Method for making clean fuels

A clean fuel and reaction product technology, applied in the petroleum industry, hydrotreating process, hydrocarbon oil treatment, etc., can solve the problems of difficulty in transformation and high cost, achieve the effect of process optimization and reduce the cost of primary investment and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

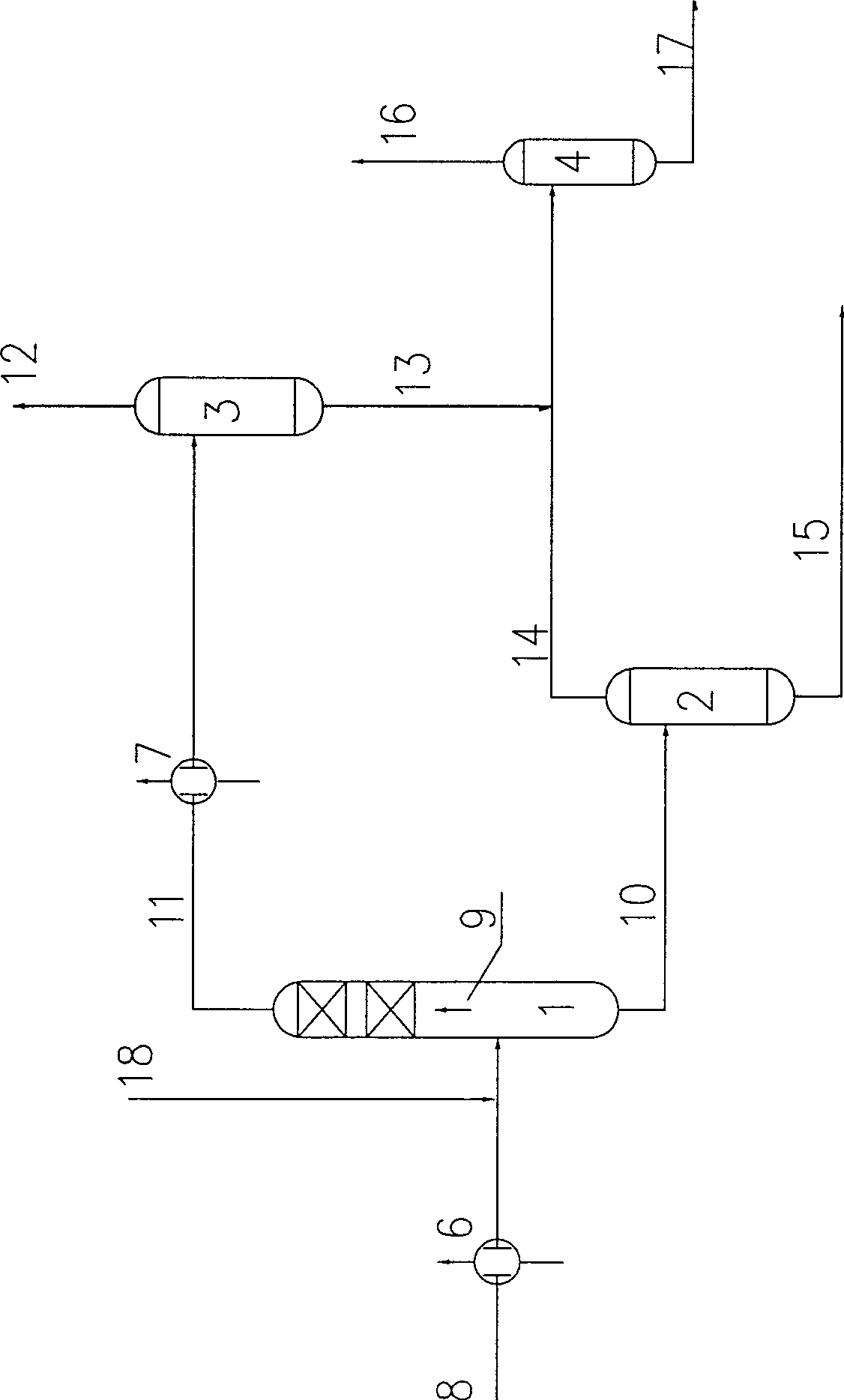

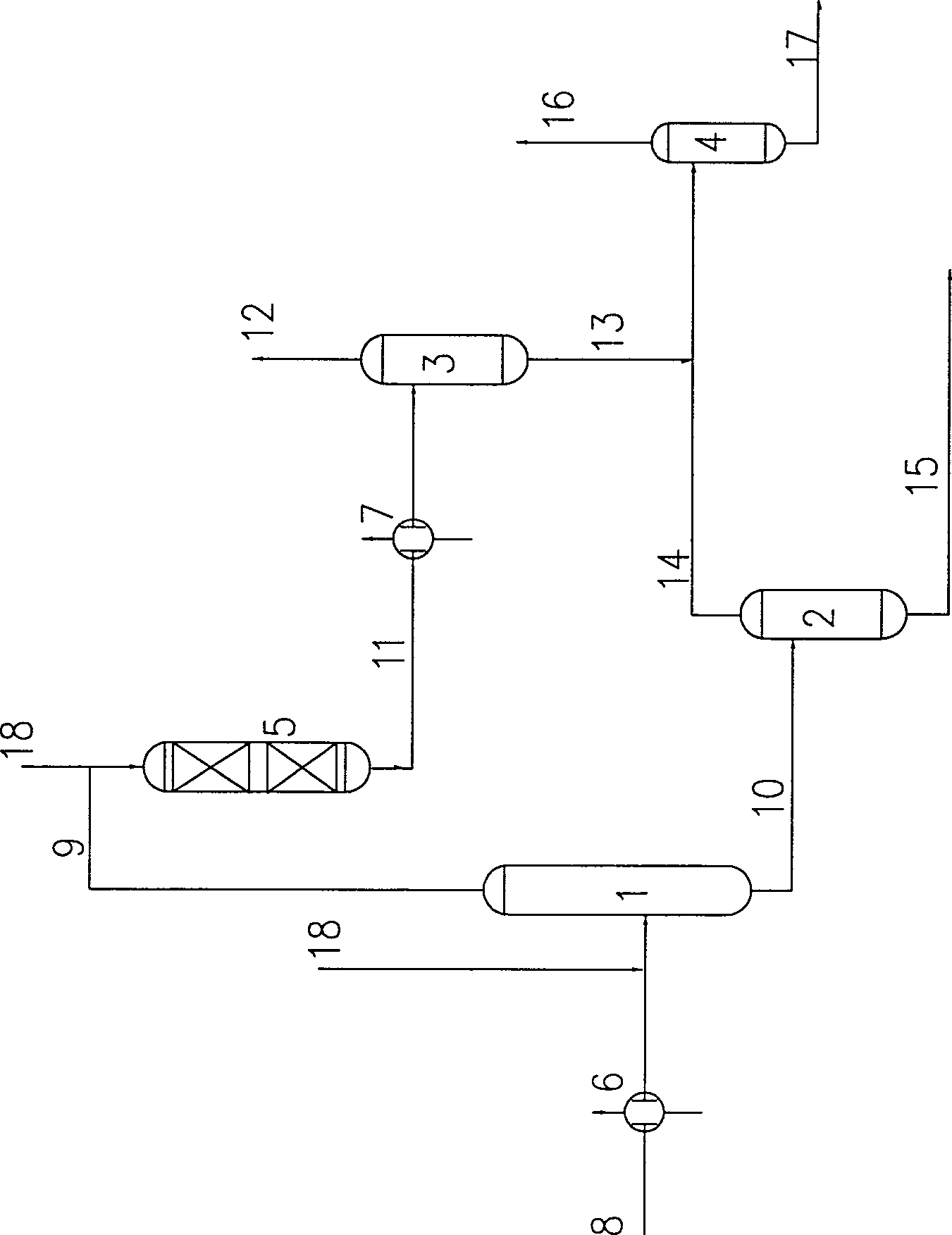

[0015] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only drawn to illustrate the basic content of the present invention, and do not limit the scope of the present invention.

[0016] Such as figure 1 As shown, the hydrocracking reaction effluent 8 is heat-exchanged by the high-pressure heat exchanger 6 and enters the hot high-pressure separator 1 alone or together with the hydrocarbon oil 18 to be refined for gas-liquid separation. The hot high-pressure separator 1 is usually at a pressure of 5.0 Operate under the conditions of ~20.0MPa and temperature 200~400℃. The gas phase 9 of the hot high-pressure separator is a mixture of hydrogen, small molecule hydrocarbons and light oil, which passes through the refined catalyst bed arranged on the top of the hot high-pressure separator from bottom to top, and the usual range of liquid hourly space velocity (LHSV) is 0.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com