High-efficiency composite slag lotion

A technology of composite slag and slag washing agent, which is applied in the field of iron and steel smelting, can solve the problems of rising melting temperature and decreasing desulfurization capacity, and achieve the effects of promoting melting, enhancing fluidity and increasing desulfurization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

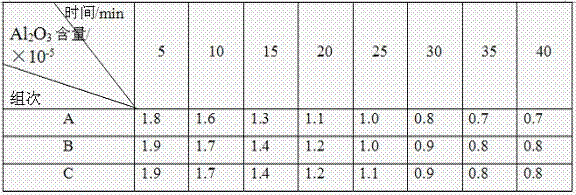

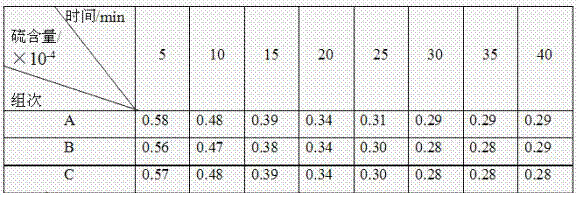

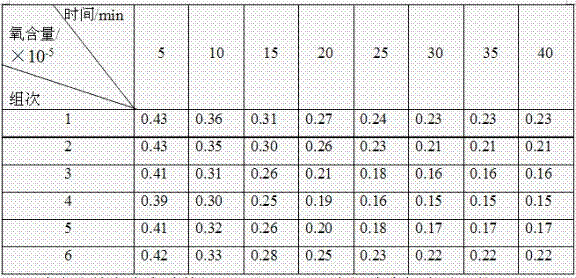

Image

Examples

Embodiment 1

[0030] The preparation of efficient composite slag lotion of the present invention can follow the steps:

[0031] ① Raw material inspection and proportioning: according to the raw material formula and material requirements, weigh 49 parts of calcium powder, 45 parts of aluminum ash, 5 parts of high alumina cement, and 1.0 part of CMC, and stir them evenly to prepare a mixture;

[0032] ② Stirring with water: add 18 parts of water to the mixture and stir;

[0033] ③Pellet making: Using conventional disc granulation technology, the mixed material after adding water is made into granules;

[0034] ④ Drying in the pit: Dry the obtained particles at 65°C, and determine the components of the high-efficiency composite slag lotion obtained after drying: CaO 30%, Al 2 o 3 40%, Al 5%, SiO 2 7.7%, MgO 8%, H 2 O 0.3%.

Embodiment 2

[0036] The preparation of efficient composite slag lotion of the present invention can follow the steps:

[0037] ① Raw material inspection and proportioning: According to the raw material formula and material requirements, weigh 50 parts of calcium powder, 40 parts of aluminum ash, 8.8 parts of high alumina cement, and 1.2 parts of CMC, and stir them evenly to prepare a mixture;

[0038] ② Stirring with water: add 19 parts of water to the mixture and stir;

[0039] ③Pellet making: Using conventional disc granulation technology, the mixed material after adding water is made into granules;

[0040] ④ Drying in the pit: Dry the obtained particles at 69°C, and determine the components of the high-efficiency composite slag lotion after drying, including: CaO 31.2%, Al 2 o 3 37%, Al 4.5%, SiO 2 8%, MgO 7.8%, H 2 O 0.35%.

Embodiment 3

[0042] The preparation of efficient composite slag lotion of the present invention can follow the steps:

[0043] ① Raw material inspection and proportioning: According to the raw material formula and material requirements, weigh 55 parts of calcium powder, 35 parts of aluminum ash, 9.5 parts of high alumina cement, and 0.5 part of CMC, and stir them evenly to prepare a mixture;

[0044] ② Stirring with water: add 20 parts of water to the mixture and stir;

[0045] ③Pellet making: Using conventional disc granulation technology, the mixed material after adding water is made into granules;

[0046] ④ Drying in the pit: Dry the obtained particles at 71°C, and determine the components of the obtained high-efficiency composite slag lotion after drying, including: CaO 35.5%, Al 2 o 3 32.7%, Al 3.9%, SiO 2 7.2%, MgO 6.5%, H 2 O 0.53%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com