Heat treatment method of solar-grade silicon crystal

A heat treatment method and solar-grade technology, applied in the directions of post-processing, crystal growth, post-processing details, etc., can solve the problems affecting the photoelectric conversion efficiency and life of crystalline silicon solar cells, reducing the diffusion length of minority carriers, and affecting the performance of photovoltaic devices, etc. The effect of improved resistivity and resistivity distribution, easy industrial production, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A 6.5-inch solar-grade gallium-doped monocrystalline silicon crystal prepared by the Czochralski method commonly used in the solar industry.

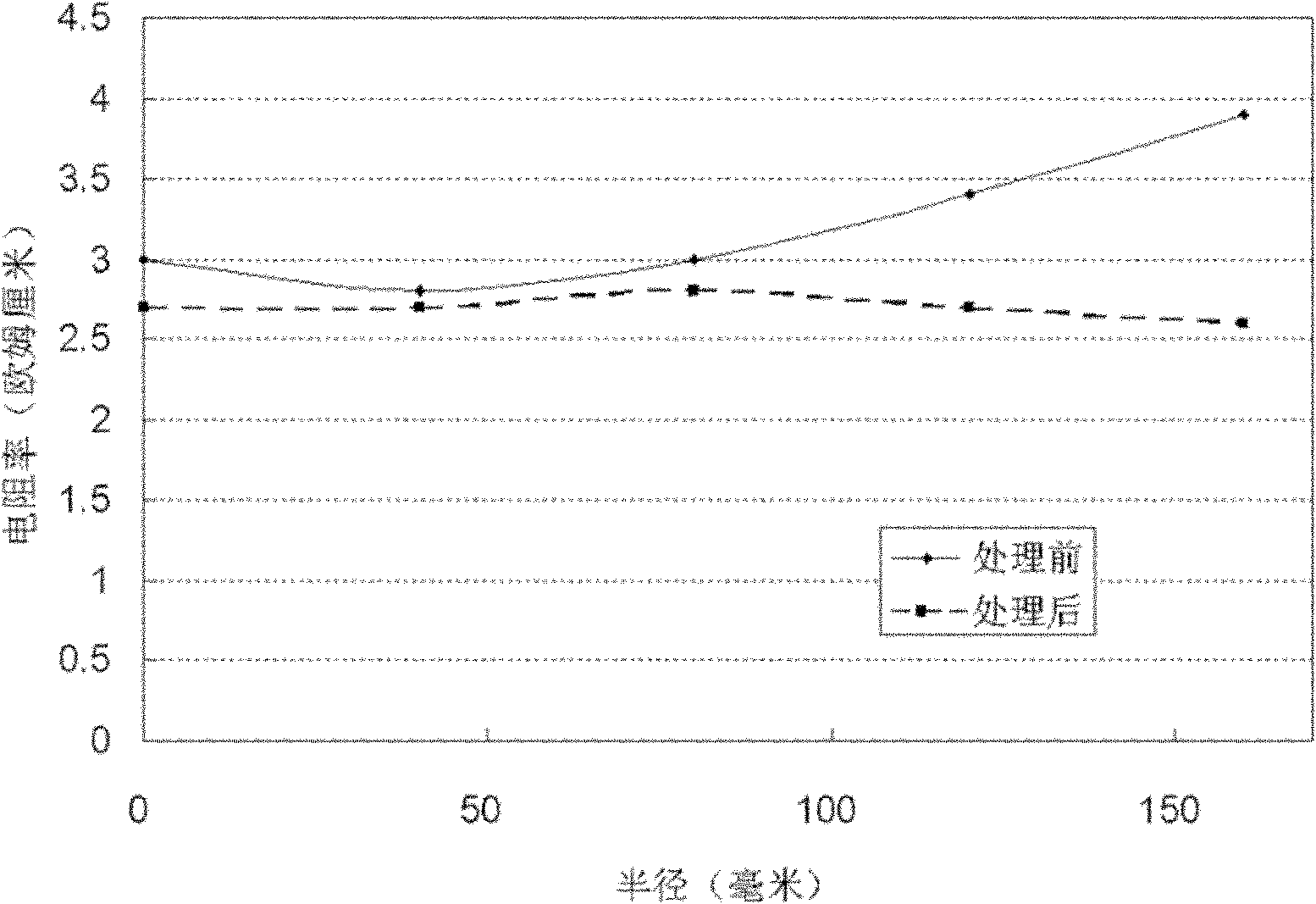

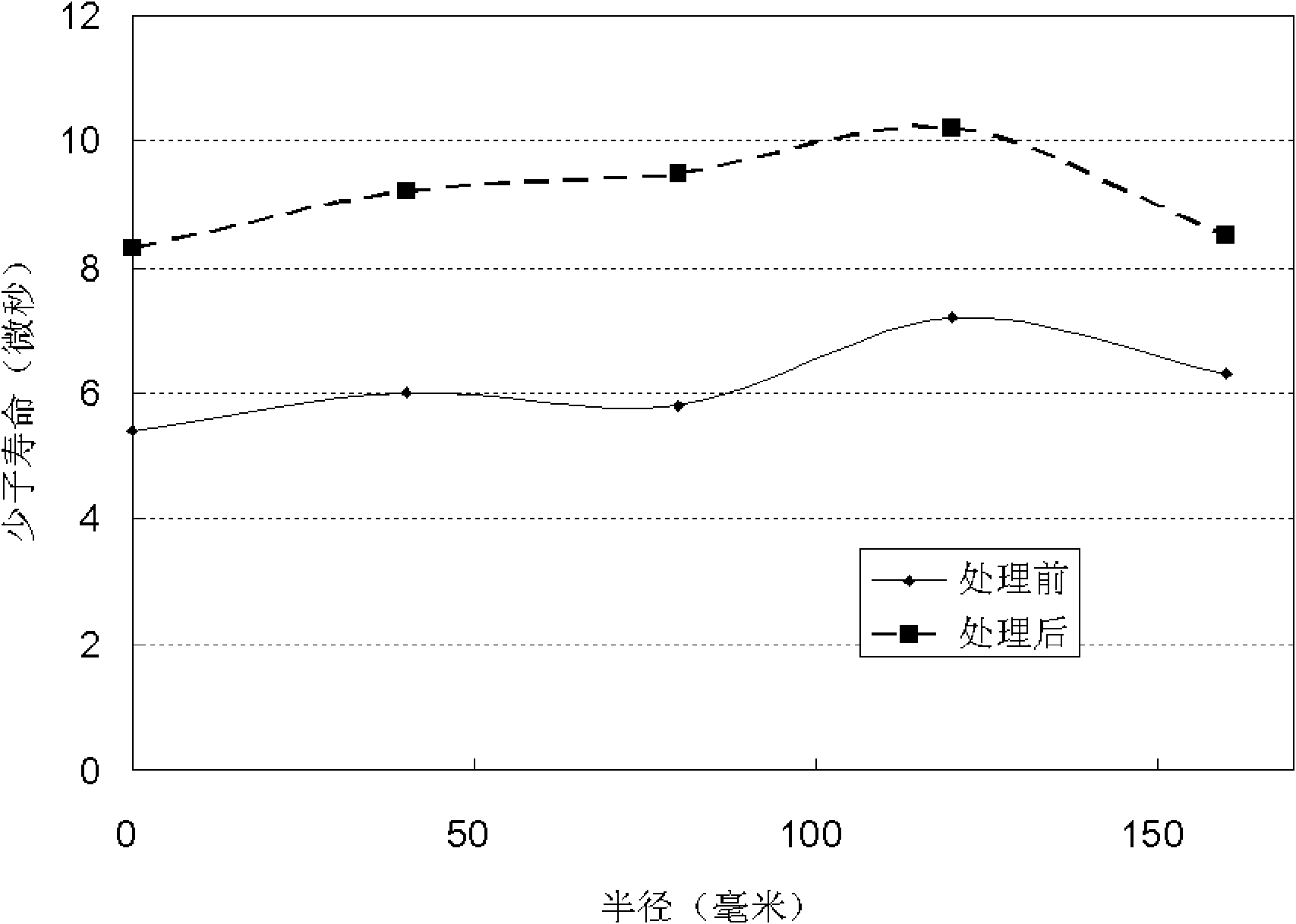

[0036] Take a section of 200 mm long from the head of the single crystal silicon crystal (the part that is first pulled out of the crucible), and the resistivity distribution of the upper end surface (the part that is first solidified) is as follows: figure 2 As shown in the curve before treatment, the minority carrier lifetime distribution is as follows figure 1The curve before processing is shown in the middle. Put the above-mentioned single crystal silicon crystal into a vacuum heating furnace. After the furnace is evacuated to below 5Pa, a mixed gas of argon and hydrogen with a volume ratio of 1:1 is introduced, and the flow rate of the protective gas passing through the surface area of the silicon crystal is 2.5-100 slpm / m 2 , so that the vacuum degree in the furnace reaches about 1000Pa under the action of the vacuum p...

Embodiment 2

[0038] The silicon crystal was processed using the process of Example 1, except that the protective gas was 100% hydrogen, and the flow rate of the protective gas and the pumping rate of the vacuum pump were properly adjusted to control the pressure in the furnace at about 500 Pa.

Embodiment 3

[0040] The silicon crystal was processed using the process of Example 1, except that the silicon crystal was a single crystal silicon ingot grown by directional solidification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com