Patents

Literature

64 results about "Impurity absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

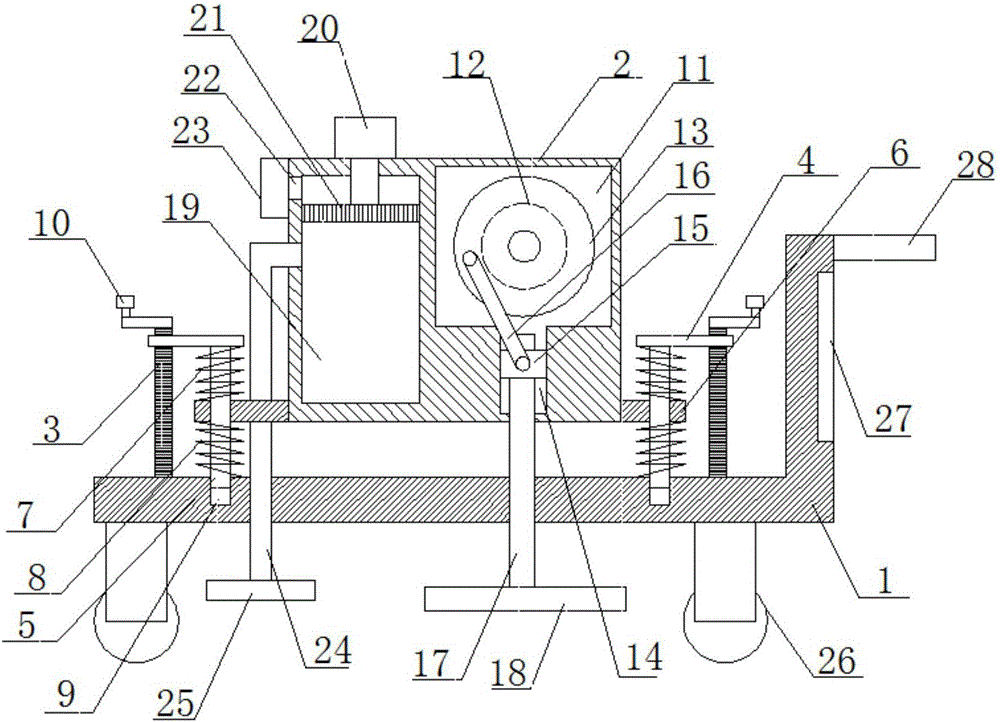

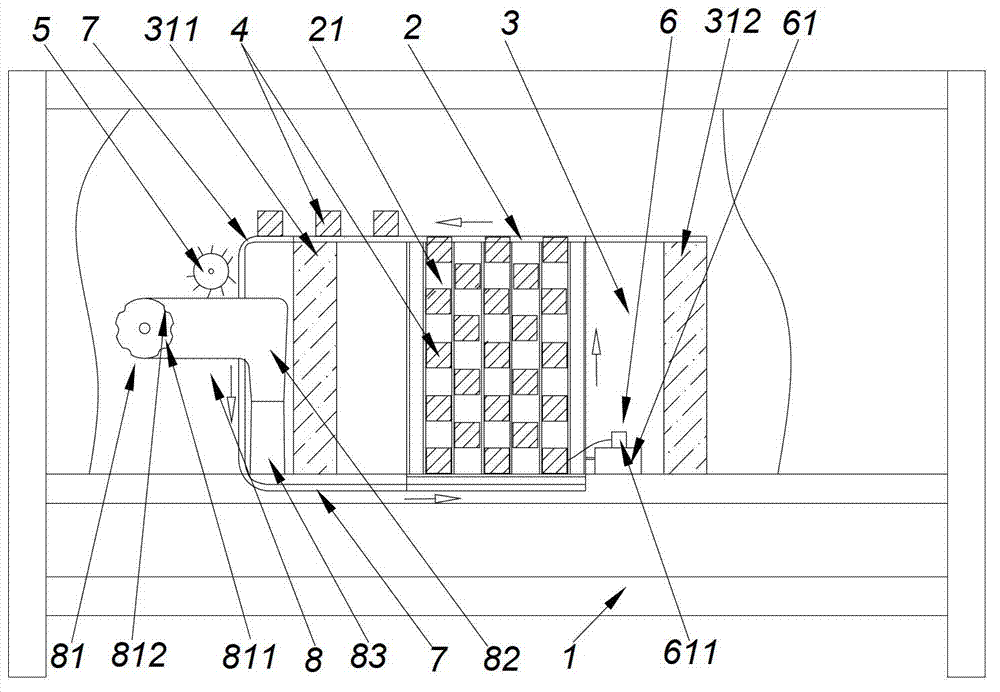

Rammer compactor used for building construction

InactiveCN106522070AAvoid frequent replacementGuaranteed flexibilityRoads maintainenceArchitectural engineeringEngineering

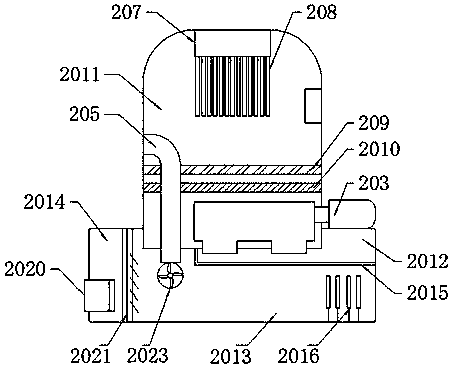

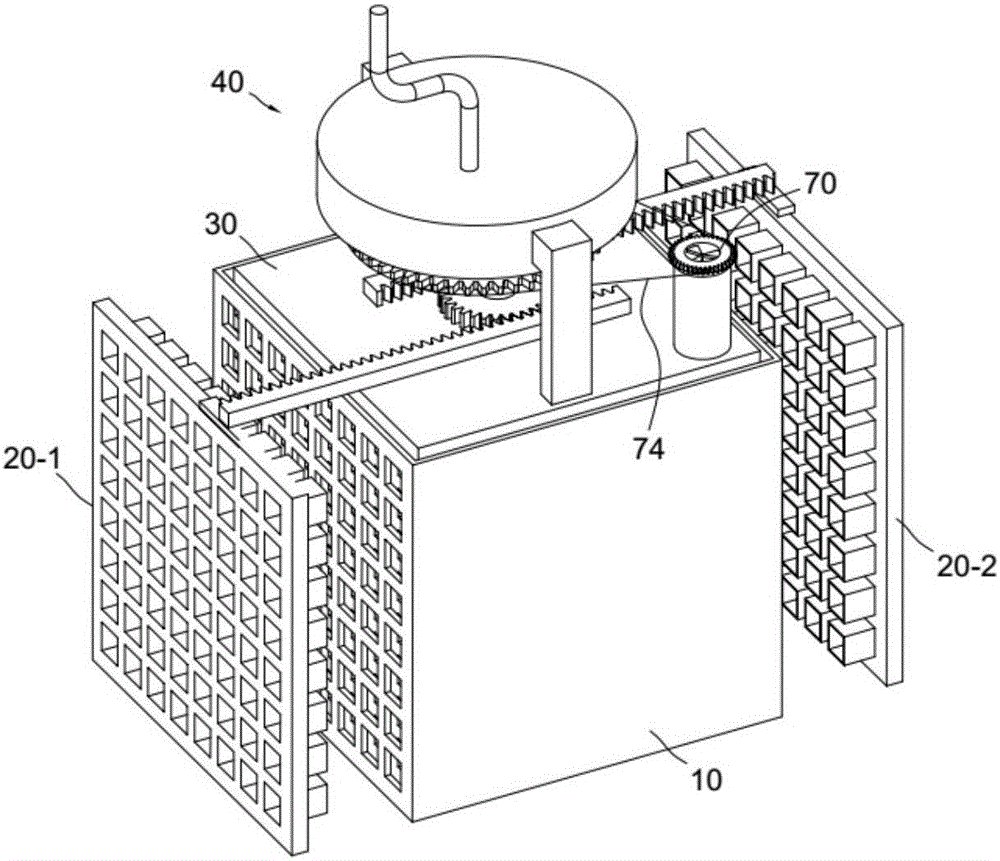

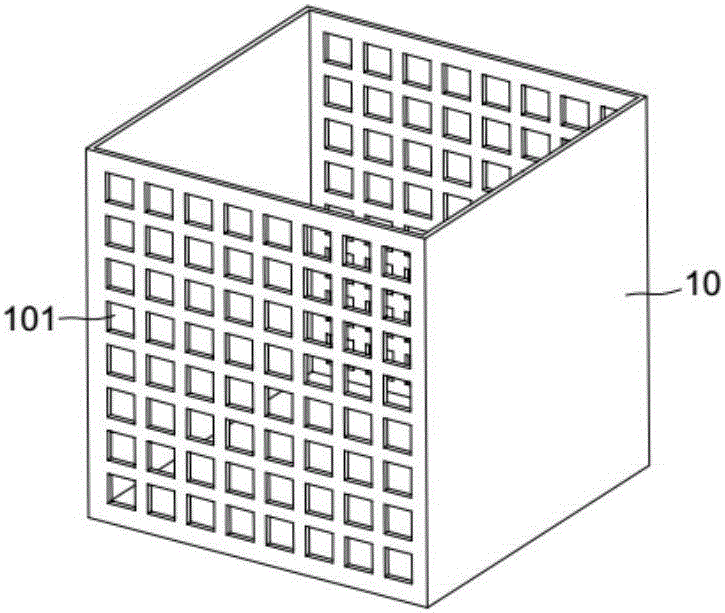

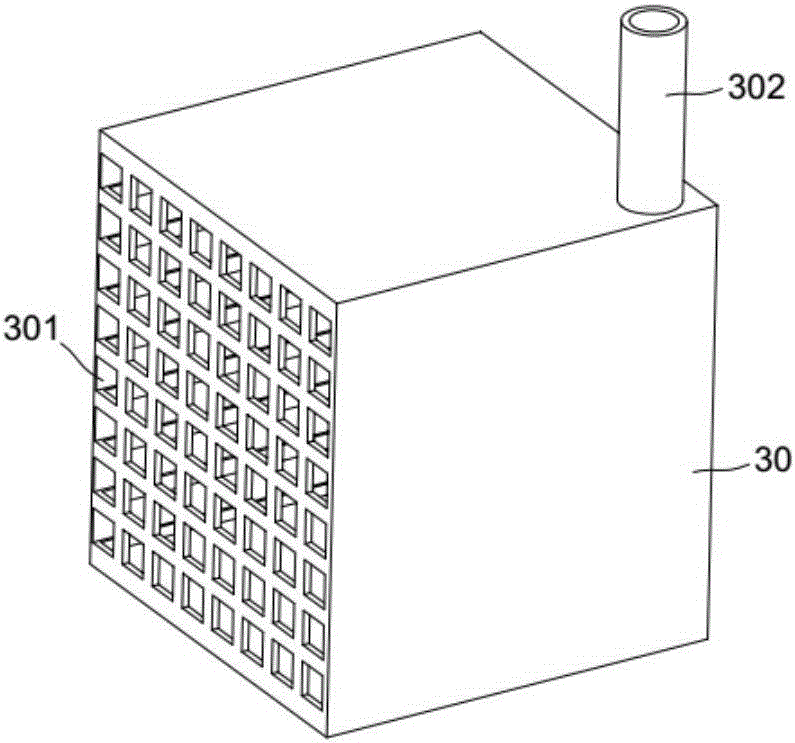

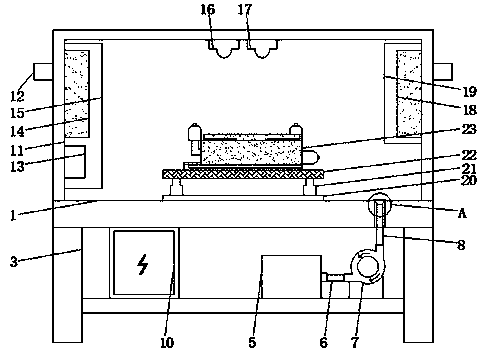

The invention discloses a rammer compactor used for building construction. The rammer compactor comprises a base frame and a box body. Threaded rods are arranged at the left end and the right end of the upper side of the base frame through connecting seats, the threaded rods are connected with adjusting plates in a thread mode, and a supporting rod is arranged at the lower ends of the adjusting plates; connecting plates are symmetrically arranged on the left and right sides of the box body, the connecting plates are connected with the supporting rod in a sliding mode, and upper damping springs and lower damping springs are arranged on the upper side and the lower side of the connecting plates of the connecting plates correspondingly; a motor cavity is formed in the right portion of the box body, an impurity absorption cavity is formed in the left portion of the box body, and an air inlet is formed in the upper portion of the left side of the impurity absorption cavity; a draught fan is arranged on the outer portion of the air inlet, an impurity absorption tube is connected to the draught fan, and the lower end of the impurity tube stretches out of the lower end of the base frame and is provided with an impurity absorption cover; a telescopic device is arranged at the upper end of the impurity absorption cavity, the lower end of the telescopic device stretches into the impurity absorption cavity, and a dust filter plate is arranged at the lower end of the telescopic device. According to the rammer compactor, the structure is simple, the using is convenient, the damping effect is good, maintenance cost is lowered, and the tamping quality is improved.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

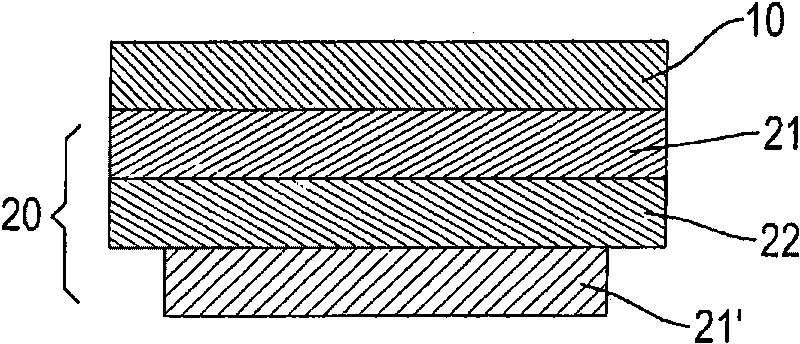

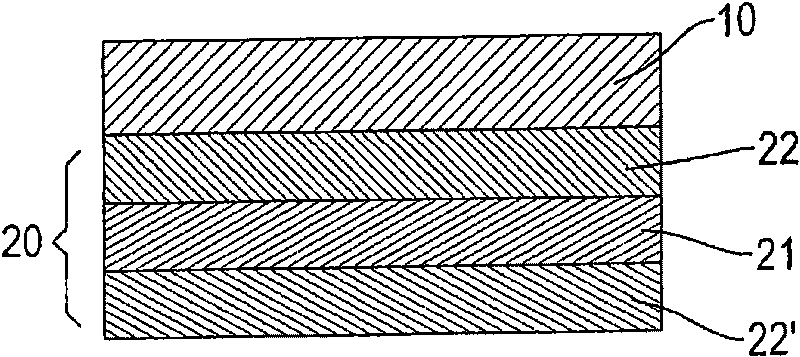

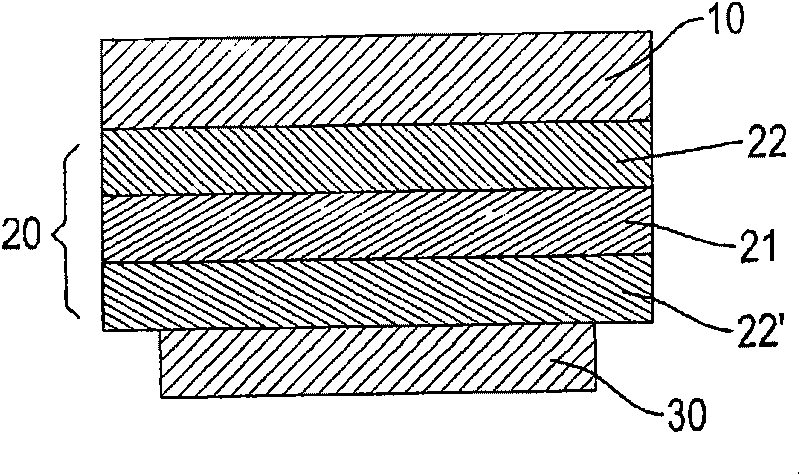

Encapsulation structure for wafer backside

InactiveCN101740525AEasy to adjust bowEasy to adjust warpageSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSilicon dioxide

The invention relates to an encapsulation structure for wafer backside. The structure comprises a semiconductor substrate and a multilayered structural layer which is arranged at the bottom of the semiconductor substrate and is formed by combining a polysilicon layer and an insulating layer (such as a silicon dioxide layer); the multilayered structure can promote the effect of impurity absorption, effectively prevents automatic doping, improves the phenomenon of burr, and saves process cost; and through the structure, the bowing degree and the warping degree of the silicon substrate are easily adjusted.

