Method and device for removing hydrogen sulfide in shale gas with high sulfur content

A shale gas, high sulfur content technology, applied in gas fuel, petroleum industry, only multi-stage serial refining process treatment, etc., can solve the new requirements that cannot meet the operation flexibility and desulfurization accuracy, no patent literature involved, page Issues not involved in the application of rock gas treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

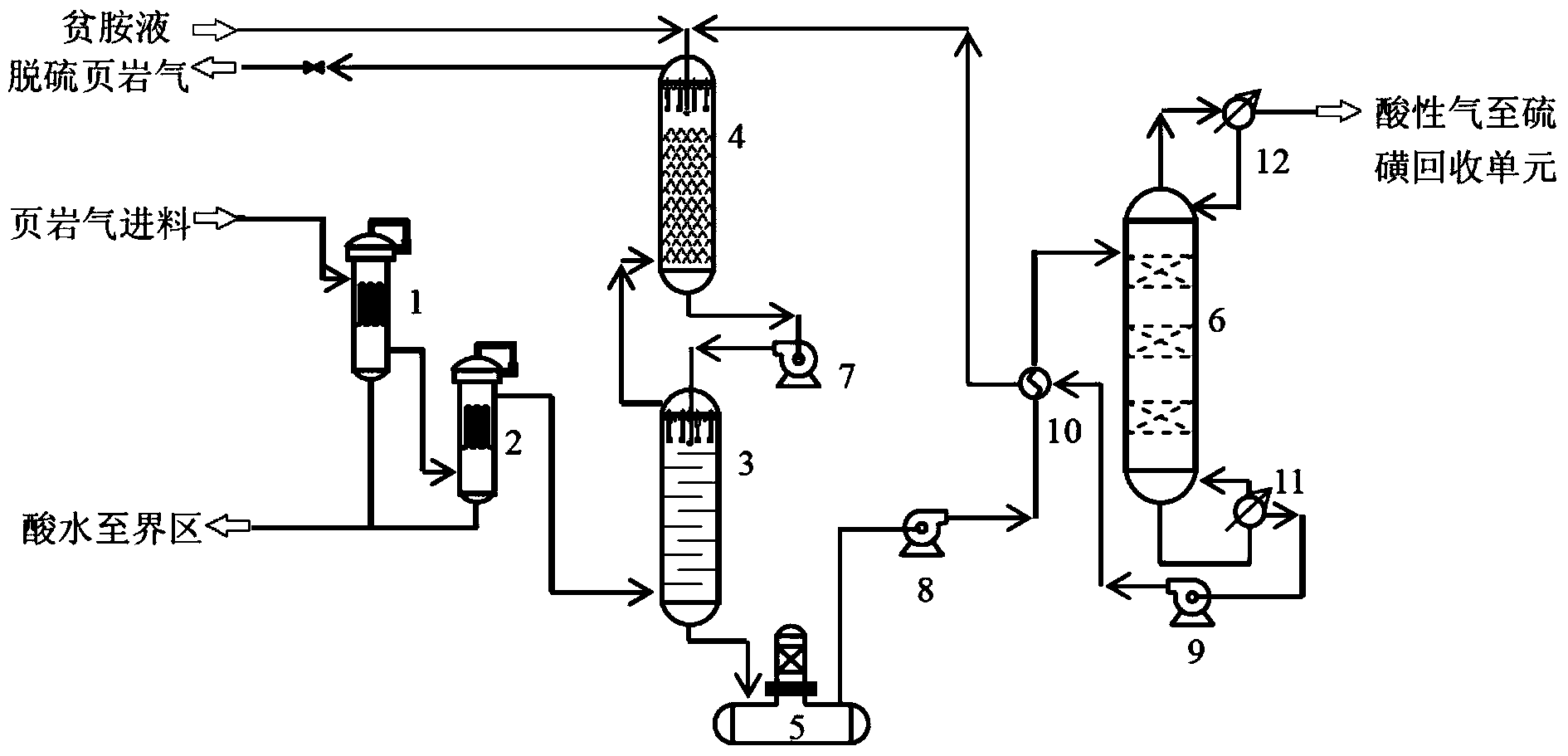

Method used

Image

Examples

Embodiment 1

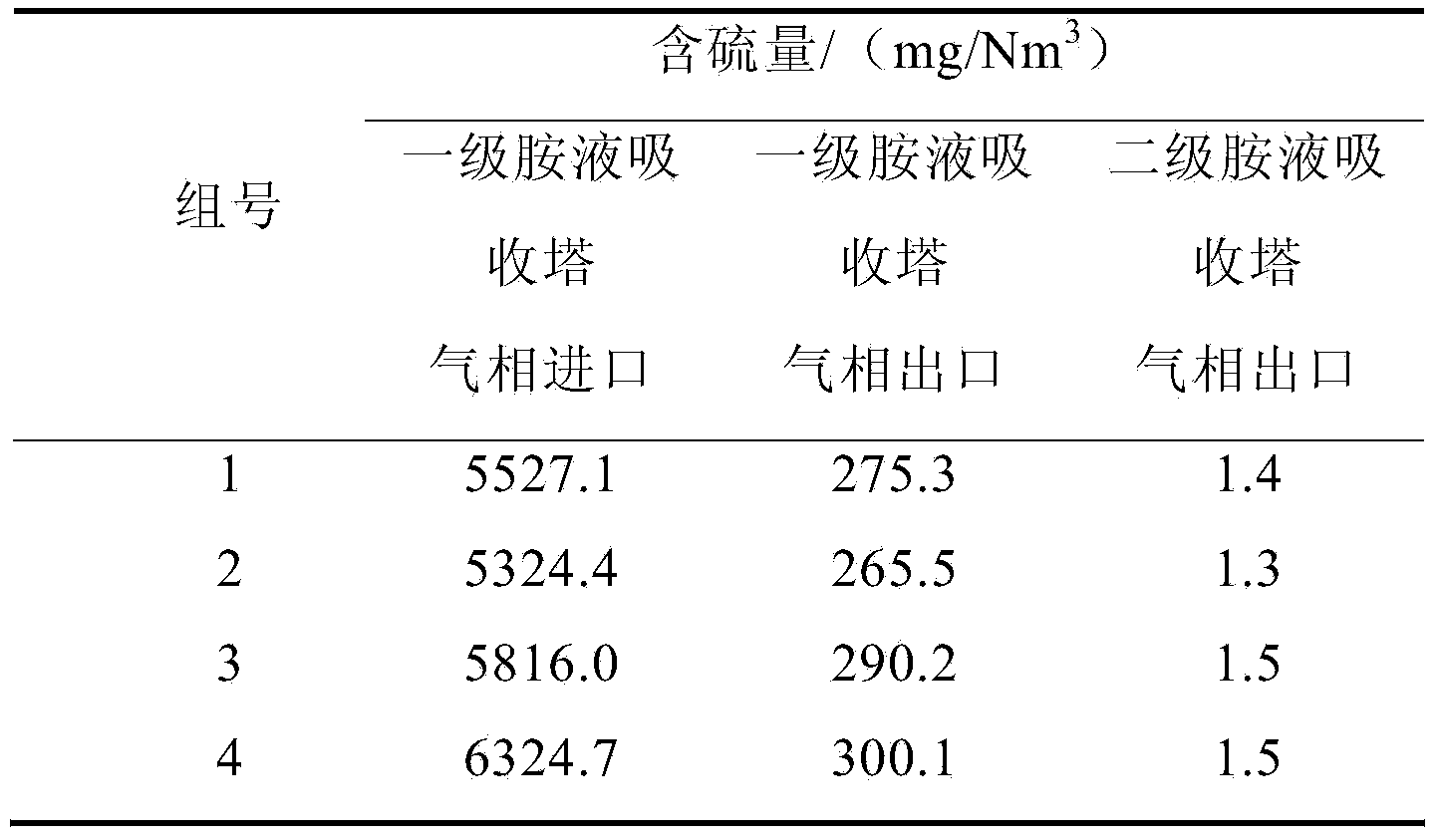

[0058] in a 50,000m 3 In the production and treatment process of high sulfur-containing shale gas per h, the device implemented according to the method of the present invention is used to absorb and separate the acidic shale gas containing hydrogen sulfide, so that the shale gas meets the requirements of product specifications. The operation process and effect are described as follows:

[0059] 1. The nature and operating conditions of the gas to be treated

[0060] The gas to be treated is high-sulfur shale gas, the main component is alkanes, of which methane accounts for the vast majority, and a small amount of ethane, propane and butane, and generally contains hydrogen sulfide, carbon dioxide, nitrogen and water vapor, and Trace amounts of inert gases, such as helium and argon, have a specific sulfur content of about 1%. Natural gas processing capacity is 50,000 m 3 / h, the operating temperature of the gas phase density is 50°C. The absorbent is N-methylglycolamine solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com