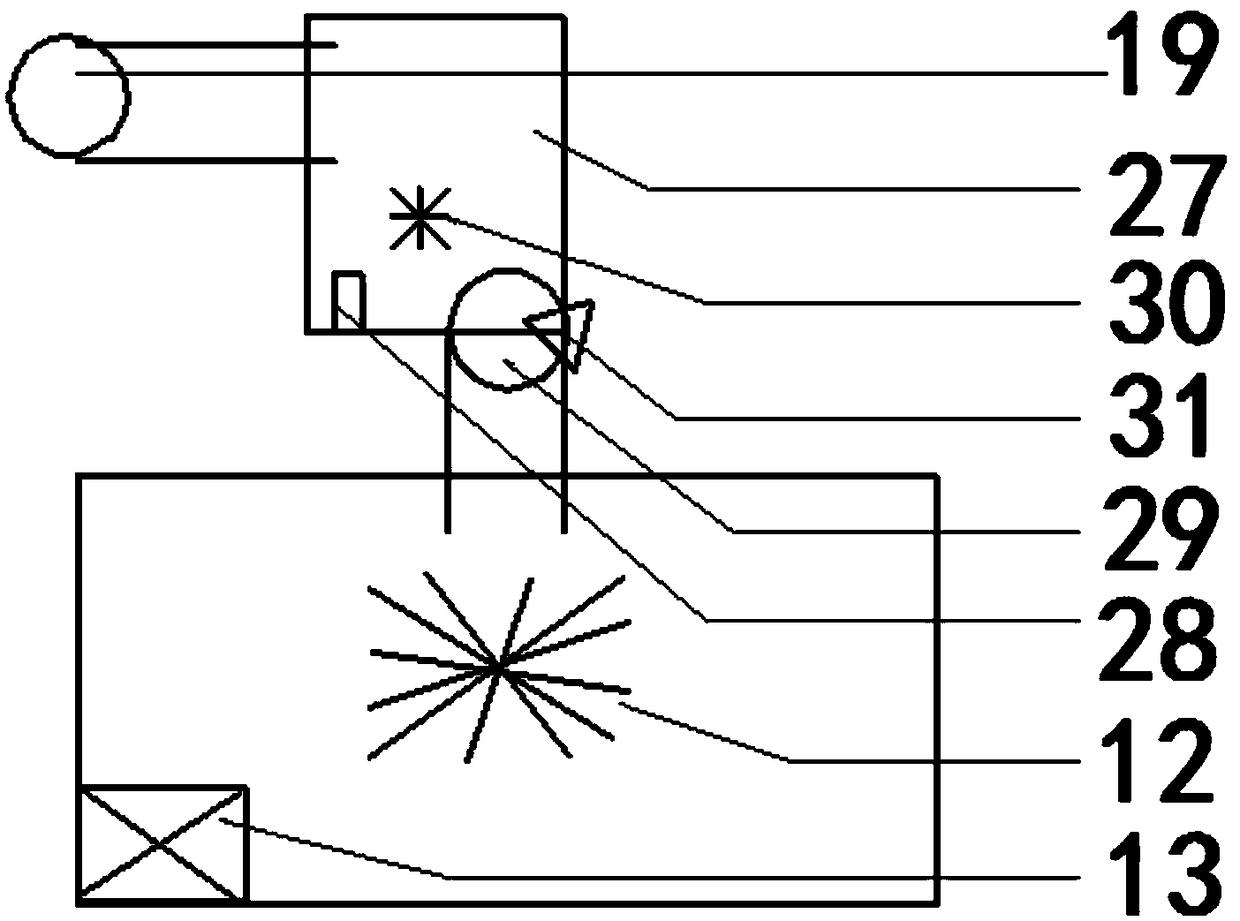

The invention discloses a flue gas desulphurization system and a method for flue gas desulfurization. The system comprises a flue gas desulphurization tower, an ash storage device, a gypsum preparing device and an air induction device, wherein the flue gas desulphurization tower comprises a tower body, a fume extractor, a defrosting device, a rotational flow reaction device, a gas uniformizing device and a multi-functional collecting reservoir, the fume extractor, the defrosting device, the rotational flow reaction device, the gas uniformizing device and the multi-functional collecting reservoir are communicated from top to bottom in sequence, a flue is provided with a dry powder inlet communicated with a dry powder desulfurizing agent spraying device, the multi-functional collecting reservoir is arranged under the gas uniformizing device, the rotational flow reaction device comprises a rotational flow shell and at least one rotational flow chamber provided with at least one swirler inside, each rotational flow chamber is provided with a circular reaction slurry inlet and communicated with the gas uniformizing device, and each swirler comprises an impeller shell, an impeller center shaft and at least five swirl vanes surrounding the impeller center shaft. By the adoption of the system, flue gas desulphurization effect and degree can be improved, space can be saved, a slurrying pool and a slurry precipitation pool are not needed, maintenance is convenient, cost is low, energy is saved, and environment pollution is avoided.

Owner:龙创信恒(北京)科技有限公司

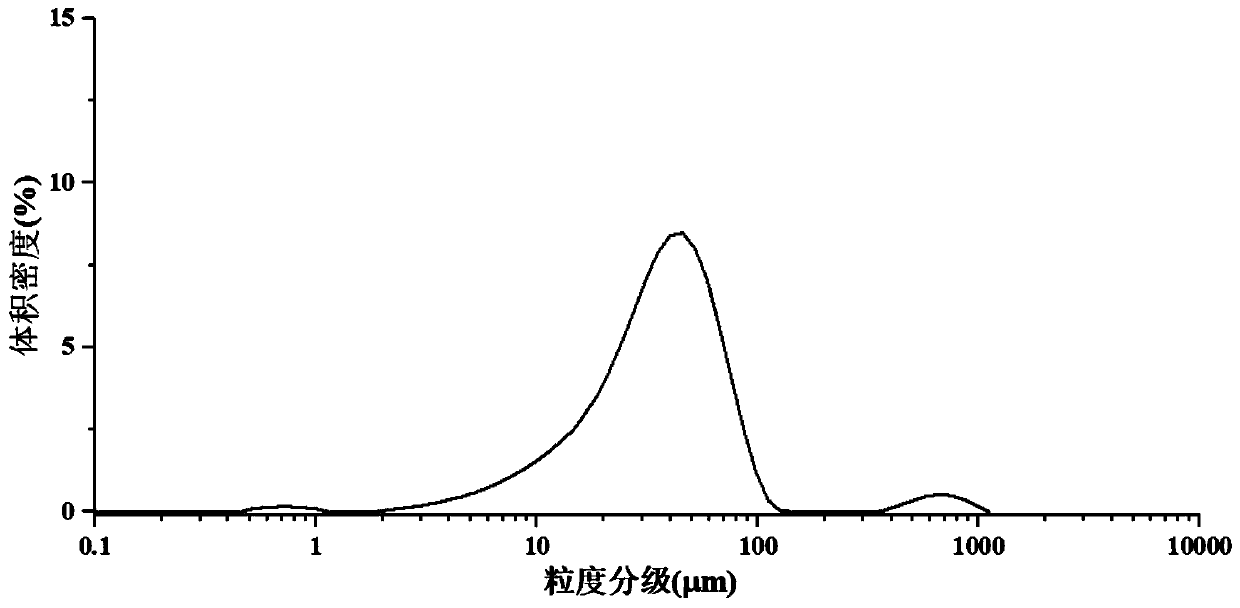

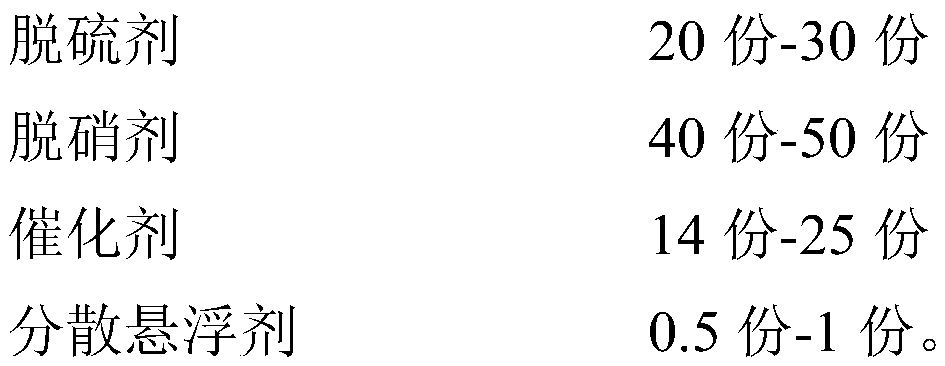

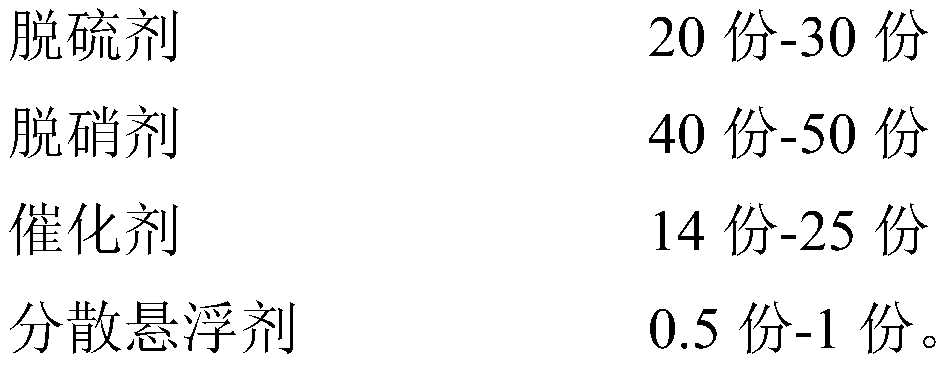

Synergistic desulfurization and denitration agent, preparation and application thereof

ActiveCN110624380AReduce dosageImprove desulfurization and denitrification efficiencyGas treatmentDispersed particle separationFlue gasSuspending Agents

The invention discloses a synergistic desulfurization and denitration agent, preparation and application thereof. The synergistic desulfurization and denitration agent is prepared from the following raw materials by weight: 20-30 parts of a desulfurization agent, 40-50 parts of a denitration agent, 14-25 parts of a catalyst and 0.5-1 part of a dispersion suspending agent. The synergistic desulfurization and denitration agent is based on the denitration agent and the desulfurization agent, is assisted by the catalyst and the dispersion suspending agent, does not need flue gas pre-dedusting treatment, and realizes direct desulfurization and denitration of flue gas in a high-temperature furnace. NH2 free radicals generated in situ are used as a reducing agent to realize denitration, H2O generated in the denitration process further improves the contact between the desulfurization agent and SO2, thus promoting the desulfurization reaction, the desulfurization agent component is employed toabsorb a certain amount of NO2, the two parts play a synergistic role, and remarkably improve the desulfurization and denitration rate and effect of the flue gas, the reaction process can be basicallycompleted within 2s-5s, and the concentrations of SO2 and NOx in the treated flue gas meet the ultralow emission requirement. The preparation method of the product is simple in operation, is suitablefor industrial large-scale production, and the treatment cost is low, therefore the synergistic desulfurization and denitration agent can be widely applied to flue gas purification.