Owner:WAFER WORKS

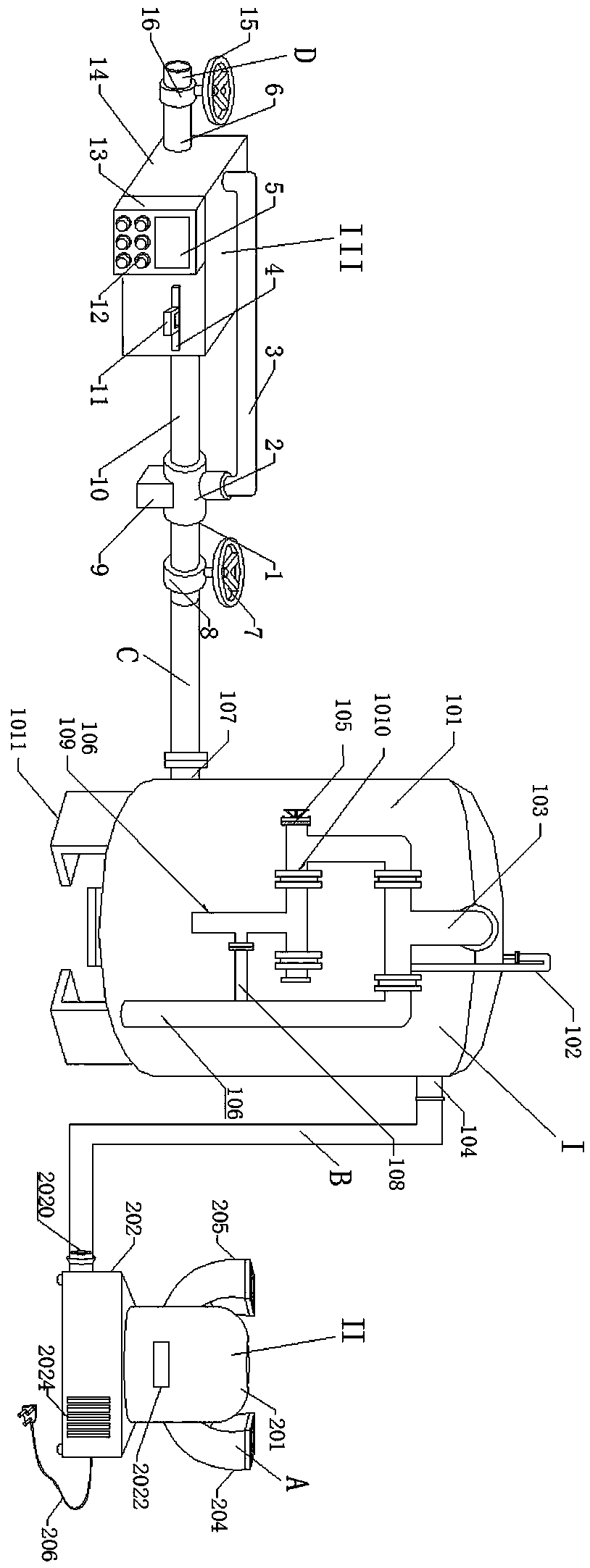

Method for extracting m-phthalic acid-5-sodium sulfonate from ternary-monomer industrial waste water

ActiveCN104003910ALow costReduce pollutionOrganic chemistryOrganic compound preparationIndustrial waste waterDecomposition

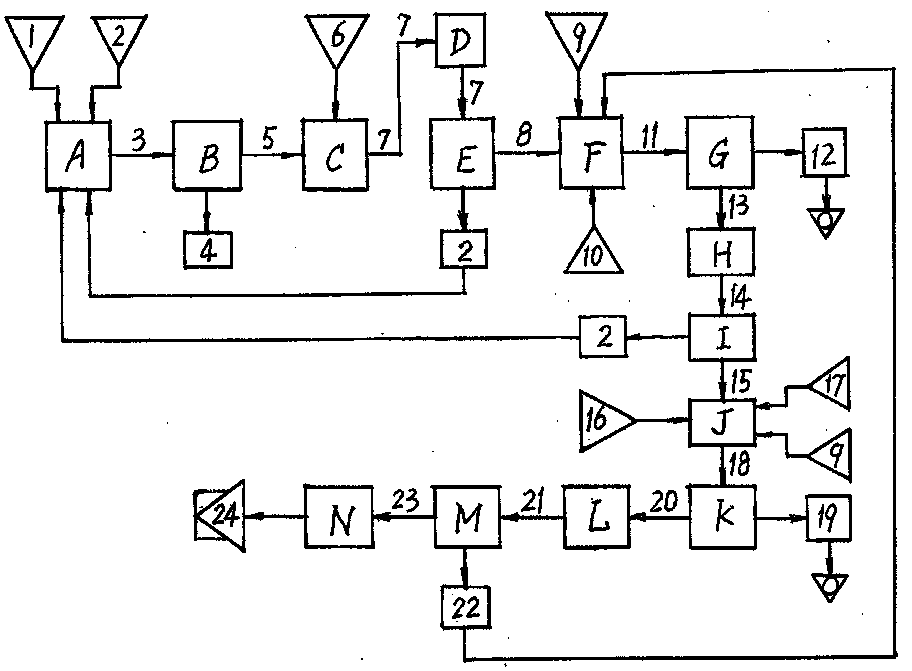

Provided is a method for extracting m-phthalic acid-5-sodium sulfonate from ternary-monomer industrial waste water. A sediment crystallization tank (A), a pressure filter (B), an ester decomposition tank (C), a high-pressure pump (D), a distillation tower (E), a decoloration and impurity absorption kettle (F), a filter (G), a concentration and crystallization kettle (H), a centrifugal hydroextractor (I), a flash melting kettle (J), a fine filter (K), a secondary concentration and crystallization kettle (L), a rubber lining water extractor (M) and a drying machine (N) are connected to be a production line, the ternary-monomer industrial waste water serves as the main raw material, an organic precipitant (2), sodium hydroxide (6), activated carbon (9), deionized water (16), sulfuric acid (17) and activated carbon (9) are sequentially added in related devices according to process requirements through the process procedures of various processes, and finished m-phthalic acid-5-sodium sulfonate (24) is prepared under the specific temperature, time and process conditions of the process procedures of various processes. The method can further extract out sodium sulfate crystals (4) in the waste water. Pollution is reduced, environment is protected, waste is turned into wealth, and double purposes are achieved.

Owner:SHANDONG JINSHENG NEW MATERIAL TECH

Method for reducing metal impurities in polysilicon

The invention relates to the technical field of preparation of polysilicon for solar cells and particularly relates to a method for reducing metal impurities in polysilicon. The method comprises the following steps of: 1) rinsing: immersing a primary silicon chip into an RCA (ricinus communis agglutinin) I solution and an RCA II solution in succession for rinsing; 2) drying; 3) fast heat treatment: placing the silicon chip after drying into a fast heat treatment furnace for performing fast heat treatment under a nitrogen atmosphere; and 4) impurity absorption: placing the silicon chip in a diffusion furnace for performing single-side phosphorus diffusion, performing vapor deposition of aluminum on the surface without the phosphorus diffusion of the silicon chip after the phosphorus diffusion in a vacuum film plating machine, and then performing phosphorus and aluminum co-impurity absorption treatment under the nitrogen atmosphere; cleaning: soaking the silicon chip in an HCl solution and a mixed acid solution of HF and HNO3 in succession; and drying. The method has the beneficial effects that: after PECVD (plasma enhanced chemical vapor deposition) passivation treatment of the silicon chip treated through the method according to the invention, the mu-PCD (microwave photoconductive decay) method is utilized for performing minority carrier lifetime testing, and the result finds that the minority carrier lifetime is obviously prolonged.

Owner:TRINA SOLAR CO LTD

Metallic silicon surface treatment purification method

The invention discloses a metallic silicon surface treatment purification method, comprising the following steps: deoiling and cleaning metallic silicon; carrying out ball-milling on the metallic silicon with alcohol or ketone as medium and then drying the metallic silicon with argon; heating the dried metallic silicon quickly and carrying out heat preservation and reduction in succession and then cooling; taking out the cooled metallic silicon and dipping the metallic silicon into a mixed solution of muriatic acid and hydrofluoric acid; and cleaning the dipped metallic silicon with deionized water. In the invention, principles of impurity outdiffusion and surface impurity absorption of metallic silicon are adopted, a large area of defect is created on the surface of the metallic silicon artificially to form an affected layer, impurities in the metallic silicon are absorbed at high temperature, and preliminary purification treatment is carried out on the surface of the metallic silicon to improve the purity of the metallic silicon to 99.99%-99.999% (4-5N), so that the invention can be applied to silicon used for solar cell or further-purified material for subsequent purification technology.

Owner:ZHEJIANG UNIV

Heat treatment method of solar-grade silicon crystal

InactiveCN101942701AImprove life expectancyAvoid/Minimize Performance ImpactPolycrystalline material growthAfter-treatment detailsHydrogenHydrogen atom

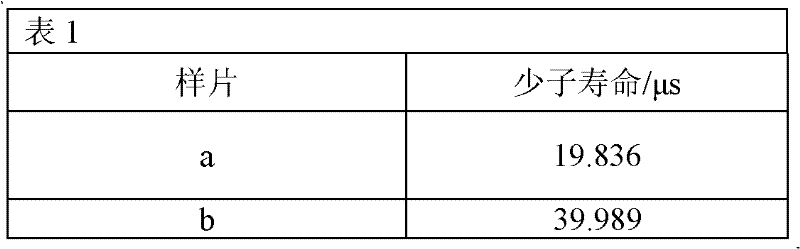

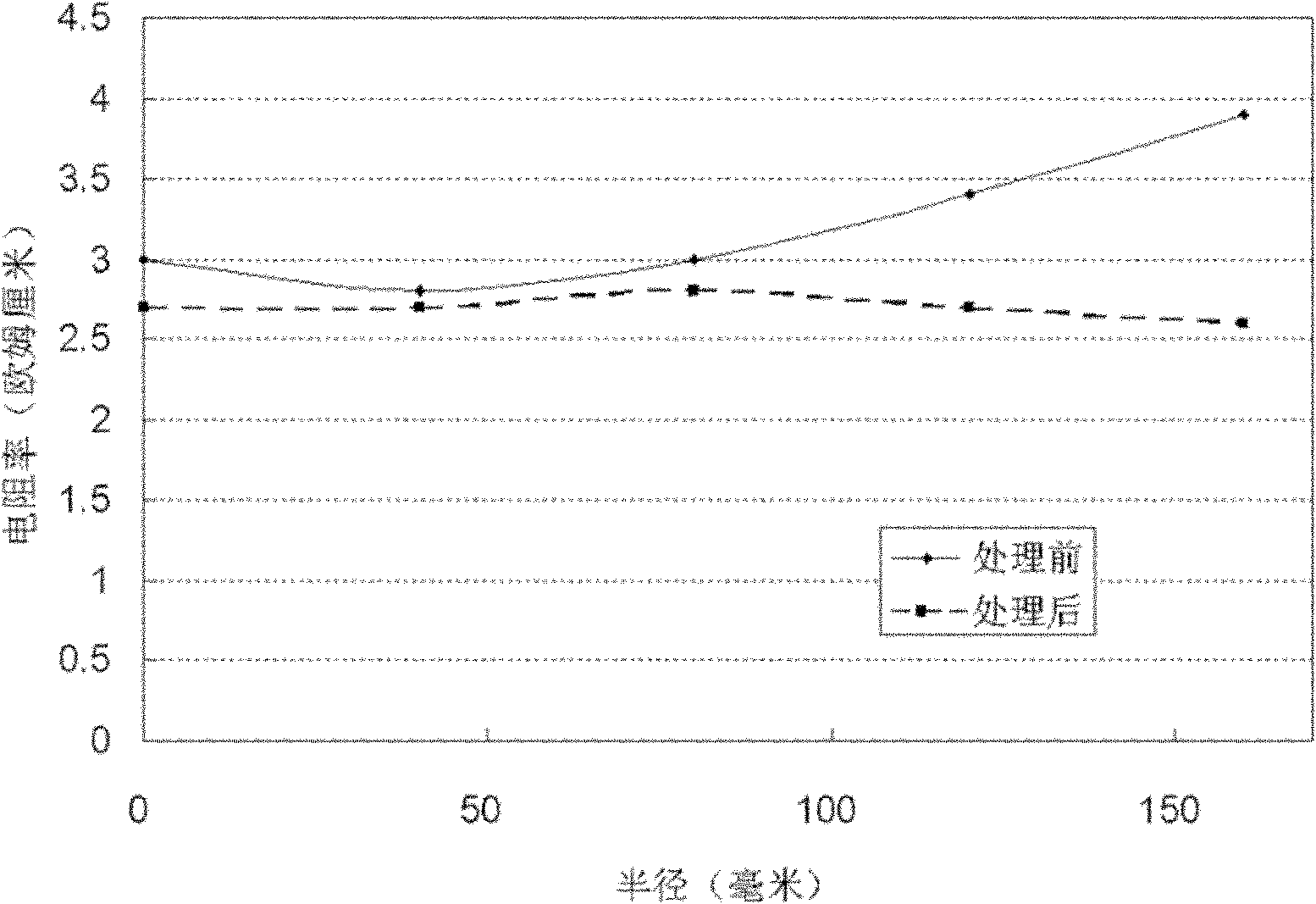

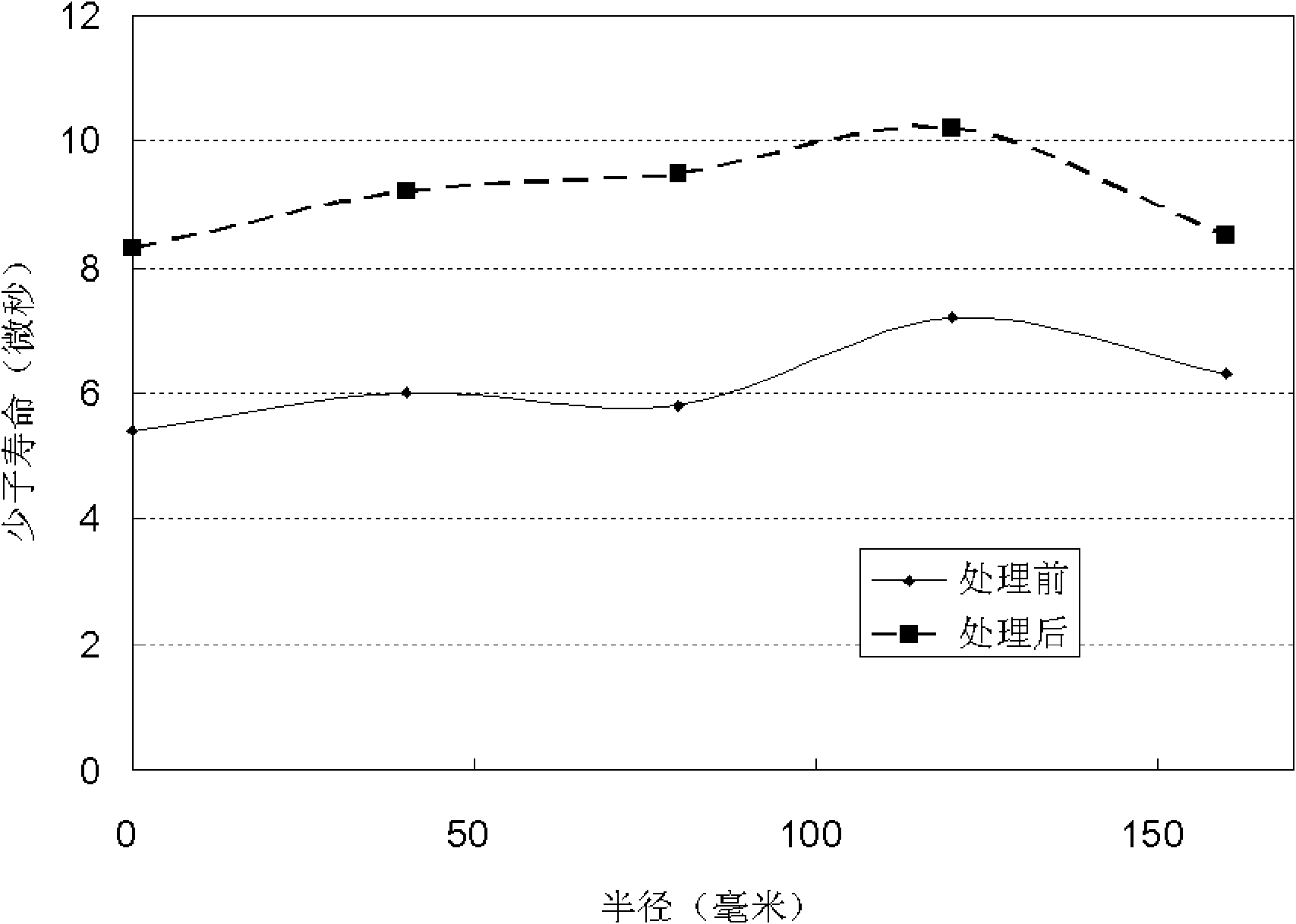

The invention discloses a heat treatment method of a solar-grade silicon crystal, which comprises the steps of placing the silicon crystal into a vacuum heating furnace, introducing protective gas into the vacuum heating furnace and leading the protective gas to flow through the surface of the silicon crystal during the heat treatment process of the silicon crystal, wherein the protective gas is a) gas containing hydrogen atoms; or b) mixture of the gas containing the hydrogen atoms and inert gas. The adoption of the method for carrying out heat treatment on the silicon crystal can significantly prolong the minority carrier lifetime of the silicon crystal, simultaneously regulate the distribution uniformity of radial resistivity of the silicon crystal and lead the resistivity of the silicon crystal to be more uniform on the radius direction of the crystal due to the roles of passivation, impurity absorption and the like of H to impurities and defects in the silicon crystal. The method is simple to operate and easy to carry out industrial production, and can significantly improve the quality of a product.

