Flue gas desulfurization system

A desulfurization system and flue gas technology, applied in gas treatment, combined device, membrane technology, etc., can solve the problems of insufficiency of desulfurization process, increase of sulfur content in coal combustion, serious equipment loss, etc., to maintain speed and increase contact area, the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

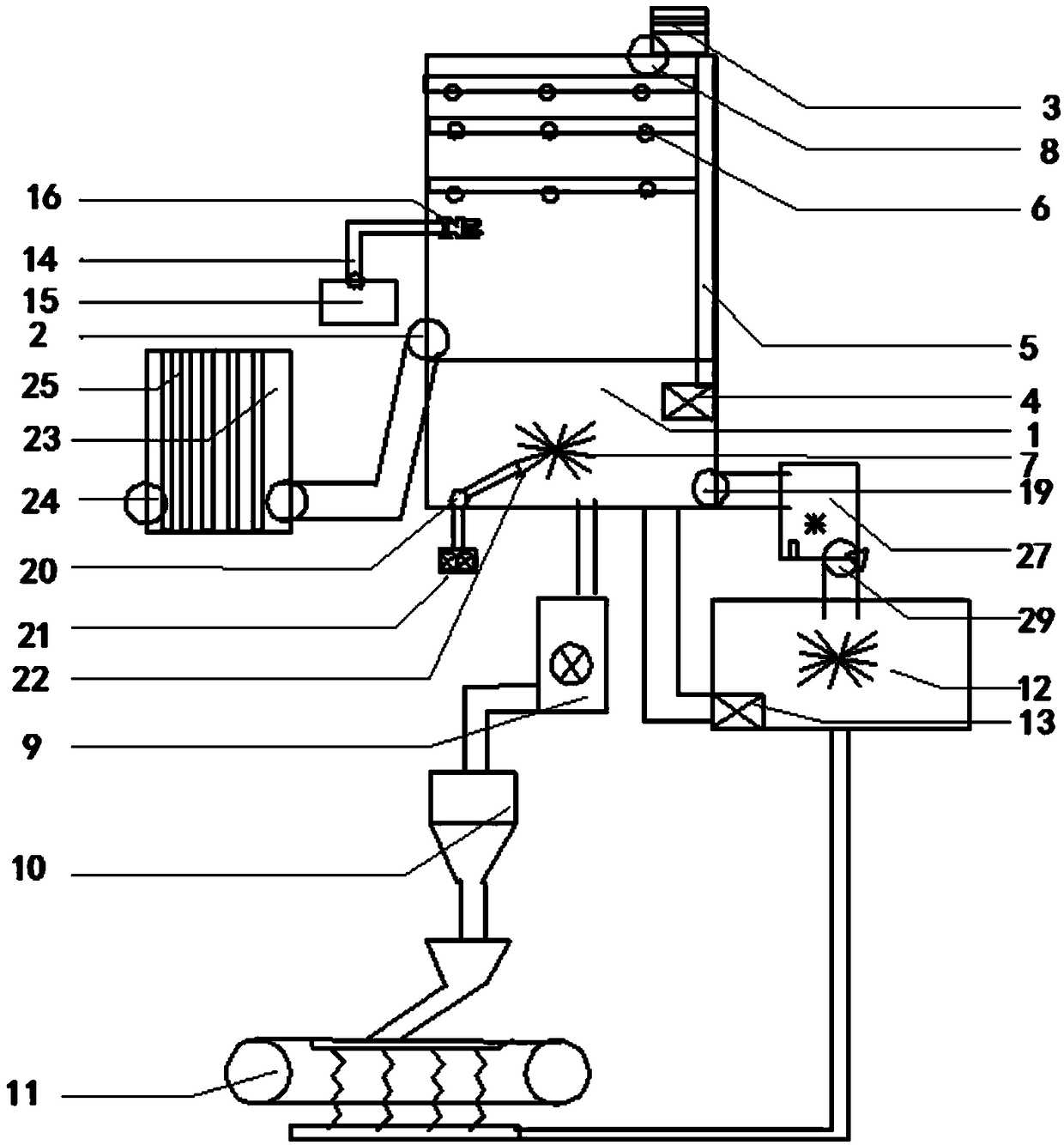

[0031] A flue gas desulfurization system, comprising:

