KR stirring paddle and manufacture method thereof

A production method and technology of stirring paddles, which are applied in the field of KR stirring paddles and its production, can solve the problems of shortening the service life of KR stirring paddles, falling off of local pits, and reducing desulfurization efficiency, so as to shorten the time of stirring desulfurization, reduce production costs, The effect of improving working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

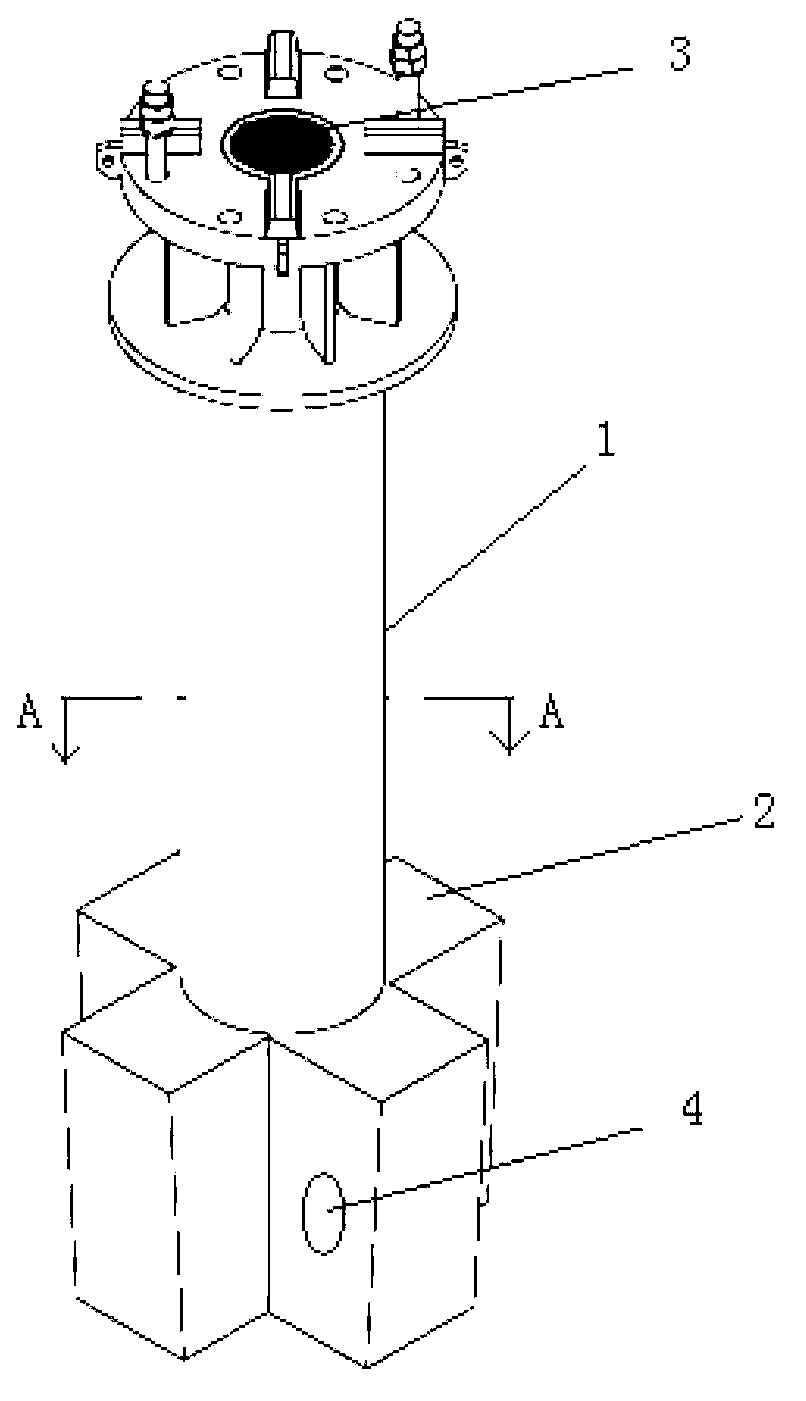

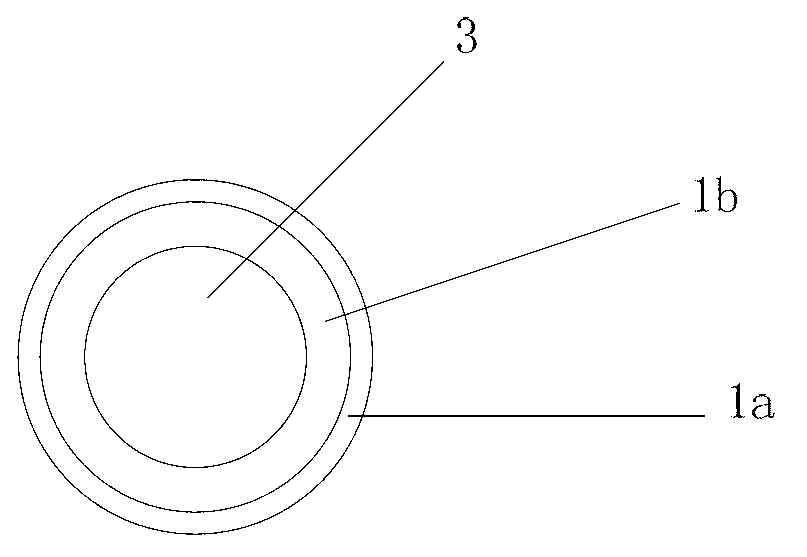

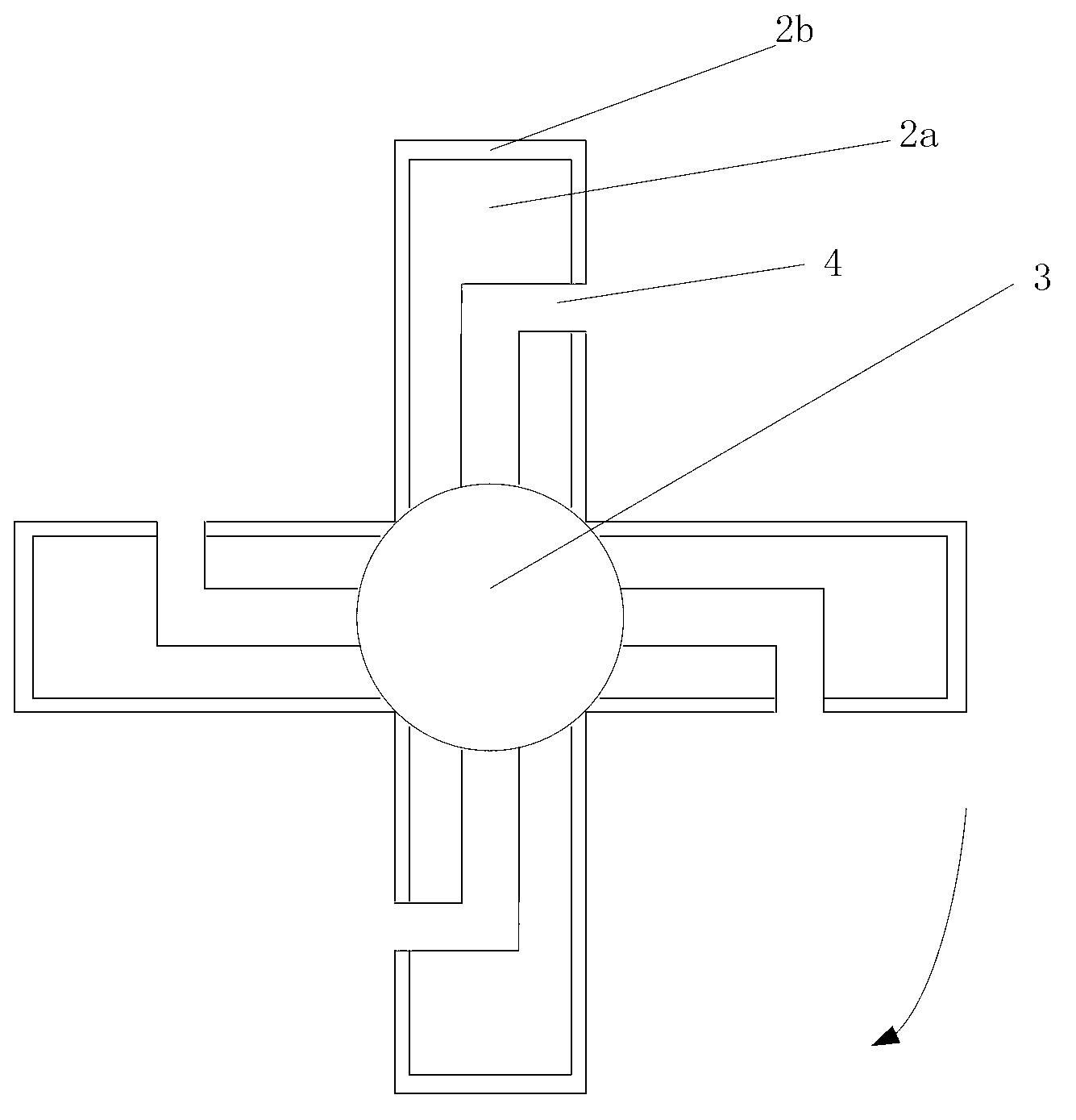

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] From the principle of KR desulfurization and its agitation desulfurization process, the stirring paddle is inserted into the molten iron at a certain depth to rotate, and the desulfurization agent is sucked in the center of the vortex under the entrainment action of the vortex, and is discharged radially from the paddle blades to float up. The mixing and contacting of molten iron completes the desulfurization reaction. In order to improve the desulfurization effect or shorten the desulfurization time, in the past, technicians often started from increasing the desulfurization rotation speed, and the increase in the rotation speed of the propeller will reduce its life. In order to improve the service life of the KR agitator, it is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com