Owner:GREENERGY CRYSTAL TECH

Novel solar cell P diffusion impurity absorption process

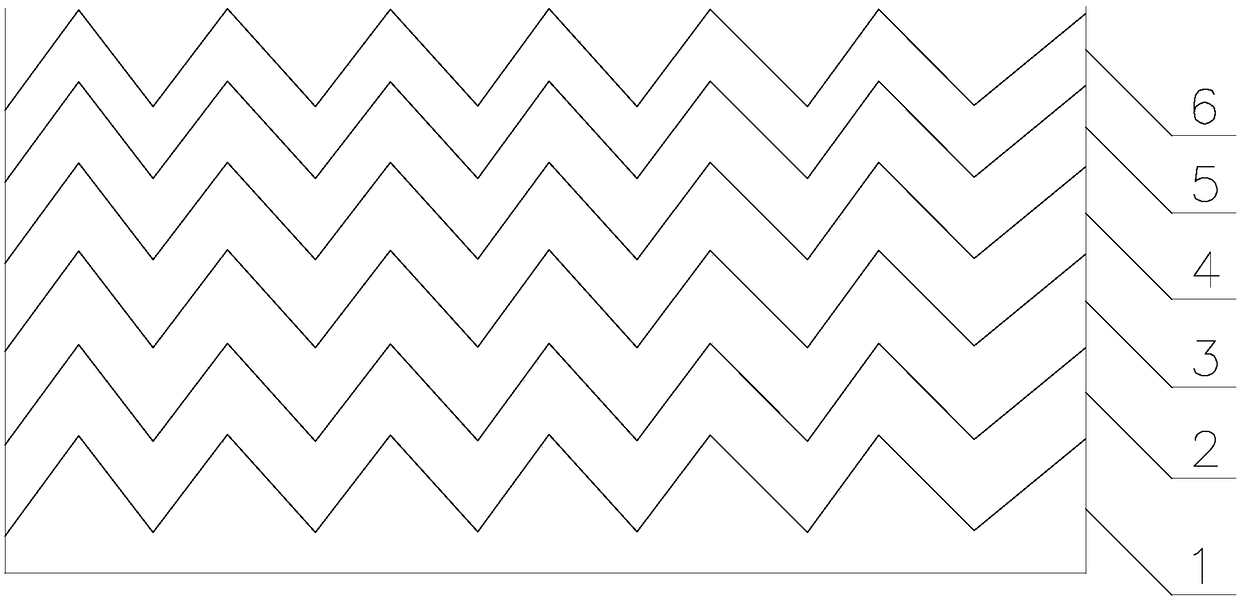

InactiveCN104269456AHigh gettering capacitySatisfy Diffusion NeedsFinal product manufactureSemiconductor/solid-state device manufacturingLow temperature depositionSolar cell

The invention discloses a novel solar cell P diffusion impurity absorption process. The novel solar cell P diffusion impurity absorption process is characterized by including the steps of low temperature feeding, rapid heating, high temperature stabilization, high temperature deposition, high temperature propulsion and oxidation, rapid cooling, low temperature deposition, low temperature propulsion and oxidation and low temperature discharging, wherein according to the high temperature deposition step, 8.5-9 L of N2, 500 ml of O2 and 1000 ml of N2-POCl3 are introduced per minute, the temperature of a furnace tube is controlled to be lower than or equal to 830 DEG C, and 12-13 minutes are consumed; according to the high temperature propulsion and oxidation step, 7.5-8 L of N2 and 800 ml of O2 are introduced per minute, the temperature of the furnace tube is controlled to be lower than or equal to 830 DEG C, and 8 minutes are consumed. The novel solar cell P diffusion impurity absorption process belongs to the varying temperature diffusion technology, can guarantee a good P diffusion effect, can improve the impurity absorption capacity during P diffusion and prolong the minority carrier lifetime of a solar cell, and facilitates promotion of conversion efficiency of the solar cell.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

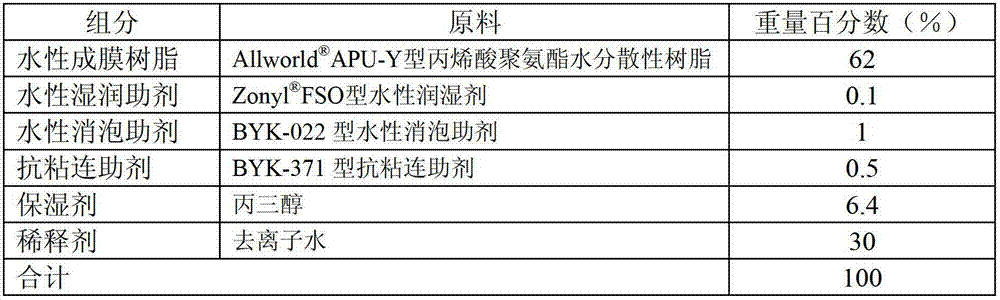

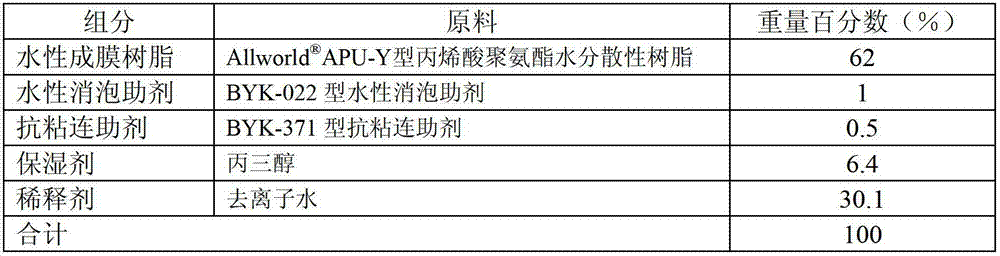

Temporary protective paint composition for water base environment-friendly lens and preparation method of composition

ActiveCN102863894ALow priceReduce surface tensionPolyurea/polyurethane coatingsWater basedTectorial membrane

The invention relates to a temporary protective paint composition for a water base environment-friendly lens and a preparation method of composition. A temporary protective film of the paint composition, which is formed on a coating lens surface, can prevent surface abrasion, impurity absorption and center bias during lens transport, lens storage and lens dispensing processing, and the temporary protective film is easy to remove after lens dispensing processing. The problems of moist coating of water base paint on low surface coating lens surfaces are solved. The paint can replace conventional solvent based coating of the same type and is environment friendly.

Owner:CHINA NAT OFFSHORE OIL CORP +3

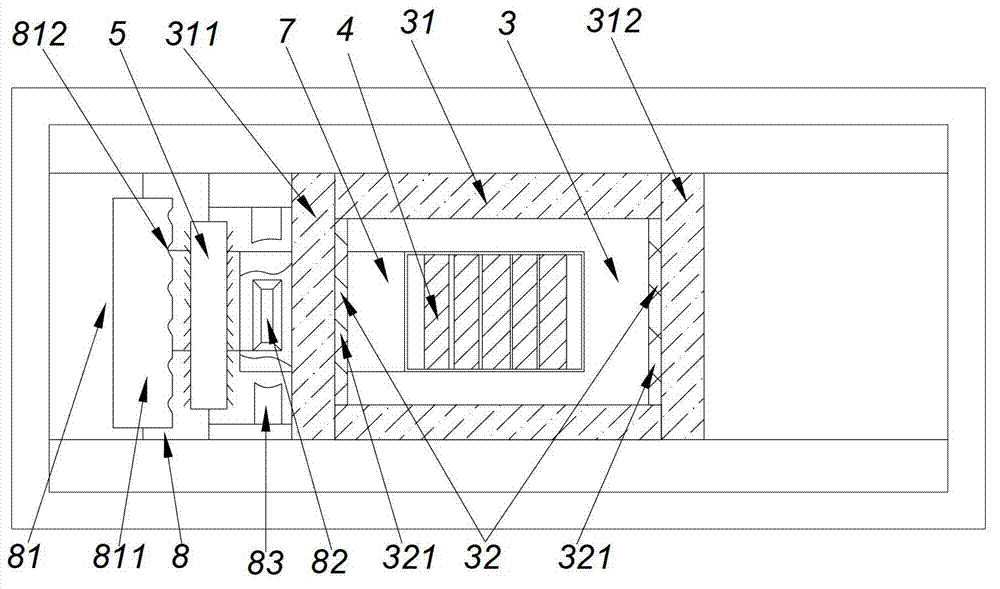

Circulating type automatic iron removing machine

InactiveCN102728460AIncrease the magnetic field strengthImprove adsorption capacityMagnetic separationSoft magnetEngineering

The present invention relates to a circulating type automatic iron removing machine. With the circulating type automatic iron removing machine, a magnetic region used for magnetic separation is designed into a structure with a closed periphery to gather magnetic induction lines and form a closed magnetic circuit of magnetic induction line circulation, circulation of the magnetic induction lines inside the magnetic region is adopted to enhance magnetic field strength, and a clean problem of a magnetic conductive media after iron impurity absorption is effectively solved. The magnetic region is formed by semi-enclosing a soft magnet, wherein the soft magnet is provided with a permanent magnet, the synonym poles of the permanent magnet are located oppositely, and a working chamber is arranged in the magnetic region. The exterior of the magnetic region is provided with a brush body. A pushing device for pushing the magnetic conductive media and a transimisson device for conveying the magnetic conductive media to generate friction between the magnetic conductive media and the brush body are mounted on the working chamber, wherein the pushing device and the working chamber form a head-tail connection. The circulating type automatic iron removing machine of the present invention has characteristics of simple structure, low cost, and high automation degree, and can be widely used in fields of dry powder iron removing and ceramic. With the circulating type automatic iron removing machine of the present invention, iron can be removed completely, and cleaning is performed completely.

Owner:廖明勇

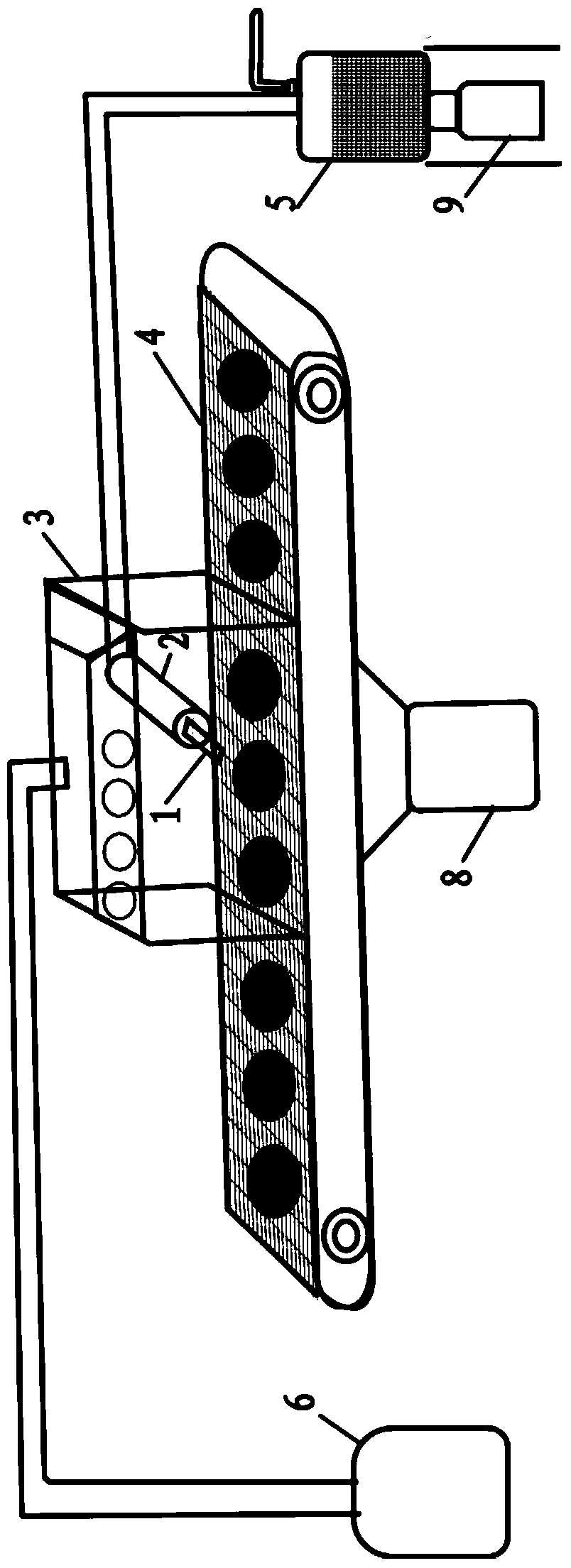

Device for removing oxidation fog on silicon polishing surface by impurity absorption source prepared on back of silicon wafer by sand blasting

ActiveCN103846813ASpray evenlySmall caliberAbrasive machine appurtenancesAbrasive blasting machinesSand blastingSilicon

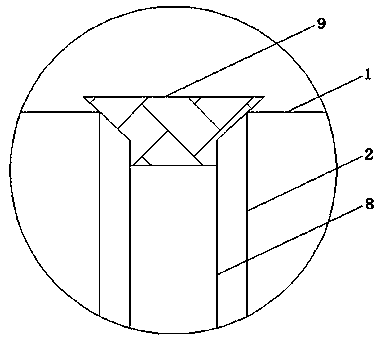

The invention relates to a device for removing oxidation fog on a silicon polishing surface by an impurity absorption source prepared on the back of a silicon wafer by sand blasting. The device comprises a carborundum nozzle, a nozzle moving device, a dust removal air cabinet, a silicon wafer conveyor belt, a carborundum storage tank and a first dust collecting tank, wherein the carborundum nozzle is arranged on the nozzle moving device and is arranged above the silicon wafer conveyor belt; the carborundum nozzle can move left and right above the silicon wafer conveyor belt under the action of the nozzle moving device; the dust removal air cabinet is arranged above the silicon wafer conveyor belt and extends into the upper surface of the silicon wafer conveyor belt from the upper part of the silicon wafer conveyor belt; the carborundum nozzle is arranged in the dust removal air cabinet; the top of the dust removal air cabinet is provided with through holes; the dust removal air cabinet is communicated with the first dust collecting tank by the through holes through a pipeline; the carborundum nozzle is communicated with the carborundum storage tank by a pipeline.

Owner:洛阳杰芯电子科技有限公司

UV makeup process for broad-width holographic embossing mother set

ActiveCN106814576AHas antistatic propertiesImprove adhesion stabilityPhotomechanical apparatusPlate printingElectrical resistance and conductanceAdhesive

The invention discloses a UV makeup process for a broad-width holographic embossing mother set. Antistatic treatment layers are manufactured at a transparent mother set and a plastic basement membrane of a unit board by using a UV makeup adhesive with the antistatic property. The process comprises: making a film sheet; making a mother set and an antistatic treatment layer of a plastic basement membrane; copying the pattern of the mother set unit one by one at the antistatic treatment layer of the plastic basement membrane by using an antistatic UV makeup adhesive until completing all makeup; and carrying out metallization processing to form a metal layer to obtain a broad-width holographic embossing mother set. The Plastic basement membrane thickness is 0.1 to 0.2mm; and the surface resistance value of the anti-static UV makeup coating after curing is 5*10<6>omega. The makeup adhesive has the antistatic property, so that the static electricity generation probability during the whole makeup process can be reduced, floating impurity absorption in air can be avoided, and the makeup quality and the makeup yield can be improved. With the antistatic treatment layer, the attachment stability of the UV makeup adhesive to the basement membrane can be improved, the makeup yield can be improved, and the makeup efficiency can be enhanced.