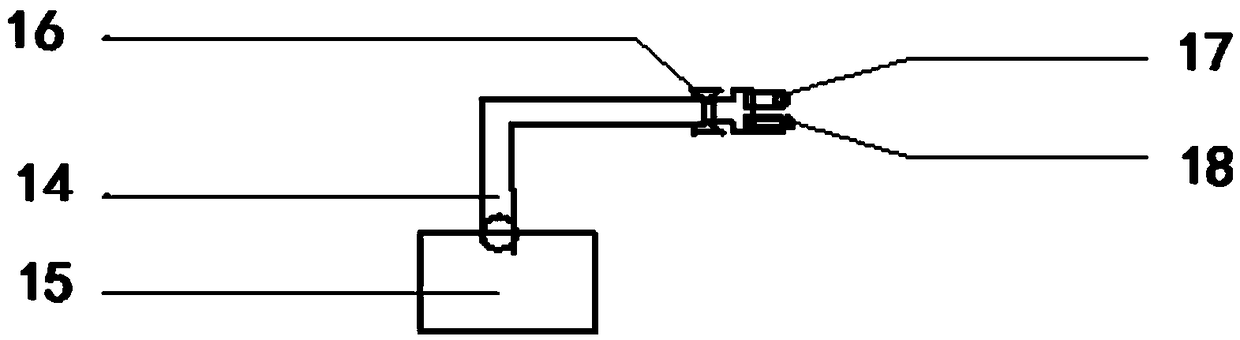

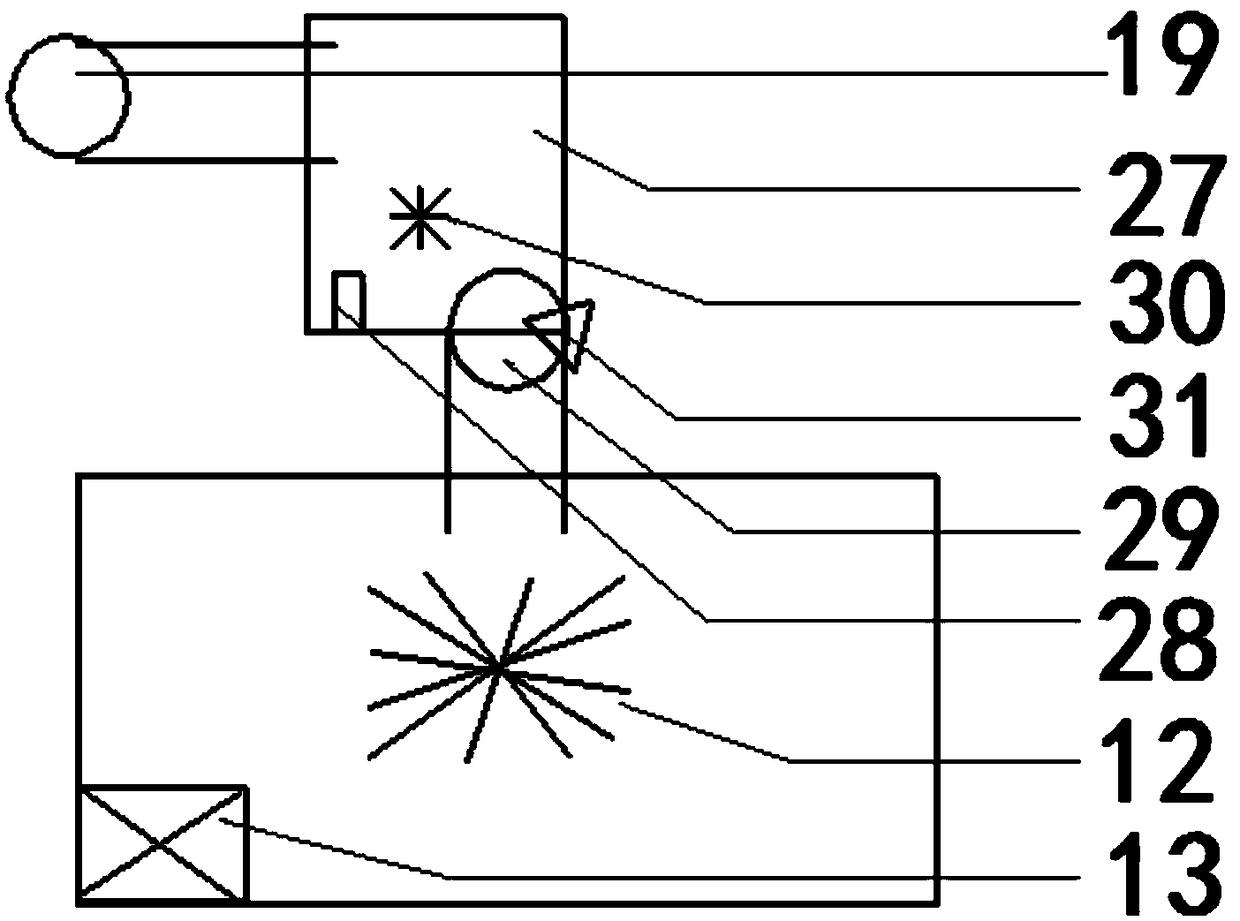

[0032]An absorption tower, which includes a slurry tank arranged at the bottom of the absorption tower, a flue gas inlet for passing flue gas into the absorption tower, a spray device arranged above the flue gas inlet, and a Smoke outlet; the spraying device includes: a circulation pump connected to the slurry pool, a delivery pipe connected to the circulation pump and an atomizing nozzle connected to the delivery pipe, the circulation pump is arranged in the slurry pool, the The first end of the delivery pipe communicates with the circulating pump, the second end is attached to the inner wall of the absorption tower and extends upward to the top of the absorption tower, and the second end of the delivery pipe is provided with a plurality of branches, so The branch is arranged along the inner wall of the absorption tower, the atomizing nozzle is arranged on the branch and the atomizing nozzle is vertically directed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com