Owner:江苏海默环保科技有限公司

System for desulfurizing limestone in circulating fluidized bed boiler on basis of flow state reconstruction

InactiveCN103672874AExtend reaction residence timeImprove sulfur fixation effectFluidized bed combustionApparatus for fluidised bed combustionFluidized bedInlet valve

A system for desulfurizing limestone in a circulating fluidized bed boiler on the basis of flow state reconstruction comprises a hearth, a conveying mechanism, a storage bin mechanism and a pipeline, wherein the conveying mechanism comprises a temporary storage bin, a mixer and a fan; a temporary storage feed port and an exhaust port are formed in the upper part of the temporary storage bin; the storage bin mechanism comprises a storage bin, a warehouse top dust collector, a through pipeline, an electric heater and a fan; the system further comprises an air separator communicated with an exhaust gas outlet of the hearth, a return feeder, an air chamber arranged at the bottom of the hearth and led into the hearth from a primary air duct, secondary air pipes distributed on the front wall and the rear wall of the hearth, an inlet valve set communicated with the secondary air pipes and used for desulfurizing limestone in the boiler, a tail flue arranged at the top of the separator, as well as a return feeder leg integrated with the separator; the inlet valve set is connected with the mixer through the pipeline; and the return feeder is connected with the bottom of the return feeder leg. The system has the advantages that the structure is simple, the separation efficiency is high, discharging is facilitated and the like.

Owner:TAIYUAN BOILER GROUP +1

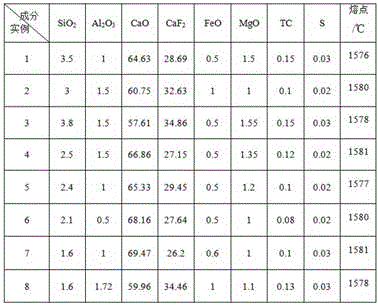

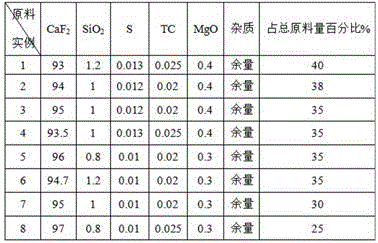

Desulfurizing agent for RH furnace

The invention belongs to the technical field of steel smelting and particularly relates to a desulfurizing agent for an RH furnace. The desulfurizing agent comprises, by weight, 1-4.0% of SiO2, less than or equal to 2.0% of Al2O3, 57-70% of CaO, 25-35% of CaF2, less than or equal to 1.0% of FeO, less than or equal to 2.0% of MgO, less than or equal to 0.15% of TC and less than or equal to 0.03% of S. The desulfurizing agent is low in melting point, beneficial to smelting of molten steel in the RH furnace, less in use amount, remarkable in desulfurizing effect and low in cost.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

Desulfuration adsorbent as well as preparation method and application thereof

ActiveCN109433000AIncrease profitReduce consumptionGas treatmentDispersed particle separationSimple Organic CompoundsCellulose

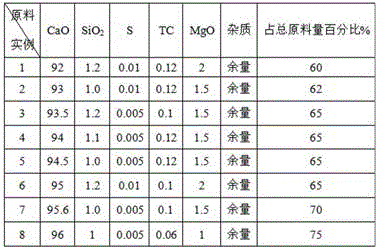

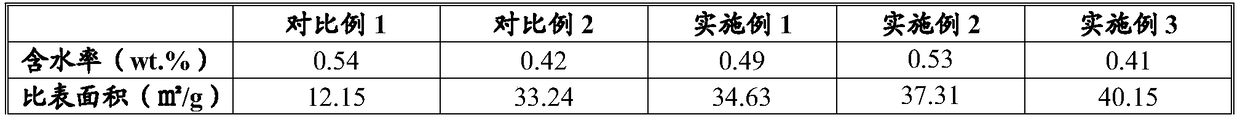

The invention discloses a desulfuration adsorbent and a preparation method thereof. The preparation method comprises the following steps: 1) putting 1000 parts by weight of quick lime, 1-10 parts by weight of a water retaining agent, 5-15 parts by weight of a poring agent and 300-1000 parts by weight of digestion process water into a digester, and stirring for digestion to obtain a digestion product; 2) drying the obtained digestion product to obtain the high-performance desulfuration adsorbent. The water retaining agent is an organic compound containing at least one water retaining functionalgroup and comprises one or more of cellulose ether, a cellulose ether derivative, lignin and a lignin derivative; the poring agent is an organic compound of which the boiling point is less than or equal to 100 DEG C. Due to addition of the water retaining agent and the poring agent, lime digestion modification is implemented, the specific surface area of the prepared desulfuration adsorbent is upto 30m<2> / g or greater, the pore volume is up to 0.2cm<3> / g or greater, and the BJH (Barrett, Joyner and Halenda) aperture is concentrated within 5-20nm.

