Hydroxyl functionalized heteropolyacid catalyst as well as preparation method and application thereof

A heteropolyacid and functionalized technology, which is applied in the direction of carbon compound catalysts, physical/chemical process catalysts, catalysts, etc., can solve the problems of bad influence on fuel quality indicators, catalyst loss, high cost, etc., and achieve excellent recovery utilization rate and desulfurization conditions Gentle, problem-solving effect on recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

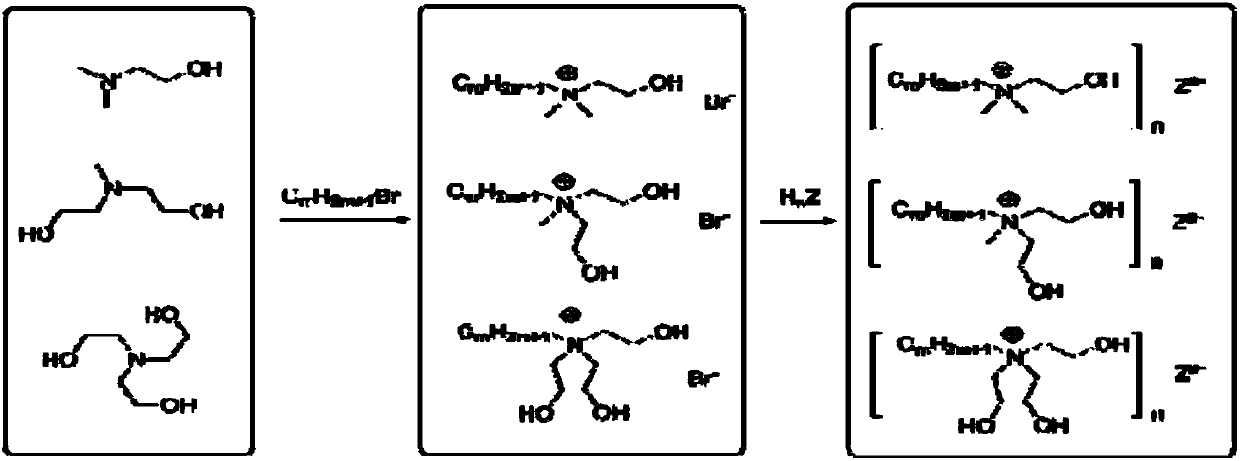

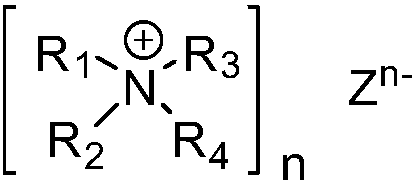

[0039] The preparation method of the hydroxyl-functionalized heteropolyacid catalyst provided by the embodiment of the present invention comprises: reacting a haloalkane with a hydroxyl tertiary amine to generate a quaternary ammonium salt intermediate, and then making the quaternary ammonium salt intermediate and the heteropolyacid in a liquid phase system Mixing reaction in medium to prepare the hydroxy-functionalized heteropolyacid catalyst.

[0040] In some embodiments, the preparation method comprises:

[0041] Mix the hydroxyl tertiary amine and halogenated alkanes in the solvent, and react at 50-90°C for 2-6h, then cool and separate to obtain the quaternary ammonium salt intermediate;

[0042] The quaternary ammonium salt intermediate and the heteropoly acid are prepared into aqueous solutions respectively, and the aqueous solution of the quaternary ammonium salt intermediate and the heteropoly acid are mixed and reacted at 10-30°C for 1-3h, and then the obtained solid ...

