System for super clean removal of sulfur dioxide in coal-fired flue gas and process of system

A technology for sulfur dioxide and coal-fired flue gas, which is used in air quality improvement, chemical instruments and methods, and dispersed particle separation. Ultra-clean emission standards and other problems, to achieve the effect of not easy to scale and great economic and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

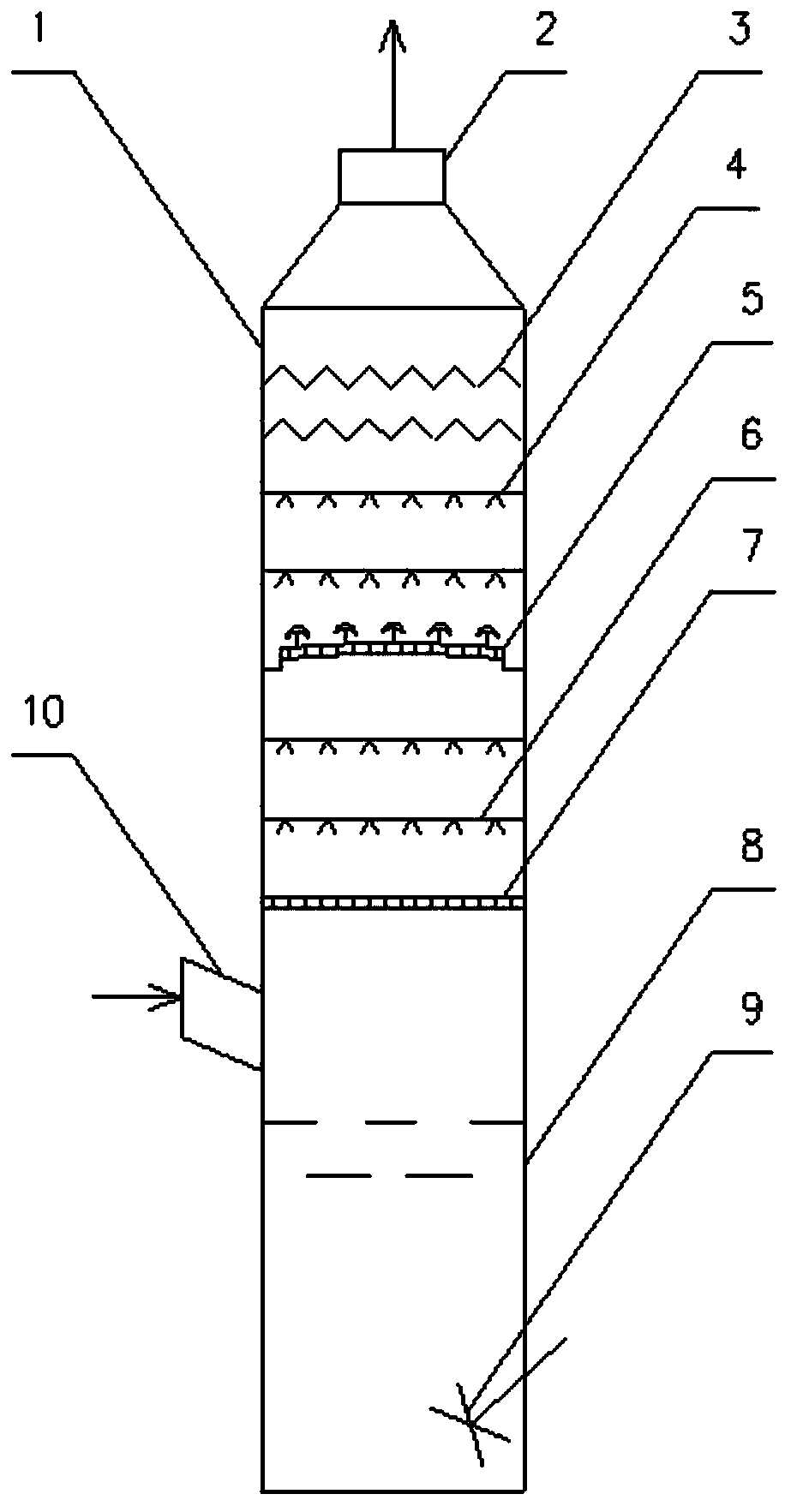

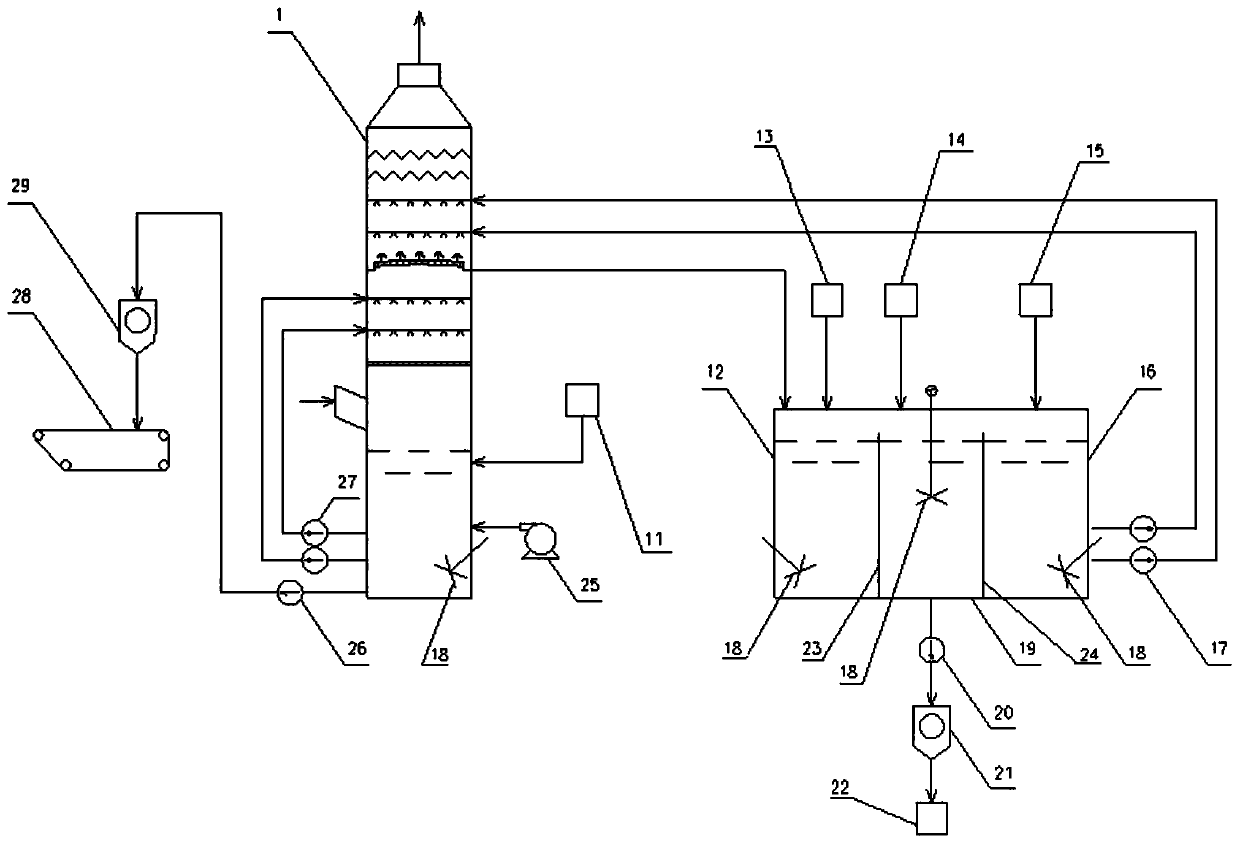