Owner:WUHAN HUAGONG IMAGE TECH & DEV

Surface cleaning device for drying cylinder

InactiveCN106824843ADoes not affect normal workImprove drying efficiencyDryer sectionCleaning using toolsFiberSurface cleaning

The invention relates to a surface cleaning device for a drying cylinder. The surface cleaning device comprises a chemical spray device, a scraper, a friction roller, a cleaning roller and an impurity absorption device, wherein mist spray sprayed from the chemical spray device is used for prompting sticker particles on a cylinder body of the drying cylinder to be gathered into flocs, so that the binding force between the flocs and the cylinder body of the drying cylinder is significantly reduced; after the flocs and fine fibers rotate to preliminary cleaning of the scraper, second cleaning of the friction roller, third cleaning of the cleaning roller and fourth cleaning of the impurity absorption device along with the drying cylinder, the effect is obvious, the phenomenon of sticking on the cylinder and an accident of paper breaking are avoided, the dried paper surface is also prevented from generating oil spots, and the surface cleaning device is conducive to improvement of the drying operation efficiency of the drying cylinder and reduction of the consumption of the scraper.

Owner:SHANYING INT HLDG CO LTD

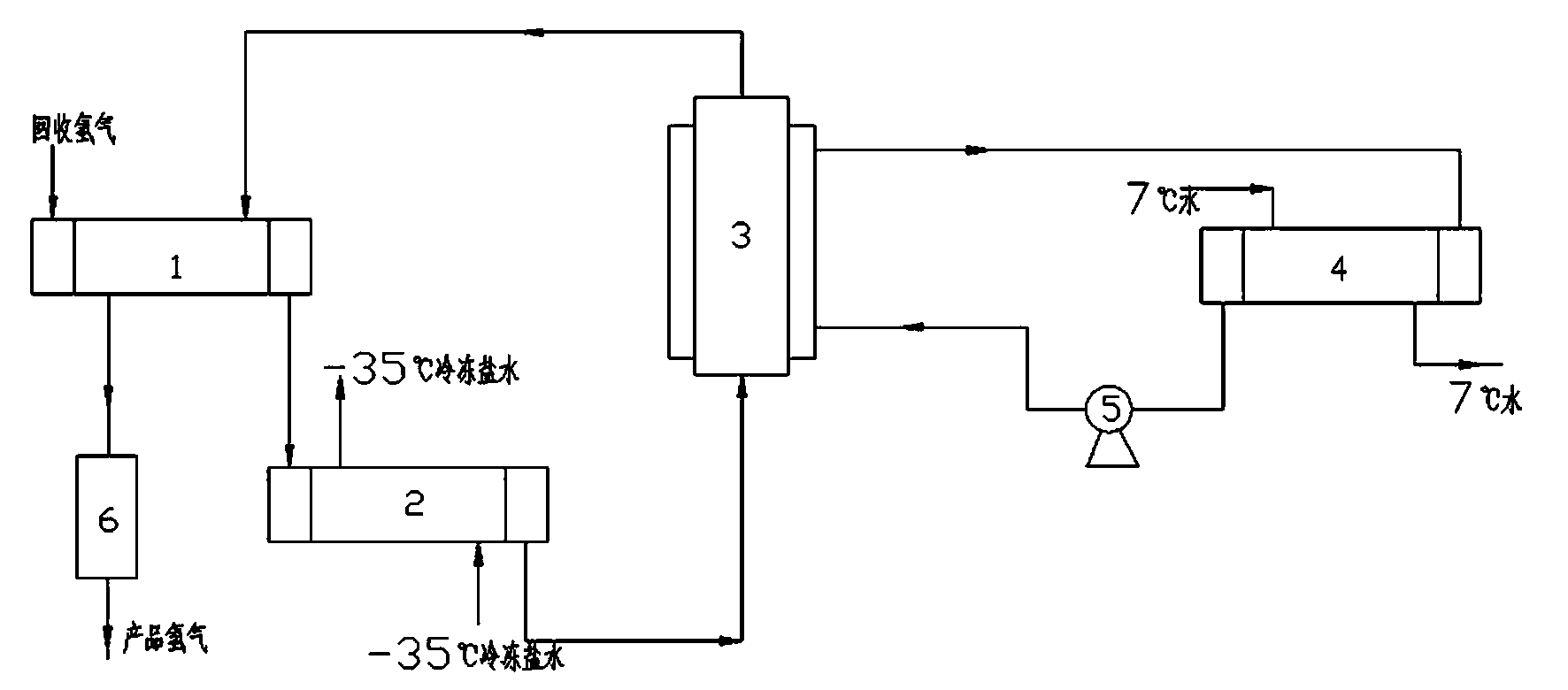

Treatment process for purifying recycled hydrogen during production of electronic-grade polycrystalline silicon

ActiveCN103588170AReduce contentMeet production requirementsHydrogen separationSilicon compoundsActivated carbonHydrogen

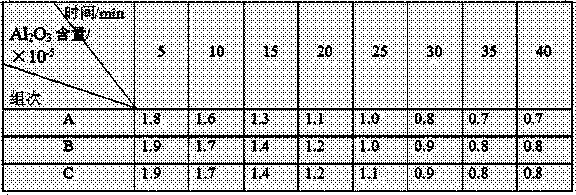

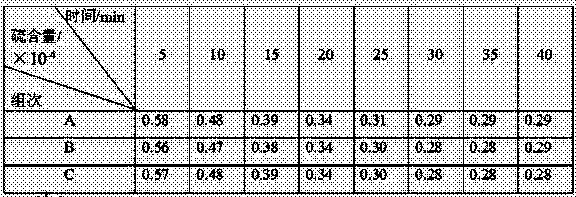

The invention relates to the field of gas separation and purification engineering, provides a treatment process for purifying recycled hydrogen during production of electronic-grade polycrystalline silicon and aims to solve the problem that the production of the electronic-grade polycrystalline silicon is influenced due to the fact that the content of impurities such as BCl3, borane, phosphine, PCl5, POCl3 and the like in hydrogen cannot be effectively reduced although activated carbon is adopted for absorbing and purifying recycled hydrogen during the production of the electronic-grade polycrystalline silicon. According to the purification scheme, the recycled hydrogen is pre-cooled and then cooled to the temperature below 0 DEG C, and then, the hydrogen is fed into a modified aluminum oxide absorber for impurity absorption and filtered by a filter, so that the purity of the hydrogen reaches 99.999% (V / V), and the production requirement of the electronic-grade polycrystalline silicon is met. The treatment process has the benefits of simplicity, easiness in operation, obvious purification effect and the like.

Owner:XINTE ENERGY

Low-pressure diffusion and low-temperature oxidation gettering process

InactiveCN110323304AHigh gettering capacitySatisfy Diffusion NeedsFinal product manufacturePhotovoltaic energy generationLow temperature depositionPressure stabilization

The invention provides a low-pressure diffusion and low-temperature oxidation gettering process, and belongs to the field of solar cell gettering processes. The method comprises the steps: low-temperature normal-pressure boat entry, rapid low-pressure heating, high-temperature normal-pressure stabilization, high-temperature low-pressure oxidation, four-step high-temperature low-pressure source communication and knot pushing, long-time cooling, oxidation and impurity absorption, rapid normal-pressure cooling and low-temperature deposition, and low-temperature boat exit. The furnace tube is rapidly cooled for a long time through the steps of cooling, oxidizing and gettering for a long time and controlling the oxygen flow, so that the uniformity and repeatability of diffusion sheet resistanceare improved, the surface doping concentration and junction depth are optimized, the internal defects of a silicon wafer are reduced, and the conversion efficiency of the solar cell is improved.

Owner:江苏润阳悦达光伏科技有限公司

Medication separation and extraction apparatus

InactiveCN105107226AHeating evenlyImprove puritySolid solvent extractionFiltration circuitsTemperature controlActivated carbon

The present invention discloses a medication separation and extraction apparatus, and relates to the technical filed of medication separation apparatuses. The apparatus is characterized in that: an extraction case body is provided with a cavity design, a heating pipe is provided windingly inside the cavity, a waste outlet is provided at the bottom of the extraction case, a temperature sensor and a liquidometer are provided respectively on an inner side wall of the extraction case, the temperature sensor is connected with a temperature controller, and the temperature controller is connected with the heating pipe, the liquidometer is connected with an alarm, a feed inlet is provided on the top of the extraction case, the extraction case is connected with a stirring tank by a medicinal liquid delivering pipe, a filter screen is provided inside the medicinal liquid delivering pipe, and the medicinal liquid delivering pipe is mounted with a one-way valve, and a stirring apparatus is provided inside the stirring tank. According to the present invention, a structure design is reasonable and novel, the heating pipe is provided with a uniformly winding design, and therefore the extraction case can be heated more uniformly, and an activated carbon adsorption net is provide in the stirring apparatus, and is capable of impurity absorption, so that the medication is good in purity, and the whole process is convenient in operation, the device is stable and reliable in running and high efficient in extraction and seperation.

Owner:HUBEI UNIV FOR NATITIES

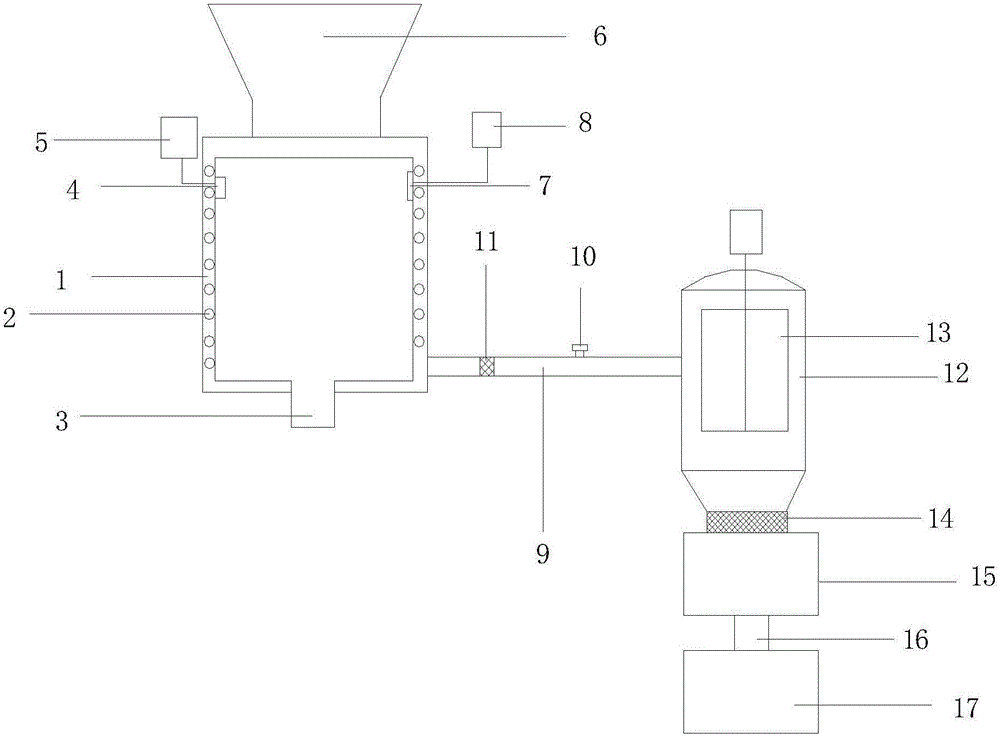

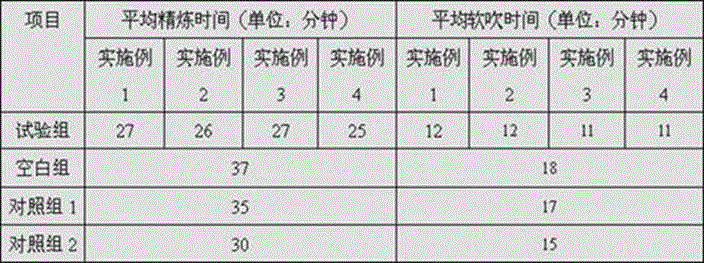

Compound slag cleaning agent for electric furnaces and converters and preparation method thereof

ActiveCN105132630AReduce smelting costReduce refining timeProcess efficiency improvementElectric arc furnaceSlag

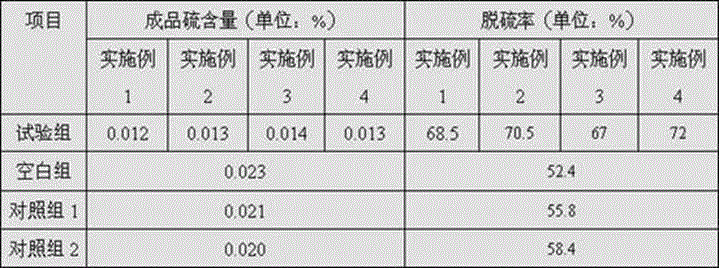

The invention provides a compound slag cleaning agent for electric furnaces and converters and a preparation method thereof, and belongs to the technical field of metallurgical auxiliary materials. The compound slag cleaning agent comprises the following components in percentage by weight: calcium oxide 30-50%, alumina oxide 20-40%, barium oxide 5-20%, magnesium oxide 3-15%, and a reducing agent 5-15%. The comprehensive performance of the slag cleaning agent is outstanding the deoxidization, desulphurization and dephosphorization effect of the existing slag cleaning agent is improved and increased, the LF refining time is obviously shortened, the impurity absorption capacity is good, impurities are not introduced during smelting of molten steel; moreover, the kinds and proportion of the raw materials are reasonable, so that compared with the existing dephosphorization slag cleaning agent, the cost of the compound slag cleaning agent is obviously reduced, and the compound slag cleaning agent has obvious market advantage.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Device and method for deposition of silicon-based polycrystalline silicon film

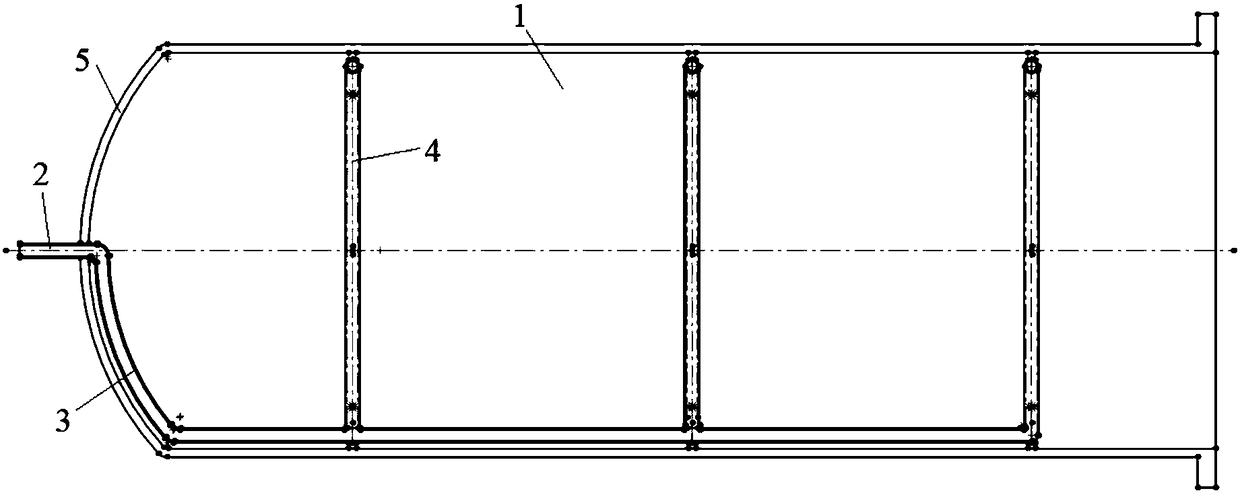

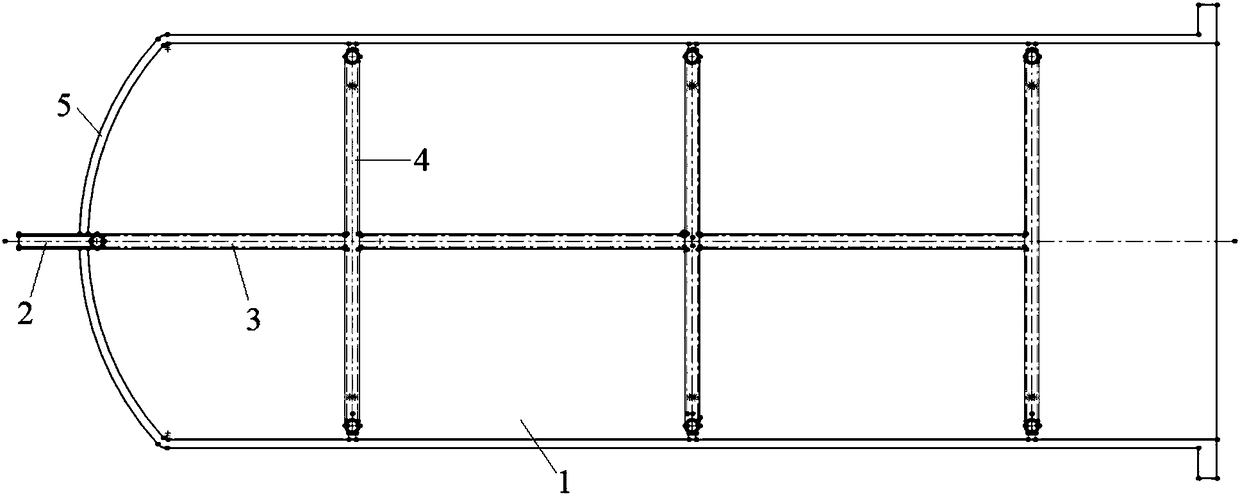

InactiveCN108179468AEasy to installGood gettering performance of membrane qualityPolycrystalline material growthSingle crystal growth detailsEngineeringGuide tube

