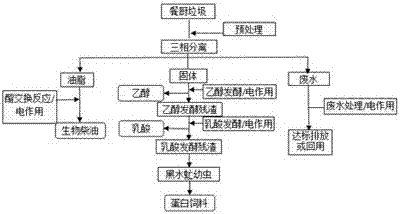

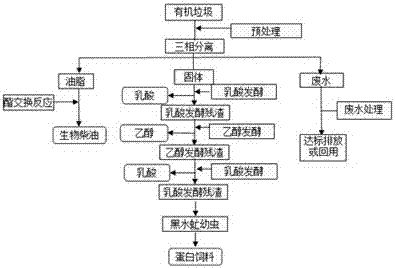

Kitchen waste high-value-application method

A kitchen waste, high-value technology, applied in chemical instruments and methods, applications, animal feed, etc., can solve the problems of air, water and soil environmental pollution, difficult to completely dispose of kitchen waste, and single treatment methods. The effect of high resource utilization, high yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A high-value utilization method of kitchen waste, said method comprising the following steps:

[0036] S1. Collect and remove impurities: collect food waste and remove debris such as plastic, metal and glass.

[0037] S2. Pretreatment: The food waste is subjected to three-step hydrothermal treatment, that is, treatment at 120°C for 100 minutes; then, the temperature is raised to 300°C for 3 minutes; finally, the temperature is lowered to 90°C for 30 minutes.

[0038] S3. Three-phase separation: The pretreated food waste is sprayed into the three-phase separator, and the upper layer of grease, middle water, and lower layer of solid food waste are subjected to three-phase separation.

[0039] S4. Preparation of biodiesel from oil: under the action of catalyst sodium methoxide, the separated oil is transesterified with ethanol to prepare biodiesel, and at the same time, a 1kV electric field is introduced into the system, 10s / time, and a total of 100min; The yield of diese...

Embodiment 2

[0044] A high-value utilization method of kitchen waste, said method comprising the following steps:

[0045] S1. Collection and removal of impurities: collect livestock carcasses, remove debris such as plastic, metal and glass, and then crush them.

[0046] S2. Pretreatment: Combined pretreatment of poultry and livestock carcasses with hydrothermal, ultrasonic and microwave, that is, after hydrothermal treatment at 200°C for 5 minutes, 1500w / L ultrasonic treatment for 5 minutes, followed by 100w microwave treatment for 120 minutes.

[0047] S3. Three-phase separation: Spray the pretreated poultry and livestock carcasses into the three-phase separator, and after standing still, perform three-phase separation of the upper layer of oil, middle water, and lower layer of solid poultry and livestock carcasses.

[0048]S4. Preparation of biodiesel from oil: use sulfuric acid as a catalyst to prepare biodiesel from the separated oil, and at the same time pass an electric field of 0.1...

Embodiment 3

[0053] A high-value utilization method of kitchen waste, said method comprising the following steps:

[0054] S1. Collect and remove impurities: collect food waste and remove debris such as plastic, metal and glass.

[0055] S2. Pretreatment: The food waste is subjected to hydrothermal treatment at a treatment temperature of 90°C and a treatment time of 100 minutes.

[0056] S3. Three-phase separation: Three-phase separation of the upper layer of grease, middle water, and lower layer of solid food waste of the pretreated food waste.

[0057] S4. Preparation of biodiesel from oil: under the action of catalyst lipase, the separated oil is transesterified with methanol to prepare biodiesel, and at the same time, a 12V electric field is introduced into the system, 10min / time, and a total of 24h; at this time, the biodiesel The yield of diesel is 93.6%.

[0058] S5. Fermentation of solid food waste to produce ethanol: add ethanol bacteria to the separated solid food waste for eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com