Patents

Literature

31results about How to "To achieve the purpose of deep desulfurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxidation sweetening process for diesel distillate

InactiveCN1504543APromote oxidationTo achieve the purpose of deep desulfurizationRefining with oxygen compoundsAcetic anhydrideDistillation

A process for diesel oil distillation oxidation sweetening comprises, adding in 0.1-20% diesel oil distillation volume of hydrogen dioxide and 0.1-20% acetic anhydride, reacting at the temperature of 30-90 deg. C, wherein the sulfide is oxygenized into sulfone or sulfoxide compounds, rinsing to remove acidic material, and removing sulfone or sulfoxide compounds from the diesel oil through adsorptive separation method. The catalyst has good regeneration effect and thus can be reutilized.

Owner:CHINA PETROLEUM & CHEM CORP +1

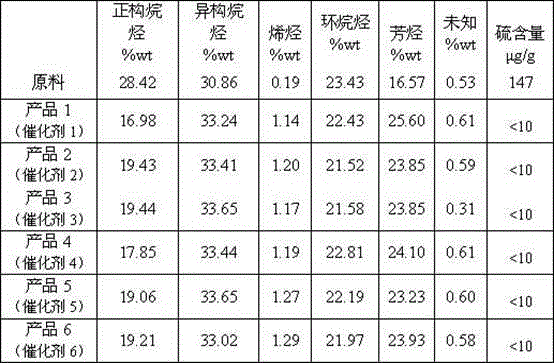

Catalyst for deep desulfuration and octane number increase for gasoline and preparation and application methods thereof

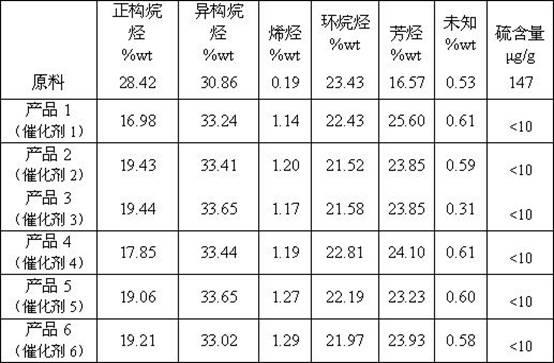

ActiveCN102343276ATo achieve the purpose of deep desulfurizationHigh aromatic contentMolecular sieve catalystsHydrocarbon oils treatmentAlkaneReaction temperature

The invention discloses a catalyst for deep desulfuration and octane number increase for gasoline and preparation and application methods thereof. The functional catalyst comprises NiM / ZnO-ZSM-5. The preparation method comprises the steps of: firstly, synthesizing nanometer zinc oxide with high specific surface by using a low-temperature solid-phase method, then respectively steeping nickel and auxiliary metal, in the form of ions, onto the surface of the zinc oxide by using a steeping method, drying, roasting, and reducing in hydrogen to obtain a nanometer composite of the nickel, the auxiliary metal and the zinc oxide, wherein the nickel and the auxiliary metal are bonded in an alloy manner and uniformly disperse on crystalline phases of the zinc oxide. The catalyst has the reaction conditions that the reaction temperature is 350-450 DEG C, the pressure is 0.5-1.6MPa, the hydrogen-oil volume ratio is 100-300 and the air speed is 2<-10>h<-1>. By using the catalyst disclosed by the invention to treat straight-run gasoline, the deep desulfuration and the aromatization of alkane and olefin are performed at the same time, so that the octane number of a product gasoline is obviously increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preparing heteropoly acid/ordered mesic porous silicon oxide catalyst, and its application

InactiveCN1947840APrevent elutionGood dispersionMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAlcoholHeteropoly acid

A heteropoly acid / ordered meso-porous silicon oxide catalyst used for removing the S-contained benzothiophenium compounds from the fractional oil of petroleum is prepared through such steps as dissolving heteropoly acid in the mixture of absolute alcohol and distilled water, adding ethyl n-silicate, magnetic stirring to obtain solution A, dissolving the polyoxyethene-polyoxypropene-polyoxyethene triblock copolymer in the mixture of absolute alcohol and distilled water to obtain solution B, slowly adding B to A, magnetic stirring to obtain sol, culturing it at 38-42 deg.C for 6-8 days, pulverizing, and calcining in N2.

Owner:WUHAN UNIV OF TECH

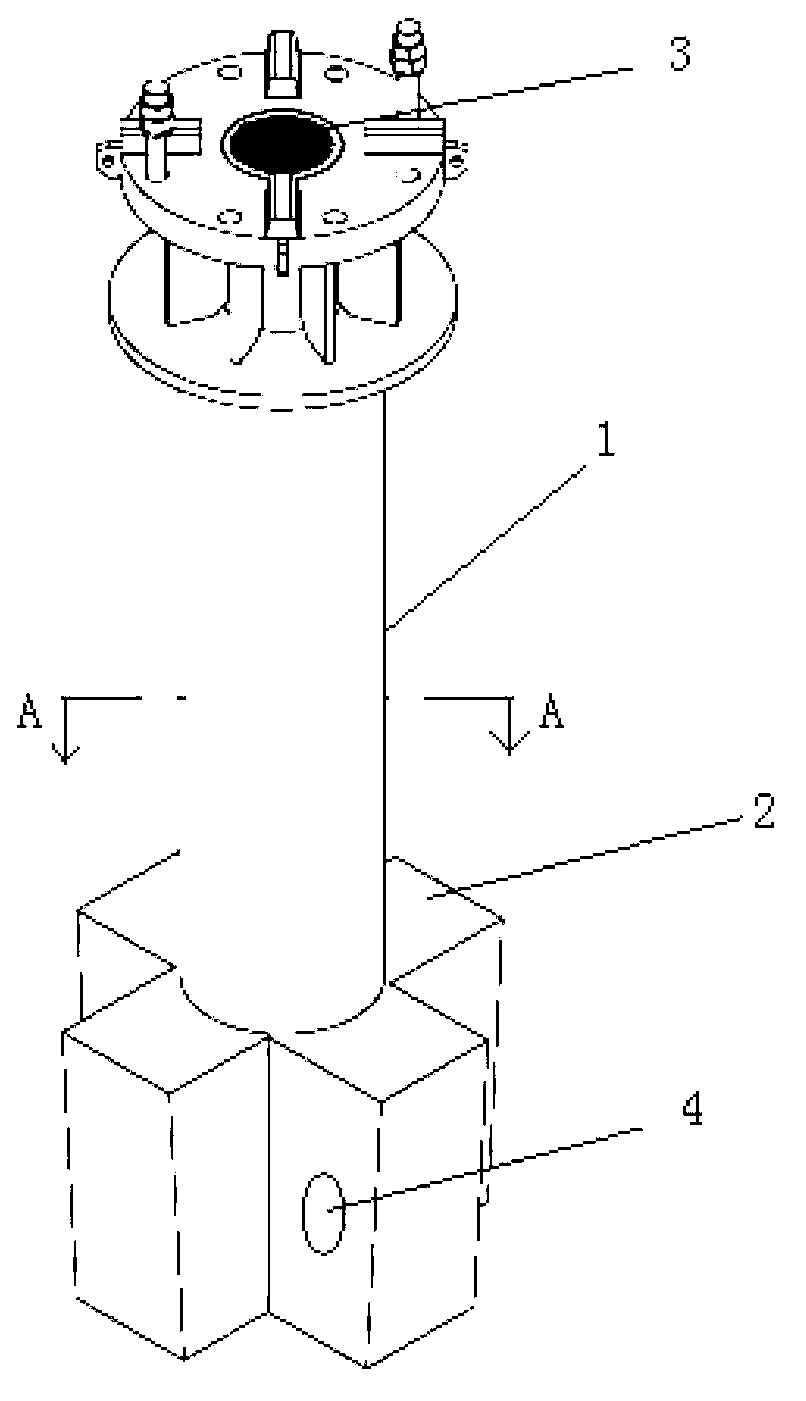

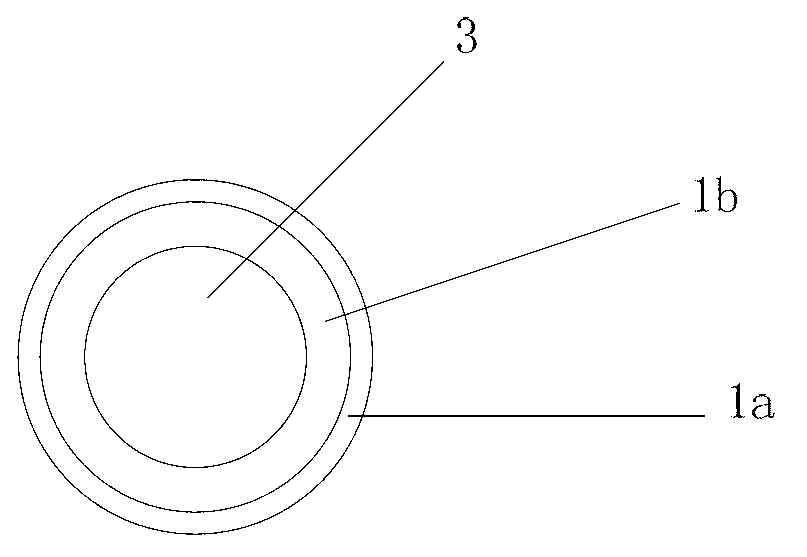

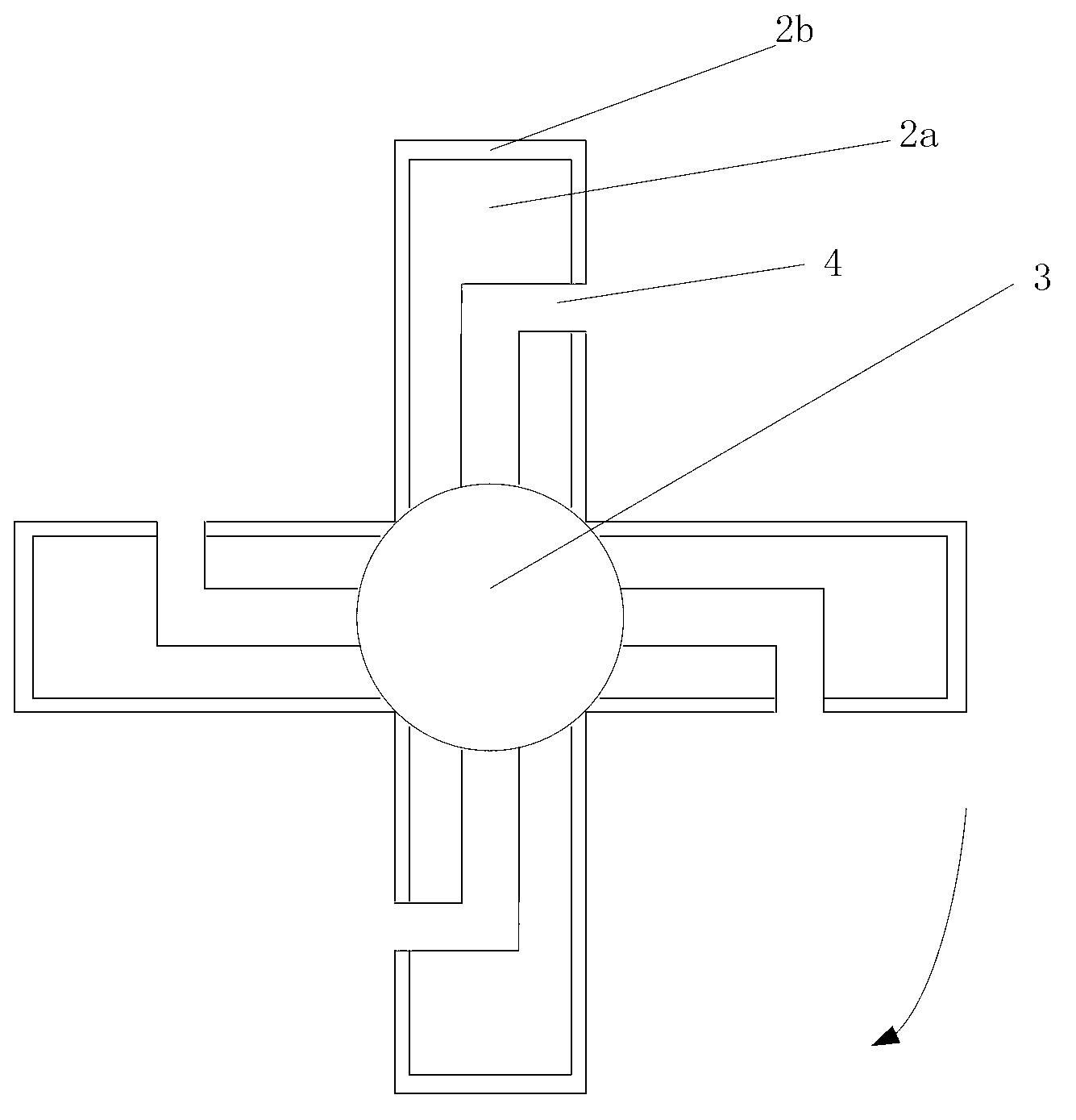

KR stirring paddle and manufacture method thereof

ActiveCN103014218APromote desulfurization reactionTo achieve the purpose of deep desulfurizationStirring devicesEngineeringHot melt

The invention discloses a KR stirring paddle and a manufacture method thereof. The KR stirring paddle is used in a hot-melt ladle desulfuration process and comprises a stirring shaft, paddles, a ventilating pipeline and ventilating holes, wherein the paddles are arranged on one end of the bottom of the stirring shaft, the core part of the stirring shaft is hollow and is used as the ventilating pipeline, the ventilating holes are formed in the paddles, one ends of the ventilating holes are communicated with the ventilating pipeline, the other ends of the ventilating holes are opened in the surfaces of the paddles, and one end of the top of the stirring shaft is connected with a gas supply device for supplying gas to the ventilating pipe. According to the invention, through the KR stirring paddle, the gas is introduced from the ventilating pipeline and is discharged from the ventilating holes, the discharged gas plays a role of reinforcing the stirring of molten ion to ensure that the molten iron is in well contact with a desulfurizing agent for reaction, therefore the desulfurization of the molten iron is accelerated, and the purpose of deep desulfurization of the molten iron is reached.