The invention discloses a device and a method for deposition of a silicon-based polycrystalline silicon film. The device comprises a main deposition chamber, a gas inlet pipe, a main gas conveying passage, an auxiliary gas conveying passage, gas dispersion holes and a sealing flange, wherein the main gas conveying passage and the auxiliary gas conveying passage are mounted in the main deposition chamber, and the auxiliary gas conveying passage is vertically connected with the main gas conveying passage; one end of the gas inlet pipe is connected with the main gas conveying passage through thesealing flange, and the other end is connected with a source gas MFC located outside the main deposition chamber; the gas dispersion holes are uniformly distributed in the auxiliary gas conveying passage. According to the device, single-tube growth can be realized, no independent gas guide tubes are used, mounting is quite simple, and the technology is simple to adjust. The film produced by the device has good impurity absorption performance, in-chip and inter-chip uniformity is small, and growth cost is reduced.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

PERC battery back passivation process

InactiveCN109192813AReduce thicknessImprove reflectivityFinal product manufactureSemiconductor devicesSilicon oxideNanotechnology

The invention relates to a PERC battery back passivation process. During the perc battery process, flocking, diffusing, phosphorus wash, and then silicon oxide is first oxidized on the back surface ofthe passivation layer after the phosphorus is washed. Then add alumina, heat treatment process, back silicon nitride using four layers and multi-layers, adding one step of silicon oxide passivation before alumina passivation, can reduce alumina thickness, reduce alumina raw material reaction cost, increase long-wave reflection, improve conversion efficiency, and increase short-circuit current ofperc battery Compared with the prior art, the backside passivation process of the PERC battery provided by the invention can keep the same efficiency with the prior art and improve the efficiency by 0.10%, and the passivation and impurity absorption effects are improved.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Preparation method of planar triode chip

ActiveCN105428234ASolve the voltage dropSolve the characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesPlatinumMetal impurities

The invention relates to the field of triode manufacturing, and particularly relates to a preparation method of a planar triode chip. According to the preparation method of the planar triode chip, the surface of a silicon wafer is cleaned, and then oxidation and photoetching processing is performed on the surface of the silicon wafer; boron diffusion, phosphorus diffusion and platinum diffusion are performed on the obtained silicon wafer so that a composite center is formed; metal impurities on the surface of the composite center are removed by a phosphorus diffusion impurity absorption technology; and steam aluminum, alloy, passivation, back thinning and back metallization processing is performed on the silicon wafer of which the metal impurities are removed so that the planar triode chip is obtained. A triode is prepared by the platinum diffusion technology so that production cost is greatly reduced, and the preparation method is suitable for batch production of the triode.

Owner:CHINA ZHENHUA GRP YONGGUANG ELECTRONICS CO LTD STATE OWNED NO 873 FACTORY

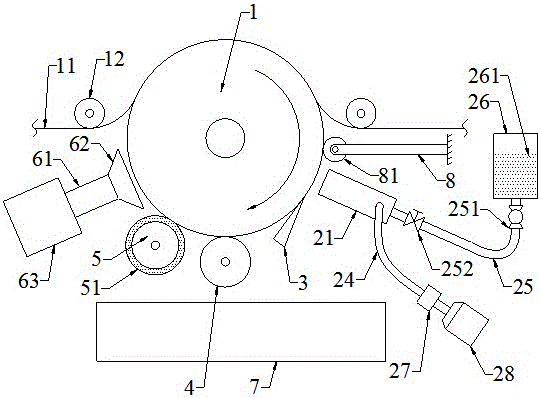

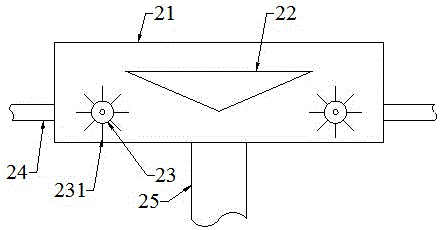

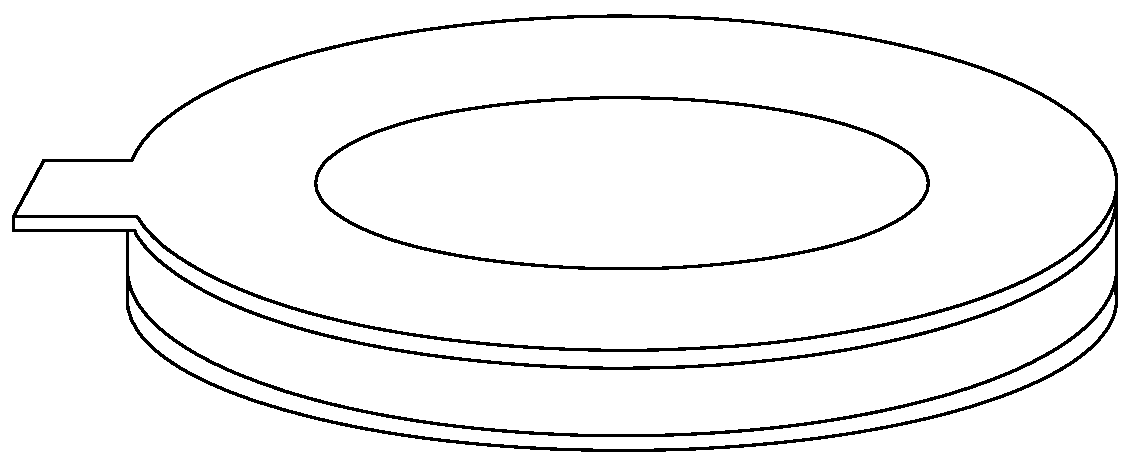

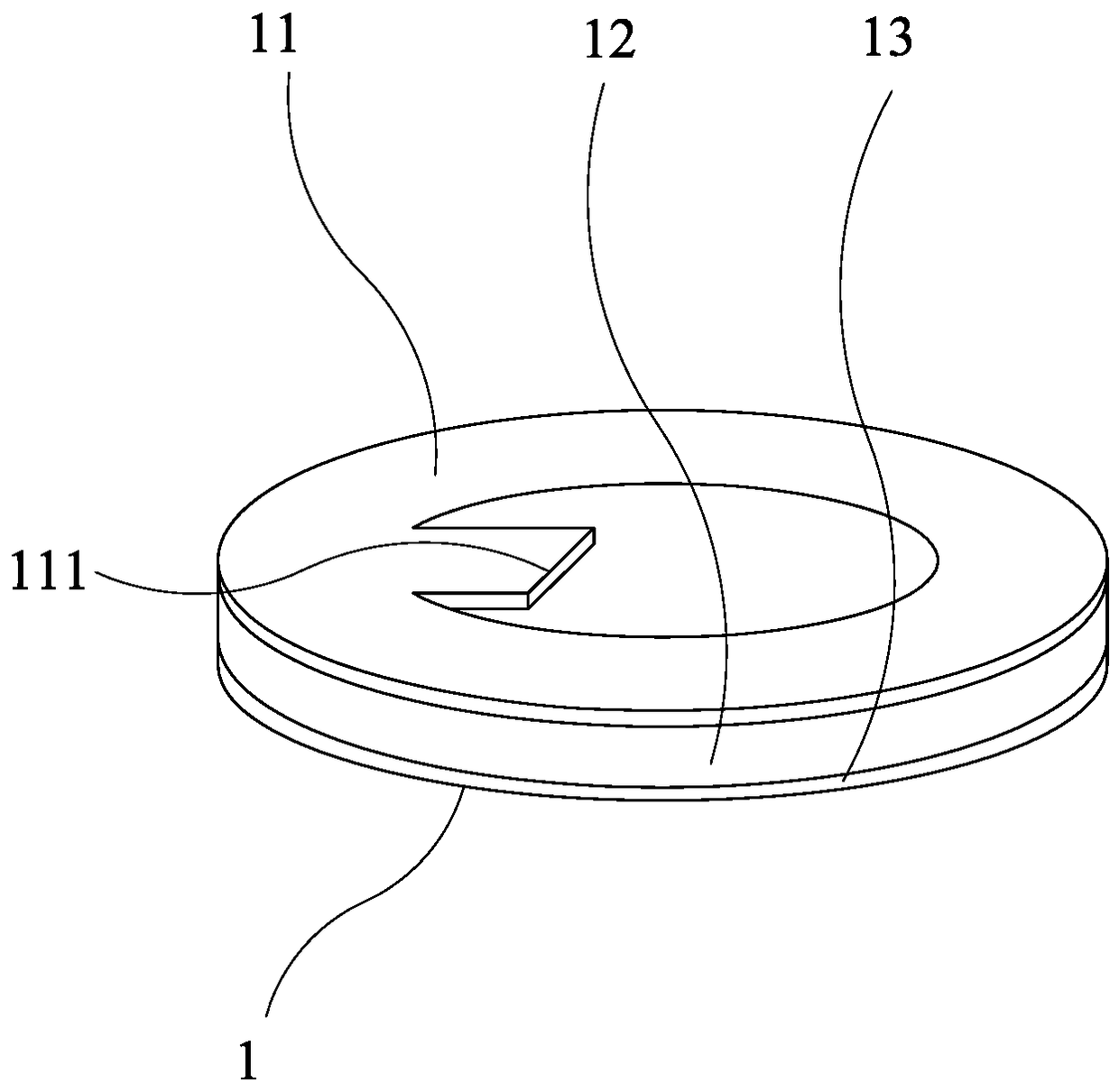

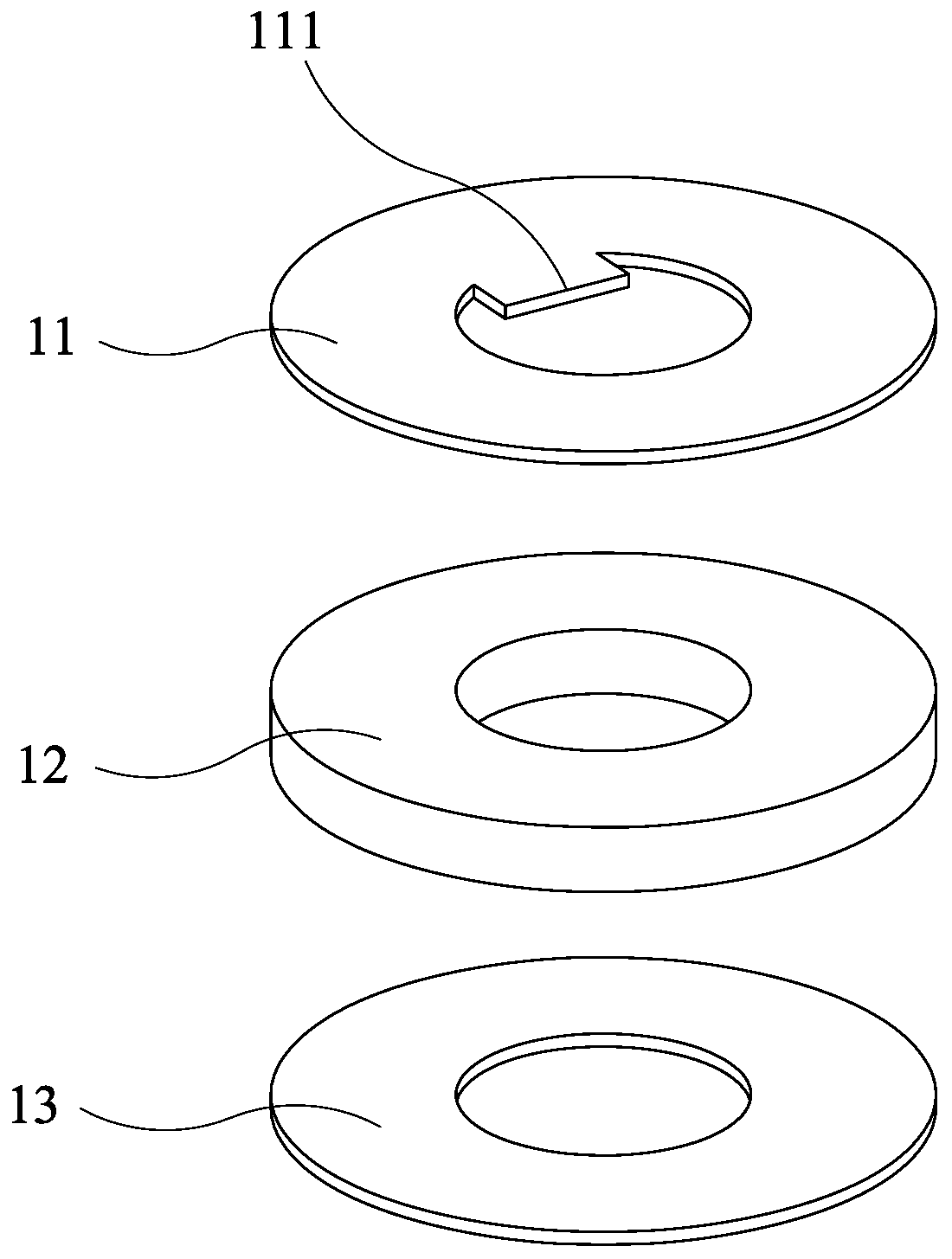

Annular double-sided adhesive tape and equipment and technology for producing annular double-sided adhesive tape

PendingCN109015893AAvoid drawingAvoid adsorptionLaminationLamination apparatusEngineeringMechanical engineering