Owner:厦门朗净钙业科技有限公司 +1

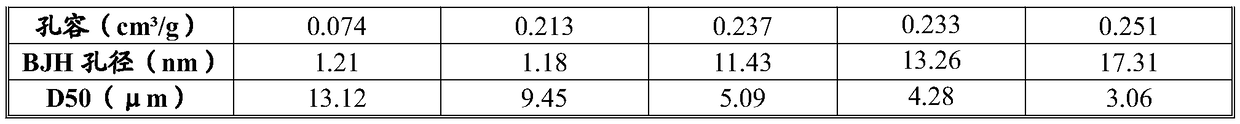

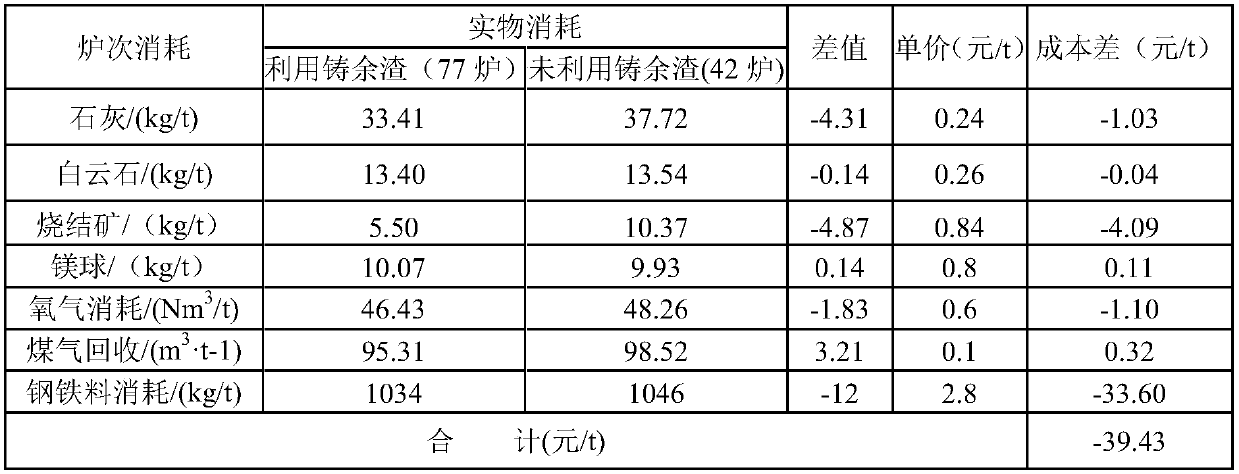

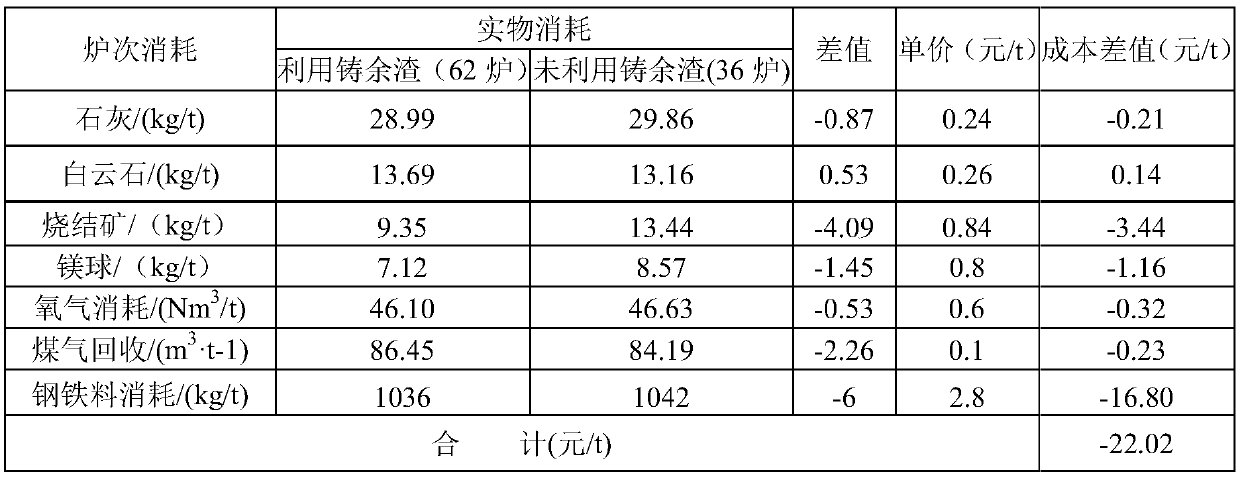

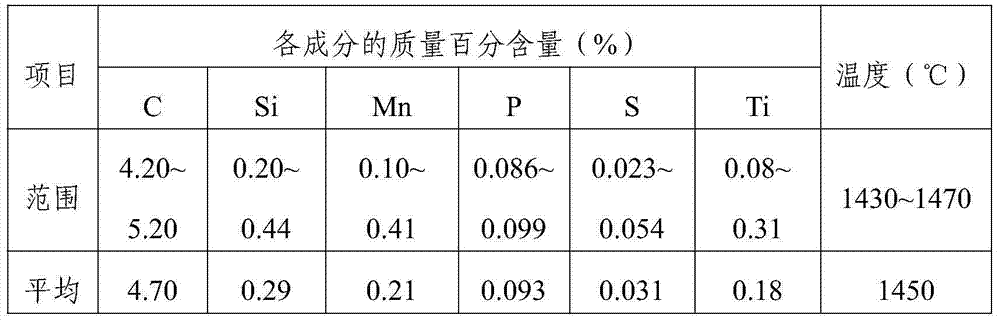

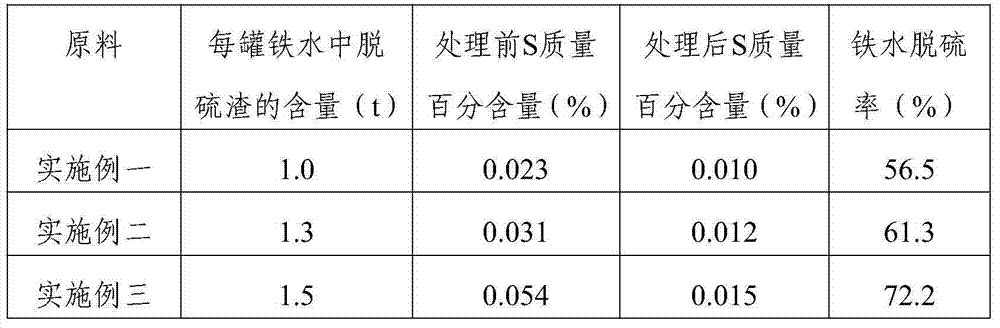

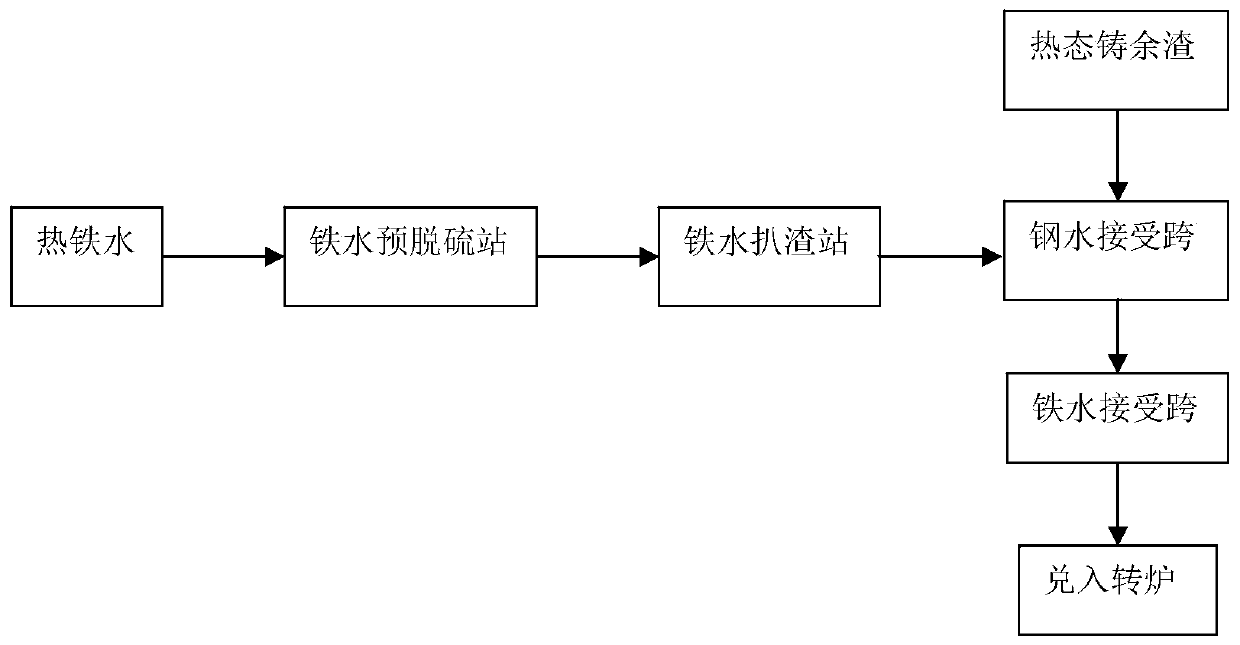

Method for recycling steel-ladle hot-state casting residues by means of converter

ActiveCN109609721AReduce steel consumptionUse efficientlyManufacturing convertersFerrous metallurgySmelting

The invention discloses a method for recycling steel-ladle hot-state casting residues by means of a converter, and belongs to the technical field of ferrous metallurgy. The problem that the casting residues and self waste heat of the casting residues cannot be effectively utilized in the prior art is solved. The method comprises the following steps that the hot-state casting residues remaining inthe steel ladle after molten steel pouring are returned to the converter steelmaking process for recycling and utilization, and the alkalinity of the hot-state casting residues ranges from 6 to 8. According to the method, the liquid-state continuous casting residues are used in an energy-saving, environment-friendly, effective and stable manner for realizing the heat-state recycling of the castingresidues; and the consumption of steel materials can be reduced, the sensible heat of furnace slag can be effectively utilized, the smelting efficiency can be improved, the steelmaking production cost is reduced, the quality of molten steel is improved, and the environment-friendly benefit is obvious.

Owner:CENT IRON & STEEL RES INST

Method for desulfurizing molten iron

The invention discloses a method for desulfurizing molten iron, and belongs to the technical field of steelmaking. The method comprises the following steps: when discharging iron from a blast furnace, adding active lime into a molten iron tank, feeding a Ca wire into the molten iron by using a wire feeding machine for desulfurizing after the molten iron arrives at a steel mill, fishing out the desulfurizing residues by using a slag removing rake, and then adding a heat insulation agent into the molten iron. The method for desulfurizing molten iron disclosed by the invention needs less time and can be used for effectively reducing the loss of molten iron temperature in the desulfurizing process, the method of feeding the Ca wire to desulfurize the molten iron is adopted to effectively ensure the full reaction of Ca, so that the desulfurizing effect is good, the application amount of a desulfurizing agent is small and the desulfurizing cost is low.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

Preparation method for load type iron-based sulfureted hydrogen removal agent under room temperature

ActiveCN102489150AGood dispersionHigh activityOther chemical processesDispersed particle separationAlkaline activationFixed bed

The invention discloses a preparation method for a load type iron-based sulfureted hydrogen removal agent under room temperature. The preparation method comprises first preparing alkali activation carrier clay, preparing slurry by utilizing the clay and water, adding NaOH to adjust the potential hydrogen (pH) value of solution, then performing dipping and activation to obtain the clay by means of centrifugal separation, cleaning the clay with distilled water and obtaining centrifugal objects by means of the centrifugal separation, and drying the centrifugal objects to obtain the alkali activation carrier clay; then depositing iron by means of homogeneous precipitation, adding the alkali activation carrier clay into molysite solution, adding urea and stirring the solution, reflowing the solution, controlling reaction temperature and reaction time, then obtaining a product by means of the centrifugal separation, cleaning the product till the product has no counter ion, then drying the product, burning the product to obtain an iron-based carrier object; and finally performing sulfuration and activation, placing the iron-based load object into a fixed bed reactor of a bed layer, and feeding mixed gas under the room temperature to obtain a final sulfureted hydrogen removal agent. The preparation method for the load type iron-based sulfureted hydrogen removal agent under the room temperature effectively controls load quantity and improves conversion rate of metal salt and utilization efficiency of urea; active maters are dispersed well in a carrier, and the preparation method can improve mass transfer rate and has a good function of sulfureted hydrogen removal under the room temperature.

Owner:CHANGZHOU UNIV

An ultra-low temperature exhaust gas energy-saving boiler

InactiveCN102297439AImprove running stabilityCause corrosiveLighting and heating apparatusSorbentEngineering

An ultra-low temperature smoke-exhausting energy-saving boiler relates to an energy-saving boiler capable of reducing pollution discharge. The invention aims to solve the problems of low fuel utilization efficiency caused by high dust concentration and high carbon content of fly ash in exhaust gas of existing coal-fired industrial boilers, and wear and tear of heat exchange equipment such as convection tube bundles and economizers at the tail of the boiler. The upper end of the furnace body communicates with the upper end of the vertical flue through the cyclone dust collector, the bottom end of the cyclone dust collector communicates with the furnace body, and a desulfurizer spout is opened on the upper end surface of the furnace body. The invention realizes the recycling of the desulfurizer in the effective area of high-temperature sulfur fixation, greatly reduces the SO3 content in the flue gas while improving the SO2 removal efficiency, and improves the energy efficiency of the boiler by more than 10%; the unburned carbon particles are sent back for reburning The carbon content of the fly ash can be reduced to less than 2%, and at the same time, it can improve energy efficiency and reduce equipment wear. The energy-saving boiler of the invention can be used not only for newly-built boilers, but also for technical transformation of existing boilers.