Owner:DAYE SPECIAL STEEL CO LTD

Method for desulfurization of coal by electrochemical catalytic oxidation

InactiveCN101899351AReduce material consumptionLess side effectsSolid fuelsEnvironmental chemistryStrong acids

The invention relates to a method for desulfurization of coal by electrochemical catalytic oxidation, although the exiting coal chemical desulfurization methods can almost remove all inorganic sulfur and part of organic sulfur in the coal, most of the methods need strong acid, strong base and strong oxidants and need to be operated under the conditions of high temperature and high pressure, the process conditions are harsh and the cost is high; furthermore, a plurality of chemical methods can cause series damages to the structure and the nature of the coal. The invention discloses the method for desulfurization of the coal by the electrochemical catalytic oxidation, which comprises the following steps: (A) adopting NaI with the concentration of 1.5mol / L as supporting electrolyte, weighing a certain amount of the electrolyte, adding into an anode chamber in an electrolysis bath, simultaneously adding the supporting electrolyte in the same volume and the same composition into a cathode chamber, and well connecting a gas collecting system; (B) adding a coal sample with the particle size of below minus 200 meshes into the anode chamber of the electrolysis bath, and controlling the concentration of coal slurry at 0.05g / ml; (C) connecting with circulating water of a water bath tank, and energizing for electrolysis; and (D) filtering electrolyte solution after energizing for 4 hours, washing the coal sample, drying, weighing and carrying out sulfur, calorific value, ash content and infrared spectrum analysis. The technology is used for the coal desulfurization.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

Method for making clean fuels

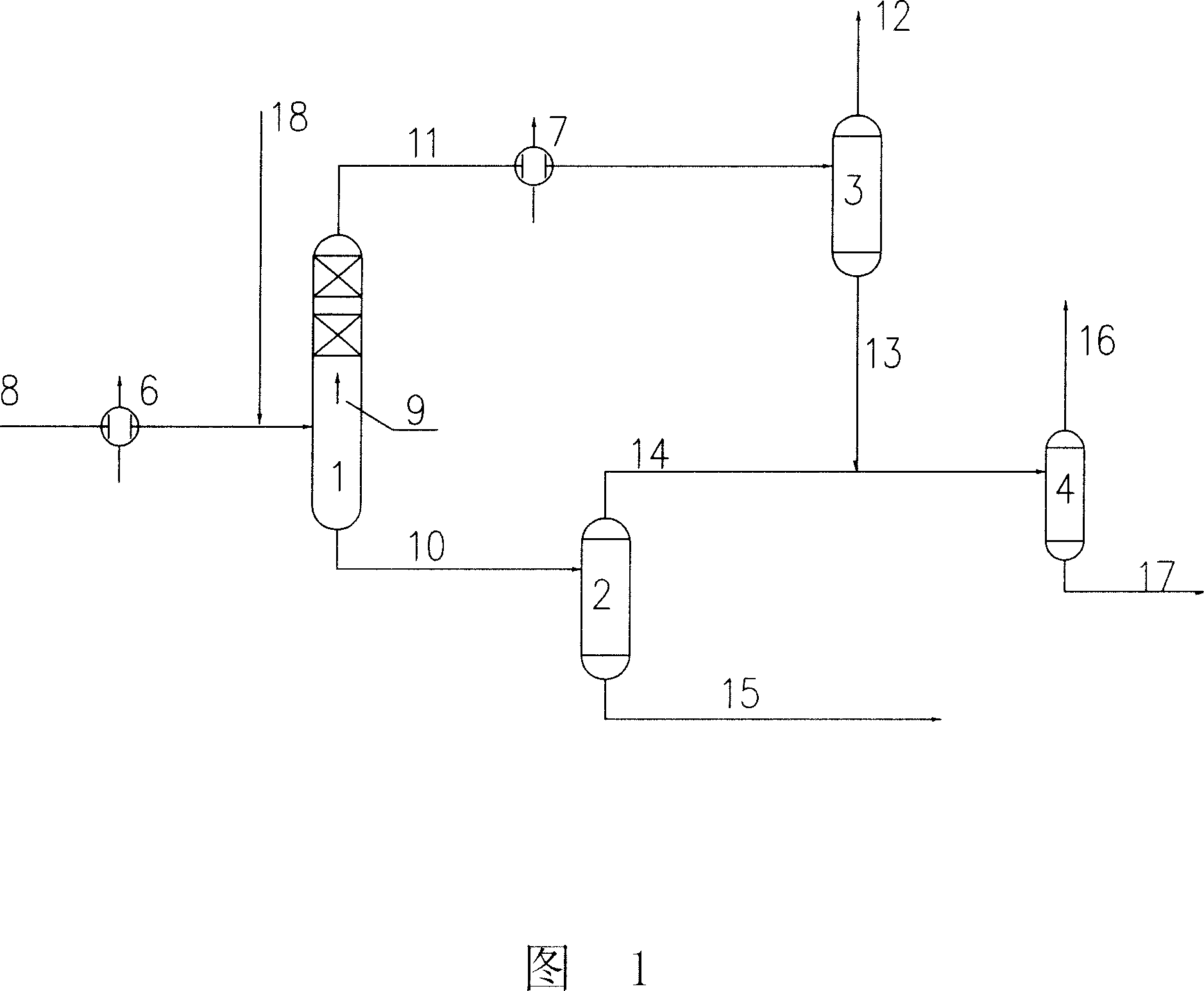

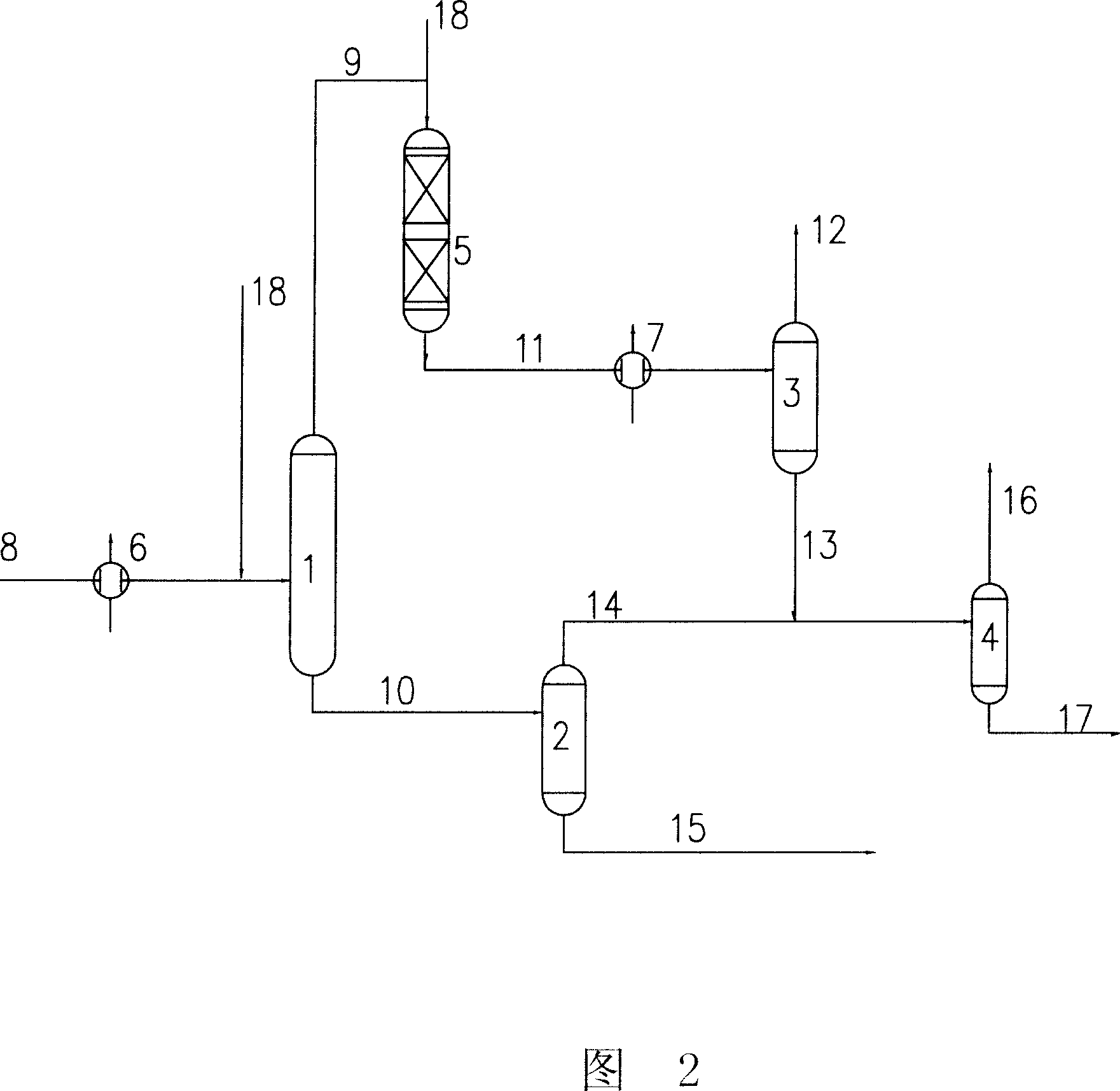

ActiveCN1962828AHigh saturationTo achieve the purpose of deep desulfurizationTreatment with hydrotreatment processesHydrogenProcess engineering

The invention discloses a manufacturing method of clean fuel, which is characterized by the following: adding catalyst bed on the heat low-pressure separator or hydrogenating refining reactor between heat low-pressure separator and cold low-pressure separator; cracking the hydrocarbon oil; manufacturing light-quality and clean fuel.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

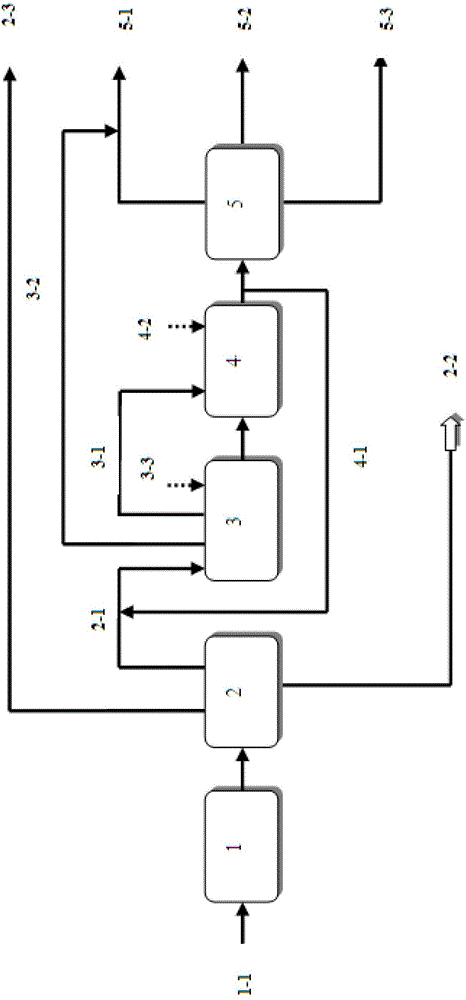

Method for improving shale oil hydrorefining denitrification rate

ActiveCN105838418AImprove utilization efficiencyImprove the level of comprehensive utilizationTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaFractionation

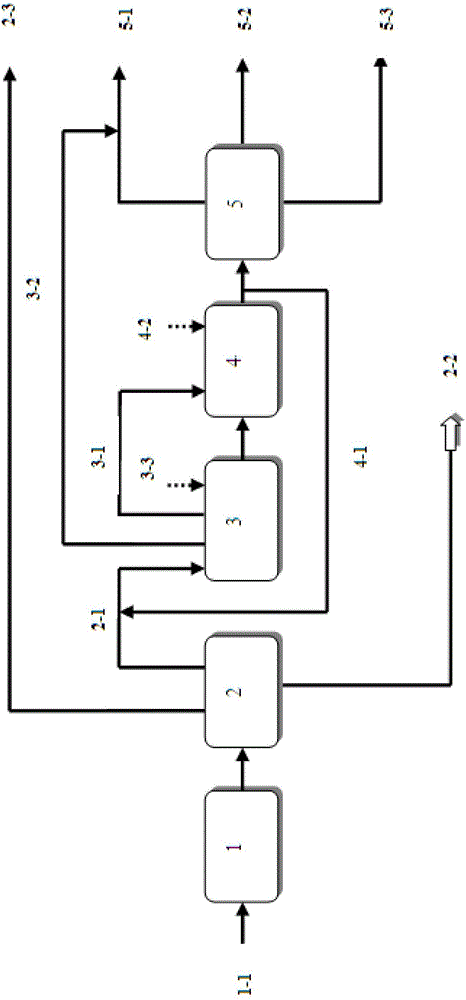

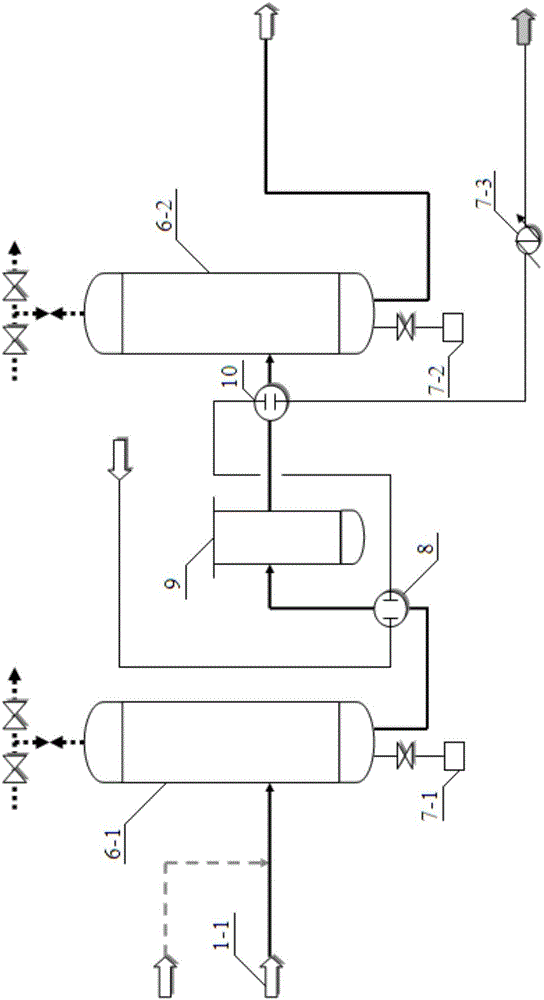

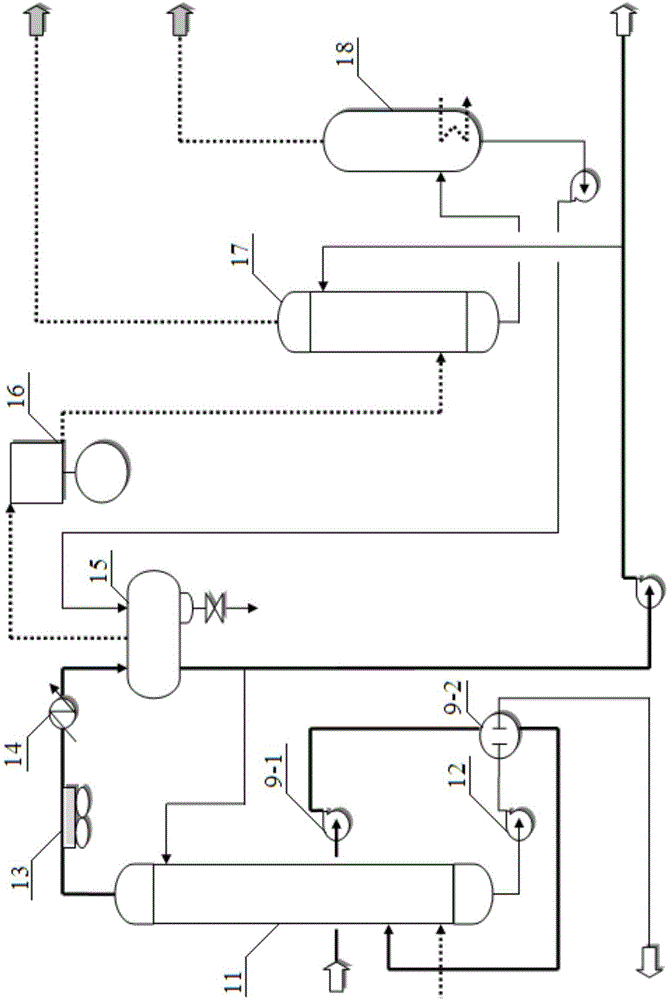

The invention provides a method for improving the shale oil hydrorefining denitrification rate, and relates to a whole fraction shale oil hydro-denitrification process. The method aims at solving the technical problems that in the existing method for producing diesel oil through shale oil hydrorefining, the stability of a diesel oil product is low, and the operation running period of a hydrorefining catalyst is short. According to the method, a raw material pretreatment unit 1, a raw material pre-fractionation unit 2, a primary hydrorefining reaction unit 3, a secondary hydrorefining reaction unit 4 and a product fractionation unit 5 are used. When the method provided by the invention is used for processing shale oil, the light oil yield is high; the nitrogen content of the diesel oil product is low; the chromaticity and the stability conform to national V standard requirements; the goal of light oil product deep denitrification can be achieved; the service life of the hydrorefining catalyst is prolonged; the operation running period of the catalyst is improved. A main product of the method is hydrorefining diesel oil; byproducts are high-value LPG and hydrogenated naphtha; heavy shale oil and hydrogenation tail oil thrown out in the technical process can be further processed and used in a downstream device. The method provided by the invention belongs to the field of whole-fraction shale oil deep processing.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Method for removing sulphur in gasoline by electrochemical oxidation

