A kind of refining method of liquefied petroleum gas

A technology of liquefied petroleum gas and a refining method, which is applied in the refining field of liquefied petroleum gas, can solve the problems of complicated process flow, unqualified copper sheet corrosion, and excessive total sulfur of liquefied gas, and achieves simple process flow, convenient operation, and removal of good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

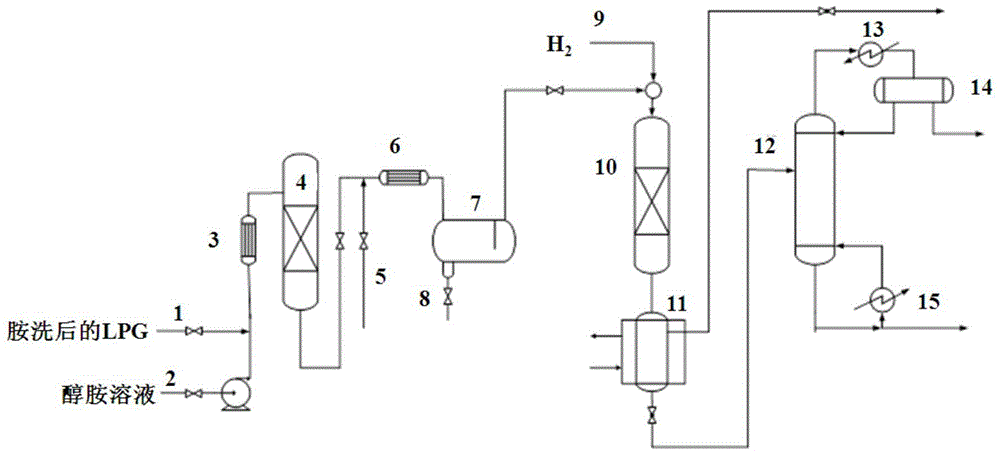

[0051] This embodiment provides a refining method for liquefied petroleum gas, its technological process is as follows figure 1 As shown, the method specifically includes the following steps:

