Method and device for refining C4 ionic liquid alkylation raw material by utilizing C4 after ether

A post-ether C4 and ionic liquid technology is applied in the field of using post-ether C4 to refine C4 ionic liquid alkylation raw materials, which can solve the problems of periodic regeneration of catalysts, high energy consumption, low adsorption capacity, etc., so as to reduce the load , the effect of low energy consumption and strong refining ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to have a clearer understanding of the technical features, purposes and beneficial effects of the present invention, the technical solution of the present invention is described in detail below, but it should not be construed as limiting the scope of implementation of the present invention.

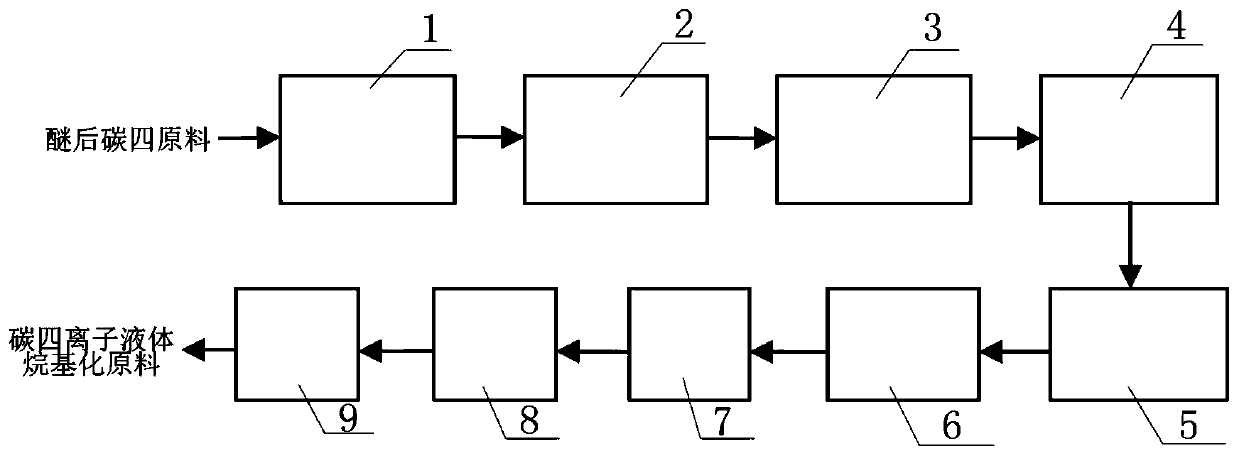

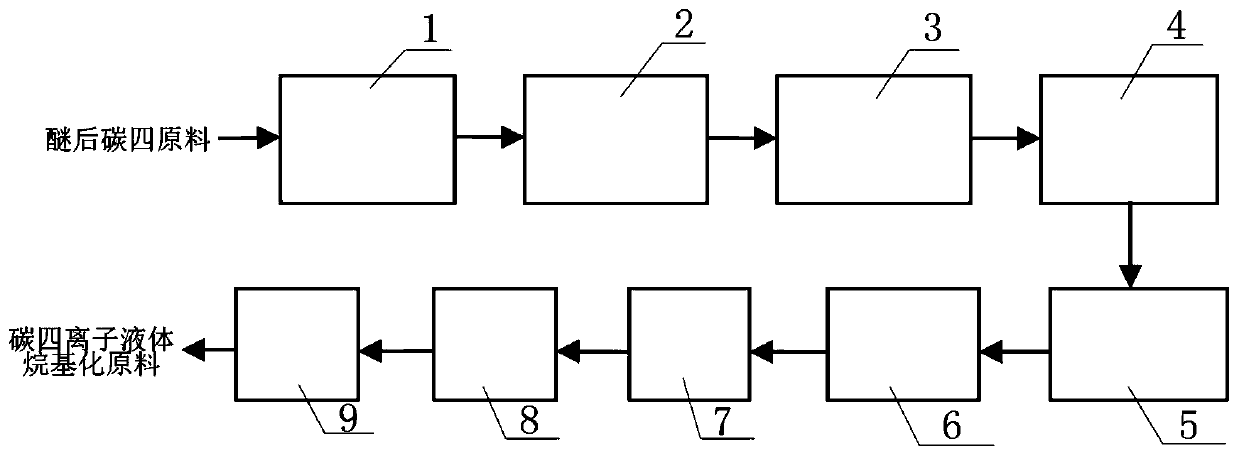

[0055] The liquefied petroleum gas produced by the catalytic cracking unit of the refinery reacts with methanol to produce a large amount of raffinate C4, which contains n-butane, isobutane, n-butene and other components. Catalysts are used to produce alkylated oil. An oil refinery with a processing capacity of 10 million tons / year of crude oil can produce about 100,000 to 150,000 tons of post-ether C4 per year. Generally, the C4 composition after the ether obtained after the MTBE device raffinates is shown in Table 1 below:

[0056] Table 1:

[0057]

[0058]

[0059] Ionic Liquid Alkylation Reaction Et 3 NHCl-xAlCl 3 The system catalyst has very strict requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com