InactiveCN101457157AReduce sulfur contentMild operating conditionsRefining by electric/magnetic meansSupporting electrolyteSodium acetate

The present invention relates to a method to remove sulphur in gasolene by using electrochemistry measure, which comprises the following procedures: first mix gasolene with an electrolytic system that consists of polar solvent, supporting electrolyte and water and place the mixture into an isolated electric tank for electrolysis, then settling separate fat phase and electrolytic system phase, electrolytic oxidation product of sulfur-containing compound of gasoline enter into electrolytic system phase to be removed; volume ratio between gasolene and electrolytic system is 0.5-2; electrolytic temperature range is from 40 DEG C to 50 DEG C; supporting electrolytes / polar solvent is 0.1-2mol / L; volume ration between water and dissolvent is 0.1-1; polar solvent is one of acetic acid and ethyl hydrate or the mixture; supporting electrolytes is sodium chloride or sodium acetate; water is used to provide oxygen source in the process; operation condition is mild; dissolvent and supporting electrolytes can be used for periodic duty in electrolytic process; zero discharge can be realized primarily; hydrogen gas is produced secondarily; octane ratio lowing down problem because of hydrogenation in oil-extraction plant gasoline catalysis and cracking process can be solved.

Owner:PETROCHINA CO LTD

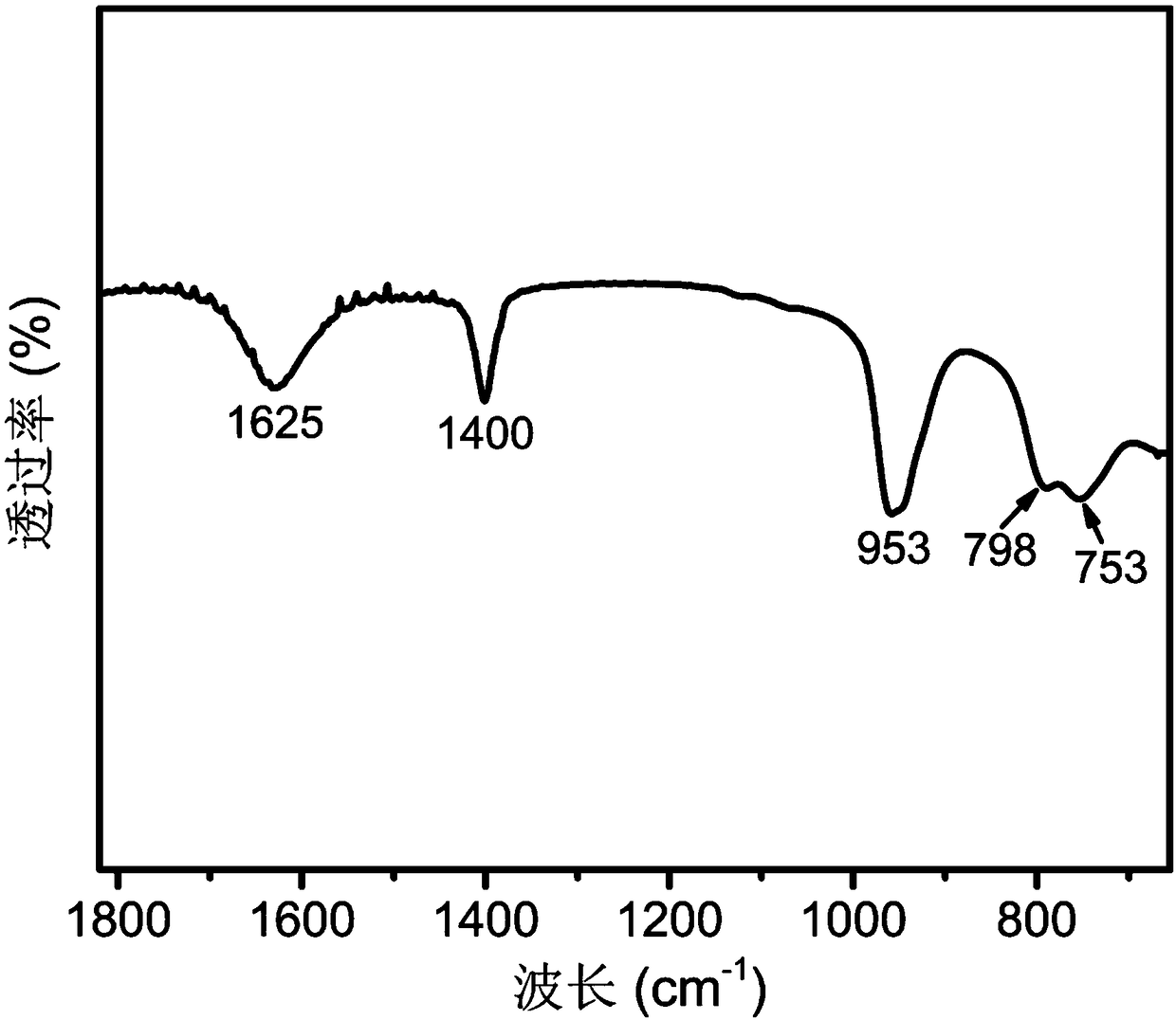

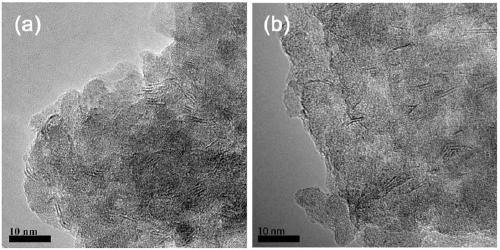

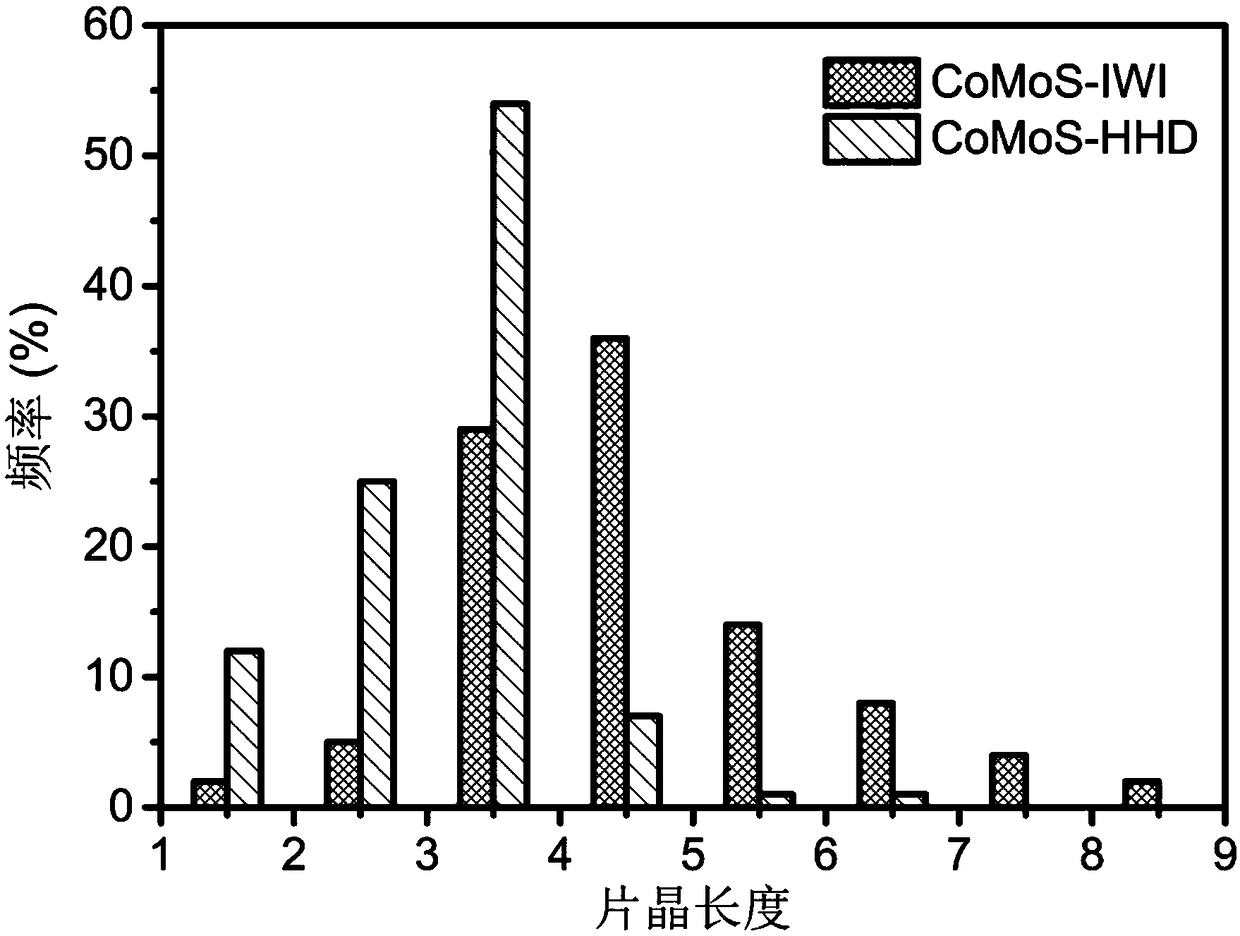

Deep desulfurization catalyst and preparation method and application thereof

ActiveCN109289876ATightly boundIncrease the level of retouchingCatalyst activation/preparationHydrocarbon oils treatmentWater bathsAcetic acid

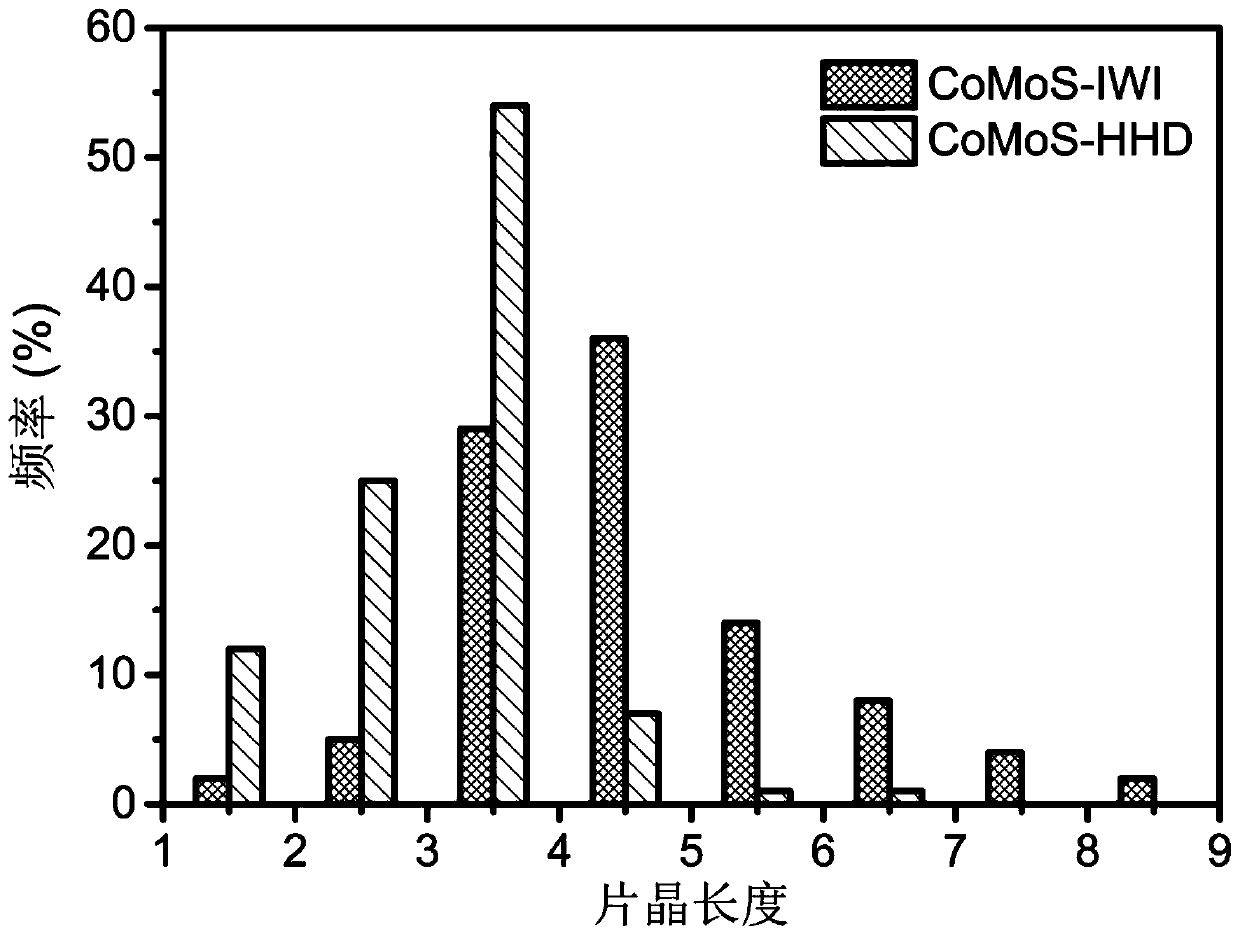

The invention provides a deep desulfurization catalyst and a preparation method and application thereof. The preparation method of the deep desulfurization catalyst includes: weighing ammonium paramolybdate and cobalt acetate tetrahydrate, dissolving into glacial acetic acid and water mixed solution, stirring to dissolve, adding hydrazine sulfate, stirring to dissolve, performing stirring reactionin a constant-temperature water bath to obtain a cobalt-molybdenum heteropoly compound after reaction is finished; dispersing the cobalt-molybdenum heteropoly compound into water, ultrasonically treating, adding aluminum oxide, well stirring, and performing hydrothermal load dispersion in an autoclave to obtain the desulfurization catalyst after reaction is finished. The desulfurization catalystis high in dispersion performance and activity, deep desulfurization can be realized, and the desulfurization rate is up to 94.1%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