Owner:HARBIN INST OF TECH

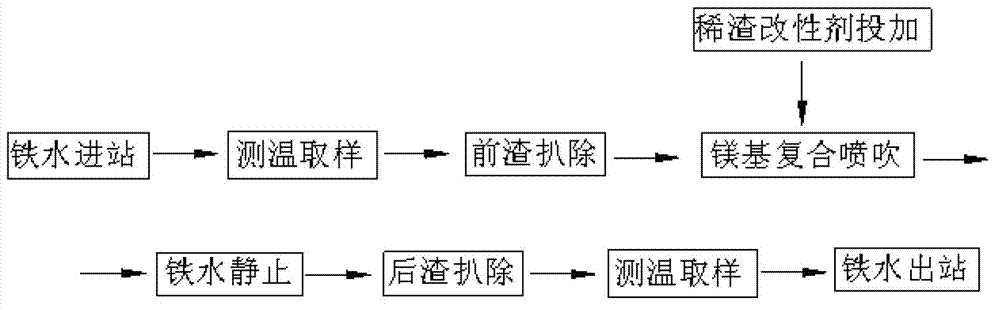

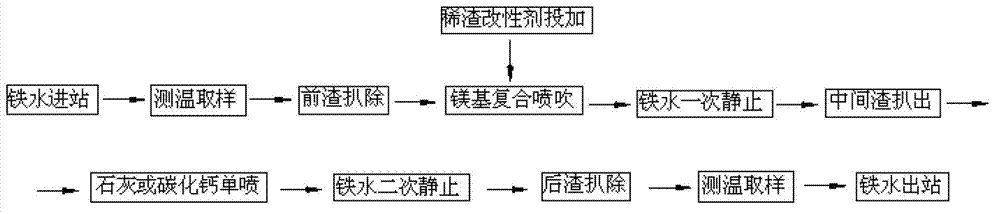

Deep desulfuration method for magnesium-based composite jetted molten iron

The invention discloses a deep desulfuration method for magnesium-based composite jetted molten iron. The deep desulphurization method comprises the following steps of: after the molten iron is fed and subjected to temperature measurement and sampling, scrabbling primary slag before a slag scrabbling station; subsequently desulfurating the molten iron in a magnesium-based composite jetting mode at a jetting and desulfuration station, adding a lean slag modifier in the jetting process and modifying the lean slag of the solid or semi-molten desulfurated slag; subsequently transferring to the slag scrabbling station to carry out primary standing on the molten iron and accomplish middle slag scrabbling; separately jetting lime or calcium carbide at the jetting and desulfuration station so as to carry out deep desulfuration on the molten iron and coagulate and modify residual liquid slag; after the separate jetting, transferring the molten iron tank to the slag scrabbling station to carry out secondary standing on the molten iron and accomplish later slag scrabbling; and after the later slag scrabbling, measuring the temperature, sampling and discharging the molten iron so as to meet the requirements on a molten iron material of a low-sulfur steel. The deep desulfuration method adopts a mode that desulfurated slag of different properties is respectively modified and scrabbled, and has the advantages of simplicity in operation, convenience in application and sufficiency in desulfurated slag modification.

Owner:武汉钢铁有限公司

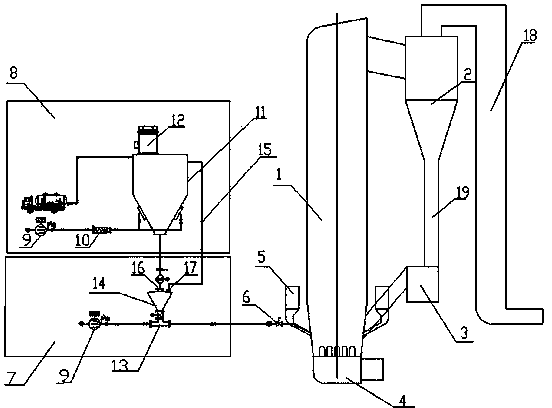

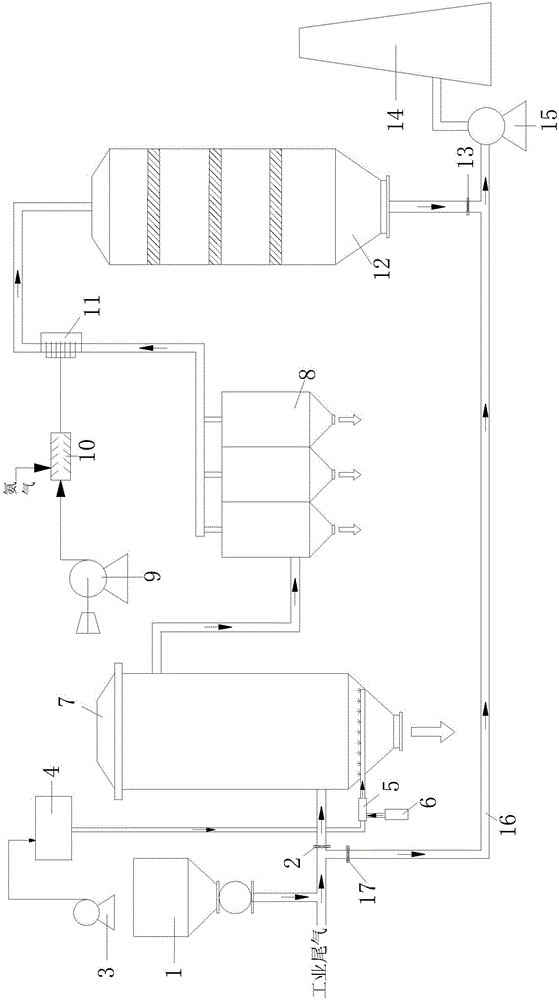

Environmental-protection comprehensive treatment system and environmental-protection comprehensive treatment process for high-pollution-factor low-temperature flue gas

InactiveCN105771612AEasy to handleGuaranteed uptimeDispersed particle filtrationEnvironmental resistanceTherapeutic effect

The invention discloses an environmental-protection comprehensive treatment system for high-pollution-factor low-temperature flue gas. The environmental-protection comprehensive treatment system comprises a full-automatic desulfurizer delivery device, a desulfurization tower and a medium-and-low-temperature SCR (selective catalytic reduction) reactor. The full-automatic desulfurizer delivery device is connected with a gas inlet of the desulfurization tower through a flue gas pipeline. A water pump is connected with one end of a water tank. The other end of the water tank is connected with the desulfurization tower through a double-fluid spray gun. The double-fluid spray gun is connected with an air compressor. A gas outlet of the desulfurization tower is connected with a bag-type dedusting unit through a flue gas pipeline. A dilution fan is connected with an ammonia-air mixer through a pipeline. An ammonia inlet is arranged on the pipeline between the dilution fan and the ammonia-air mixer. The ammonia-air mixer and the bag-type dedusting unit are connected with the medium-and-low-temperature SCR reactor after passing an ammonia spraying grille. An outlet of the medium-and-low-temperature SCR reactor passes a draught fan to be connected with a chimney. The environmental-protection comprehensive treatment system has the advantages that flue gas heat and temperature gradient are utilized reasonably, high-temperature dedusting processes are reduced, stable efficient operation of a denitration system and service life of catalysts can be guaranteed, and flue gas treatment effect can be improved.

Owner:湖北思搏盈环保科技股份有限公司

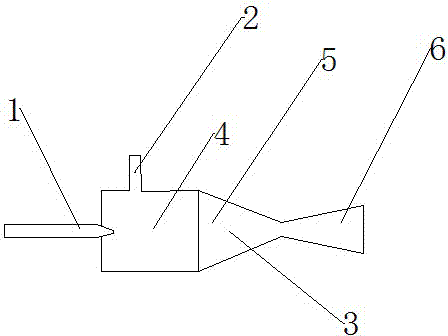

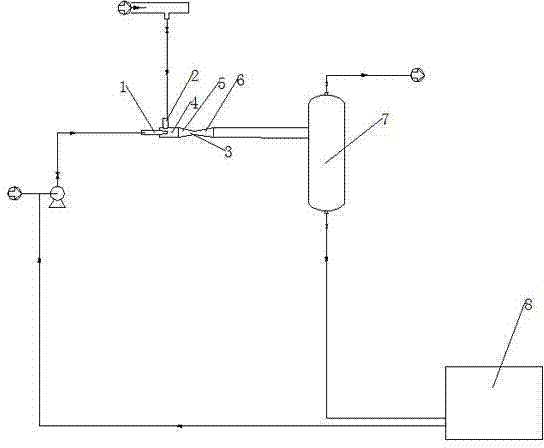

Desulfurization device for purifying gas

ActiveCN103111175AIncrease contact areaReduce energy consumptionDispersed particle separationGaseous fuelsVapor–liquid separatorEngineering

The invention relates to a desulfurization device which comprises a desulfurizer and a gas-liquid separator, wherein the desulfurizer is sequentially connected with and provided with a buffer region, a front-end convergence region and a back-end diffusion region in the transverse direction; the buffer region is provided with a gas inlet and a liquid nozzle for spraying desulfurization slurry; the back-end diffusion region is provided with a gas outlet; the front-end convergence region is a cylinder which is gradually contracted in the gas flow direction; the back-end diffusion region is a cylinder which is gradually expanded in the gas flow direction; the ratio of the lengths of the buffer region, the front-end convergence region and the back-end diffusion region in the transverse direction is (3-5):(4-6):(3-5); the gas-liquid separator is provided with a gas outlet and a liquid outlet; and the gas-liquid separator is connected with the gas outlet of the back-end diffusion region through a pipeline. The desulfurization device provided by the invention is low in construction cost, low in operation energy consumption and high in desulfurization efficiency.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

