A method for oxidative desulfurization of diesel oil with a metal oxide modified nano-iron oxide catalyst

A technology of nano-iron oxide and oxidative desulfurization, which is applied in the chemical industry and can solve the problems of reduced yield, low yield of diesel oil, and deterioration of oil products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

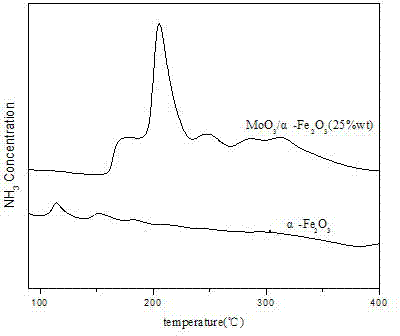

[0024] Weigh 3g of ammonium molybdate tetrahydrate, dissolve it in 5ml of distilled water, stir to dissolve, add 10g of nano-iron oxide to it, and ultrasonicate at 40°C for 30min; after ultrasonication, let it stand for 12h, dry at 120°C, grind it, and put it in a resistance furnace Calcined at 500 °C for 2 h to obtain MoO with a loading of 25% (wt) 3 / α-Fe 2 o 3 catalyst.

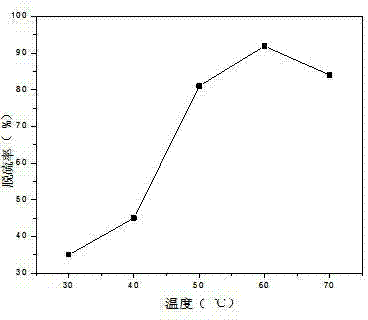

[0025] In a clean round-bottomed flask, add 0.1g of the above catalyst and 10ml of diesel oil sample, stir and react at a certain temperature for 90min, stop stirring, separate the catalyst and diesel in a centrifuge, extract with extractant DMF, and use a dosage of extractant The oil ratio is 1:1, continuous extraction is performed three times, the upper oil phase is taken, and the sulfur content is measured with a microcoulomb instrument. The gasification temperature is 600°C, the combustion temperature is 810°C, and the temperature in the stable section is 700°C. The sulfur content before and after th...

Embodiment 2

[0027] Weigh 2g each of ammonium molybdate tetrahydrate and nickel sulfate, dissolve them in 5ml of distilled water, stir to dissolve, add 10g of nano-iron oxide to it, and ultrasonicate at 40°C for 30min; after ultrasonication, let stand for 12h, dry at 120°C, grind, The catalyst was calcined at 500°C for 2 h in a resistance furnace to obtain a catalyst with a loading of 30% (wt).

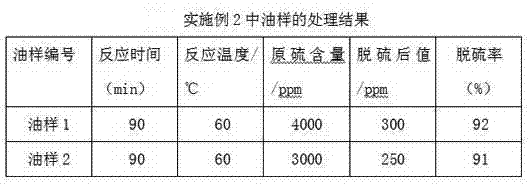

[0028] Take 0.05 g of the above catalyst and 10 ml of diesel oil samples, react according to the method of Example 1, react at 60° C., and measure the samples. image 3 It is the treatment result of several oil samples. After the reaction, the sulfur content in diesel oil in oil sample 1 dropped from 4000ppm to 300ppm, and the sulfur content in diesel oil in oil sample 2 dropped from 3000ppm to 250ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com