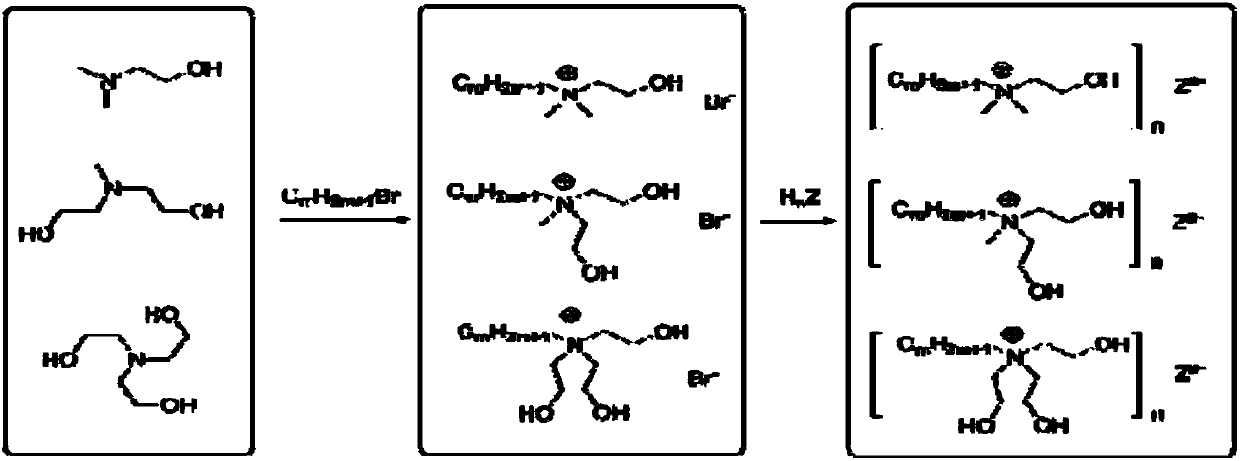

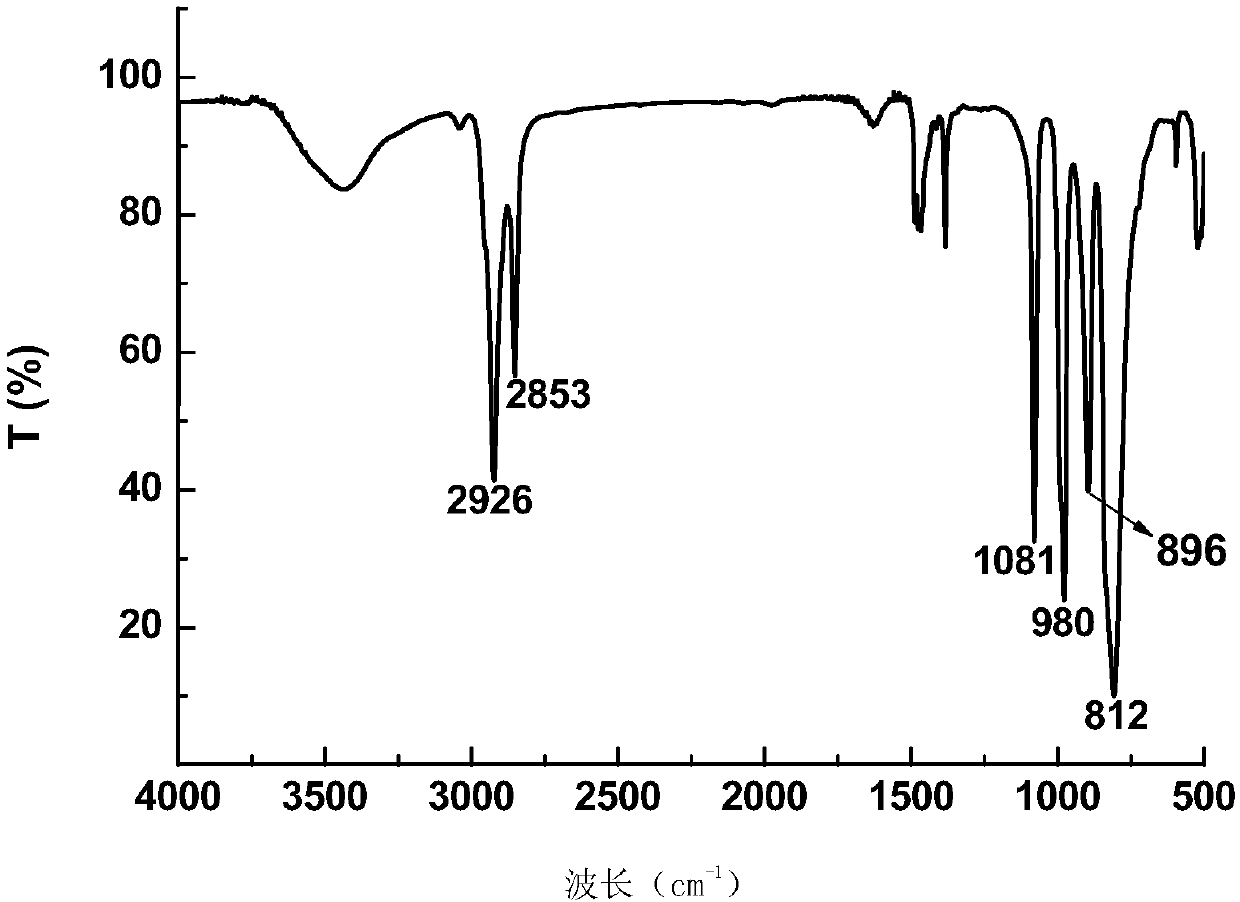

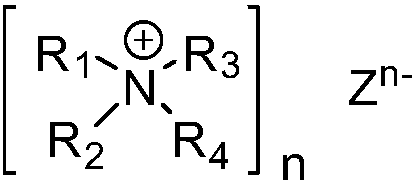

Hydroxyl functionalized heteropolyacid catalyst as well as preparation method and application thereof

InactiveCN107866281ASolving Recycling ProblemsLow costOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsSulfur contentAlkene

The invention discloses a hydroxyl functionalized heteropolyacid catalyst as well as a preparation method and an application thereof. The cationic structure of the hydroxyl functionalized heteropolyacid catalyst contains hydroxyl. Preferably, the hydroxyl functionalized heteropolyacid catalyst has the structure shown in the description, wherein R1 is C2-C45 alkyl, R2, R3 and R4 are selected from C1-C25 alkyl or hydroxyalkyl, at least one of R2, R3 and R4 contains hydroxyl, Zn- is heteropolyacid radical, and n is any integer of 1-8. The hydroxyl functionalized heteropolyacid catalyst can be used in the oxidative desulfurization process, for example, the sulfur content of fuel can be decreased to 70% or below at the normal temperature while the quality indexes such as olefin content, octanenumber and the like of fuel are not affected, besides, and the hydroxyl functionalized heteropolyacid catalyst can still keep 50% desulfurization efficiency or above after being recycled.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