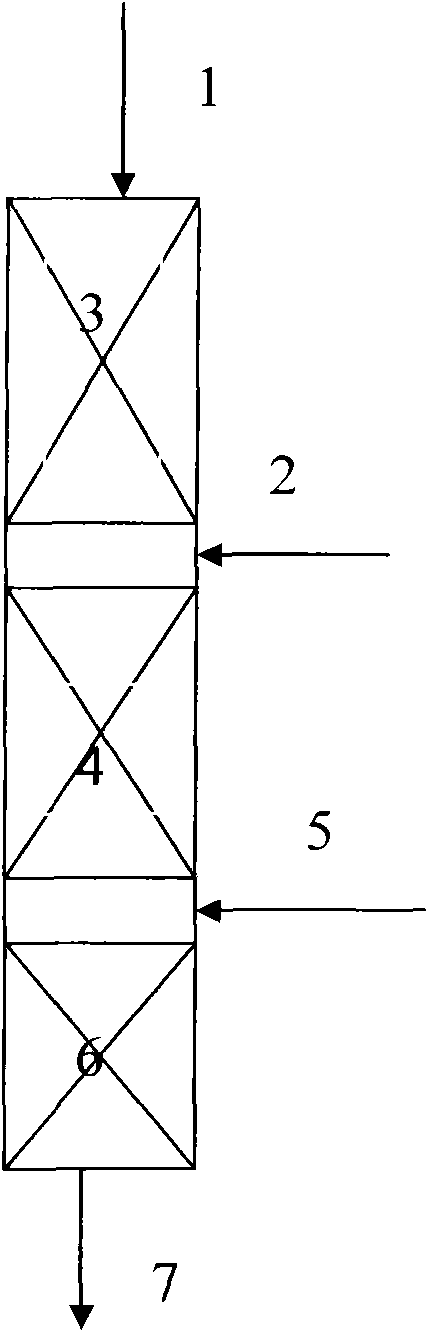

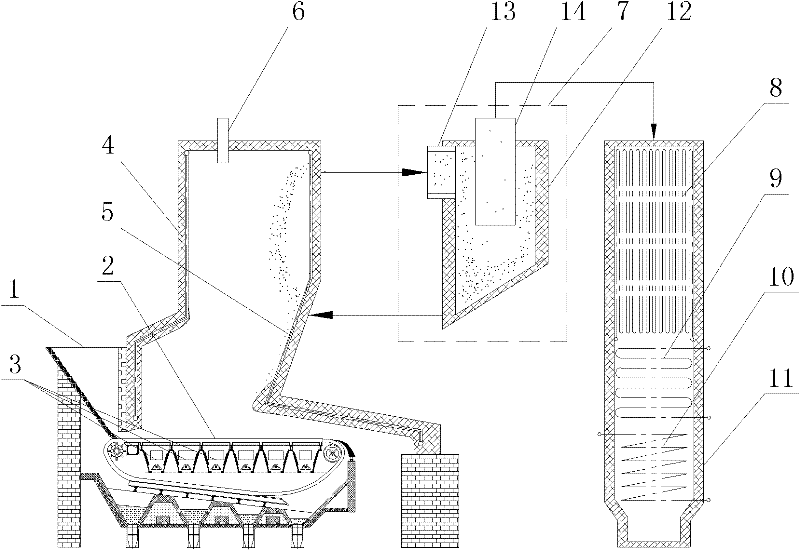

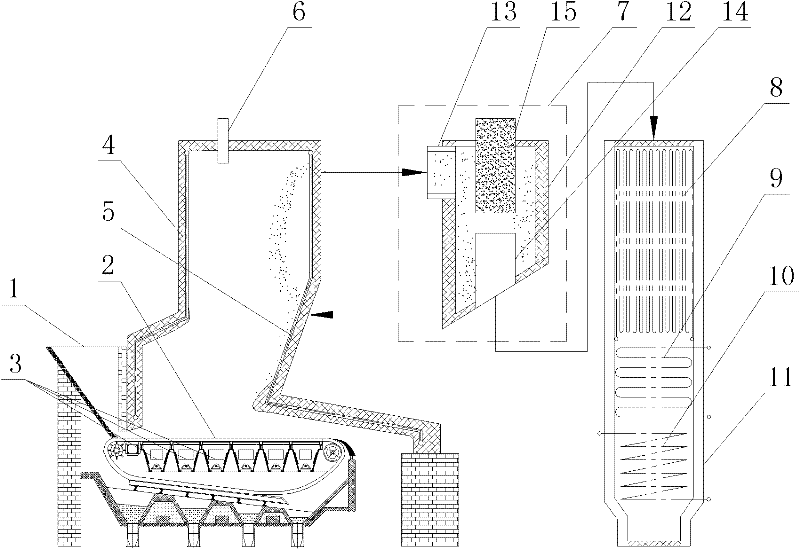

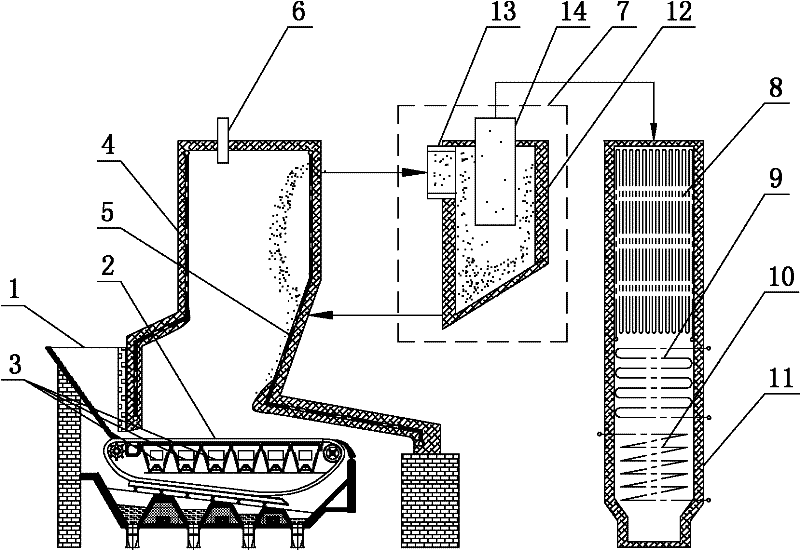

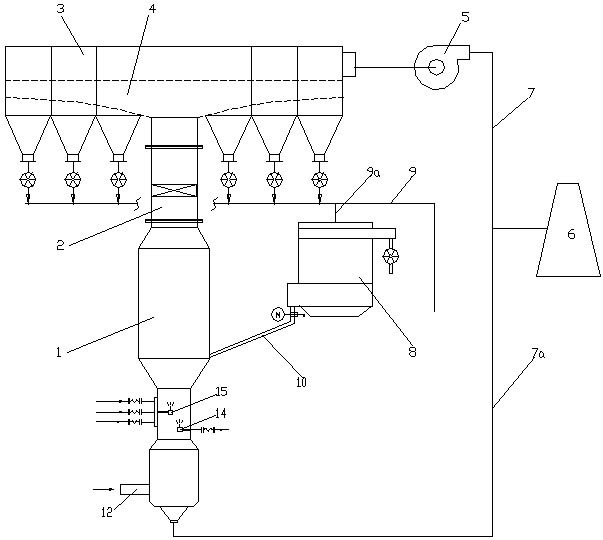

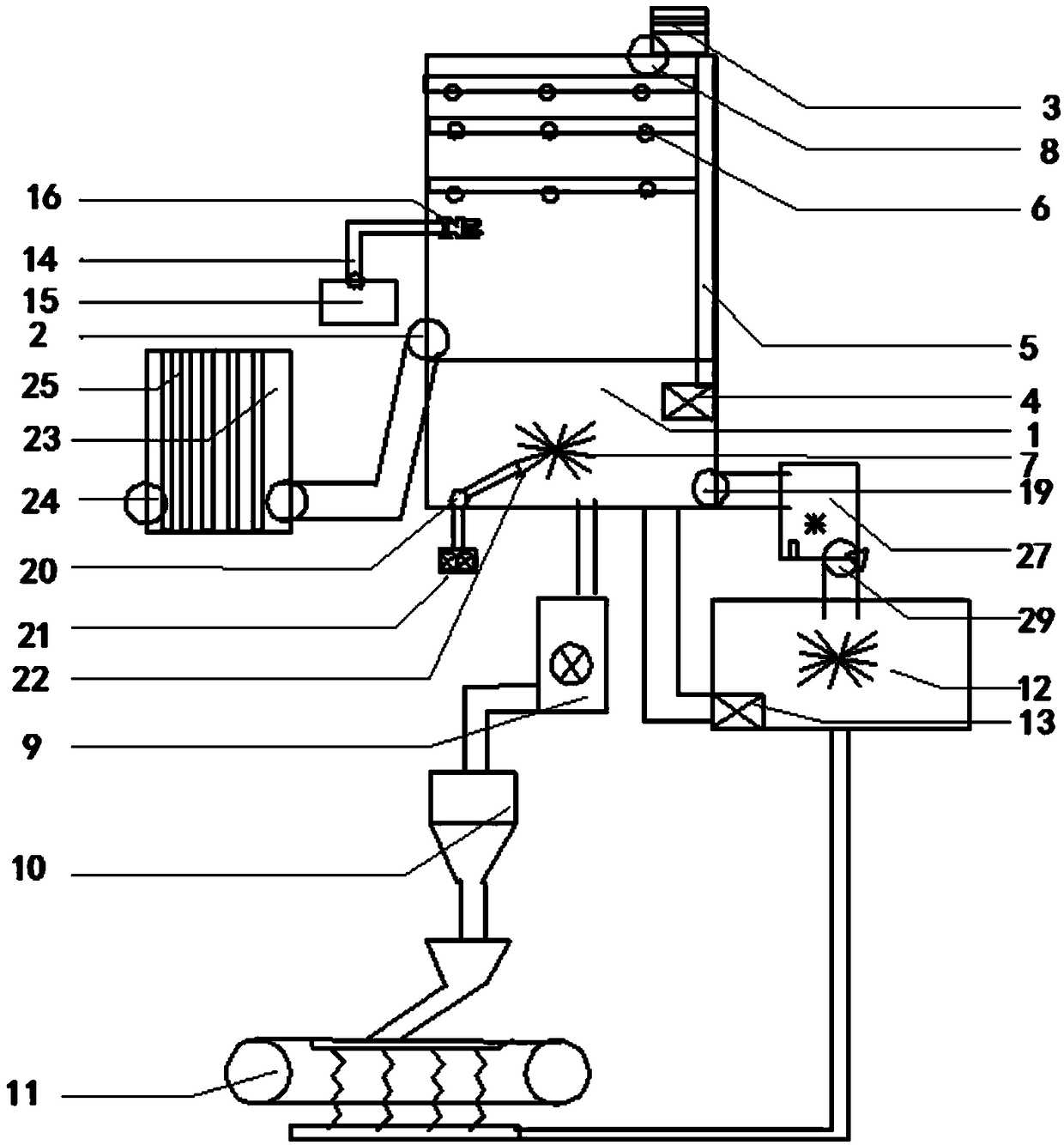

Lime slurry jetting circulating fluid bed semi-dry process desulfurizer

ActiveCN102000492AReduce workloadPromote desulfurization reactionDispersed particle separationSlurryEngineering

The invention discloses a lime slurry jetting circulating fluid bed semi-dry process desulfurizer which comprises a desulfurization reaction column, a gas-solid separator and a draught fan, wherein the lower part of the desulfurization reaction column is provided with a lime slurry nozzle and a fume inlet; an after-reaction gas outlet of the desulfurization reaction column is communicated with the gas-solid separator through a spoiler; and the spoiler is positioned on the upper part of the after-reaction gas outlet of the desulfurization reaction column. In the invention, the upper part of the gas outlet of the desulfurization reaction column is provided with the spoiler which can forcibly mix the gas-solid mixture discharged by the desulfurization reaction into a turbulent condition, thereby strengthening the desulfurization reaction of the mixture; and meanwhile, part of unreacted slurry particles return to the desulfurization reaction column for reaction after colliding with each other in the spoiler, thereby enhancing the desulfurization efficiency. The desulfurizer can reduce the working load of the gas-solid separator under the condition of high fume flow on the premise of ensuring the separating effect, and is applicable to high-flow fume desulfurization. When the fume flow is low, the turbulence is strengthened by the spoiler, thereby prolonging the contact reaction time and enhancing the desulfurization efficiency.

