Treatment system for smelting high-sulfur-content tailings

A treatment system and flue gas treatment system technology, which is applied in the field of smelting high-sulfur tailings treatment system, can solve the problems of unsatisfactory recovery of organic metals, high sulfur content of materials, and large differences in sulfur taste, so as to achieve ideal desulfurization effect and combustion Sufficient reaction and stable sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

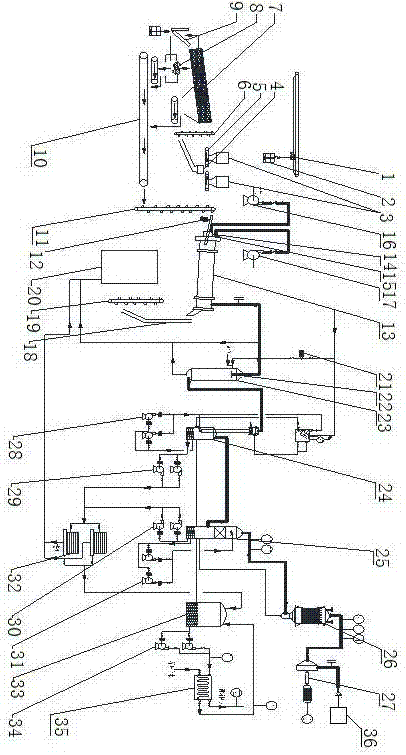

[0018] see figure 1 , a treatment system for smelting high-sulfur tailings, characterized in that it includes: a raw material supply system, a pretreatment system, a reaction system, a flue gas treatment system, and a dry stock bin;

[0019] The raw material supply system is composed of an electric hoist 1 and a hopper 2 controlled by the electric hoist 1; the pretreatment system is provided below the raw material supply system;

[0020] The pretreatment system includes a double-roll crusher 9 and a jaw crusher 8, a belt conveyor 10 is arranged below the double-roll crusher and the jaw crusher, the belt conveyor is connected to a bucket elevator, and the bucket elevator is connected to the Feed device connection in the reaction system;

[0021] The reaction system includes a rotary kiln 13, the kiln mouth of the rotary kiln 13 is provided with a feeding device, and the tail of the rotary kiln is connected to the quench tower pipeline in the flue gas treatment system;

[0022...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com