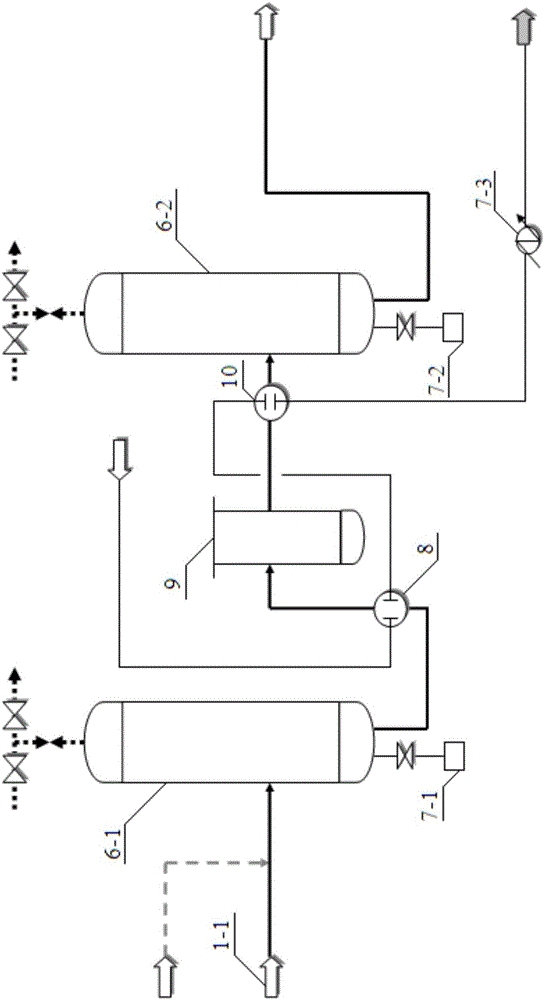

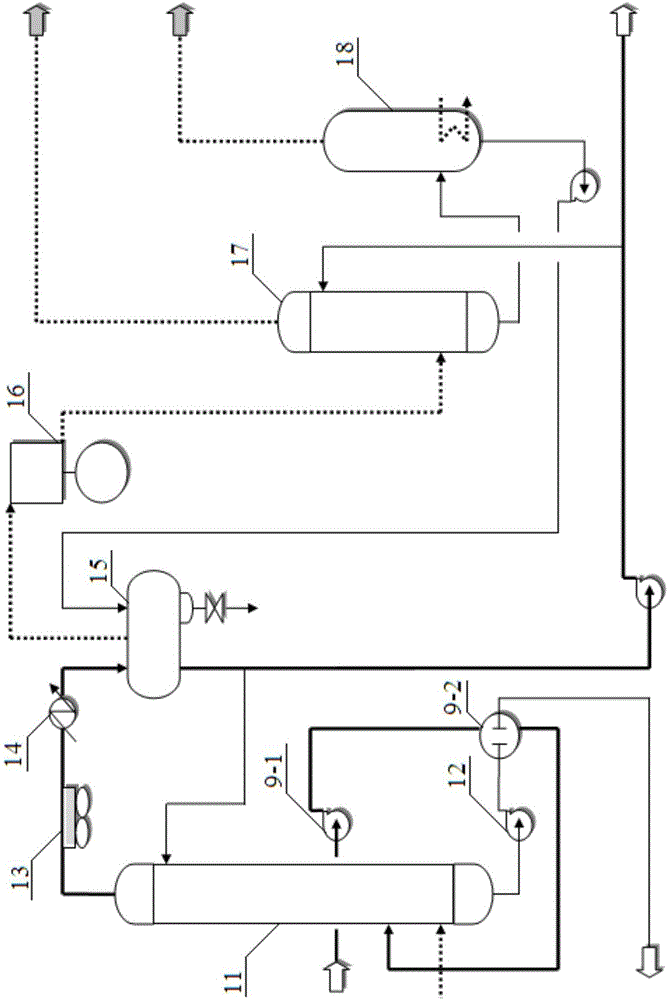

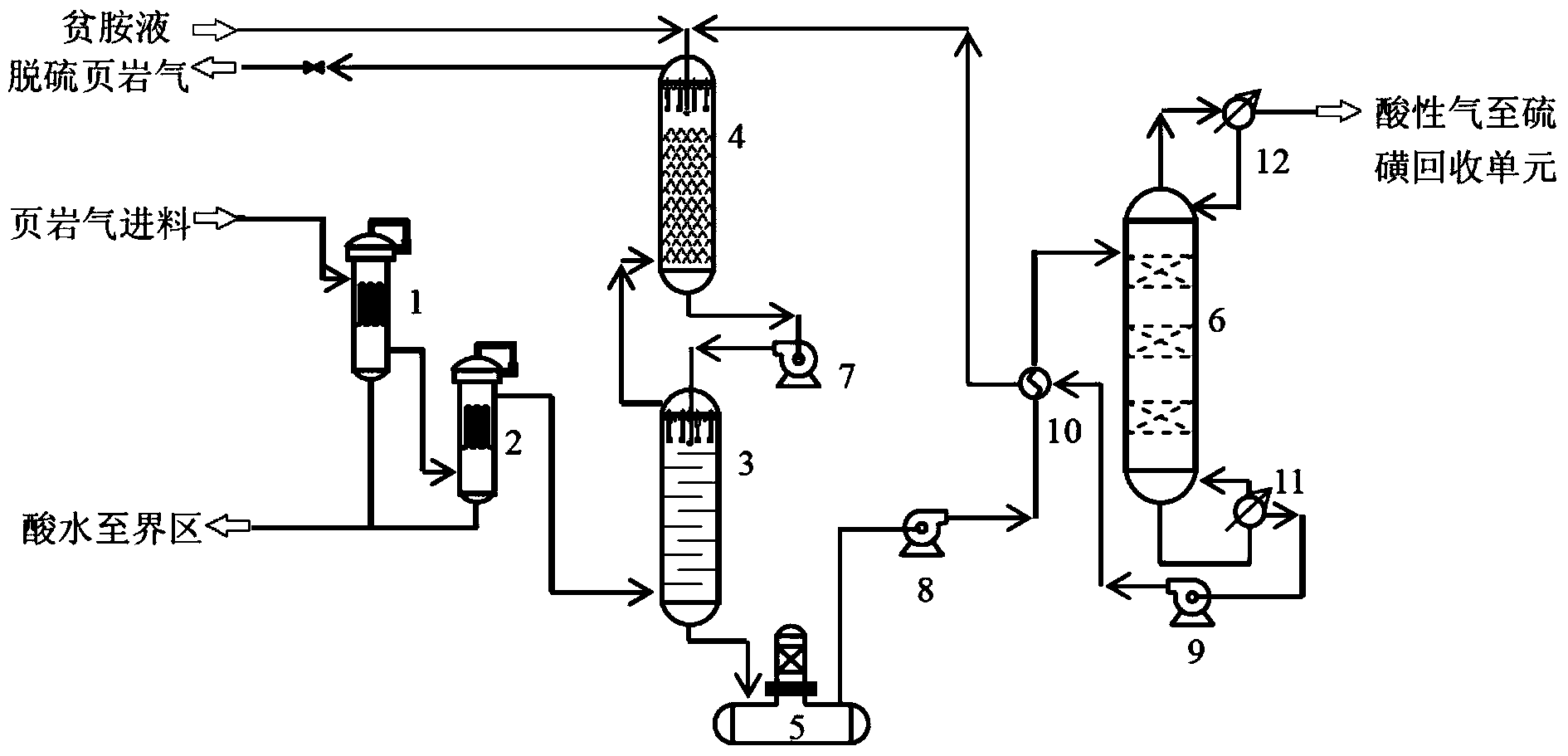

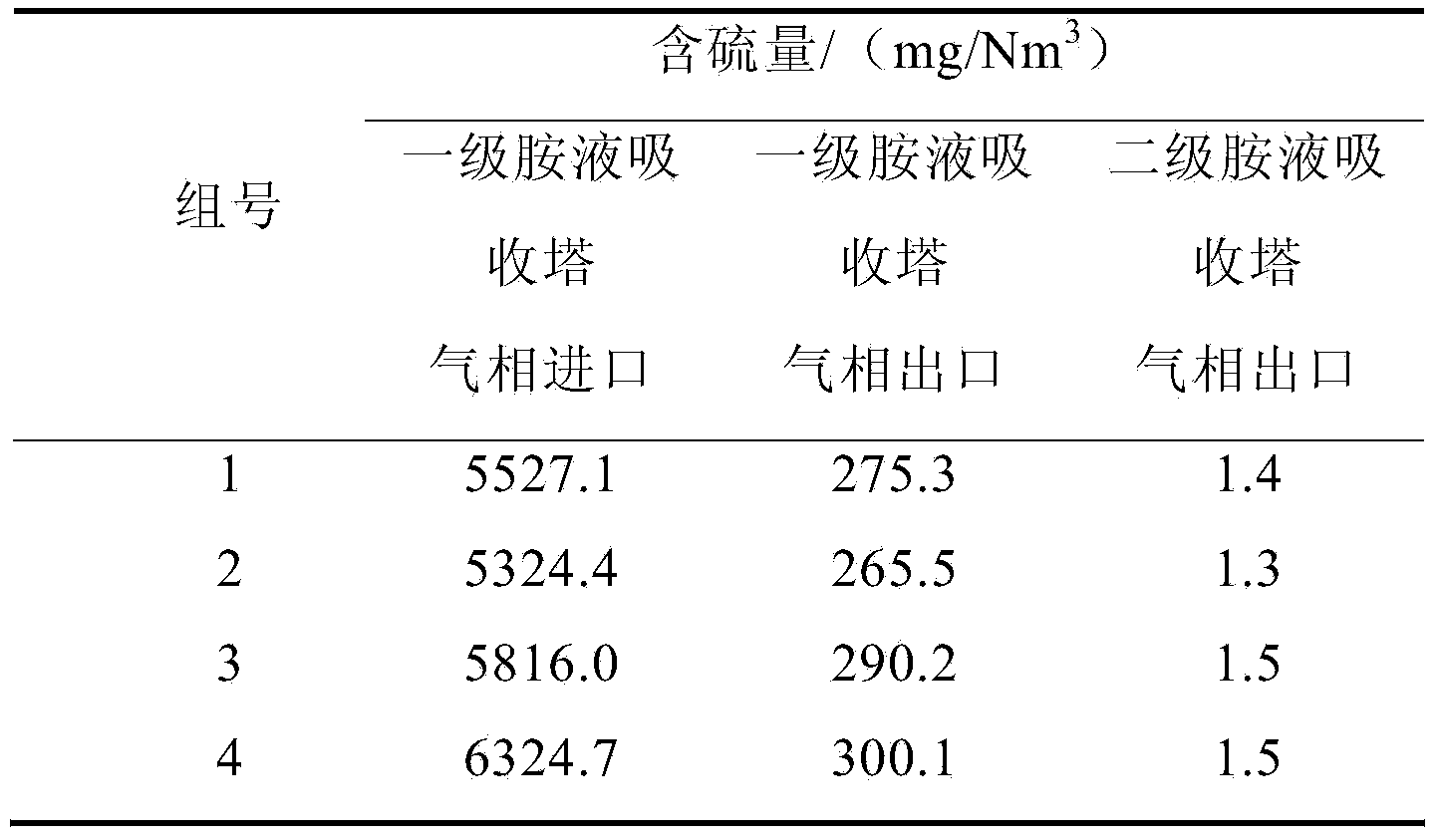

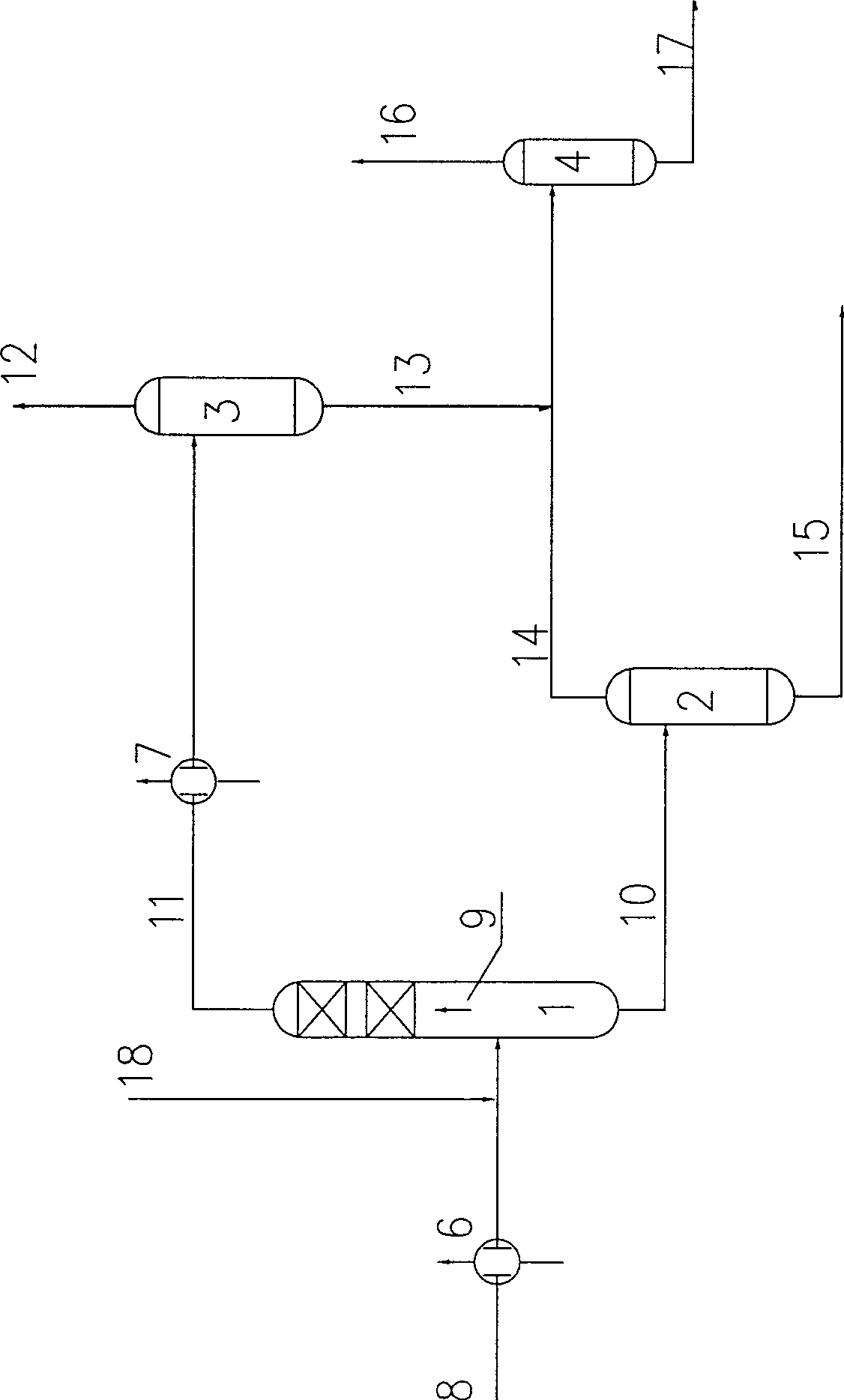

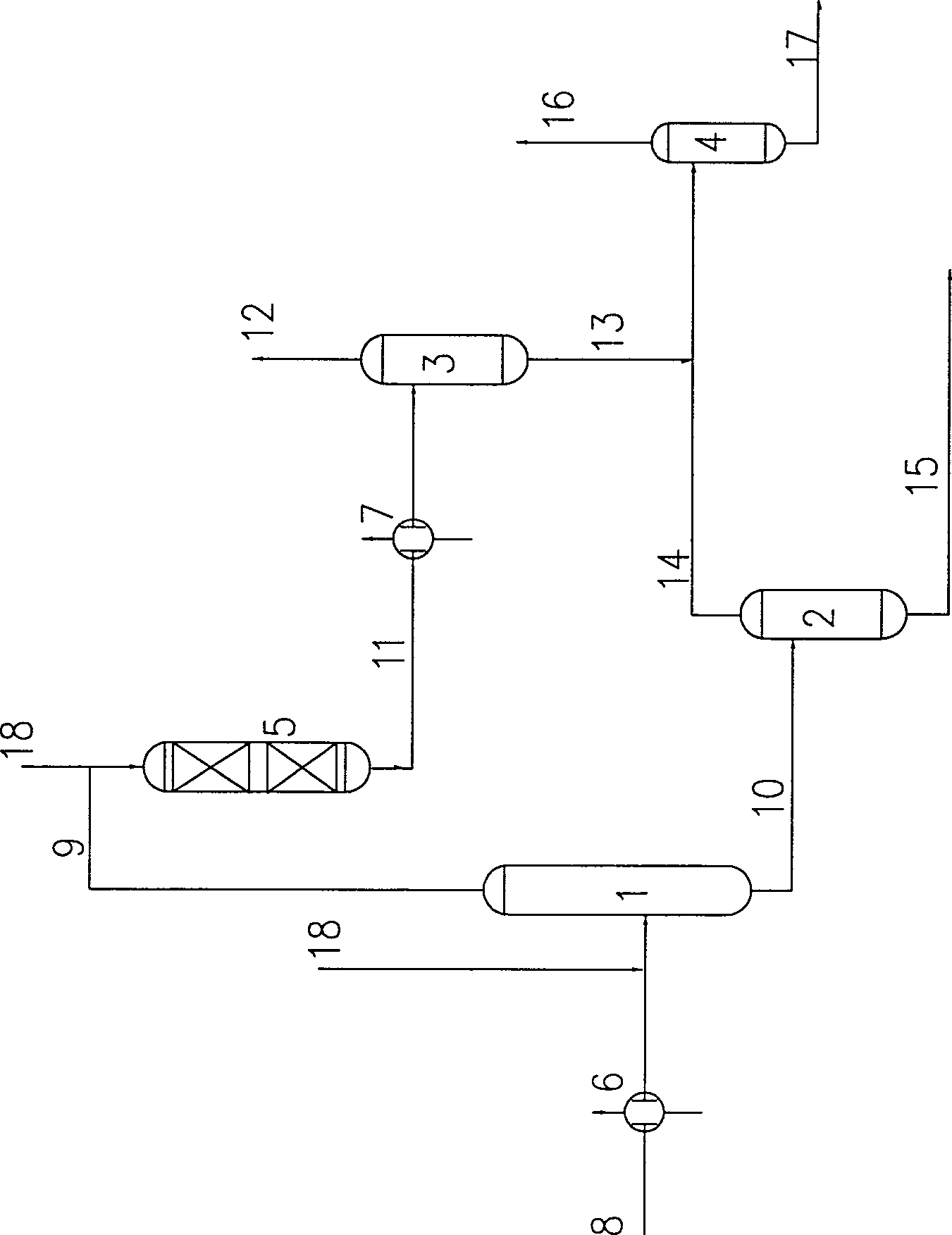

Method and device for removing hydrogen sulfide in shale gas with high sulfur content

InactiveCN103525491ARealize the use of rich and poor gradesReduce usageGaseous fuelsTreatment with plural serial refining stagesShale gasChemistry

The invention relates to a method and device for removing hydrogen sulfide in shale gas with high sulfur content, and particularly relates to a method for removing hydrogen sulfide in shale gas with high sulfur content. The method comprises the following steps of (1) filtering and separating the shale gas with high sulfur content to remove contained solid particles and liquid drops in the shale gas; (2) sequentially carrying out primary amine desulfuration and secondary amine desulfuration on the filtered shale gas with high sulfur content, wherein the desulfuration process intensification and amine solution removal coupling operation is realized by using a rotational flow field provided by a micro rotational flow in an amine desulfuration process, and a desulfurized shale gas product which does not contain amine liquid drops is obtained; (3) carrying out flash distillation on an amine rich solution to remove light hydrocarbon, and then, regenerating an amine solution to ensure that the amine solution can be recycled, wherein the amine solution is obtained in the amine desulfuration process. The invention also provides a device for removing hydrogen sulfide in shale gas with high sulfur content.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

Method for making clean fuels

ActiveCN100503788CHigh saturationTo achieve the purpose of deep desulfurizationTreatment with hydrotreatment processesHydrogenProcess engineering

The invention provides a method for producing clean fuels, utilizing the relatively high temperature and pressure of the hot high-pressure separator in the existing hydrocracking process, and having the characteristics of a hydrogen-facing environment at the same time, through the upper part of the hot high-pressure separator Fill the refined catalyst bed or install a hydrofinishing reactor between the hot high-pressure separator and the cold high-pressure separator to refine the product of the hydrocracking unit and other refined hydrocarbon oils from outside the unit, with a set of hydrogenation The cracking unit can realize the effect of producing light and clean fuel products at the same time.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Catalyst for selective oxidation desulfurization of fuel oil as well as preparation method and application of catalyst

ActiveCN104475155AMolecular polarityReduce interactionOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsHeteropoly acidFuel oil

The invention provides a catalyst for selective oxidation desulfurization of fuel oil as well as a preparation method and an application of the catalyst. The catalyst for selective oxidation desulfurization of fuel oil comprises the following raw materials: 80wt%-95wt% of polybenzimidazole and 5wt%-20wt% of heteropoly acid, wherein the total amount of the raw materials of the catalyst for selective oxidation desulfurization of fuel oil is 100wt%. The invention also provides a preparation method of the catalyst for selective oxidation desulfurization of fuel oil. The catalyst for selective oxidation desulfurization of fuel oil prepared by the method, has the advantages of high catalytic desulfurization efficiency when the catalyst is used for catalyzing the selective oxidation desulfurization of fuel oil and can also be recycled.