Owner:CISDI ENG CO LTD

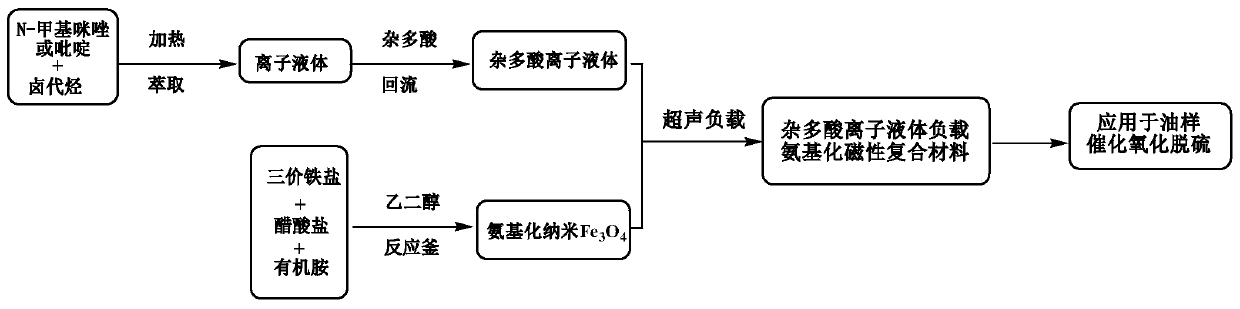

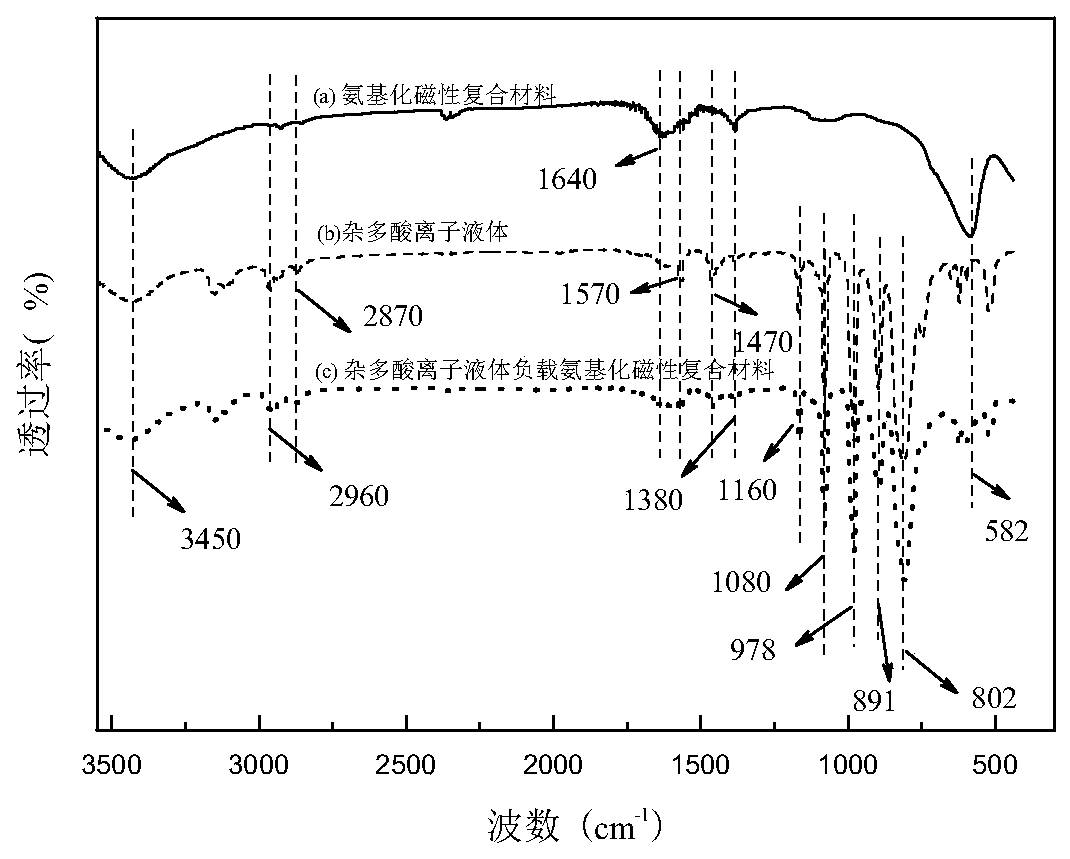

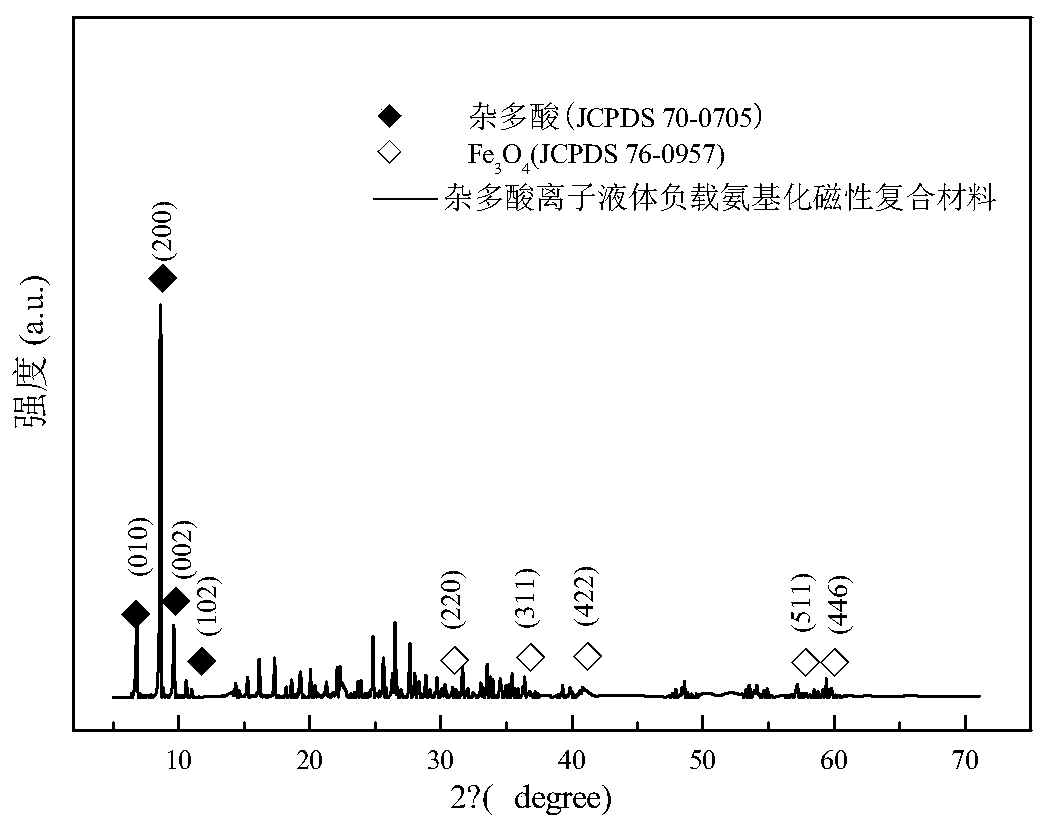

Heteropolyacid ionic liquid supported aminated magnetic composite of date cake structure, preparation method and application

ActiveCN109908962AEasy reunionSimplify operation stepsOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsChemistryPetroleum

The invention discloses a heteropolyacid ionic liquid supported aminated magnetic composite of a date cake structure, a preparation method and an application. The composite is prepared from raw materials including a heteropolyacid ionic liquid and an aminated magnetic composite by supporting the heteropolyacid ionic liquid on an aminated nano magnetic material with an ultrasonic immersing method.The preparation steps are shown as follows: firstly, the heteropolyacid ionic liquid is prepared through a substitution reaction, the aminated magnetic composite is prepared with a solvothermal method, and the heteropolyacid ionic liquid supported aminated magnetic composite is prepared with an ultrasonic supporting method. The product obtained with the method is powdery and brown, has uniform particle size distribution and has the date cake structure and stable properties. The defect of high probability of agglomeration of the magnetic materials is overcome, and the obtained material has gooddispersity, high magnetism and high yield, and raw materials are easy to obtain; the composite has magnetism and catalytic activity and can be effectively used for a catalyst for desulfuration of petroleum samples, and the catalyst can be separately recycled.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Dry desulfurization agent and preparation method thereof

PendingCN111974210AEasy to separateIncrease response rateGas treatmentDispersed particle separationActivated carbonPtru catalyst

The present invention provides a dry desulfurization agent and a preparation method thereof. The dry desulfurization agent comprises the following components in parts by weight: 90-95 parts of modified nano calcium carbonate, 0.1-1 part of a catalyst and 0.1-1 part of activated carbon. A surfactant is used to modify nano calcium carbonate to obtain the modified nano calcium carbonate. The catalystis loaded on the activated carbon by pre-mixing the catalyst and activated carbon, and the catalyst-loaded activated carbon and nano calcium carbonate are mixed to obtain the dry desulfurization agent. The dry desulfurization agent can greatly improve a desulfurization rate, at the same time, has recyclability and reduces cost of a hazardous waste treatment.

