Treatment process for purifying recycled hydrogen during production of electronic-grade polycrystalline silicon

A technology for purification treatment and polysilicon, applied in the fields of silicon compounds, hydrogen separation, inorganic chemistry, etc., can solve the problems of inability to mass-produce electronic-grade polysilicon, impurity content cannot be effectively reduced, etc., to achieve easy operation, improve quality, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below according to the drawings and embodiments.

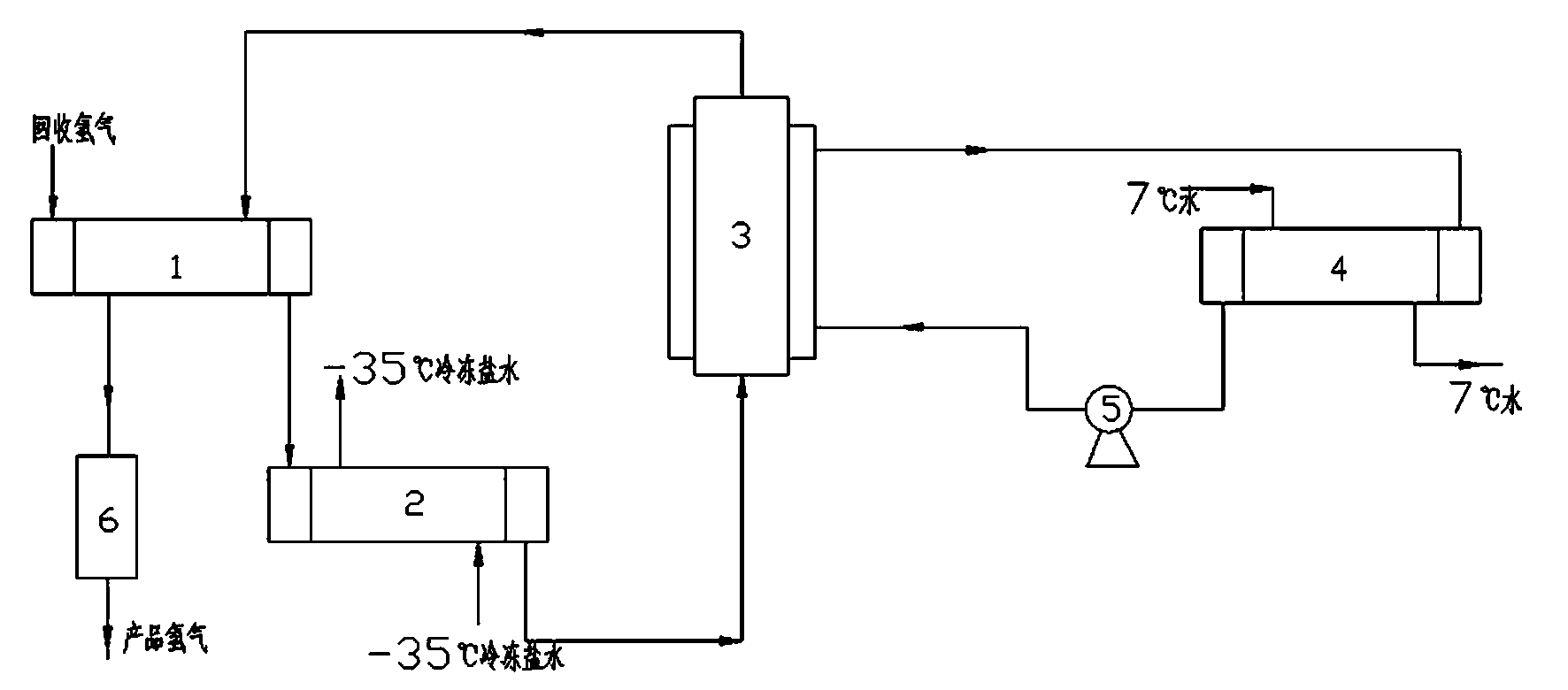

[0037] Such as figure 1 The shown embodiment of the present invention describes a recycling hydrogen purification process in the production of electronic-grade polysilicon, including recycling hydrogen pre-cooling, recycling hydrogen cooling, recycling hydrogen adsorption, and hydrogen filtration to finally obtain 99.999% V / V high-purity hydrogen, which satisfies the Electronic grade polysilicon production requirements.

[0038] The specific implementation steps are:

[0039] 1. Feed refrigerant 7°C water into the 4th shell side of the circulating water cooler;

[0040] 2. The circulating water pump 5 is turned on, and the circulating water is passed into the jacket of the adsorber 3 to cool the adsorber 3. The cooled circulating water enters the circulating water cooler 4 tube side to cool down, and the cooled circulating water returns to the circulation The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com