A deep desulfurization catalyst and its preparation method and application

A desulfurization catalyst and deep desulfurization technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This implementation provides a kind of preparation method of desulfurization catalyst, and this method comprises the following steps:

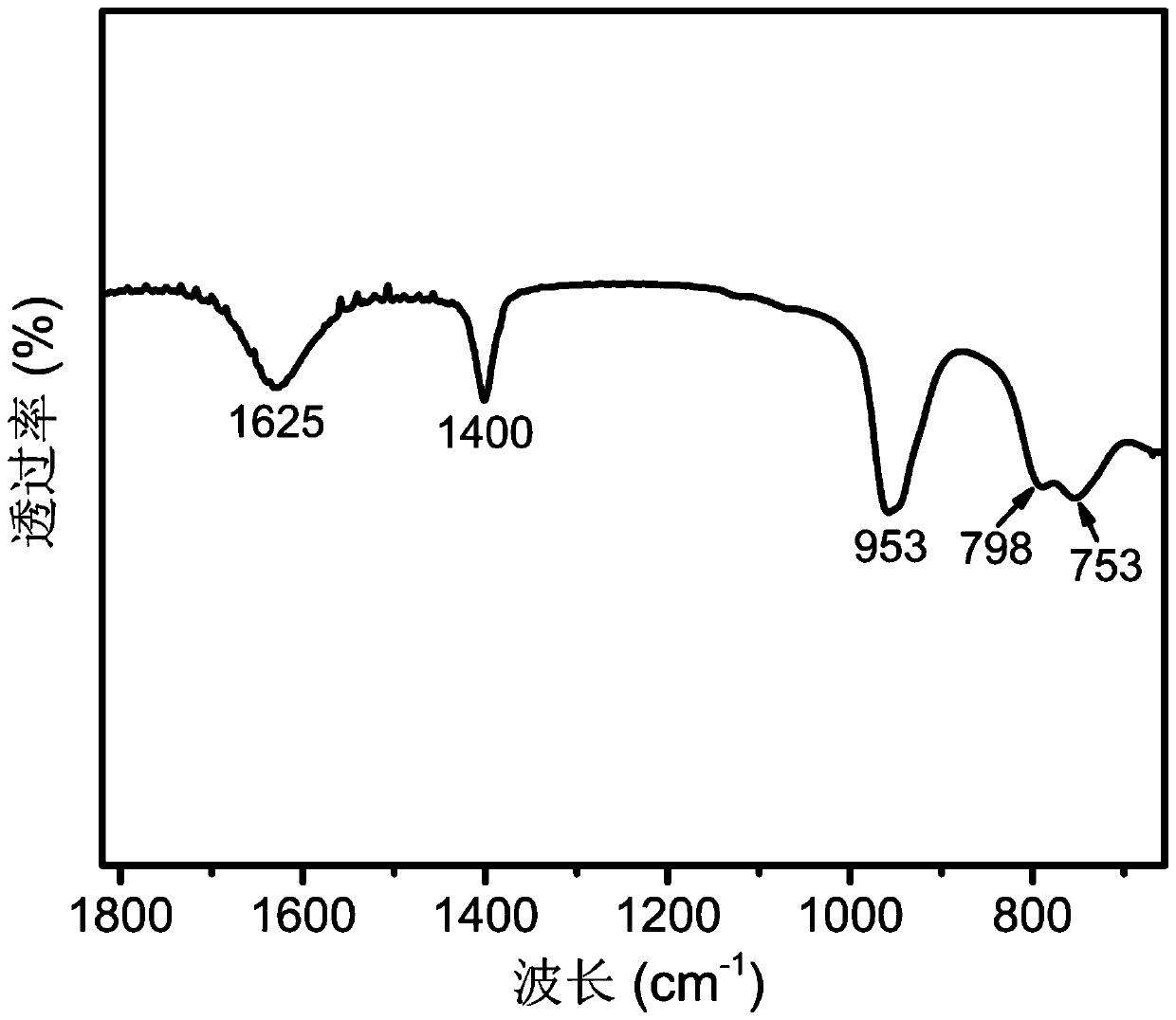

[0043] Step 1, take by weighing 1.34g ammonium heptamolybdate tetrahydrate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) and 4.50 g of cobalt acetate tetrahydrate (Co(OOCCH 3 ) 2 4H 2 (2), it was added to 8mL glacial acetic acid and 100mL water mixed solution and stirred to dissolve, then 0.25g of hydrazine sulfate was added to stir to dissolve, and stirred at a constant temperature at 65°C for 3d, the crystal product obtained was suction filtered, washed and dried, A heteropoly compound is obtained.

[0044] Step 2, disperse 0.14g of heteropoly compound in 70mL of deionized water for 5h ultrasonic treatment, then add 1g of aluminum oxide (20-40 mesh), stir evenly, transfer to a polytetrafluoroethylene-lined high-pressure In the still, under the condition of 120 ℃, the hydrothermal dispersion loading reaction was carried out for 24 hours. After ...