Owner:菏泽万清源环保科技有限公司

A method for recycling hot-state casting slag in a converter

The invention discloses a method for recycling steel-ladle hot-state casting residues by means of a converter, and belongs to the technical field of ferrous metallurgy. The problem that the casting residues and self waste heat of the casting residues cannot be effectively utilized in the prior art is solved. The method comprises the following steps that the hot-state casting residues remaining inthe steel ladle after molten steel pouring are returned to the converter steelmaking process for recycling and utilization, and the alkalinity of the hot-state casting residues ranges from 6 to 8. According to the method, the liquid-state continuous casting residues are used in an energy-saving, environment-friendly, effective and stable manner for realizing the heat-state recycling of the castingresidues; and the consumption of steel materials can be reduced, the sensible heat of furnace slag can be effectively utilized, the smelting efficiency can be improved, the steelmaking production cost is reduced, the quality of molten steel is improved, and the environment-friendly benefit is obvious.

Owner:CENT IRON & STEEL RES INST

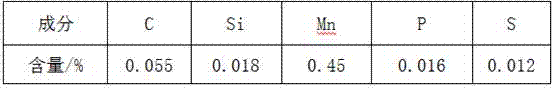

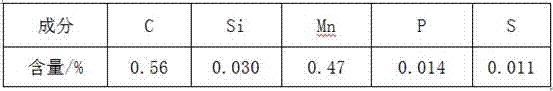

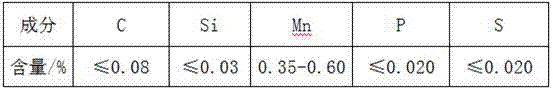

Method of refining and desulfurizing for low-silicon steel

The invention discloses a method of refining and desulfurizing for low-silicon steel. The method includes the steps of adjustment of a slag system, slagging, heating and desulfurizing; the to-be-refined low-silicon steel comprises the components of less than or equal to 0.03% of Si and 0.020-0.030% of S. Aluminum powder is added in a steel ladle to regulate the slag system to reduce oxidability ofslag firstly, and then lime and fluorite are added to perform slagging. Calcium carbides are added when liquid steel is heated to a temperature of more than 1600 DEG C, the weak reducibility of the calcium carbides are used for removing oxygen of the refined slag to further accelerate desulfurization, and achieving the purpose of reducing sulphur content in the liquid steel. The reducibility of the calcium carbides is weak and cannot restore silicon in the slag, so that the increasing of the silicon content in the liquid steel can be avoided, oxidative product of the calcium carbides is carbon monoxide, and the submerged arc effect in the refining process can be improved.

Owner:HEBEI IRON AND STEEL

Flue gas desulfurization system

InactiveCN108905551AIncrease contact areaPromote desulfurization reactionCombination devicesGas treatmentSulfurFlue gas

The invention discloses a flue gas desulfurization system. The flue gas desulfurization system comprises an absorption tower, a wet type electric dust collector, a dehydrating unit and a circulating unit, wherein the absorption tower further comprises a slurry tank which is arranged at the bottom layer of the absorption tower, a flue gas inlet for introducing flue gas into the absorption tower, aspraying device arranged above the flue gas inlet, and a flue gas outlet which is formed in the top of a desulfurization tower. Through the absorption effect of the absorption tower, further dust removal is performed through the wet type electric dust collector, so that a sulfur component and other harmful components in the flue gas are removed, and a second product generated by absorption effectof the absorption tower is processed. Compared with the prior art, the flue gas desulfurization system can improve desulfurization efficiency, reduces corrosion loss in desulfurization reaction, can recycle wastewater generated in a recycling process, and is environmentally friendly and energy-saving.

Owner:百色皓海碳素有限公司

Low energy consumption and long period hydrogenation process for producing diesel oil

ActiveCN111321005AIncrease concentrationRaise the outlet temperatureTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystNaphtha

The invention discloses a low energy consumption and long period hydrogenation process for producing ultralow-sulfur diesel oil. The hydrogenation process comprises the following steps: (a) fractionating diesel raw oil to obtain two fractions, namely a light fraction and a heavy fraction; (b) carrying out a hydro-desulfurization reaction on the heavy fraction diesel raw oil obtained in the step (a) in a first hydrogenation reaction zone under the action of a hydro-desulfurization catalyst; (c) reacting the material flow obtained in the step (b) with the light fraction diesel raw oil obtained in the step (a) in a second hydrogenation reaction zone under the action of a hydro-desulfurization catalyst; and (d) separating the material flow obtained in the step (c) into a gas phase and a liquidphase, and separating the liquid phase to obtain gas, naphtha and diesel oil products. The hydrogenation process has the advantages of low energy consumption, long operation period and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

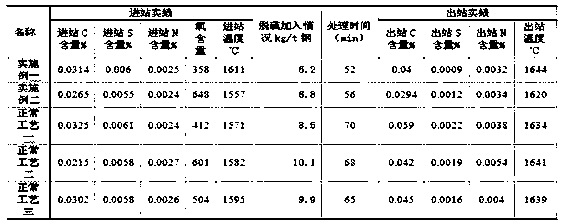

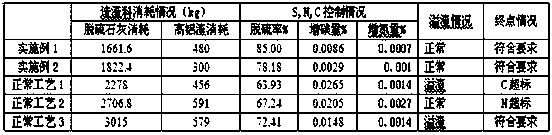

lf furnace desulfurization control carbon nitrogen control method

The invention relates to a LF furnace desulphurization carbon-control nitrogen-protection controlling method. The controlling method comprises the following steps: 1) pull-in molten steel is observed, a rapid temperature thermocouple is used for temperature measurement and sampling is carried out, 2) after slugging the molten steel in the step 1), under condition that the slag amount is insufficient, and the fluidity is good, the molten steel is easily exposed, an electrode is brushed, at the same time, desulfurized lime and a high-aluminum deoxidizer submerged arc material are continuously added, 3) when the molten steel temperature is increased to 1590-1600 DEG C, the surface of the molten steel is covered by a layer of protection slag, then submerged-arc heating is carried out, the deoxidation depth is controlled, white residues are generated and deep desulphurization is performed, submerged arc heating is carried out for carbon protection, the nitrogen is controlled; and 4) the dedusting opening degree is adjusted at 20-40% for stabilizing the micro-positive pressure in the furnace, the micro-positive pressure atmosphere in the furnace is guaranteed during a whole processing course of a LF furnace, according to the practical status of ladle permeability, and the argon flow at each phase is set in a reasonable mode.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

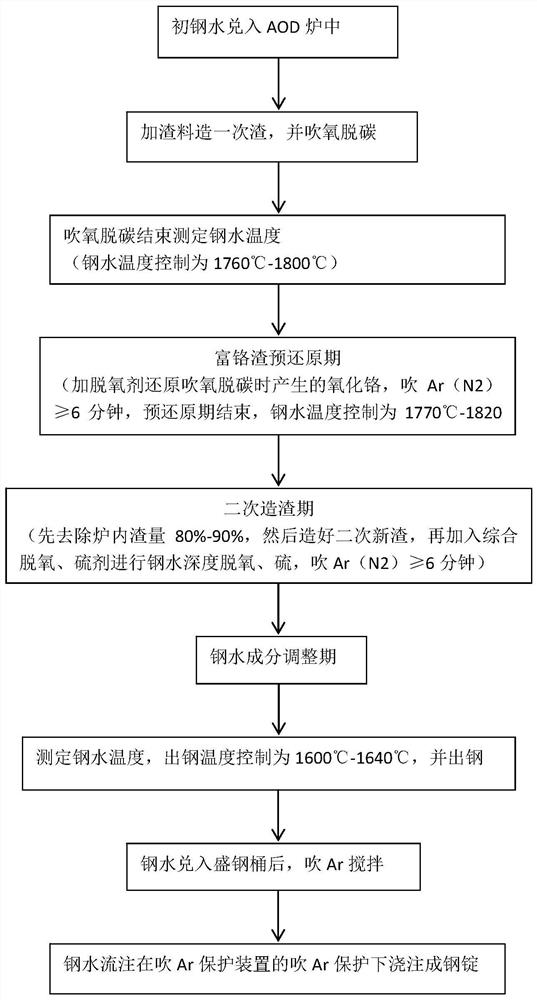

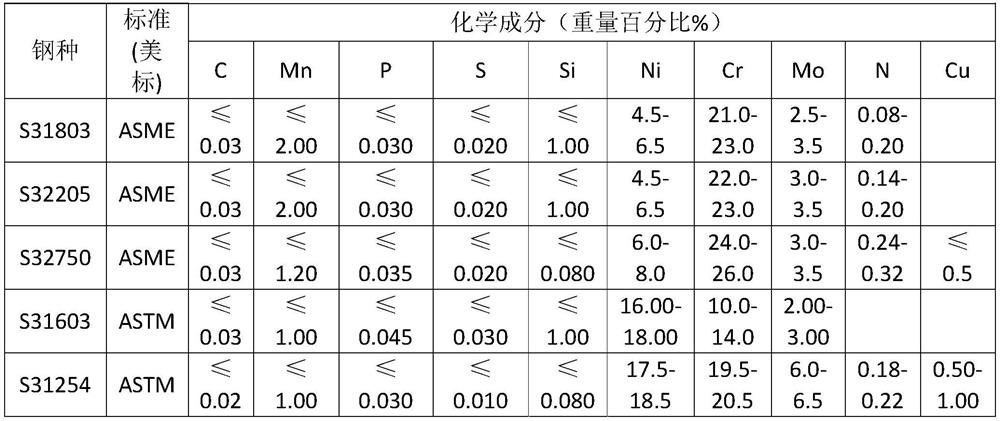

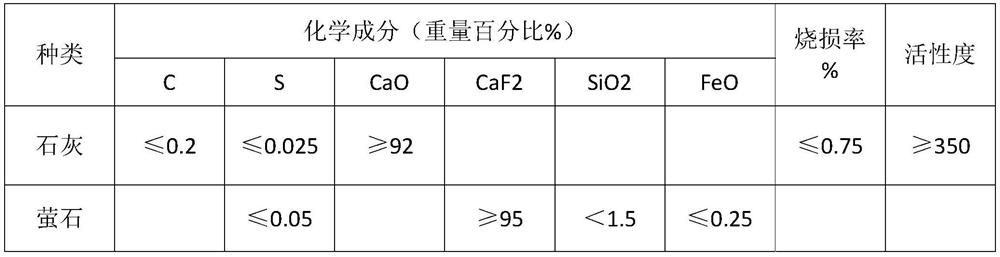

Comprehensive deoxidizing and desulfurizing process for smelting stainless steel by using small-capacity AOD (Argon Oxygen Decarburization) furnace