Owner:汇精(厦门)电子科技有限公司

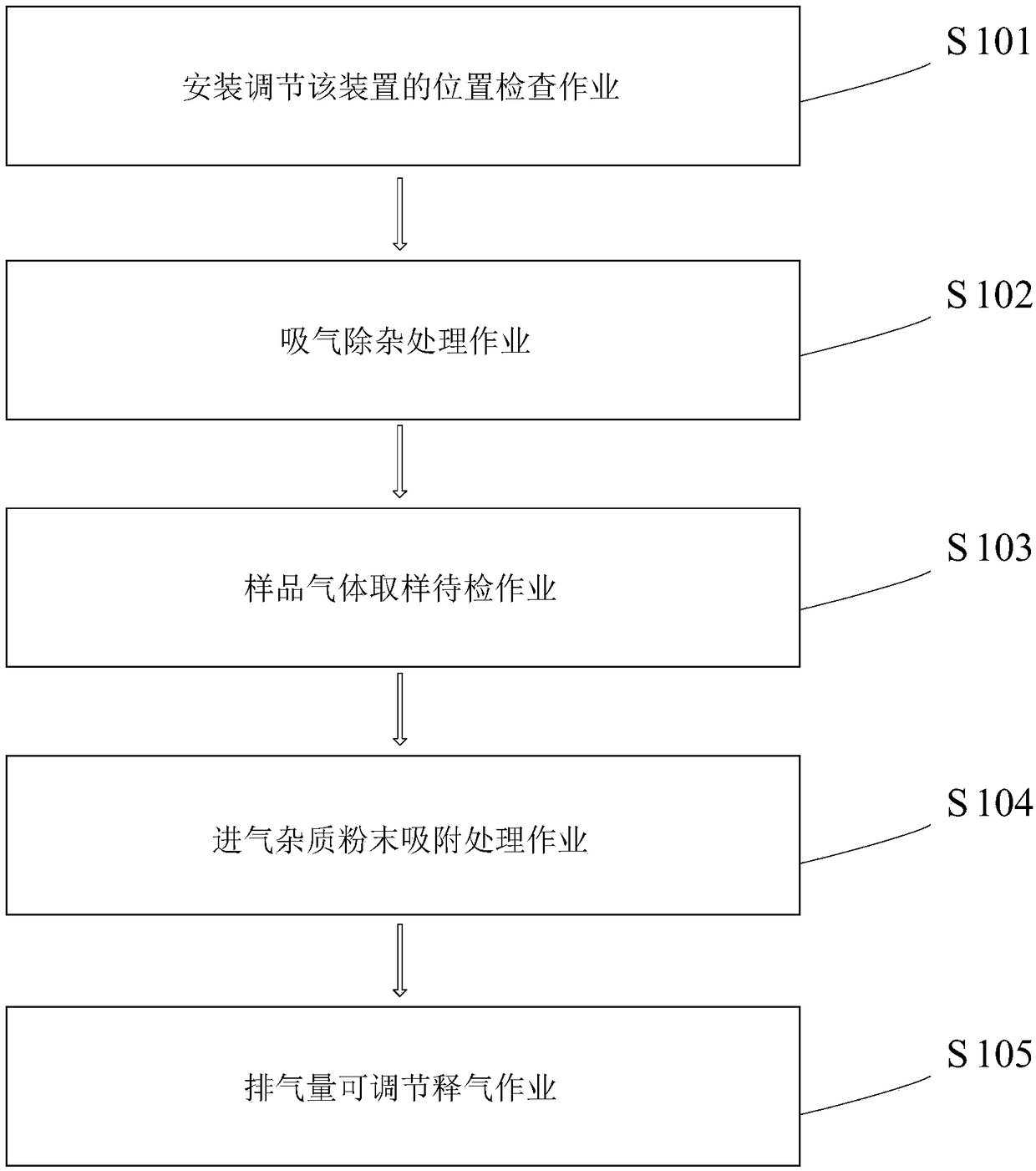

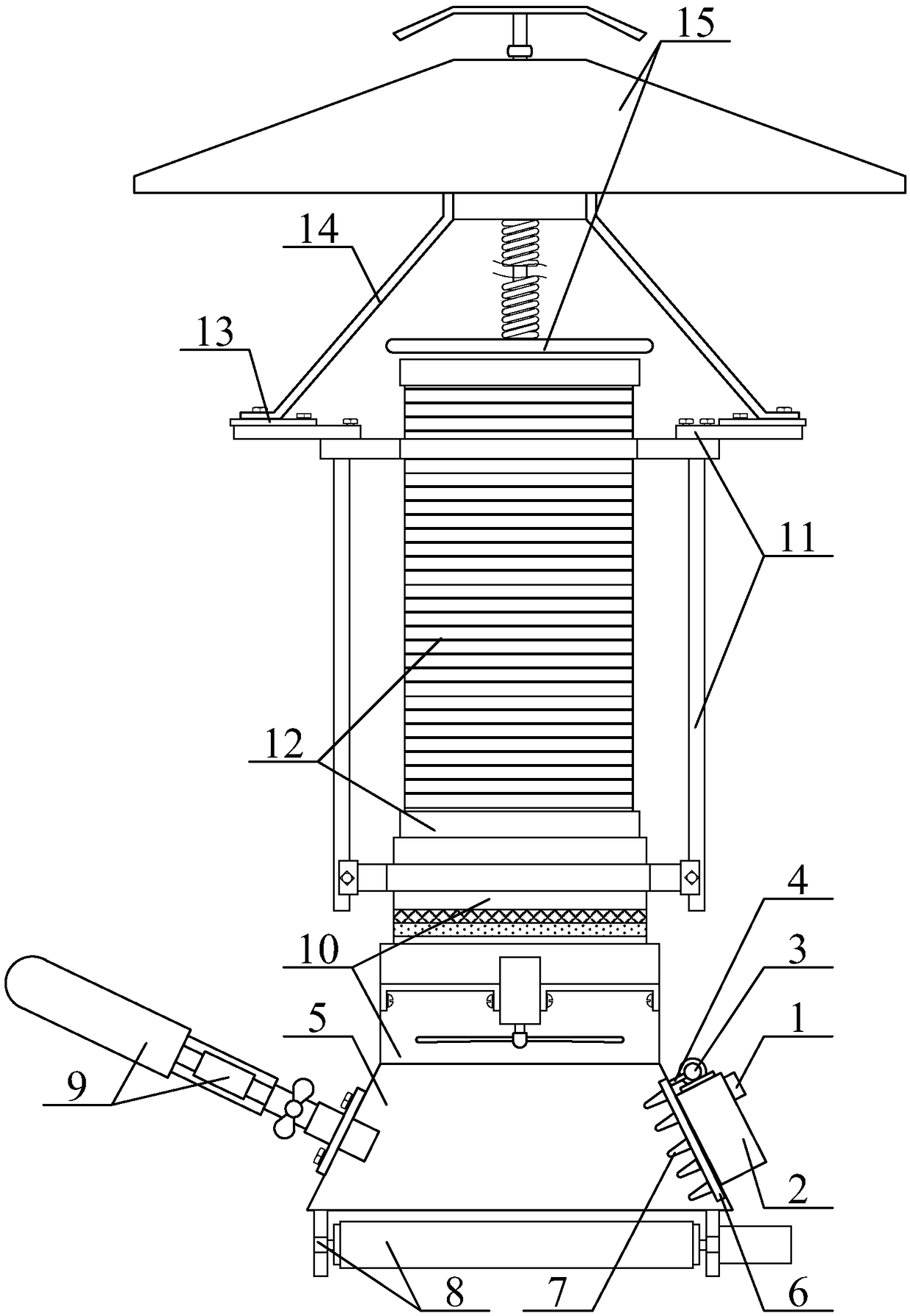

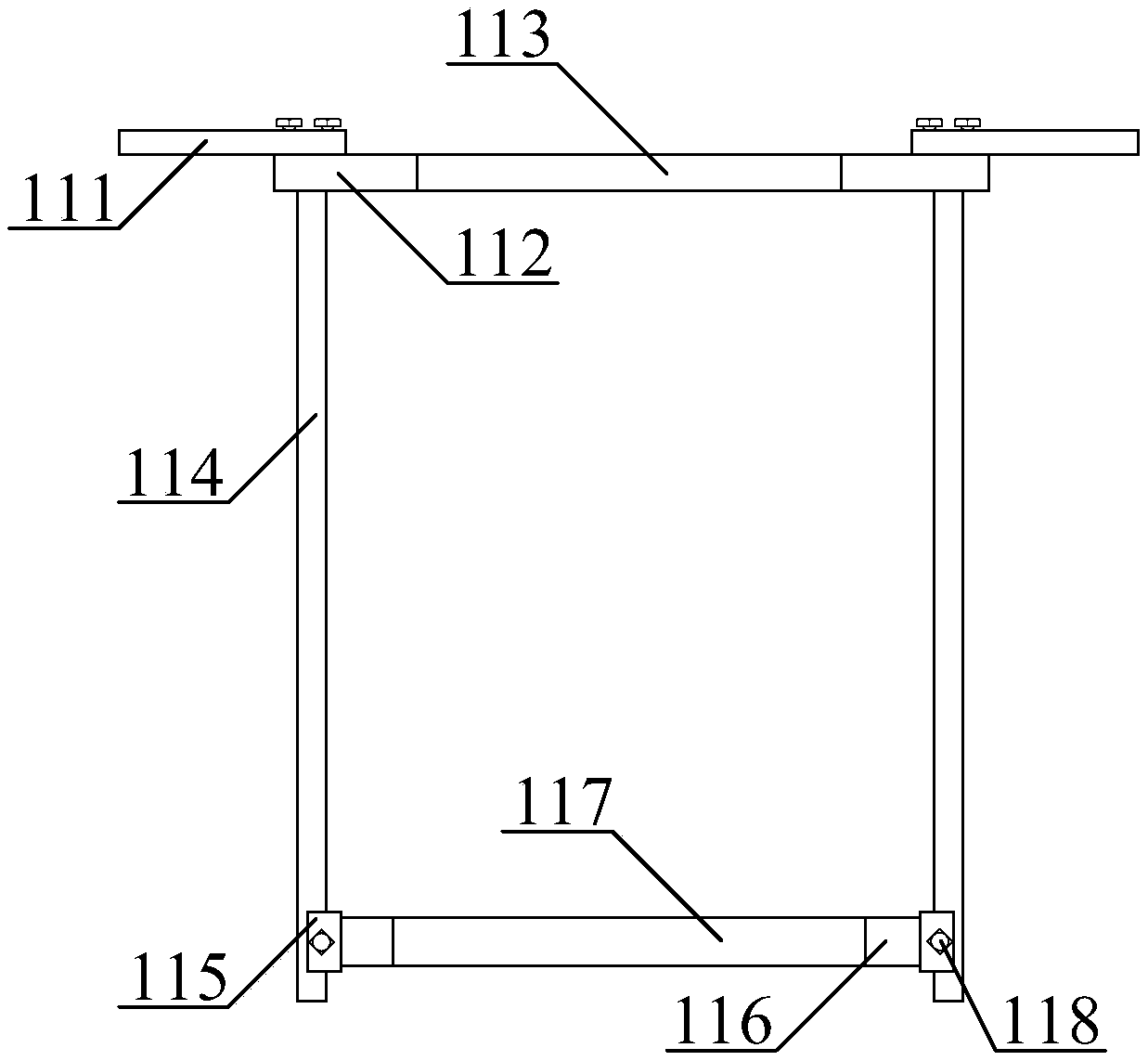

Environment-friendly gas absorption device used in chemical workshop, and using method of environment-friendly gas absorption device

ActiveCN108854281AGuaranteed to be environmentally friendlyNo pollution in the processDispersed particle filtrationSpray nozzleEngineering

The invention provides an environment-friendly gas absorption device used in a chemical workshop. The device comprises a rubber cap, a chemical agent tank, a suction pump, a liquid guiding tube, a gasabsorption hood, a chemical agent spray strip, spray nozzles, an air impurity absorption wheel structure, a gas sample absorption and return bottle structure, a gas impurity filter gas-suction guidefan, an adjustable quick mounting rack, a gas guide metal hose, a connecting seat, a support frame and an exhaust volume adjustable baffle cover structure, wherein the rubber cap is connected with anentrance at the right upper part of the chemical agent tank by means of screw threads. The environment-friendly gas absorption device solves the problems that the installation height cannot be adjusted, environmental pollution is easily caused by the improperly treated gas, the gas in the workshop cannot be sampled and detected, the fine particles cannot be absorbed before the gas is exhausted, and the gas output is not conveniently adjusted timely.

Owner:江苏爱科固体废物处理有限公司

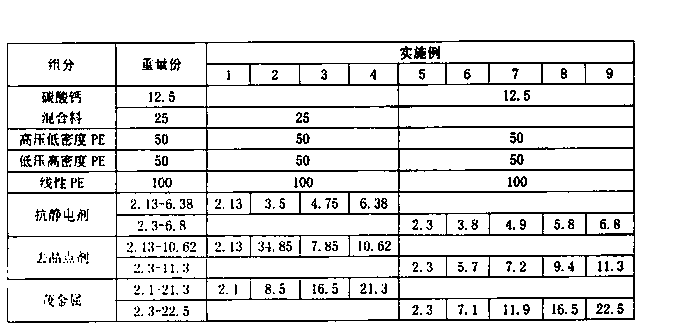

CPE pattern isolating membrane of glass interlayer PVB membrane and production method thereof

ActiveCN103881228ALess crystal pointImprove longitudinal strengthLow-density polyethyleneLinear low-density polyethylene

The invention relates to a CPE pattern isolating membrane of a glass interlayer PVB membrane. The CPE pattern isolating membrane is prepared from the following components in parts by weight: 12.5 or 25 parts of calcium carbonate mixed material, 50 parts of high pressure low density polyethylene, 50 parts of low pressure high density polyethylene, 100 parts of linear high pressure low density polyethylene, 2.13-6.38 or 2.3-6.8 parts of PE antistatic agent, 2.13-10.62 or 2.3-11.3 parts of PE-A crystal point removing agent and 2.1-21.3 or 2.3-22.5 parts of metallocene. The rolled isolating membrane product is colorless and semitransparent, the thickness is 20+ / -2 mu m, the gram per square meter is less than or equal to 20+ / -2, the surface detail height is less than 100 mu m, the vertical strength is greater than 10MPa, the vertical or lateral elongation is greater than 150%, and the lateral strength is greater than 8MPa. The product is prepared by the following six steps: preparation of the calcium carbonate mixed material; stocking; mixing; casual inspection; drying; feeding. The isolating membrane prepared is weak in static electricity, unremarkable in hitting people, difficult in dust collection and impurity absorption, high in rate of graded product, few in crystal point, flat and smooth in surface, high in membrane strength and good in malleability.

Owner:TIANTAI JIUDING PLASTIC CO LTD

Efficient composite slag lotion

InactiveCN104073598AImprove liquidityLow viscosityProcess efficiency improvementSlagEconomic benefits

The invention discloses efficient composite slag lotion which comprises the following raw materials in percentage by weight: 49-70% of calcium powder, 20-45% of aluminum ash, 5-12% of high-alumina cement and 0.5-2.0% of sodium carboxymethylcellulose. The calcium powder, the aluminum ash and the high-alumina cement are applied to synergic desulfuration, and are used for mutually filling and refining the porous structure of the slag lotion, and the obtained efficient composite slag lotion is good in deoxidation and desulfuration effect and impurity absorption effect and rapid in slagging speed, and has a remarkable function in improving the comprehensive economic benefits of steel plate companies.

