Preparation method of liquid desulfurizing agent and liquid desulfurizing agent

A desulfurizing agent and liquid technology, applied in the field of desulfurization of oil and gas wells, can solve problems such as affecting on-site construction progress, sedimentation and plugging, and achieve the effects of enhancing desulfurization temperature adaptability, improving desulfurization rate, and good emulsification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 100ml of ethanol as a solvent in the reactor;

[0034] Add 0.5mol 1,3,5-trihydroxyethylhexahydro-s-triazine, 1.0mol diethylenetriamine, 1.0mol epichlorohydrin and 1.5mol potassium hydroxide to the reactor;

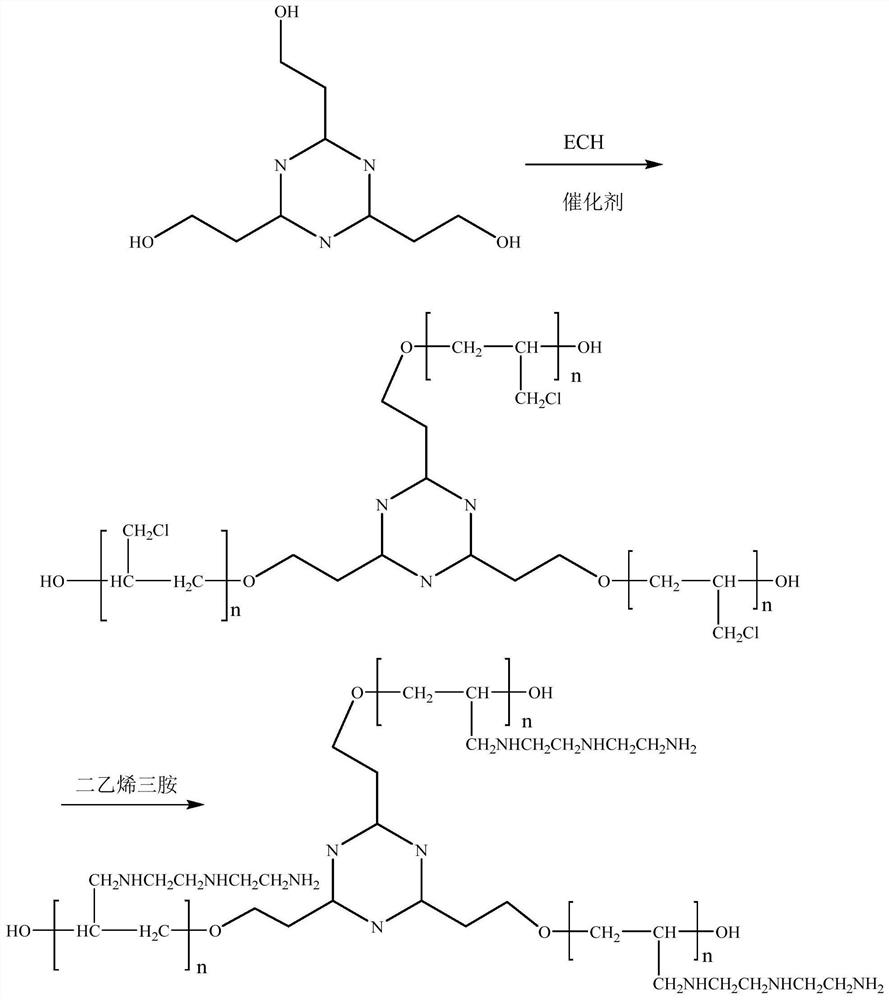

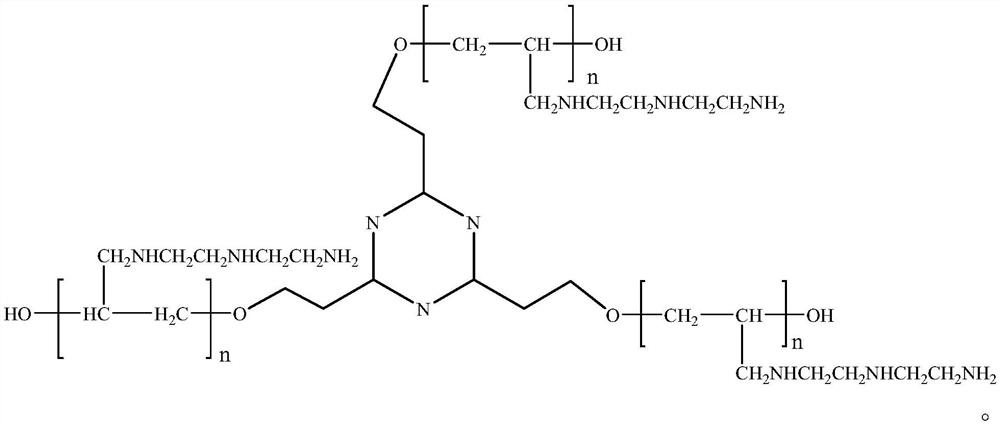

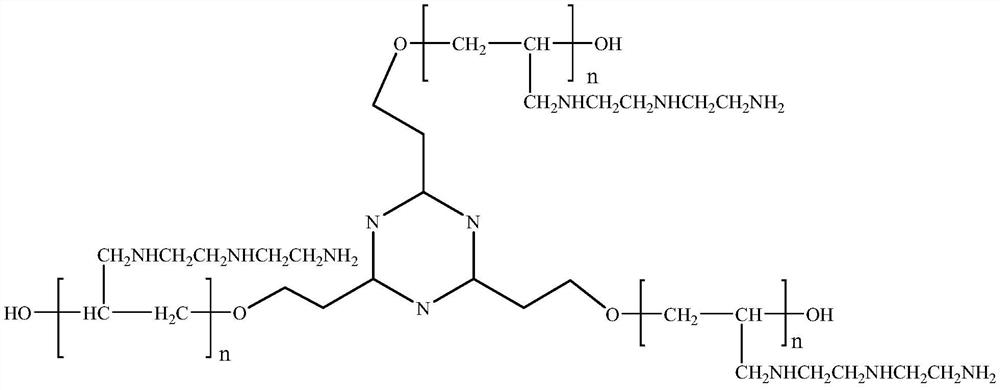

[0035] Turn on electric stirring, raise the temperature to 110°C, and react for 4 hours to prepare a liquid desulfurizer. The synthesis circuit diagram is as follows figure 1 shown.

Embodiment 2

[0037] The difference from Example 1 is that 0.5 mol of 1,3,5-trihydroxyethylhexahydro-s-triazine, 1.5 mol of diethylenetriamine, 1.5 mol of epichlorohydrin and 1.5 mol of potassium hydroxide were added.

[0038] Turn on electric stirring, raise the temperature to 120°C, and react for 4 hours to prepare a liquid desulfurizer. The synthesis circuit diagram is as follows figure 1 shown.

Embodiment 3

[0040] The difference from Example 1 is that 0.5 mol of 1,3,5-trihydroxyethylhexahydro-s-triazine, 2.5 mol of diethylenetriamine, 2.5 mol of epichlorohydrin and 1.5 mol of potassium hydroxide were added.

[0041] Turn on electric stirring, raise the temperature to 130°C, and react for 4 hours to prepare a liquid desulfurizer. The synthesis circuit diagram is as follows figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com