lf furnace desulfurization control carbon nitrogen control method

A control method and technology of molten steel, applied in the field of metallurgy, can solve problems such as unstable control ability of desulfurization process, improvement of molten steel production quality, insufficient desulfurization capacity, etc., and achieve the effect of ingenious design, promoting slag melting, and increasing the contact area of steel slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

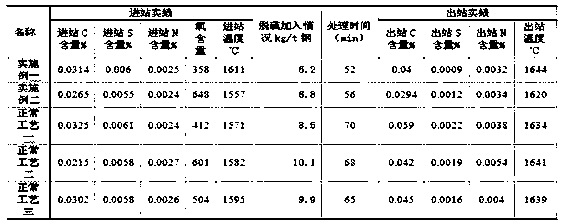

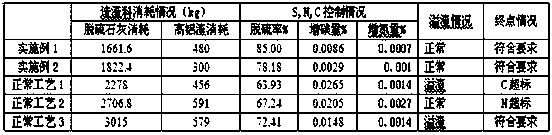

Embodiment 1

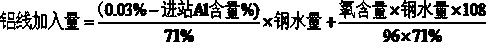

[0020] Manufacture order number 270872 steel type JU6716A6 is processed in a 250-ton LF furnace for a total period of 52 minutes, the entry temperature is 1611°C, [C]=0.0314%, [S]=0.006%; the set flow rate of the bottom blowing at the entry station is 300L / min, observe Bottom blowing effect is good, add lime 3.8kg / t. steel, and add 200kg high aluminum deoxidizer at the same time for slag deoxidation; use 11 levels of voltage and 6 levels of current for submerged arc heating to heat up the slag for about 8 minutes, the slag turns yellow, and the temperature is measured Oxygenation, measured temperature 1592°C, oxygen content 358ppm, feed Al wire, carry out deoxidation treatment of molten steel, control Alt in the steel to the middle limit Al of the target range t =0.03%, add 520kg ferrosilicon alloy, add 180kg high alumina deoxidizer, 3.5 Kg / t. steel lime, heat for 15min, stop heating, set the flow rate to 180 L / min, stir with bottom blowing for 3 minutes, and turn off the botto...

Embodiment 2

[0022] Manufacture order number 517801, steel type IV5810B2, treatment time in LF furnace 56min, pure treatment cycle 31.3min; composition of steel type entering station [C]=0.0265%, [S]=0.0055%, bottom blowing flow rate of entering station 500L / min, The thickness of the slag layer is 210mm. Short-arc heating is selected for treatment. The heating time is 5 minutes. Heating rapidly, the heating time is 11 minutes, and the temperature is measured at 1601°C. At this time, the aluminum wire is fed to adjust the Al in the steel. t At the same time, add 530kg ferrosilicon alloy, add 3.5 Kg / t. steel lime, 100kg high aluminum slag for 8min deep desulfurization treatment, observe the slag condition, it has become white slag, increase the flow rate of argon to 180 L / min, stir for 3min to increase the steel type Desulfurize the contact area, add 200kg of high-aluminum slag again, reheat for 5 minutes, and heat up at 3.5 ℃ / min, further desulfurize and heat up, stir weakly for 3 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com