Owner:河南鹏钰集团有限公司

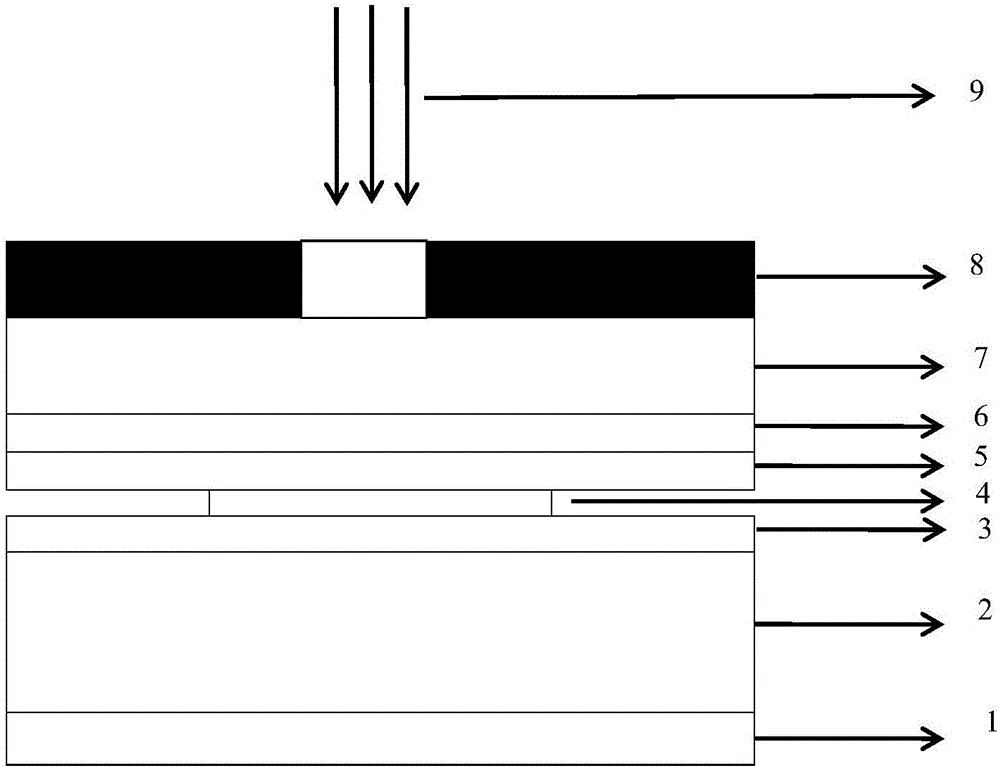

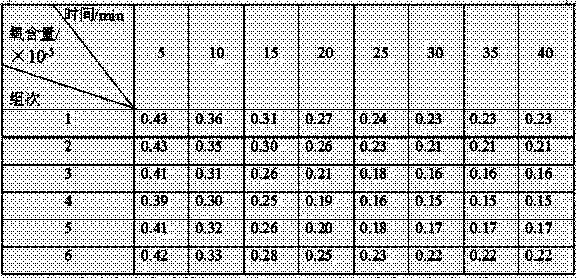

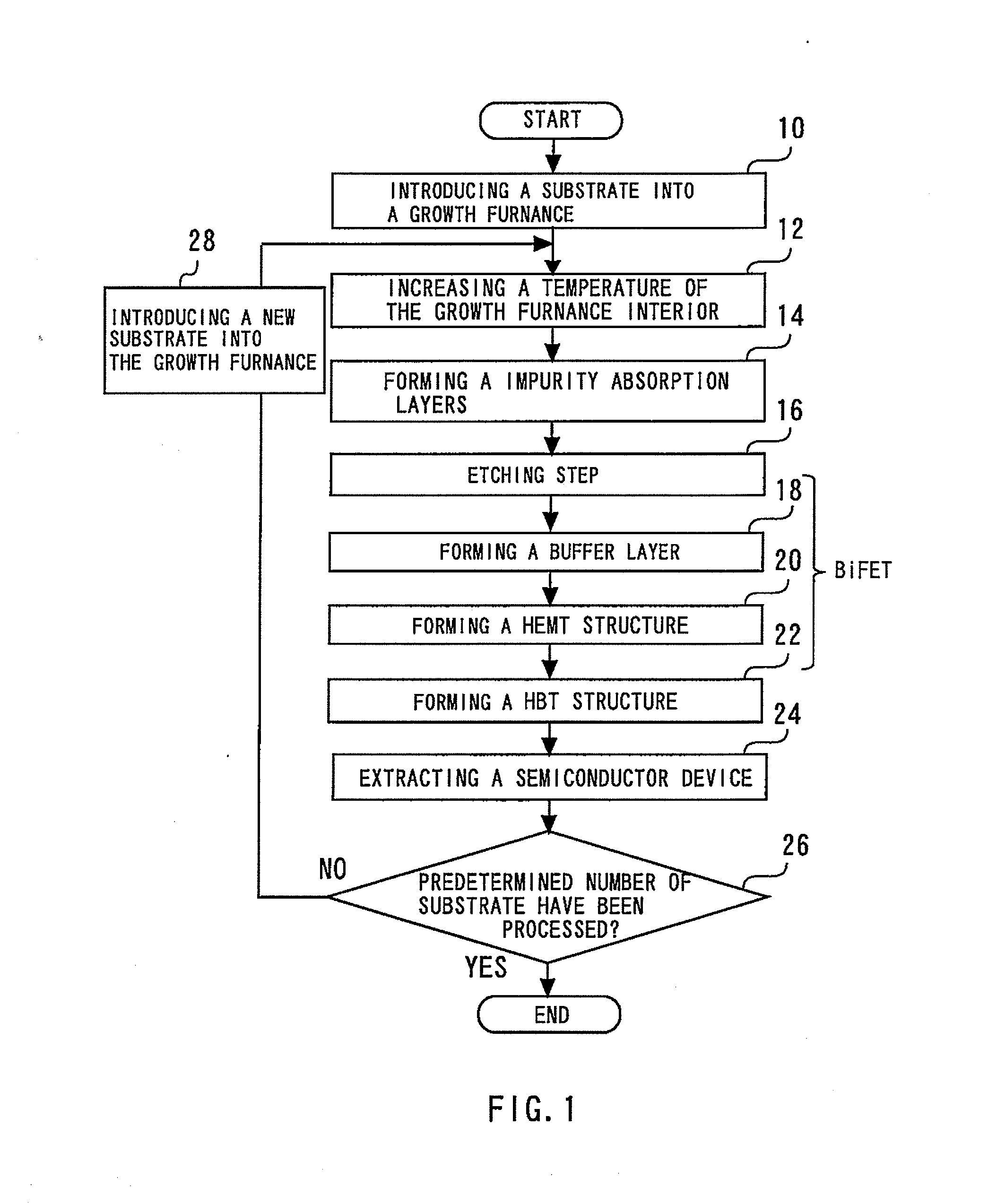

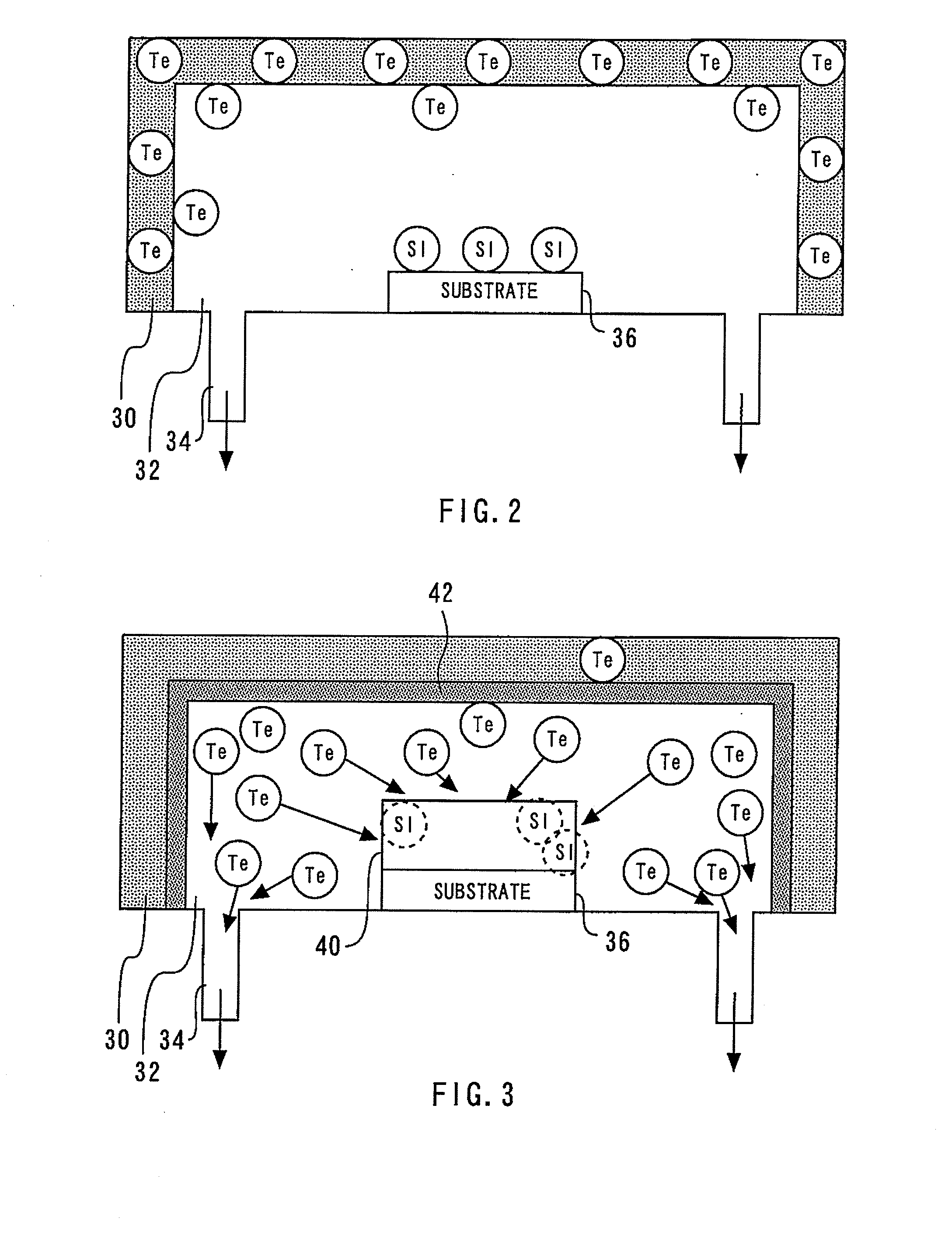

Method of manufacturing semiconductor device

InactiveUS20130109134A1Semiconductor/solid-state device manufacturingSemiconductorSemiconductor device

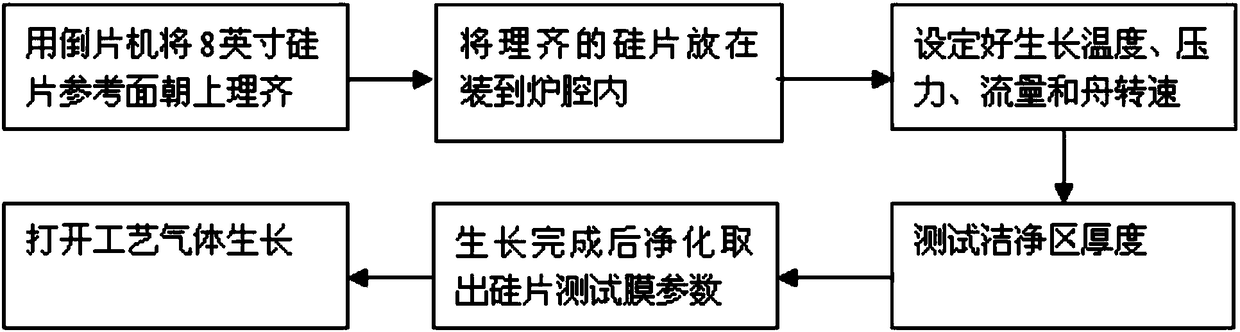

A method of manufacturing a semiconductor device, includes introducing a substrate into a growth furnace, forming impurity absorption layers on the substrate and on inner walls of the growth furnace, the impurity absorption layers absorbing impurities on a surface of the substrate and impurities in the growth furnace, etching and removing the impurity absorption layers and a portion of the substrate to produce a thinned substrate, forming a buffer layer on the thinned substrate, and forming semiconductor layers on the buffer layer.

Owner:MITSUBISHI ELECTRIC CORP

Comprehensive sewage purifying treatment equipment for environmental engineering

ActiveCN107555675AImprove adsorption efficiencyImprove processing efficiencyMultistage water/sewage treatmentTreatment effectSludge

The invention relates to comprehensive sewage purifying treatment equipment for environmental engineering. The equipment comprises a heavy metal processor, a multi-medium filter and a treatment purifier which are connected with one another integrally. The filtered outlet of the heavy metal filter is connected to a water inlet pipe of the multi-medium filter, and the discharge opening of the multi-medium filter is connected to a water inlet pipeline of the treatment purifier. The heavy metal processor has high impurity absorption efficiency, and can treat heavy metals in water through adsorption, centrifugation and electrolysis separately, so that the heavy metal sludge treatment efficiency and quality are improved effectively. The multi-medium filter has the advantages of circular filtering treatment, good filter effect and no waste of water resources and a leaker is less prone to blockage. The treatment purifier has an effect of detecting the water quality, can perform reflux treatment on sewage, and is good in sewage treatment effect.

Owner:江湖境道(武汉)环境工程有限公司

Impurity elimination device

ActiveCN106284624AGuaranteed accuracyFatty/oily/floating substances removal devicesSewerage structuresImpellerEngineering

An impurity elimination device is applied to a filtering frame of a water inlet of a sewer. The device comprises an impurity absorption body inserted in the filtering frame, a square absorption opening is formed in the side wall of the absorption body, an impurity elimination plate is arranged on the lateral side of the filtering frame and connected with the absorption body through a driving mechanism, and the elimination plate is provided with a square-frame-shaped cutter matched with filtering meshes of the filtering frame. When impurities in the filtering frame are cleaned away, the driving mechanism drives the elimination plate to move horizontally to the side wall of the filtering frame, the cutter penetrates through the filtering meshes and then is inserted the absorption opening, then an impeller assembly on an absorption cavity acts so that negative pressure can be formed in the absorption cavity, and accordingly the impurities eliminated by the cutter are absorbed.

Owner:江苏星瑞机械设备有限公司

Preparation method of collagen

InactiveCN109053878AHigh purityImprove adsorption capacityConnective tissue peptidesPeptide preparation methodsFiberSolvent

Owner:FOSHAN SENANG BIO TECH CO LTD

Automatic electric processing platform

InactiveCN109249357AEffective absorptionReduce manual operationsDirt cleaningWork benchesEngineeringDust collector

The invention relates to the technical field of processing platforms, in particular to an automatic electric processing platform, which comprises a processing platform, wherein through holes are fixedly formed in the inner wall of one end of the processing platform; the four corners of the bottom of the processing platform are fixedly connected with frames; a support plate is fixedly connected tothe top end of one side wall near the middle of the processing platform of the frame; an impurity storage box is fixedly arranged on the top wall of one side wall of the support plate near the throughhole; a first recycling pipe is fixedly connected to an opening on one side wall far away from the middle of the support plate of the impurity storage box; a dust collector is fixedly connected to one end of the first recycling pipe far away from the impurity storage box; a second recycling pipe is fixedly connected to an opening at the top of the dust collector; an impurity absorption cover is fixedly connected to the top end of the second recycling pipe; an intelligent electric cabinet is fixedly arranged at the top of one end of the support plate far away from the dust collector; and a processing observation cover is fixedly arranged on the top wall of the processing platform. The platform is scientific and reasonable in overall structural design, relatively scientific and practical inautomatic processing, and has certain use value and popularization value.