Owner:PETROCHINA CO LTD

Catalyst for deep desulfuration and octane number increase for gasoline and preparation and application methods thereof

ActiveCN102343276BTo achieve the purpose of deep desulfurizationHigh aromatic contentMolecular sieve catalystsHydrocarbon oils treatmentAlkanePtru catalyst

The invention discloses a catalyst for deep desulfuration and octane number increase for gasoline and preparation and application methods thereof. The functional catalyst comprises NiM / ZnO-ZSM-5. The preparation method comprises the steps of: firstly, synthesizing nanometer zinc oxide with high specific surface by using a low-temperature solid-phase method, then respectively steeping nickel and auxiliary metal, in the form of ions, onto the surface of the zinc oxide by using a steeping method, drying, roasting, and reducing in hydrogen to obtain a nanometer composite of the nickel, the auxiliary metal and the zinc oxide, wherein the nickel and the auxiliary metal are bonded in an alloy manner and uniformly disperse on crystalline phases of the zinc oxide. The catalyst has the reaction conditions that the reaction temperature is 350-450 DEG C, the pressure is 0.5-1.6MPa, the hydrogen-oil volume ratio is 100-300 and the air speed is 2<-10>h<-1>. By using the catalyst disclosed by the invention to treat straight-run gasoline, the deep desulfuration and the aromatization of alkane and olefin are performed at the same time, so that the octane number of a product gasoline is obviously increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Oxidation sweetening process for diesel distillate

InactiveCN1226390CPromote oxidationTo achieve the purpose of deep desulfurizationRefining with oxygen compoundsAcetic anhydrideDistillation

A process for diesel oil distillation oxidation sweetening comprises, adding in 0.1-20% diesel oil distillation volume of hydrogen dioxide and 0.1-20% acetic anhydride, reacting at the temperature of 30-90 deg. C, wherein the sulfide is oxygenized into sulfone or sulfoxide compounds, rinsing to remove acidic material, and removing sulfone or sulfoxide compounds from the diesel oil through adsorptive separation method. The catalyst has good regeneration effect and thus can be reutilized.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for improving the denitrification rate of shale oil hydrotreating

ActiveCN105838418BImprove utilization efficiencyImprove the level of comprehensive utilizationTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaFractionation

The invention provides a method for improving the shale oil hydrorefining denitrification rate, and relates to a whole fraction shale oil hydro-denitrification process. The method aims at solving the technical problems that in the existing method for producing diesel oil through shale oil hydrorefining, the stability of a diesel oil product is low, and the operation running period of a hydrorefining catalyst is short. According to the method, a raw material pretreatment unit 1, a raw material pre-fractionation unit 2, a primary hydrorefining reaction unit 3, a secondary hydrorefining reaction unit 4 and a product fractionation unit 5 are used. When the method provided by the invention is used for processing shale oil, the light oil yield is high; the nitrogen content of the diesel oil product is low; the chromaticity and the stability conform to national V standard requirements; the goal of light oil product deep denitrification can be achieved; the service life of the hydrorefining catalyst is prolonged; the operation running period of the catalyst is improved. A main product of the method is hydrorefining diesel oil; byproducts are high-value LPG and hydrogenated naphtha; heavy shale oil and hydrogenation tail oil thrown out in the technical process can be further processed and used in a downstream device. The method provided by the invention belongs to the field of whole-fraction shale oil deep processing.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

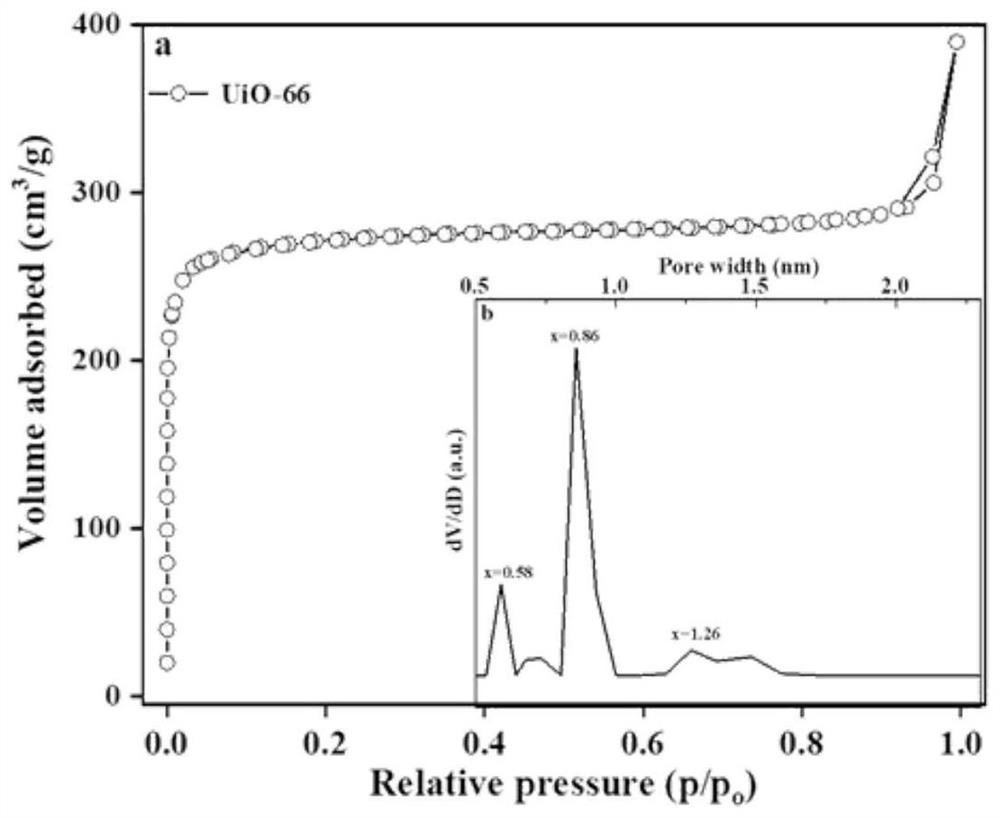

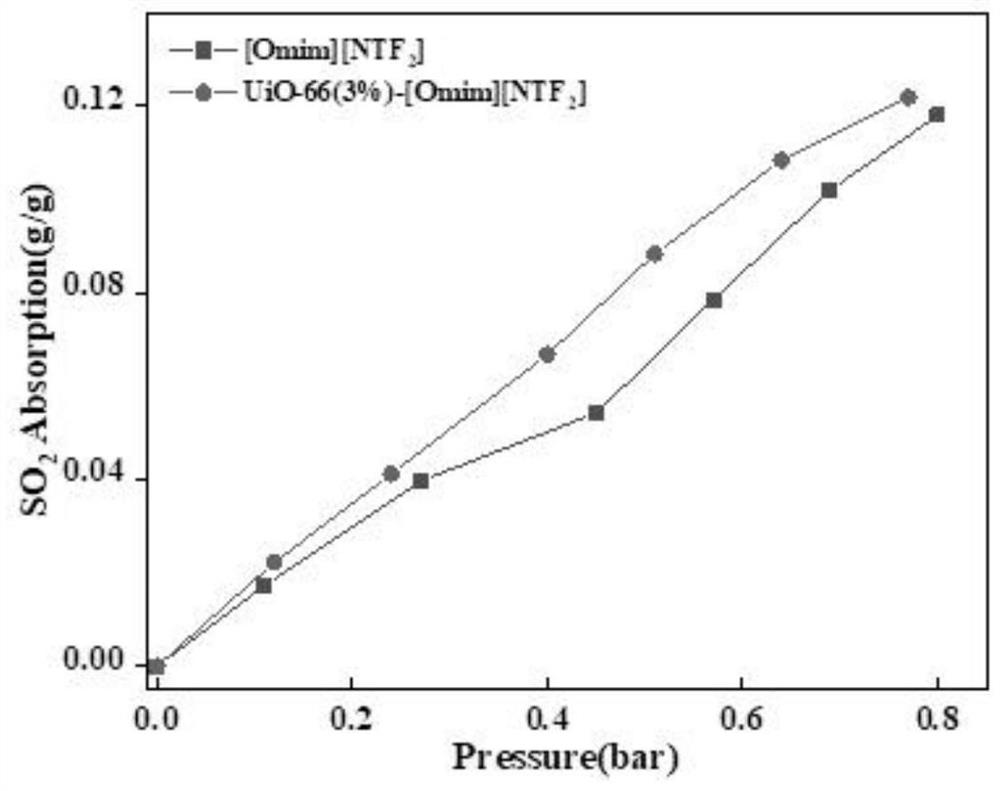

Third-class porous ionic liquid based on UiO-66 as well as preparation method and application of third-class porous ionic liquid

ActiveCN114539550AImprove mass transfer efficiencyHigh activityHydrocarbon oils refiningHydrocarbon oils treatmentMetal-organic frameworkSulfide

The invention relates to a UiO-66-based third-class porous ionic liquid, which is prepared from a metal organic framework (UiO-66) and an ionic liquid ([Omim] [NTF2]) as raw materials, the preparation process is simple and environment-friendly, and the porous ionic liquid has better oxidation removal effect and conversion effect on thiophene sulfides in oil products, especially dibenzothiophene (DBT), and has better oxidation removal effect and conversion effect on thiophene sulfides in oil products. In the oxidative desulfurization process of diesel oil, deep desulfurization can be realized after a very small amount of hydrogen peroxide (H2O2, 30%) is added.

Owner:JIANGSU UNIV

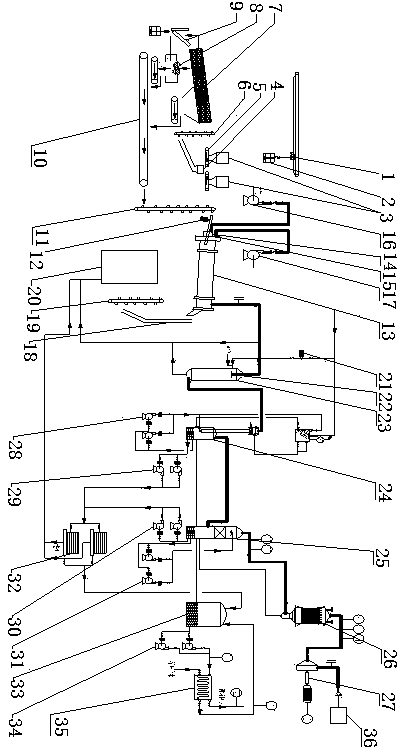

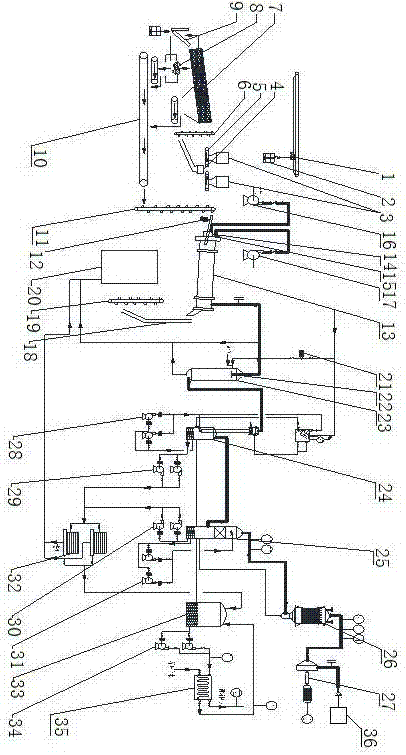

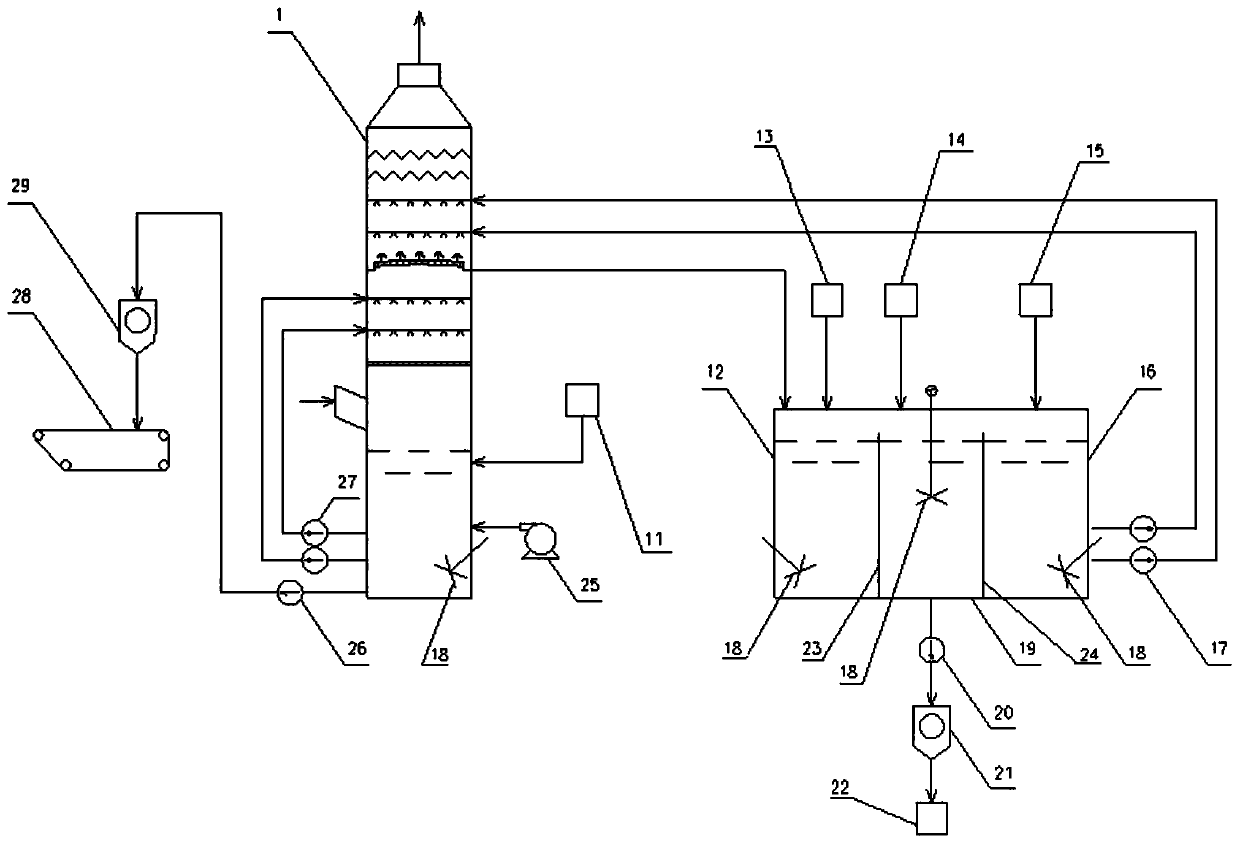

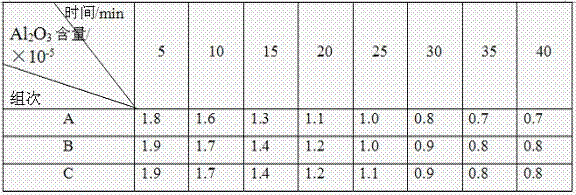

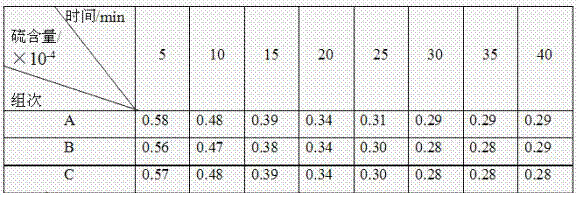

A smelting high-sulfur tailings treatment system

ActiveCN107447101BSmooth processComplete structureSulfur-trioxide/sulfuric-acidProcess efficiency improvementEngineeringProcess engineering

The invention belongs to the technical field of metallurgical and chemical processes, and particularly relates to a treatment system for smelting high-sulfur-content tailings. The treatment system for smelting the high-sulfur-content tailings comprises a raw material supply system, a pretreatment system, a reaction system, a smoke treatment system and a dry material bin. According to the treatment system for smelting high-sulfur-content tailings, the process is smooth, the structure is complete, and the requirement for large-scale continuous treatment of various types of high-sulfur-content tailings and mixtures of the high-sulfur-content tailings can be met; and the problems that a large quantity of solid tailings accumulate and valuable metal cannot be recovered easily are solved.

Owner:JINCHUAN GROUP LIMITED

Treatment system for smelting high-sulfur-content tailings

ActiveCN107447101ASmooth processComplete structureProcess efficiency improvementPre treatmentReaction system

The invention belongs to the technical field of metallurgical and chemical processes, and particularly relates to a treatment system for smelting high-sulfur-content tailings. The treatment system for smelting the high-sulfur-content tailings comprises a raw material supply system, a pretreatment system, a reaction system, a smoke treatment system and a dry material bin. According to the treatment system for smelting high-sulfur-content tailings, the process is smooth, the structure is complete, and the requirement for large-scale continuous treatment of various types of high-sulfur-content tailings and mixtures of the high-sulfur-content tailings can be met; and the problems that a large quantity of solid tailings accumulate and valuable metal cannot be recovered easily are solved.