Embodiment 2

[0054] The present implementation provides a kind of preparation method of the desulfurization catalyst of sulfuration, and it comprises the steps:

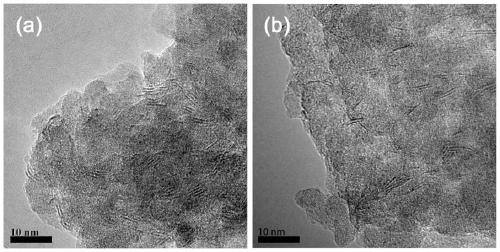

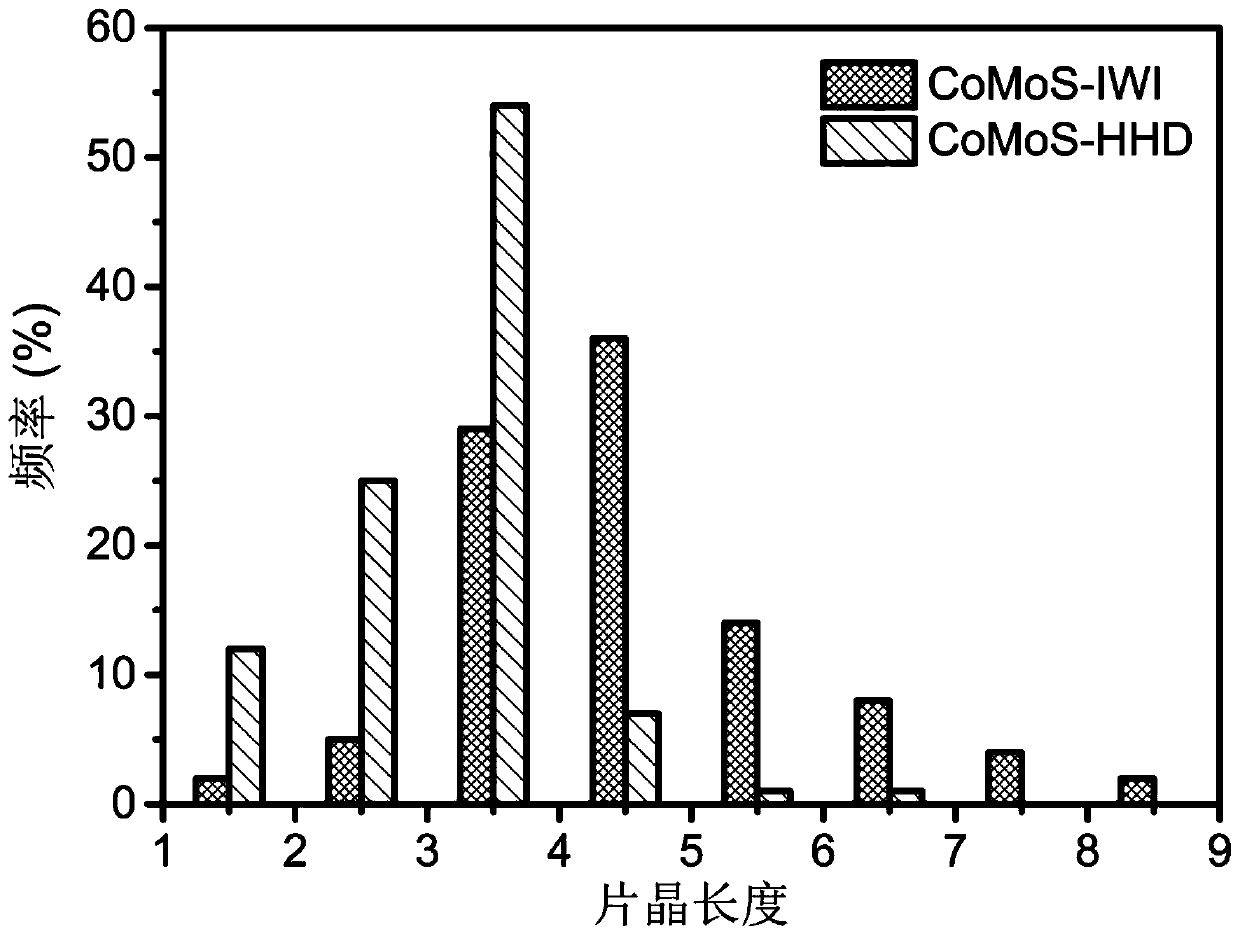

[0055] The CoMo-HHD prepared in Example 1 is diluted with quartz sand at a volume ratio of 1:1, and packed into a stainless steel reactor with an internal diameter of 8.0mm and a length of 320mm; 2 Under the conditions, dry at 120°C for 2h, and then introduce a vulcanizing agent (3wt% of CS 2 n-heptane solution), the vulcanization pressure is 4MPa, and the vulcanization agent volume space velocity is 8h -1 , the volume ratio of hydrogen to oil is 300:1, and the temperature is raised to 360°C at a rate of 2°C / min, and kept for 5h to obtain sulfided CoMo-HHD, which is designated as CoMoS-HHD.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com