Vacuum introduction manufacture method of parts with vacuum reinforced rib structure

A technology of vacuum introduction and manufacturing method, which is applied in the field of vacuum introduction and manufacturing, and can solve problems such as increased manufacturing cost, process failure, and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

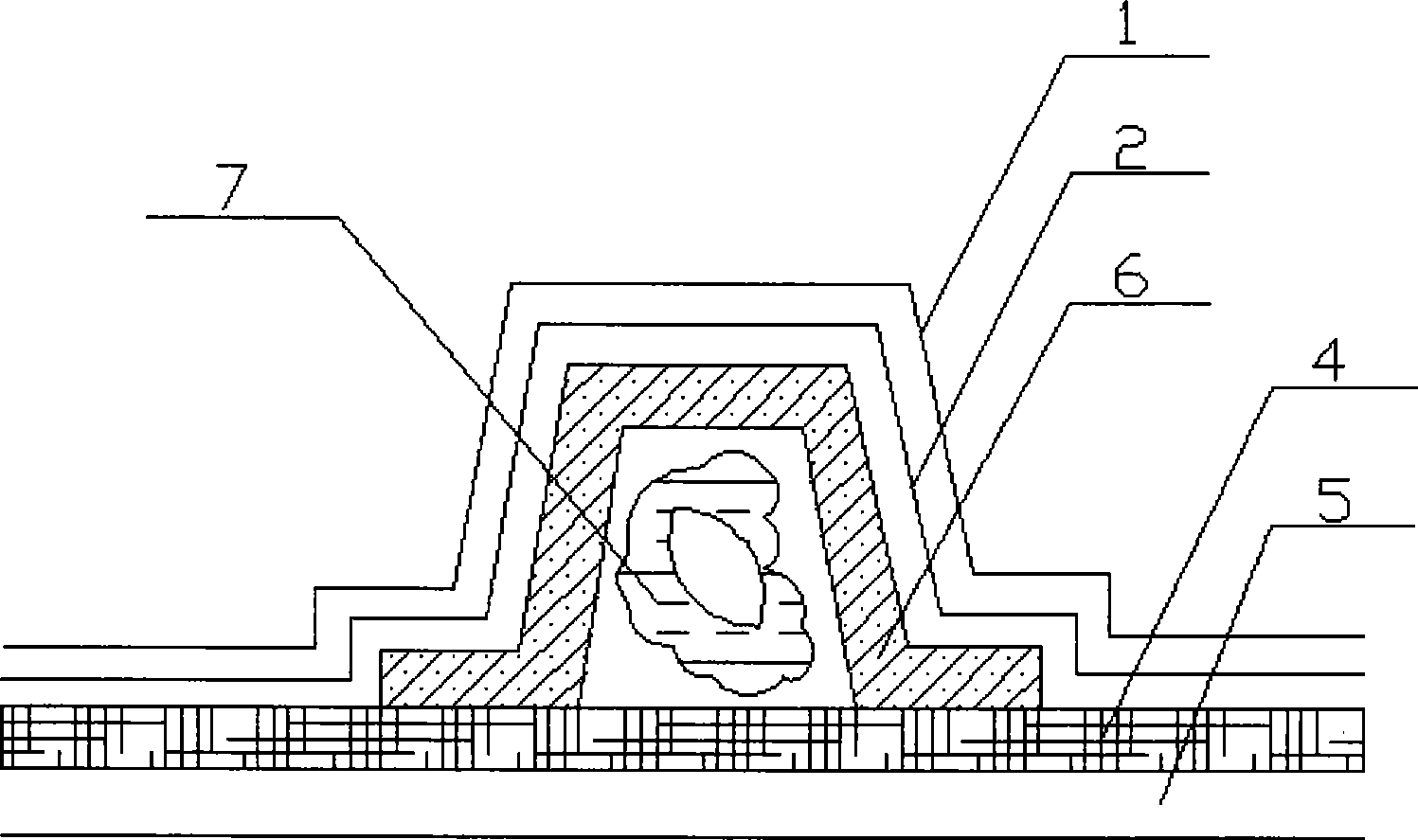

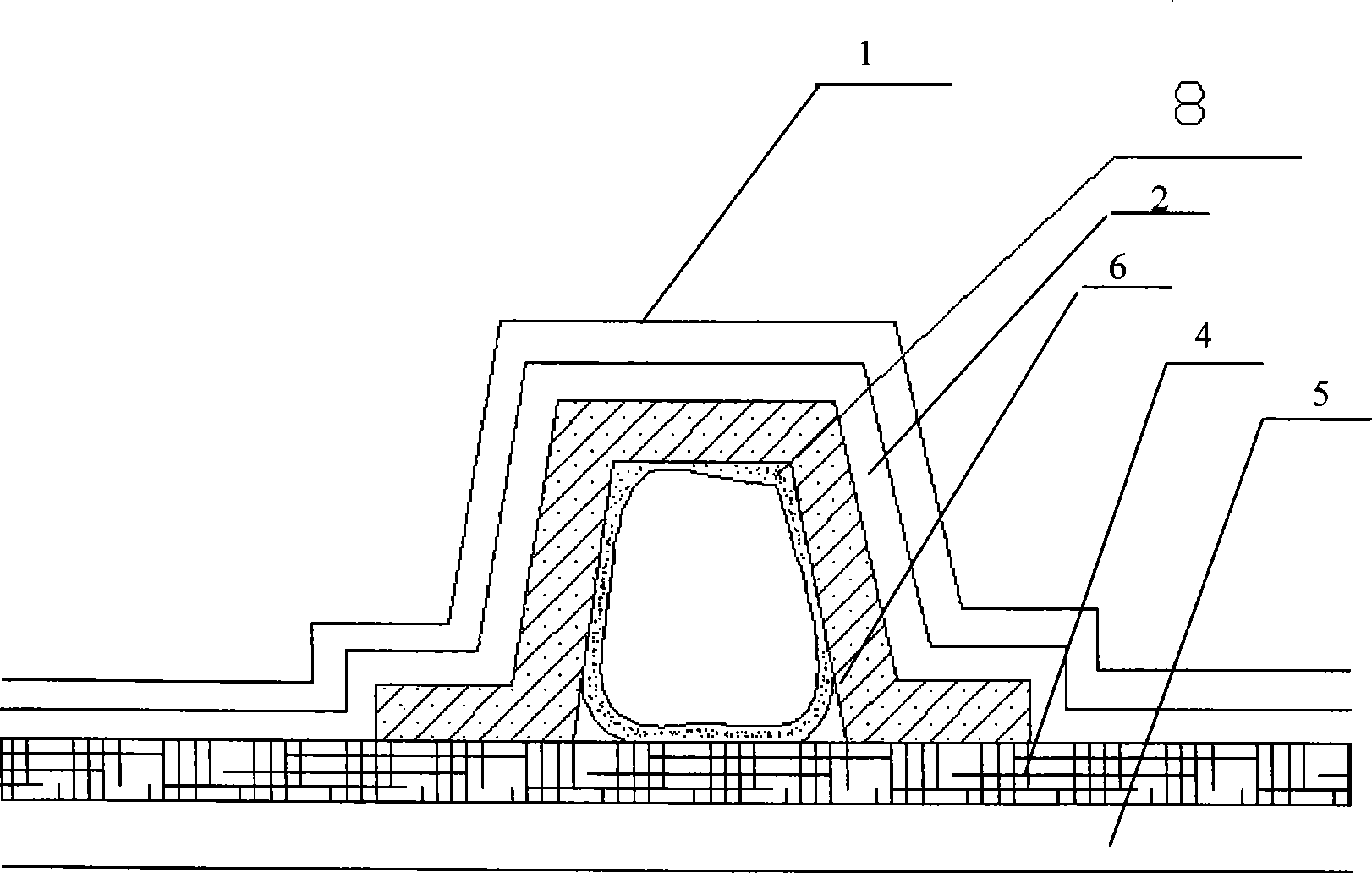

[0018] Such as figure 1 As shown, it is a schematic diagram of the structure when the method provided by the present invention is used. A vacuum introduction manufacturing method of a part with a vacuum rib structure provided by the present invention, the steps are:

[0019] Step 1, prepare the mold 5, clean the surface of the mold 5, and then spray a release agent at least once and dry it completely;

[0020] Step 2, laying the reinforcing material layer 4 on the mold 5 processed in step 1 according to the specified size and layer thickness;

[0021] Step 3, placing reinforcing ribs 6 on the reinforcing material layer 4, putting balloons 7 in the reinforcing ribs 6, and filling the balloons 7 with air;

[0022] Step 4, Lay release cloth and high flow guide medium 2 on the reinforcing ribs 6 and the reinforcing material layer 4, and lay the resin inlet and outlet as required;

[0023] Step 5. Cover with a vacuum bag 1 and seal the surrounding area. Finally, the resin enters ...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is that the balloon 7 is made of rubber. Other steps and processing conditions are identical with embodiment 1.

Embodiment 3

[0028] The difference between this embodiment and Embodiment 1 is that the balloon 7 is made of silicone plastic. Other steps and processing conditions are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com