Embodiment 1

[0077] Embodiment 1 [(C 18 h 37 )N + (CH 3 ) 2 (C 2 h 4 OH)] 3 PW 12 o 40

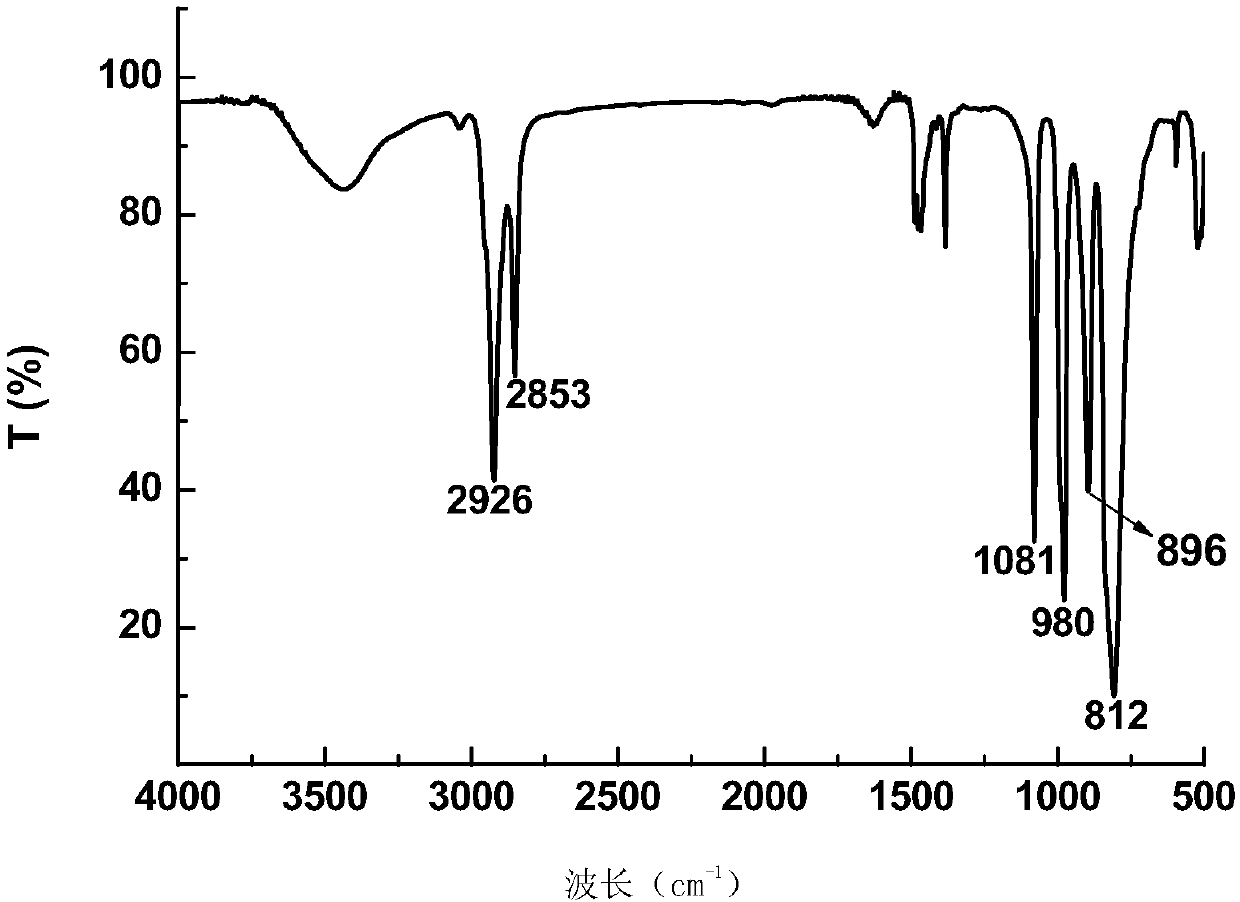

[0078] 1) Catalyst synthesis (see figure 1 )

[0079] Bromoctadecane (166.71g, 0.5mol) and N,N-dimethylethanolamine (44.56g, 0.5mol) were placed in a 1L round bottom flask, added to 400mL ethyl acetate, heated to reflux for 4h, then cooled To room temperature, separate out solid, filter to obtain 188.25g intermediate product [(C 18 h 37 )N + (CH 3 ) 2 (C 2 h 4 OH)] Br; take the intermediate product [(C 18 h 37 )N + (CH 3 ) 2 (C 2 h 4 OH)]Br (16.80g, 39.8mmol) was dissolved in 100mL deionized water, and phosphotungstic acid (38.16g, 13.3mmol) was dissolved in 100mL deionized water, and the two aqueous solutions were mixed and stirred for 2 hours, and the system produced a white precipitate , filtered, and the solid product was washed three times with 20 mL of deionized water, and dried in vacuum at 40° C. to obtain 50.14 g of a white solid, with a yield of 93.0%. 1 H NMR(400MHz...

Embodiment 2

[0086] Embodiment 2 [(C 10 h 21 )N + (CH 3 )(C 2 h 4 Oh) 2 ] 4 SiW 12 o 40

[0087] Bromodecane (110.54g, 0.5mol) and N-methyldiethanolamine (59.68g, 0.5mol) were placed in a 1L round bottom flask, added to 400mL ethyl acetate, heated to reflux for 4h, and then cooled to room temperature. Separate out solid, filter to obtain 139.56g intermediate product [(C 10 h 21 )N + (CH 3 )(C 2 h 4 Oh) 2 ] Br; Take the intermediate product [(C 10 h 21 )N + (CH 3 )(C 2 h 4 Oh) 2 ]Br (34.04g, 100mmol), dissolve it in 100mL deionized water, dissolve silicotungstic acid (71.98g, 25mmol) in 150mL deionized water, mix and stir the two aqueous solutions for 2h, the system produces white precipitate, filter, solid The product was washed three times with 20 mL of deionized water, and dried under vacuum at 40° C. to obtain 95.45 g of white solid, with a yield of 90.1%. 1 H NMR(400MHz,DMSO-d6)δ4.12(m,4H),3.73(m,4H),3.50(m,2H),3.31(s,3H),1.77(m,2H),1.26(m, 14H), 0.89(t,3H).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com