Owner:JINCHUAN GROUP LIMITED

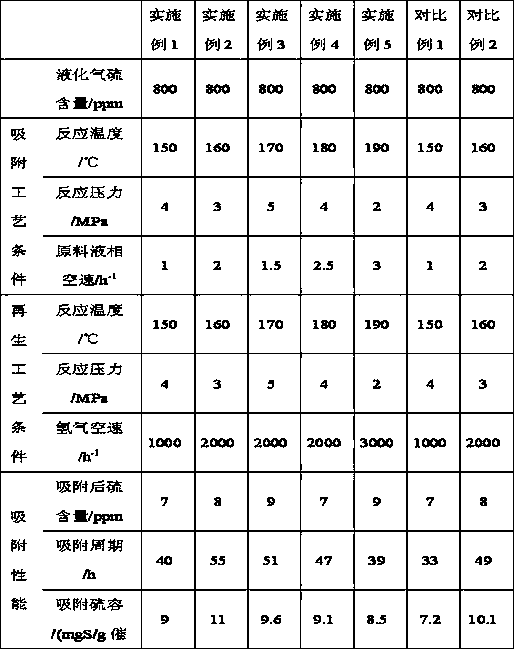

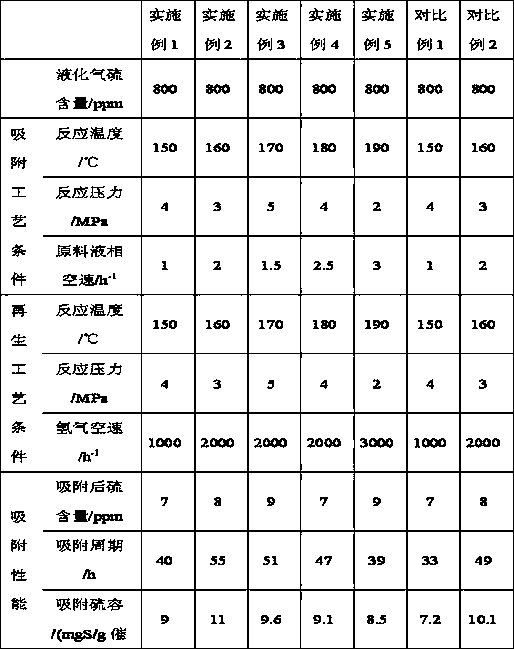

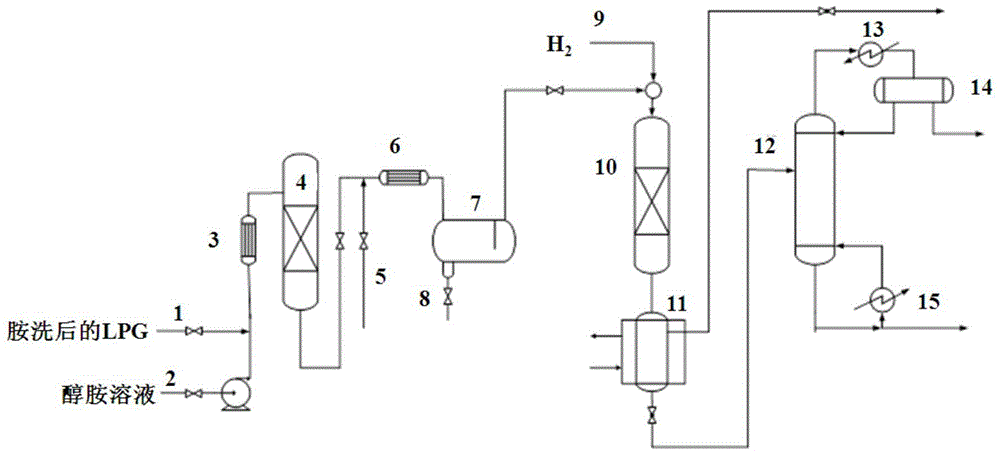

A Liquefied Petroleum Gas Adsorption Desulfurization Process

ActiveCN108070416BNo emissionsNo change in compositionGas treatmentDispersed particle separationOrganic sulfide compoundSorbent

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

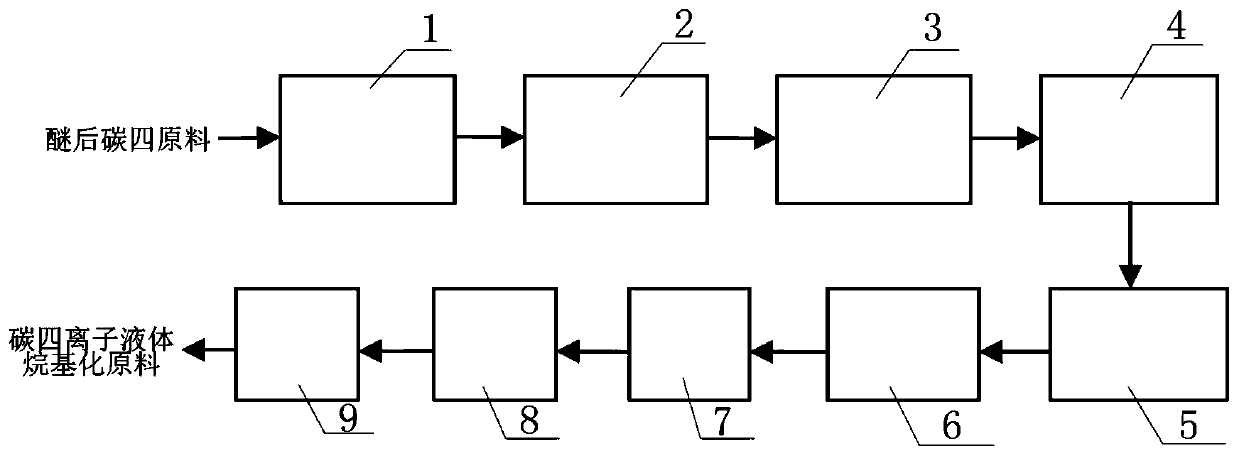

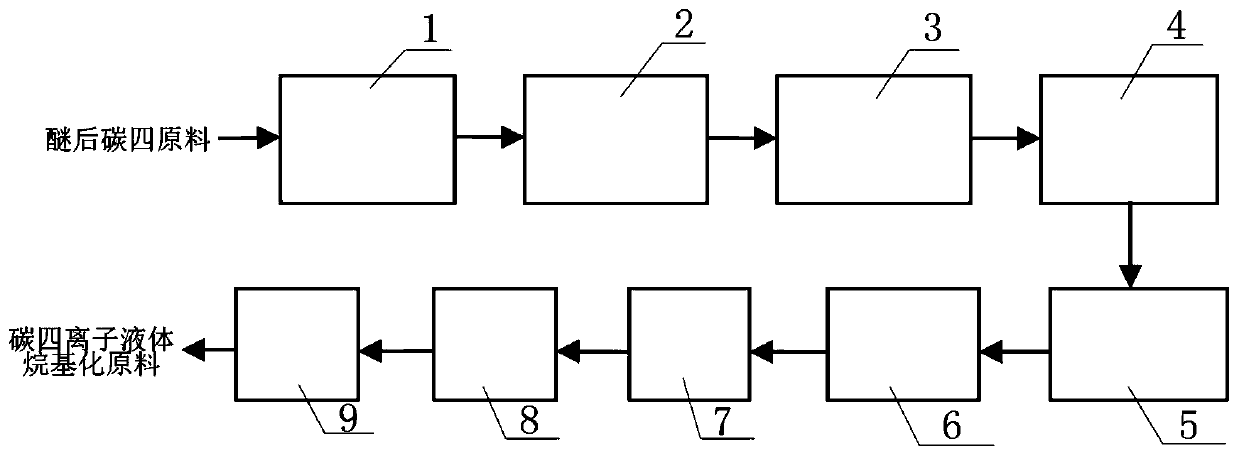

Method and device for refining C4 ionic liquid alkylation raw material by utilizing C4 after ether

ActiveCN108893141BHigh activityProtect the adsorbentTreatment with plural serial refining stagesFiberBisulfide

The invention provides a method and device for refining carbon-4 ionic liquid alkylation material by the aid of etherified carbon 4. The method includes: sequentially removing mercaptan from the carbon-4 raw material through a primary fiber liquid film contact reactor after impurities are filtered via a carbon-4 filter primarily and removing alkali and methanol through a secondary fiber liquid film contact reactor; removing light components including dimethyl ether through a light removal tower; further lowering the content of free water, carbonyl sulfide and H2S in the carbon-4 raw material components through an alkali solidifying tower; performing drying and dewatering through a molecular sieve drying tower; further removing methanol, dimethyl ether and MTBE (methyl tert-butyl ether) through a purification tower; performing dearsenification through a dearsenification tank to obtain the refined carbon-4 ionic liquid alkylation material. The method is unique in process design and low in energy consumption, the etherified carbon 4 of a refinery plant can be completely refined to obtain the highly refined carbon 4, and needs of the ionic liquid alkylation process are met.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

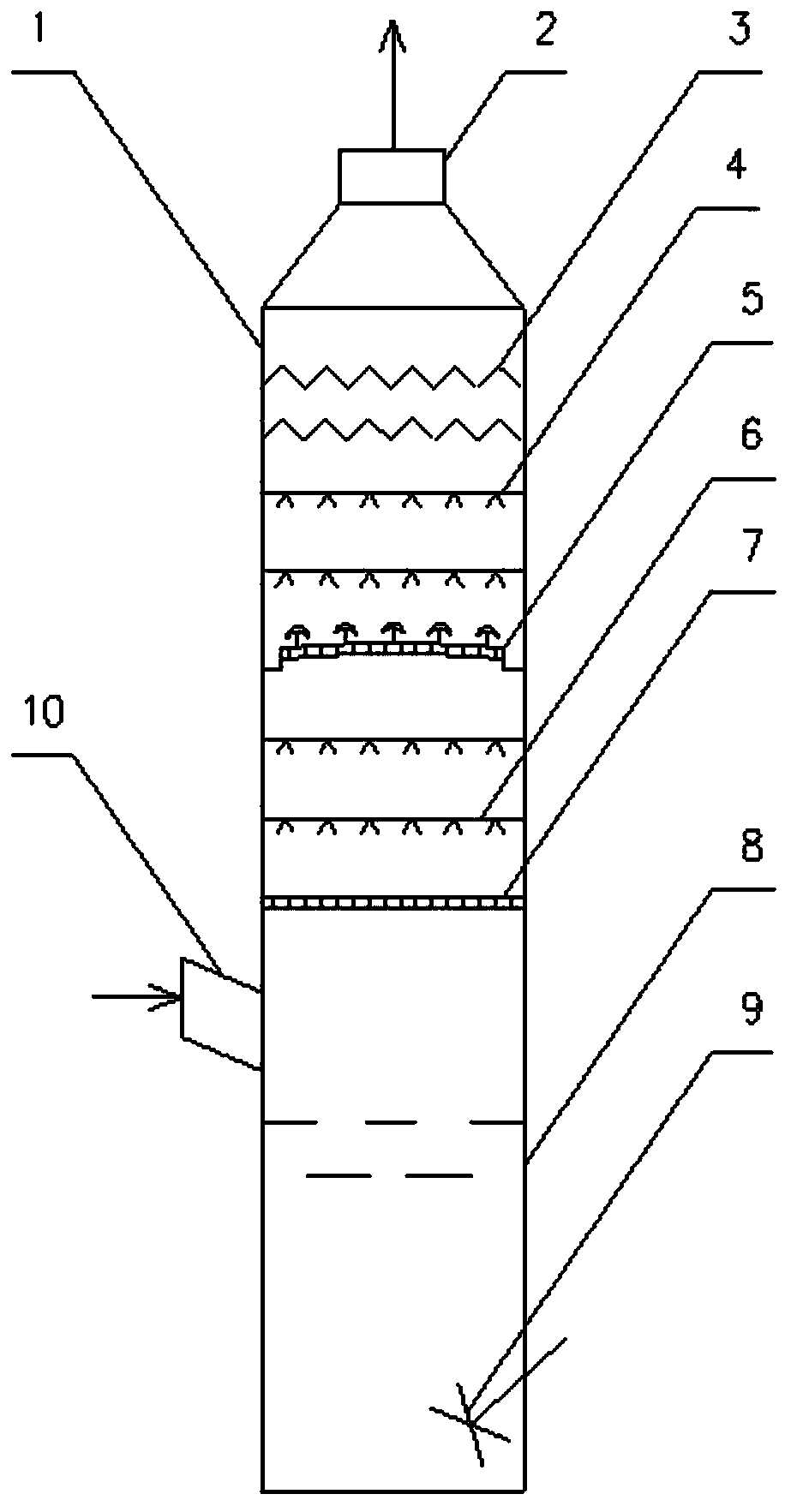

System for super clean removal of sulfur dioxide in coal-fired flue gas and process of system

InactiveCN109985498AImprove solubilityPromote oxidationDispersed particle separationAir quality improvementFlue gasEmission standard

The invention relates to the technical field of coal-fired flue gas desulfurization, and particularly provides a system for super clean removal of sulfur dioxide in coal-fired flue gas. The system comprises a desulfurization tower, a flue gas inlet is arranged in the middle lower part of the desulfurization tower, a flue gas outlet is arranged in the top end of the desulfurization tower, a main desulfurization zone, a deep desulfurization zone, and a high-efficiency demister are arranged between the flue gas inlet and the flue gas outlet from the bottom to the top, a low-pH slurry oxidation tank is arranged at the bottom end of the desulfurization tower, and a reaction tank system is arranged outside the desulfurization tower. The invention also provides a process of the system for the super clean removal of the sulfur dioxide in the coal-fired flue gas. The process comprises the following steps: the raw flue gas firstly passes through the main desulfurization zone to remove most of the sulfur dioxide in the flue gas, deep desulfurization is performed in the deep desulfurization zone, and finally after fine mist droplets carried by the flue gas are removed by the high-efficiency demister, the purified flue gas is discharged out from the desulfurization tower through the flue gas outlet. The system and process provided by the invention have a good deep desulfurization function and can strictly meet super clean emission standards of the coal-fired flue gas, and the whole desulfurization system is safe to operate and convenient to maintain.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

High-efficiency composite slag lotion

InactiveCN104073598BImprove liquidityLow viscosityProcess efficiency improvementSlagEconomic benefits

The invention discloses efficient composite slag lotion which comprises the following raw materials in percentage by weight: 49-70% of calcium powder, 20-45% of aluminum ash, 5-12% of high-alumina cement and 0.5-2.0% of sodium carboxymethylcellulose. The calcium powder, the aluminum ash and the high-alumina cement are applied to synergic desulfuration, and are used for mutually filling and refining the porous structure of the slag lotion, and the obtained efficient composite slag lotion is good in deoxidation and desulfuration effect and impurity absorption effect and rapid in slagging speed, and has a remarkable function in improving the comprehensive economic benefits of steel plate companies.