The invention discloses a comprehensive deoxidizing and desulfurizing process for smelting stainless steel by using a small-capacity AOD (Argon Oxygen Decarburization) furnace. The comprehensive deoxidizing and desulfurizing process is characterized in that the furnace capacity of the AOD furnace is less than or equal to 10 tons, and primary molten steel added into the AOD furnace meets the specified requirements. After the oxygen-blowing decarburization period ends, a chromium-rich slag pre-reduction period begins, Ar(N2) is blown for more than or equal to 6 minutes, and the temperature of the molten steel is controlled to be 1770-1820 DEG C. In the secondary slagging period, after 80 to 90 percent of slag in the furnace is removed, lime and fluorite meeting the specified requirements are added; and after secondary new slag is formed, a comprehensive deoxidizing and desulfurizing agent which is composed of a deoxidizing agent metal Al block, a composite deoxidizing and desulfurizing agent Si-Ca block and a composite deoxidizing and desulfurizing agent Si-Ca-Ba-Al block and meets the specified requirements is added, and Ar(N2) is blown for more than or equal to 6 minutes. The tapping temperature is 1600-1640 DEG C. According to the process, on the basis of the prior art, the oxygen content of steel is remarkably reduced, and the quality of high-end stainless steel for cold (hot) machining deformation is improved.

Owner:HAIYAN ZHONGDA METAL ELECTRONIC MATERIAL CO LTD

Wet flue gas desulfurization system online decontamination scale inhibitor and preparation method thereof

InactiveCN108410602AExcellent decontaminationImprove solubilityCationic surface-active compoundsDetergent mixture composition preparationChemical treatmentPhytic acid

The invention discloses a wet flue gas desulfurization system online decontamination scale inhibitor and a preparation method thereof, belongs to the field of chemical treatment agents, and particularly relates to a wet flue gas desulfurization system online decontamination scale inhibitor and a preparation method thereof. 700-1000mg of 100% mass lauryl sodium sulfate, 200-400mg of 100% mass quaternary ammonium sodium, 300-600mg of 100% mass sodium stearyl sulfate, 2-3g of 100% mass methacrylic sodium, 10-18g of 100% mass EDTA (ethylene diamine tetraacetic acid) tetrasodium, 30-40g of 100% mass phytic acid sodium salt hydrate, 50-100mg of 100% mass tributyl phosphate, 10-25mg of 100% mass potassium stearate and the rest distilled water are added into each liter of distilled water. The scale inhibitor is applicable to running wet flue gas desulfurization system online scale prevention and decontamination, the scale inhibitor is used once every 3-6 months, 0.1L of decontamination agent is added into 1L of slurry, the scale inhibitor is directly added into desulfurization slurry and used for 3-4 times every year, impurity deposition rate is reduced by 85% or more, and system blockingrate is reduced by 90% or more.

Owner:JILIN ELECTRIC POWER RES INST LTD +2

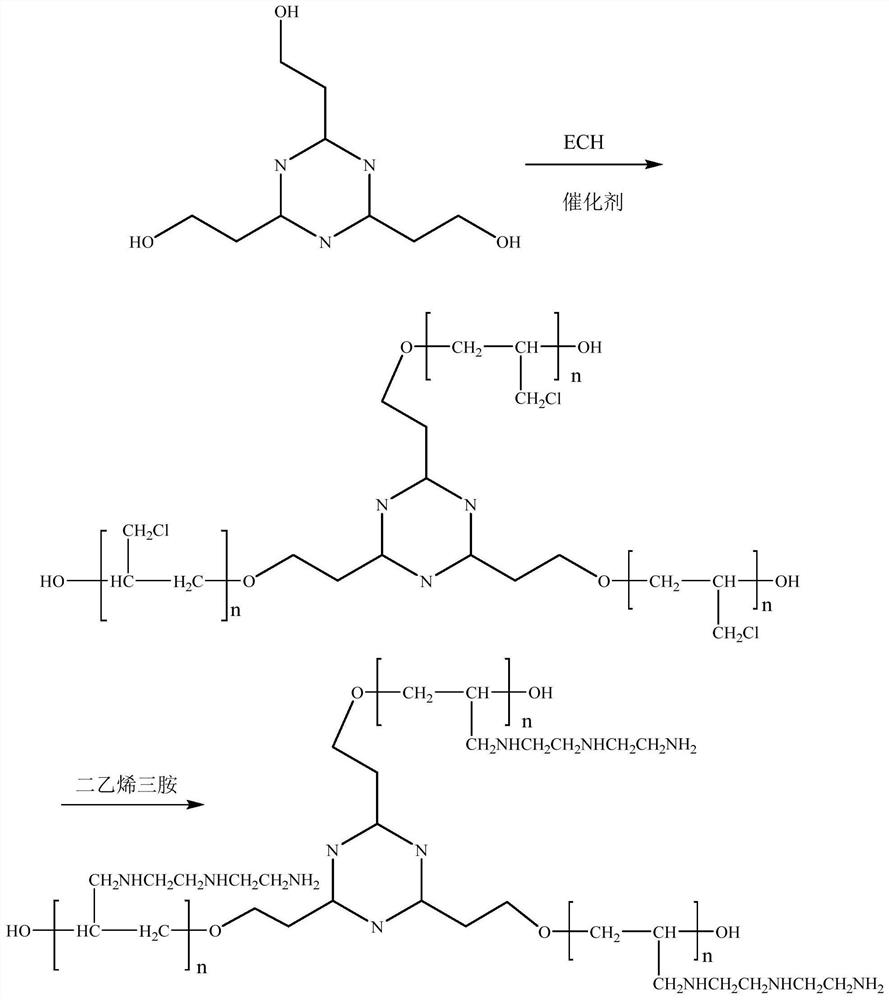

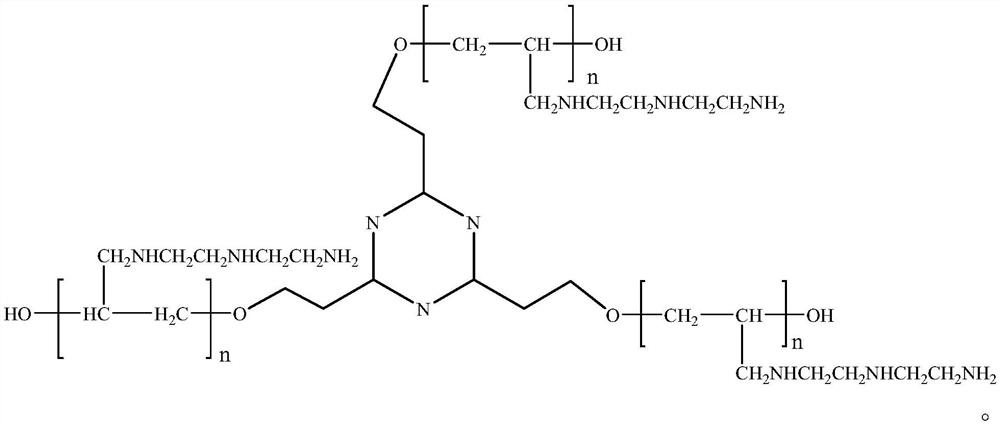

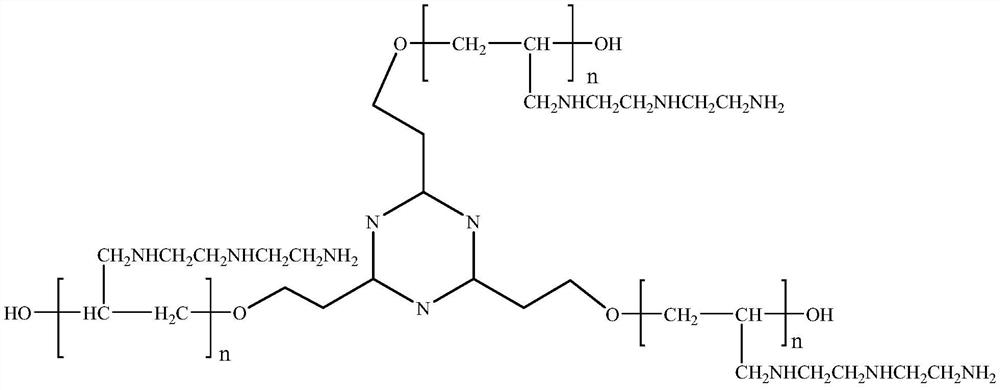

Preparation method of liquid desulfurizing agent and liquid desulfurizing agent

PendingCN113831524AReduced fouling tendencyShorten speedDispersed particle separationGaseous fuelsChemistryDiethylenetriamine

The invention provides a preparation method of a liquid desulfurizing agent and the liquid desulfurizing agent. The method comprises the following steps: adding ethanol as a solvent into a reaction kettle; then adding diethylenetriamine, epoxy chloropropane, 1, 3, 5-trihydroxyethyl hexahydro-s-triazine and a catalyst into the reaction kettle; stirring and heating the raw materials, controlling the raw materials to continuously react for a specified time at a specified reaction temperature, obtaining the liquid desulfurizing agent, the molar ratio of the catalyst to the 1, 3, 5-triethoxy hexahydro-s-triazine being 3: 1, and the molar ratio of the epoxy chloropropane to the diethylenetriamine to the 1, 3, 5-triethoxy hexahydro-s-triazine being 1: 1: (0.2-0.5). According to the technical scheme, the novel liquid desulfurizing agent is obtained, long-chain diethylenetriamino polyether substances generated after desulfurization of the liquid desulfurizing agent have good permeability and emulsifying performance, the dissolution rate of hydrogen sulfide and the mass transfer rate of hydrogen sulfide in a solution can be remarkably increased, desulfurization reaction is promoted, and environmental protection and reliability are realized.

Owner:BINZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com