Owner:潍坊晟源新能源机械设备有限公司

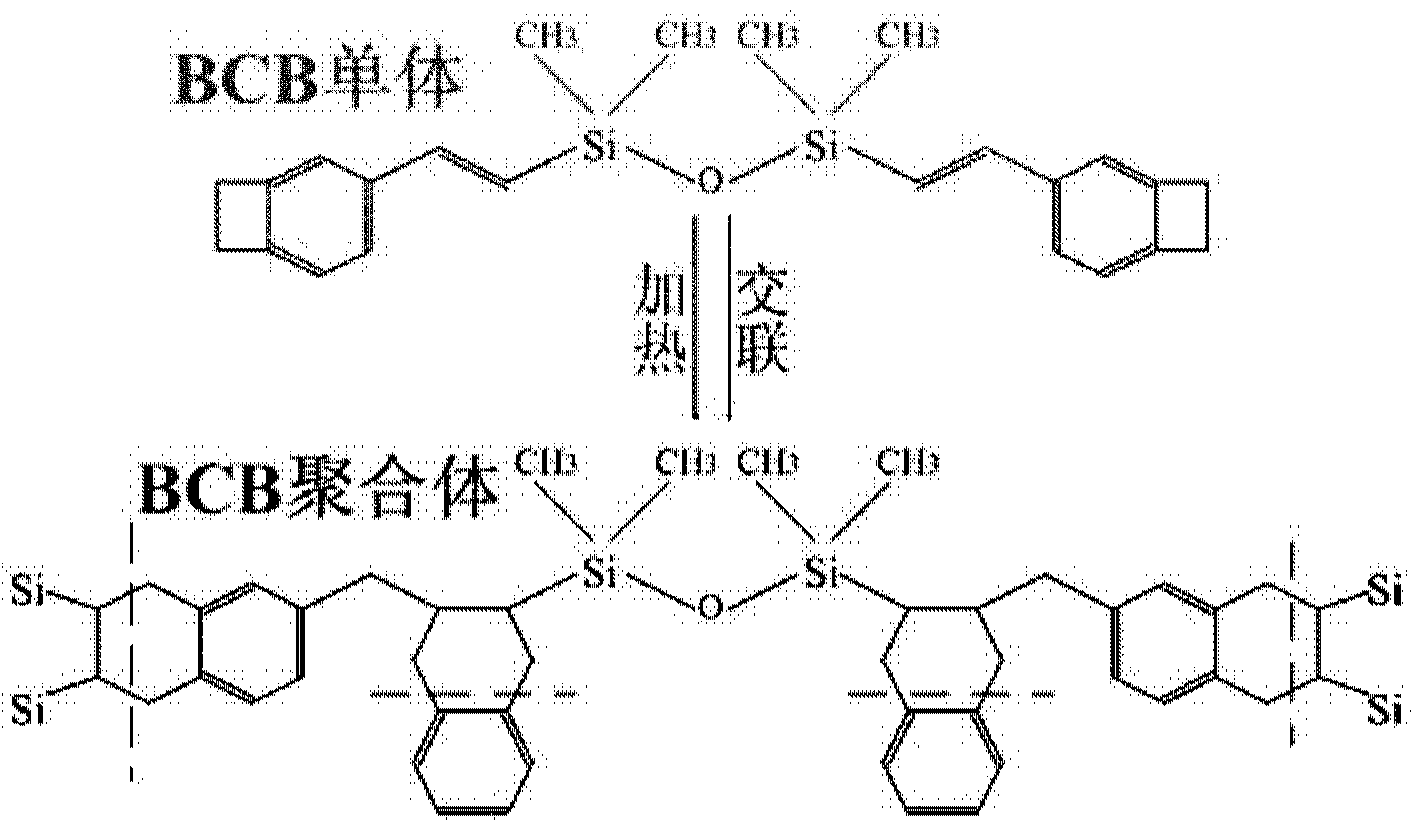

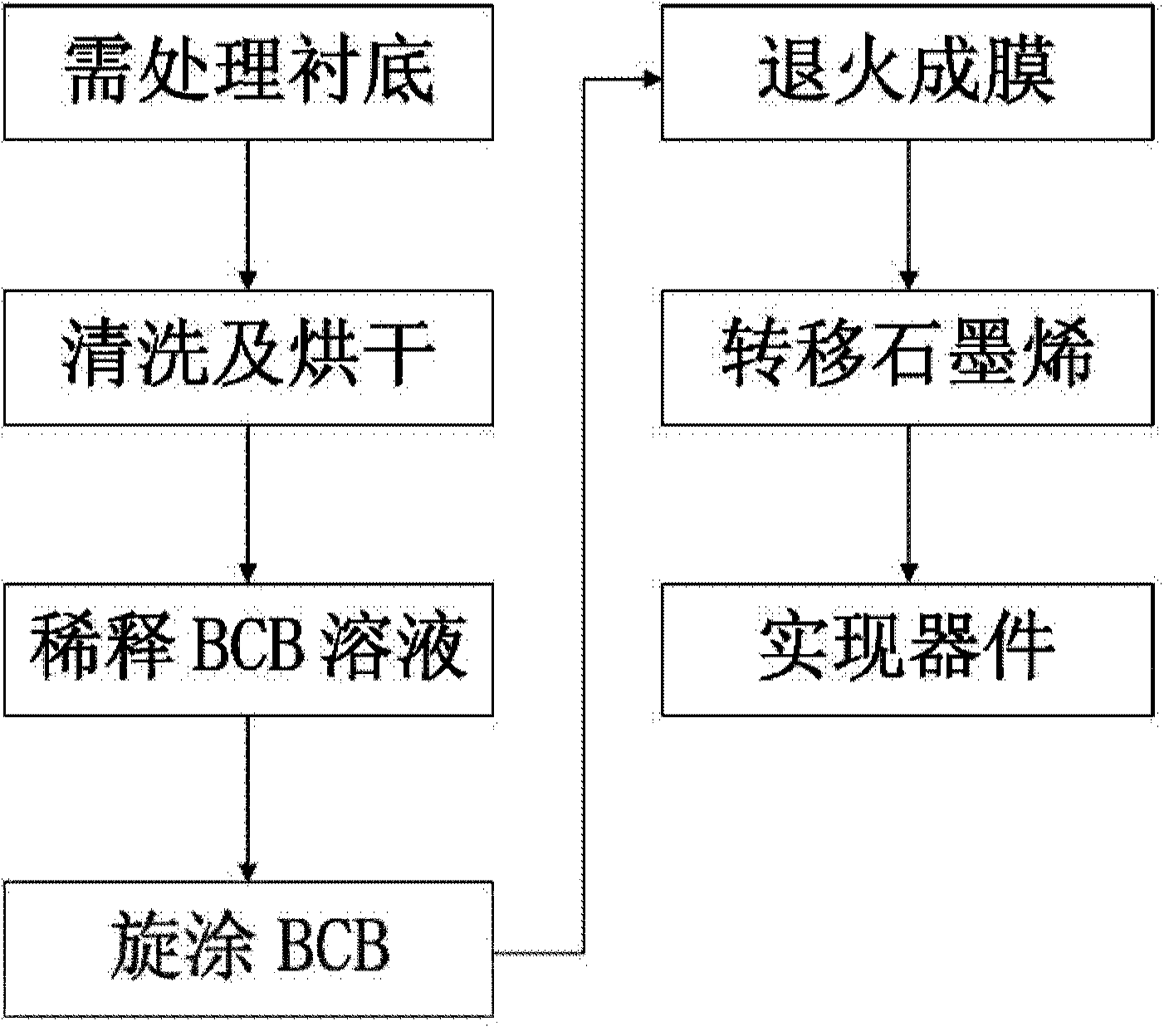

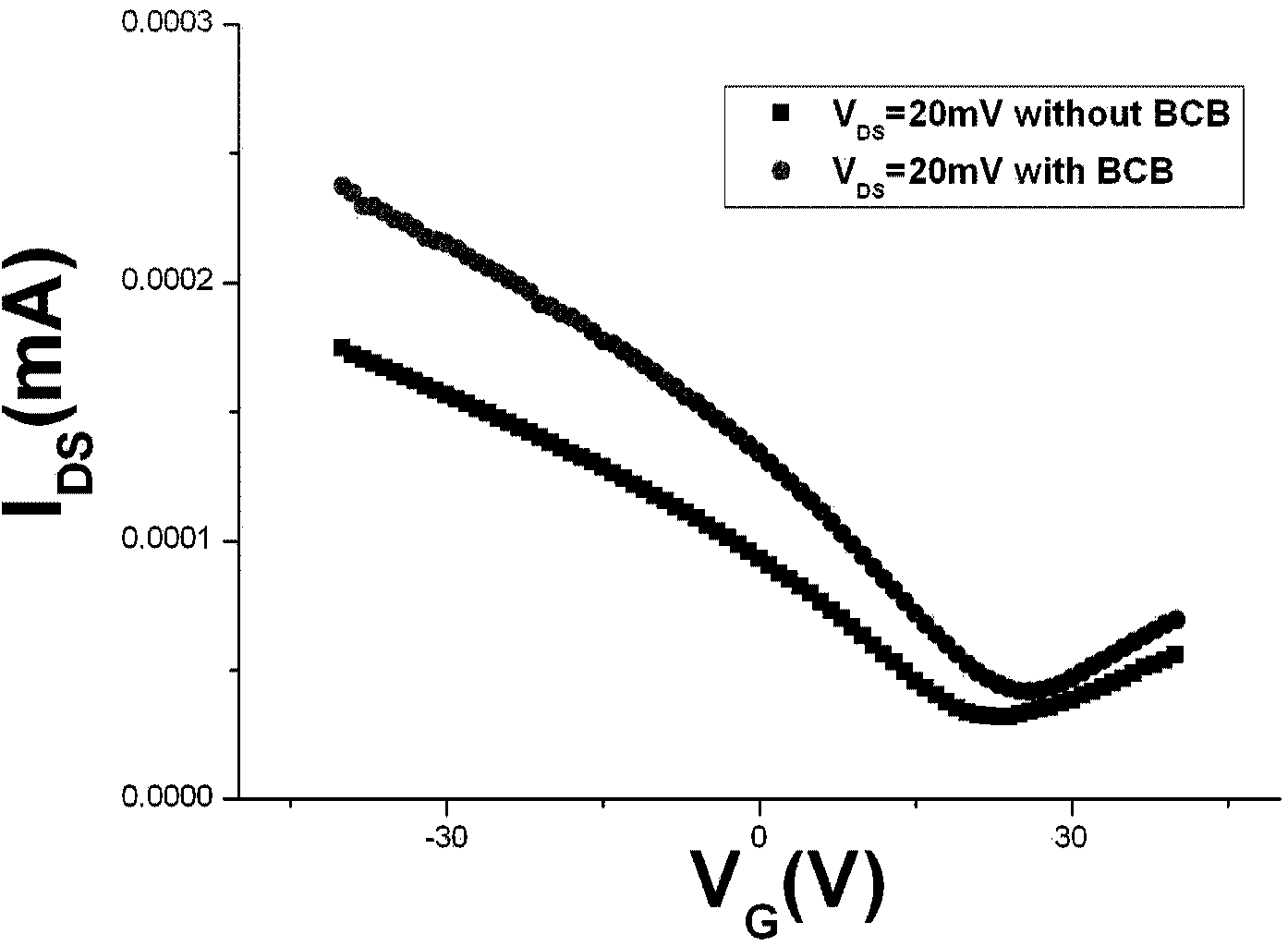

Method for pre-processing substrate in carbon-based semiconductor device manufacturing technology

ActiveCN103456607AMeet the needs of large-scale integrated circuitsMeet needsSemiconductor/solid-state device manufacturingOrganic filmCross-link

The invention discloses a method for pre-processing a substrate in a carbon-based semiconductor device manufacturing technology. The method comprises the steps that the washed substrate is placed in a drying oven, and drying processing is carried out on the substrate at 80 DEG C-200 DEG C for 5-60 minutes; BCB solutions are prepared, and are diluted through organic solutions, and the diluted BCB solutions coat the surface of the substrate in a spinning mode through a spin coater; under the protection of N2 or inert gas, the substrate with the surface coated with the BCB solutions in the spinning mode is heated to be 200 DEG C-400 DEG C, a cross-linking reaction occurs to benzocyclobutene monomers to generate a benzocyclobutene polymer, and therefore a BCB organic film layer is formed on the surface of the substrate. The method solves the problem that due to the fact that the surface of an original substrate is scattering in polarity, rough and fluctuant and impurity absorption occurs, the performance depredation of a grapheme device occurs, the BCB organic film passivates and decorates the surface of the original substrate, and meanwhile carrier mobility degeneration of grapheme cannot be caused.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

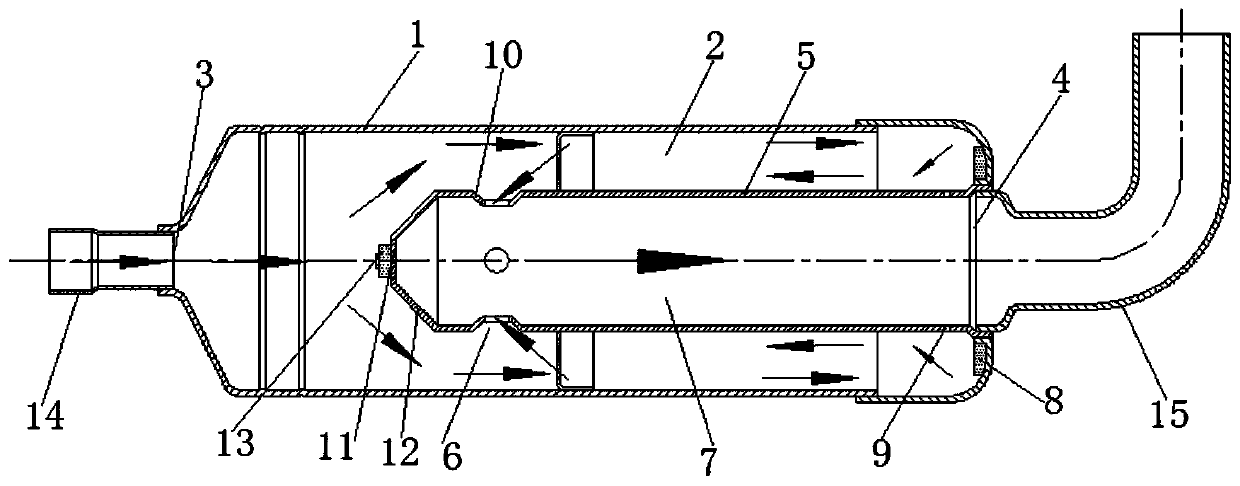

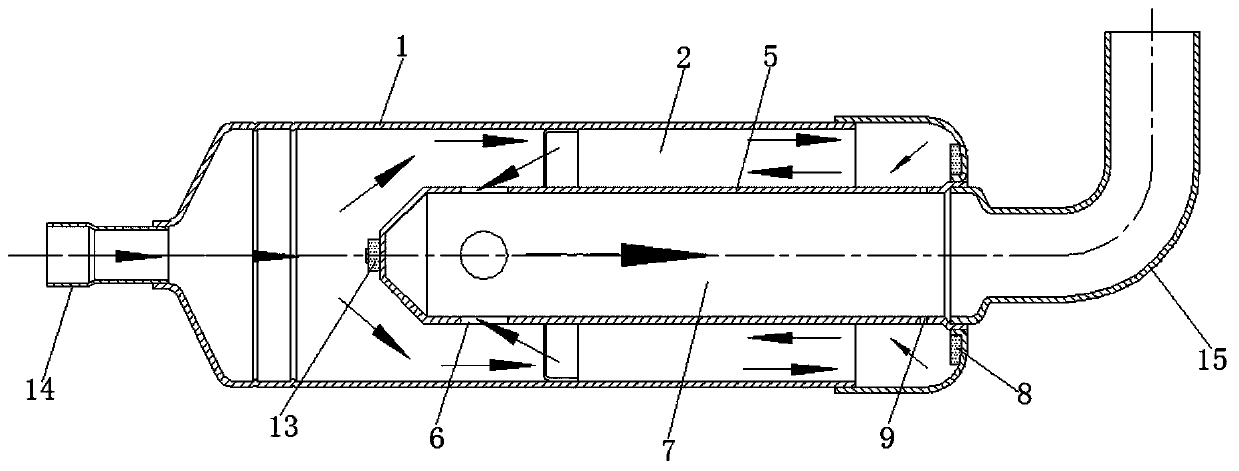

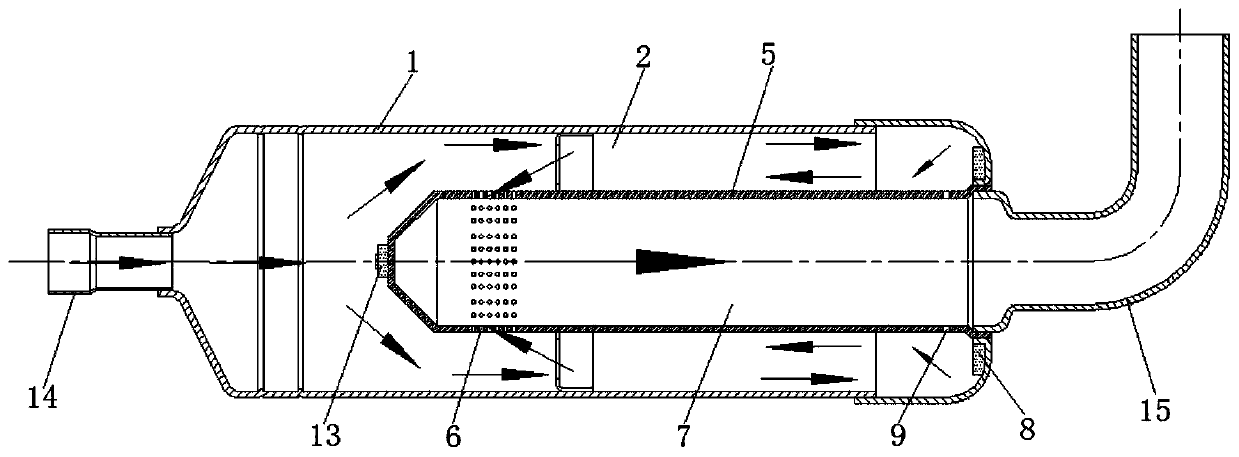

Gas-liquid separator and compressor

PendingCN110081638APrevent liquid shockAvoid damageRefrigeration componentsVapor–liquid separatorEngineering

The invention provides a gas-liquid separator. The gas-liquid separator comprises a shell, an inlet, an outlet, a flow guide pipe and an impurity absorption device, wherein the shell is provided witha gas-liquid separation cavity; the inlet is formed in one end of the shell, and communicates with the gas-liquid separation cavity; the outlet is formed in the other end of the shell and communicateswith the gas-liquid separation cavity; the flow guide pipe is arranged in the gas-liquid separation cavity and extends from the outlet towards the inlet and communicates with the outlet, and the flowguide pipe and the inlet are arranged at intervals; at least one ventilation structure is arranged on the circumferential wall of the flow guide pipe or the end wall of the back inlet, and the ventilation structures are connected with the gas-liquid separation cavity and the inner cavity of the flow guide pipe; and the impurity adsorption device comprises at least one first impurity adsorption structure and is arranged in the gas-liquid separation cavity. Due to the arrangement of the flow guide pipe, liquid refrigerant and impurities are prevented from being directly discharged to the outlet, and the gas-liquid separation effect is improved; and meanwhile, the impurity adsorption device is arranged, so that the effect of inhibiting the impurities is achieved, the impurities are preventedfrom entering the compressor, a pump body assembly is clamped, the flowing resistance of the refrigerant is not increased due to the arrangement of a filter screen, and the performance of the compressor is improved.

Owner:ZHUHAI LANDA COMPRESSOR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com