Low energy consumption and long period hydrogenation process for producing diesel oil

A long-cycle, low-energy-consumption technology, applied in hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of high energy consumption and affecting the operation cycle of the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

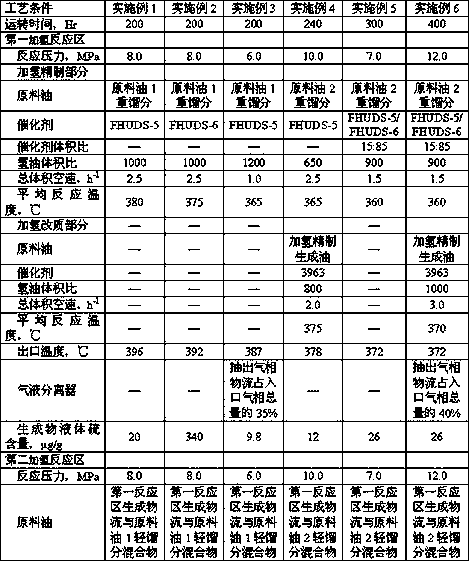

[0042] The following examples will further illustrate the process and effect of the hydrogenation process of the present invention with low energy consumption and long-term production of ultra-low sulfur diesel oil, wherein the first hydrogenation reaction zone selects a hydrogenation reactor, and the second hydrogenation reaction zone selects a hydrogenation reactor Hydrogenation reactor, but the following examples do not constitute a limitation to the method of the present invention.

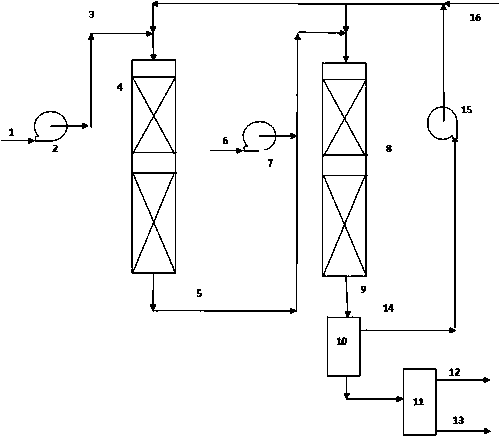

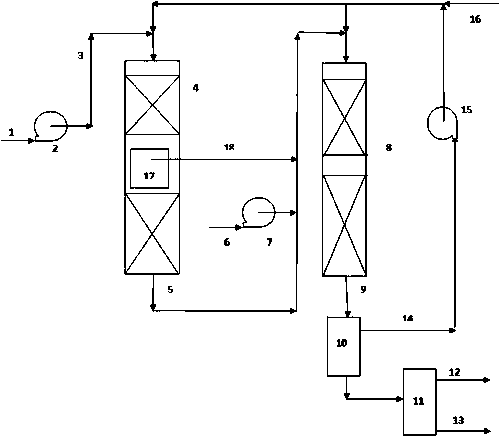

[0043] Such as figure 1 The specific implementation of the hydrogenation process for the production of ultra-low sulfur diesel oil with low energy consumption and long period of the present invention is as follows: the heavy distillate feedstock oil 1 is pressurized by the first feedstock oil pump to obtain the pressurized heavy distillate feedstock oil 3, The heavy distillate feed oil 3 after pressing continues to mix with circulating hydrogen and then enters the first hydrogenation reactor 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com