Method of refining and desulfurizing for low-silicon steel

A low-silicon steel and ladle technology, applied in the field of metallurgy, can solve problems such as low desulfurization rate, high sulfur content in molten steel, and waste casting billets, and achieve the effects of reducing sulfur content in molten steel, increasing slag alkalinity, and promoting desulfurization reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

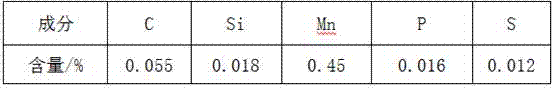

[0035] The low-silicon steel in this example is the aluminum-containing steel H08A, and the refined composition is shown in Table 3.

[0036] Table 3 Aluminum-containing steel H08A, refined inbound composition

[0037]

[0038] The method for refining and desulfurizing low-silicon steel in this embodiment includes the steps of adjusting slag system, slagging, heating, and desulfurization. The specific process steps are as follows:

[0039] (1) Adjusting the slag system process: adding aluminum powder (Al: 97%) 0.25kg / t steel to the ladle in the early stage of refining to adjust the slag system to reduce the oxidation of steel slag;

[0040] (2) Slagging process: add lime (CaO: 83%) 2.5kg / t steel, fluorite (CaF 2 : 80%) 0.5kg / t steel for slagging;

[0041] (3) Heating process: the molten steel heating temperature is 1600°C;

[0042] (4) Desulfurization process: 2.5kg / t of calcium carbide is added to steel, and the reducibility of calcium carbide is used to reduce the oxid...

Embodiment 2

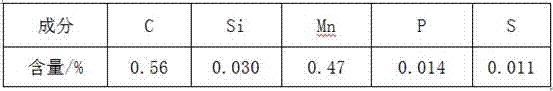

[0047] The low-silicon steel in this example is aluminum-containing steel H08A, and the composition of the refined inbound composition is shown in Table 5:

[0048] Table 5 Aluminum-containing steel H08A, refined inbound composition

[0049]

[0050] The method for refining and desulfurizing low-silicon steel in this embodiment includes the steps of adjusting slag system, slagging, heating, and desulfurization. The specific process steps are as follows:

[0051] (1) Adjusting the slag system process: adding aluminum powder (Al: 98%) 0.17kg / t steel to the ladle in the early stage of refining to adjust the slag system to reduce the oxidation of steel slag;

[0052] (2) Slagging process: add lime (CaO: 78%) 3.0kg / t steel, fluorite (CaF 2 : 75%) 0.4kg / t steel for slagging;

[0053] (3) Heating process: the molten steel heating temperature is 1610°C;

[0054] (4) Desulfurization process: add calcium carbide 2.3kg / t steel, use the reductive properties of calcium carbide to red...

Embodiment 3

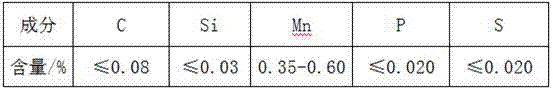

[0059] The low-silicon steel in this example is aluminum-containing steel H08A, and the composition of the refined inbound composition is shown in Table 7:

[0060] Table 7 Aluminum-containing steel H08A, refined inbound composition

[0061]

[0062] The method for refining and desulfurizing low-silicon steel in this embodiment includes the steps of adjusting slag system, slagging, heating, and desulfurization. The specific process steps are as follows:

[0063] (1) Adjusting the slag system process: adding aluminum powder (Al: 98.4%) 0.25kg / t steel to the ladle in the early stage of refining to adjust the slag system to reduce the oxidation of steel slag;

[0064] (2) Slagging process: add lime (CaO: 80%) 2.7kg / t steel, fluorite (CaF 2 : 85%) 0.5kg / t steel for slagging;

[0065] (3) Heating process: the molten steel heating temperature is 1605°C;

[0066] (4) Desulfurization process: adding 2.6kg / t of calcium carbide to steel, using the reducing property of calcium carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com