PERC battery back passivation process

A technology of backside passivation and process, applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of low short-circuit current, long time consumption, low long-wave reflection, etc., to reduce the cost of use, improve conversion efficiency, The effect of increasing reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

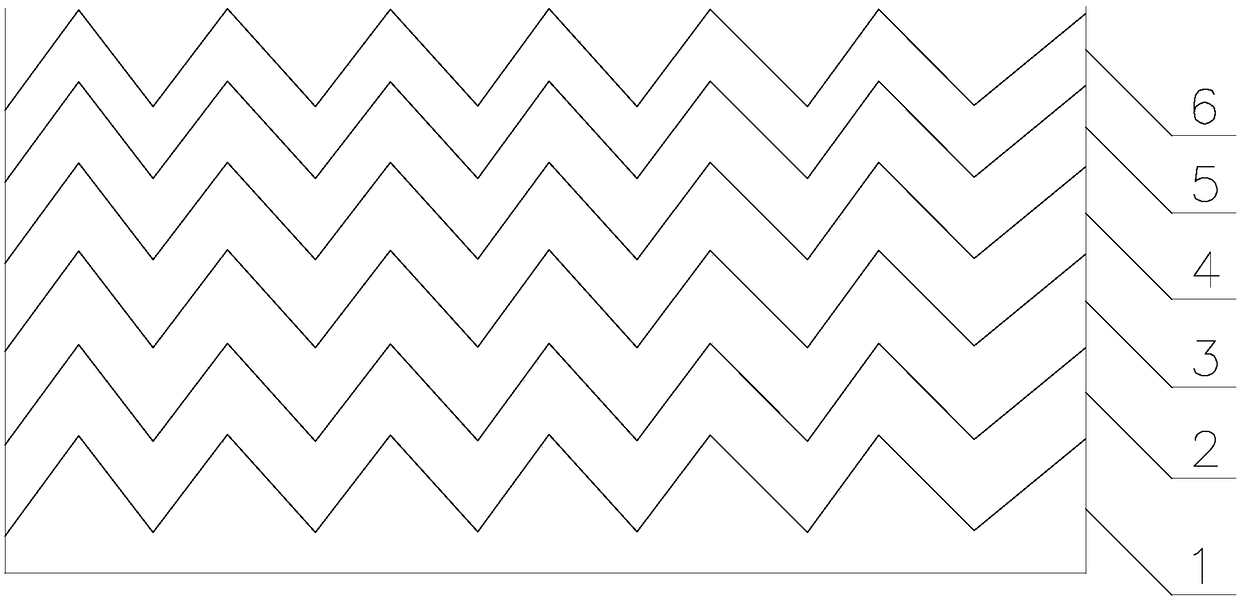

[0028] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0029] A kind of PERC battery rear passivation process of the present invention comprises the following steps:

[0030] a. The first layer of silicon oxide coating: Put the polished silicon wafer into the graphite boat and enter the tubular PECVD coating equipment. The temperature in the furnace is stabilized at 450±50°C. Open the RF power to complete the first layer of coating on the surface of the silicon wafer;

[0031] b. The second layer of aluminum oxide coating: Put the silicon wafer into the atomic deposition chamber, pass through trimethylaluminum and water vapor, and conduct atomic deposition at a temperature of 200±30°C to complete the second layer of coating on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com