Owner:河南鹏钰集团有限公司

Adsorptive desulfurization technology for liquefied petroleum gas

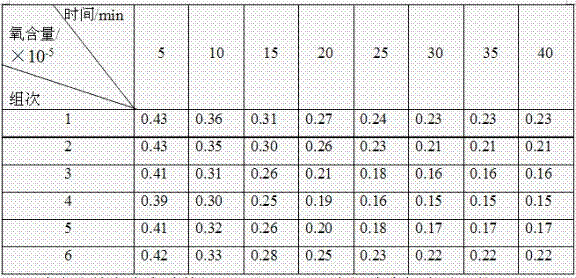

ActiveCN108070416AIncreased sulfur adsorption capacityReduce consumptionGas treatmentGaseous fuelsOrganic sulfide compoundHydrogen

The invention discloses an adsorptive desulfurization technology for liquefied petroleum gas. At least two fixed bed reactors are adopted. The method comprises the steps as follows: the liquefied petroleum gas is firstly sent into the fixed bed reactors filled with adsorbents for adsorptive desulfurization reaction; when the adsorbent reaches an adsorption saturation state, the liquefied petroleumgas is transferred to another fixed bed reactor filled with the adsorbent for adsorptive desulfurization reaction continuously, and hydrogen is introduced into the fixed bed reactor filled with the adsorbent reaching adsorption saturation for regeneration. The adsorptive desulfurization technology has the advantages that no alkali residues are discharged, desulfurization precision is high and thelike, and organic sulfide can be removed from the liquefied petroleum gas.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

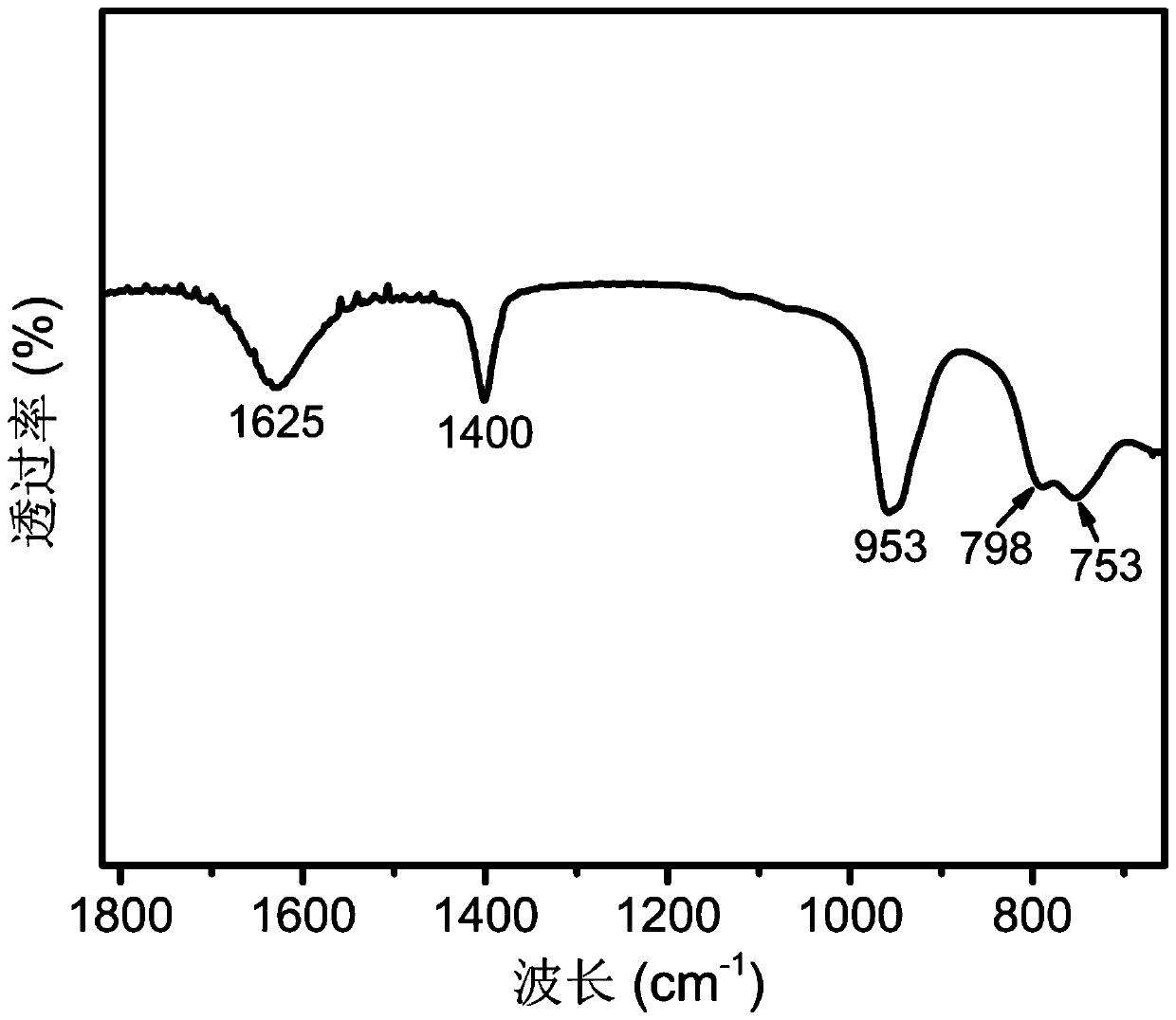

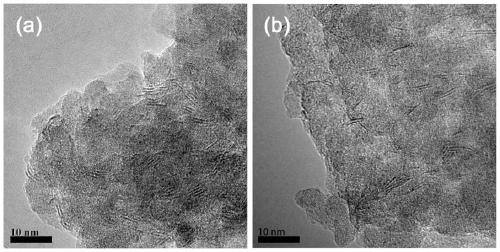

A deep desulfurization catalyst and its preparation method and application

ActiveCN109289876BTightly boundIncrease the level of retouchingCatalyst activation/preparationHydrocarbon oils treatmentHydration reactionCobalt acetate

The invention provides a deep desulfurization catalyst and its preparation method and application. The preparation method of the deep desulfurization catalyst is as follows: weigh ammonium heptamolybdate tetrahydrate and cobalt acetate tetrahydrate, dissolve them in a mixed solution of glacial acetic acid and water, stir and dissolve, then add hydrazine sulfate, stir and dissolve, and stir and react in a constant temperature water bath. After the reaction is completed, the cobalt-molybdenum heteropoly compound is obtained; the cobalt-molybdenum heteropoly compound is dispersed in water and subjected to ultrasonic treatment, then aluminum oxide is added, stirred evenly, and hydrothermally dispersed and loaded in an autoclave, and the desulfurization catalyst is obtained after the reaction is completed. The desulfurization catalyst prepared by the invention has good dispersion performance and high activity, can achieve the purpose of deep desulfurization, and has a desulfurization rate as high as 94.1%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

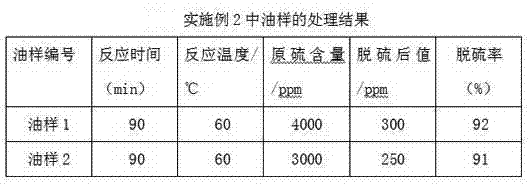

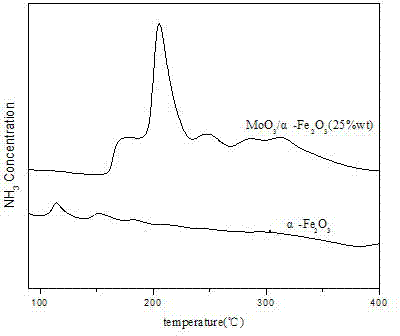

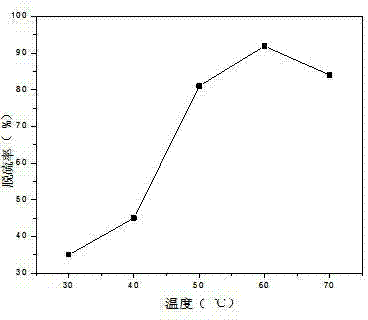

A method for oxidative desulfurization of diesel oil with a metal oxide modified nano-iron oxide catalyst

InactiveCN103436287BHigh activityEfficient removalTreatment with plural serial refining stagesMetal/metal-oxides/metal-hydroxide catalystsOrganic sulfide compoundPtru catalyst

The invention discloses a method for oxidative desulfurization of diesel oil with a metal oxide-modified nano-iron oxide catalyst, which comprises the following steps: 1) dissolving soluble metal salt in distilled water, immersing nano-α-Fe2O3 in the solution, and ultrasonically Disperse, dry, and roast in a muffle furnace; 2) Use hydrogen peroxide-acidic reagent as the oxidation system, add hydrogen peroxide-acid oxidant and catalyst, and convert organic sulfides into sulfones and sulfoxides; 3) Separate the catalyst and Diesel oil; 4) The sulfur products in the diesel oil are mixed with the extractant, left to stand for phase separation to obtain the upper phase oil phase and the lower phase extraction phase, and the sulfur content in the diesel oil is determined with a microcoulombometer. The invention adopts a diesel oxidation desulfurization catalyst with higher selective oxidation, strong acid center and high activity to carry out oxidation desulfurization, effectively removes various sulfur compounds in diesel oil, and can achieve the purpose of deep desulfurization.

Owner:南通宝聚颜料有限公司

Catalytic oxidation electrolytic desulfurization method for light oil

InactiveCN109294619AEmission complianceStandard recyclingTreatment with plural serial refining stagesCatalytic oxidationOil phase

The invention provides a catalytic oxidation electrolytic desulfurization method for light oil. The method is mainly characterized in that: an electrolytic system composed of a solvent, an oxidant, acatalyst, an electrolyte and water is mixed in an electrolytic tank for electrolysis, a carbon graphite plate serves as the positive electrode, a stainless steel plate serves as the negative electrode, settling separation of an oil phase and the mixed system is carried out, and an electrolytic oxidation product of a sulfur compound in the oil is subjected to electrolytic system removal. The methodhas the advantages that: water supplies the oxygen source for reaction, no external supply of hydrogen and oxygen is not needed, the operation is mild, the process is carried out under low temperature and atmospheric pressure, the solvent supports the recycling of the electrolyte in the electrolysis process, and at the same time zero emission is achieved. The by-product is hydrogen, is free of polluting gas, can achieve up-to-standard discharge, or the hydrogen can be recovered, thus reaching the purpose of deep desulfurization.

Owner:辽宁金品石油化工有限公司

Catalyst for selective oxidation desulfurization of fuel oil, preparation method and application thereof

ActiveCN104475155BMolecular polarityReduce interactionOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsHeteropoly acidFuel oil

Owner:PETROCHINA CO LTD

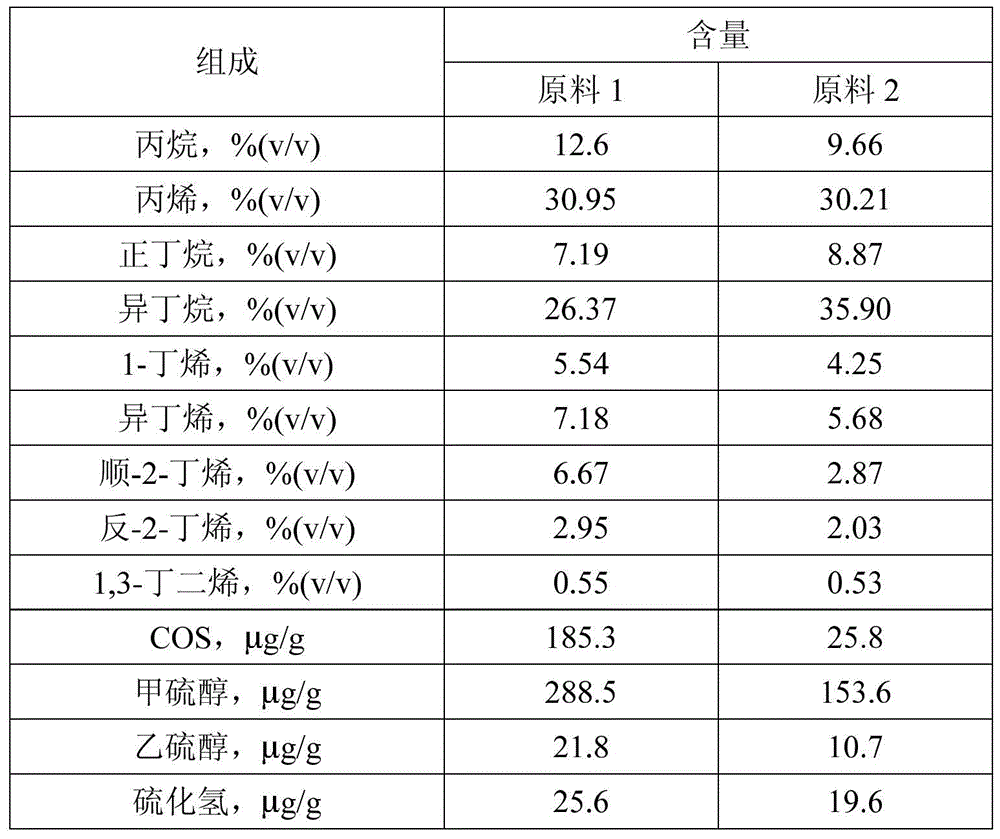

A kind of refining method of liquefied petroleum gas

The invention provides a method for refining liquefied petroleum gas. The method comprises the following steps: mixing amine-washed liquefied petroleum gas and an alcohol amine solution, and removing carbonyl sulfide and hydrogen sulfide from the liquefied petroleum gas under the coaction of a carbonyl sulfide hydrolysis catalyst and the alcohol amine solution; performing sulfur etherification reaction in contact with a sulfur etherification catalyst to ensure that mercaptan in the liquefied petroleum gas is reacted with olefin and converted into a thioether compound with a high boiling point, and simultaneously performing selective hydrogenation saturation on diolefin; performing distillation treatment, and separating the liquefied petroleum gas fraction from the thioether compound with the high boiling point to obtain a deep desulfurized liquefied petroleum gas product, wherein the refined liquefied gas can be used for producing low-sulfur methyl tertiary butyl ether and alkylation gasoline. According to the method disclosed by the invention, the carbonyl sulfide and the hydrogen sulfide are removed by adopting a one-step method, and the mercaptan is removed by using the catalytic reaction between the raw material components, so that no alkali residue is discharged, the existing process for refining the liquefied petroleum gas is simplified, meanwhile, the purpose of deep desulfurization is achieved, and the sulfur content of the refined liquefied petroleum gas is reduced to below 5mu g / g.

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

Deep desulfurization adsorbent of fuel at normal pressure and normal temperature and preparation method thereof

ActiveCN102895937BPromote regenerationHigh mechanical strengthOther chemical processesHydrocarbon oils refiningEnvironmental resistanceKerosene

The invention relates to a fuel deep desulfurization adsorbent at normal temperature and pressure and a preparation method thereof, and belongs to the fields of environmentally friendly adsorbent materials and energy and chemical materials. It is characterized by using aluminum-silicon composite oxide as the adsorbent carrier and rare earth cerium modified nickel bimetal as the adsorbent active component. Based on the mass of the carrier, the mass percentage of the active component Ni-Ce is 1 to 30%, and the element molar ratio of Ni / Ce is 2 to 19. The adsorbent is obtained by mixing saturated nickel-cerium composite solution, strongly acidic aluminum sol colloid, pseudo-boehmite, diatomite or silica sol together, aging, extruding, drying and calcining in a reducing atmosphere. The adsorbent Lewis prepared by the invention has strong acidity, high adsorption and removal efficiency of thiophene sulfur, excellent regeneration performance, high mechanical strength, good thermal stability, low cost, no secondary pollution, and simple preparation process. The adsorbent of the present invention is preferably suitable for adsorbing and removing thiophene sulfur, and is also suitable for desulfurizing JP fuel, gasoline, diesel and kerosene.

Owner:NANJING TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com