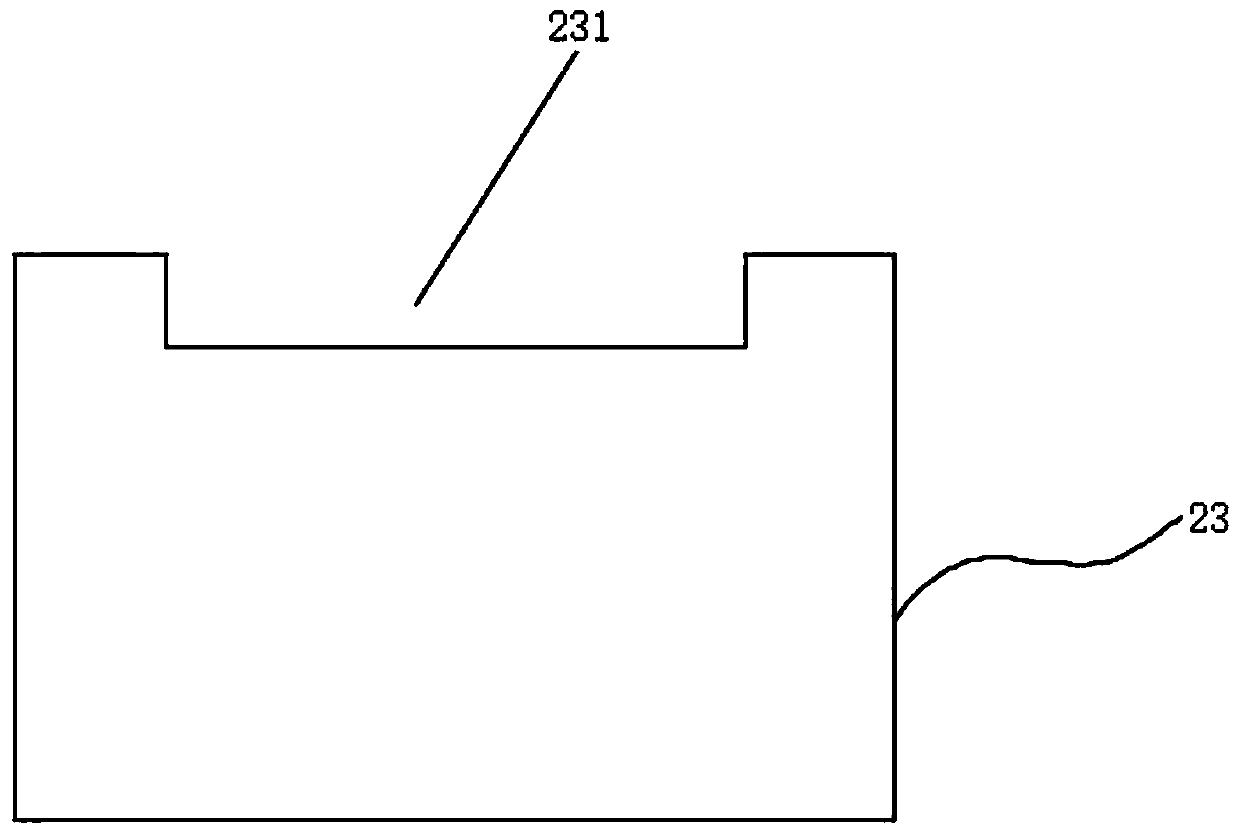

[0028] A system for ultra-clean removal of sulfur dioxide in coal-fired flue gas, comprising a desulfurization tower 1, a flue gas inlet 10 is provided at the middle and lower part of the desulfurization tower 1, a flue gas outlet 2 is provided at the top of the desulfurization tower 1, and the flue gas inlet 10 is connected to the Between the flue gas outlets 2, there are main desulfurization area, deep desulfurization area, and high-efficiency demister 3 from bottom to top. There are partitioned orifice plates 5 between the main desulfurization area and deep desulfurization area. The main desulfurization area includes several layers of low pH value slurry spray layer 6, the lowermost low pH value slurry spray layer 6 is provided with a flue gas equalizer 7, and the deep desulfurization area includes several layers of high pH value slurry spray layers 4; the bottom of the desulfurization tower 1 is set There is a low pH value slurry oxidation tank 8, and the low pH value slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com