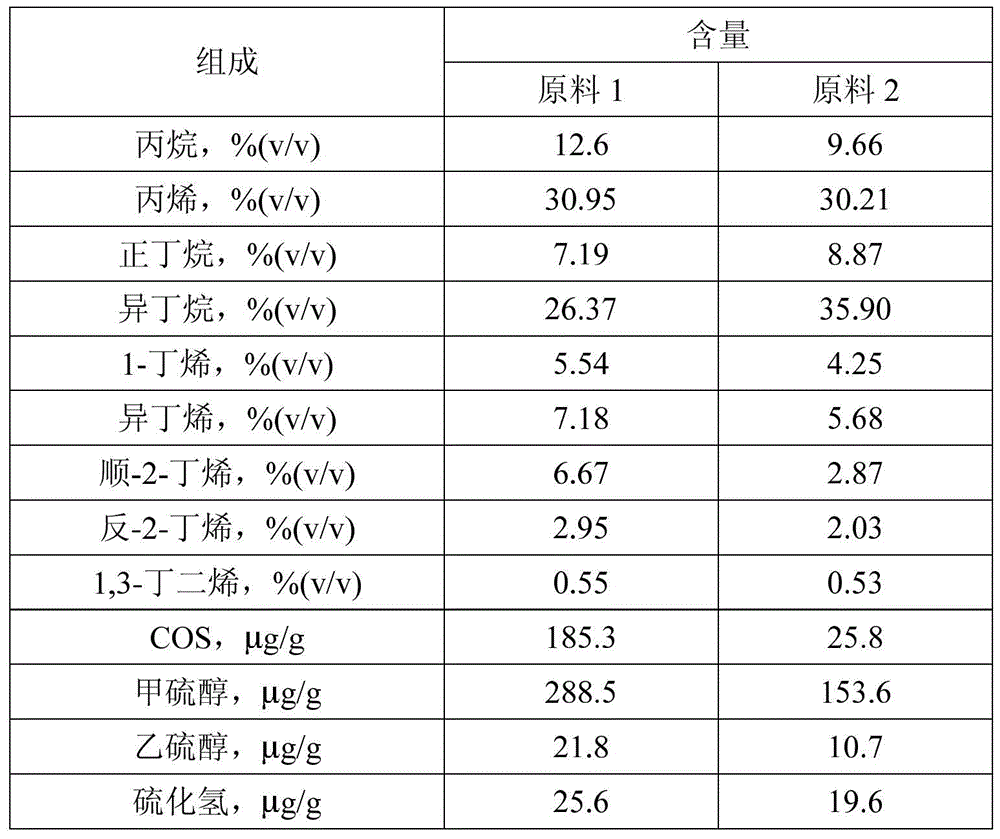

[0052] The system pressure is about 1 MPa to keep the LPG raw material in the liquid phase. The LPG raw material (liquefied petroleum gas after amine washing from Hohhot Petrochemical Company) enters the system through the first inlet 1, and the alcohol amine solution enters through the second inlet 2. In the system, the two are uniformly mixed in the first static mixer 3, enter the COS hydrolysis reactor 4, contact with the COS hydrolysis catalyst, and react to remove COS and hydrogen sulfide of LPG to obtain a reaction mixture;

[0053] The reaction mixture enters the settling tank 7 after being mixed with the tap water entered by the third sample inlet 5 in the second static mixer 6, and the alcohol amine solution and tap water are settled, and are discharged from the raffinate outle...

Embodiment 2

[0064] This embodiment provides a method for refining liquefied petroleum gas, the specific steps of which are the same as in Embodiment 1, the difference from Embodiment 1 is:

[0065] The COS hydrolysis catalyst used is CaO / γ-Al 2 o 3 +TiO 2 Catalyst, in terms of 100% mass percentage, the composition of COS hydrolysis catalyst comprises: CaO is 9wt%, TiO 2 -Al 2 o 3 91wt% (among them, Al 2 o 3 90wt% TiO 2 10 wt%), the particle size of the COS hydrolysis catalyst is 20-40 mesh.

[0066] The thioetherification catalyst used is NiO-WO 3 / SiO 2 -Al 2 o 3 Catalyst, in terms of 100% mass percentage, the composition of thioetherification catalyst comprises: NiO is 15wt%, WO 3 3wt%, SiO 2 -Al 2 o 3 is 82wt% (of which, Al 2 o 3 85wt%, SiO 2 is 15 wt%), and the particle size of the thioetherification catalyst is 20-40 mesh.

[0067] The processing parameters of refined LPG: (1) be the alcohol amine solution with the N-methyldiethanolamine solution of 30wt% with conc...

Embodiment 3

[0070] This embodiment provides a method for refining liquefied petroleum gas, the specific steps of which are the same as in Embodiment 1, the difference from Embodiment 1 is:

[0071] The COS hydrolysis catalyst used is BaO / γ-Al 2 o 3 +TiO 2 Catalyst, in terms of 100% mass percentage, the composition of COS hydrolysis catalyst comprises: BaO is 9wt%, TiO 2 -Al 2 o 3 91wt% (among them, Al 2 o 3 90wt% TiO 2 10 wt%), the particle size of the COS hydrolysis catalyst is 20-40 mesh.

[0072] The thioetherification catalyst used is NiO-MoO 3 / SiO 2 -Al 2 o 3 Catalyst, in terms of 100% mass percentage, the composition of thioetherification catalyst includes: NiO is 14wt%, MoO 3 6wt%, SiO 2 -Al 2 o 3 80wt% (among them, Al 2 o 3 85wt%, SiO 2 is 15 wt%), and the particle size of the thioetherification catalyst is 20-40 mesh.

[0073] The processing parameter of refined LPG: (1) be the diethanolamine solution of 15wt% with concentration as alcohol amine solution, its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com