Annular double-sided adhesive tape and equipment and technology for producing annular double-sided adhesive tape

A production equipment and double-sided adhesive technology, applied in adhesives, metal processing, layered products, etc., can solve problems such as low production efficiency, long processing time, and increased costs, so as to save labor, improve precision, and reduce product displacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0035] For convenience of description, "up", "down", "left" and "right" in the following are consistent with the up, down, left and right directions of the drawings themselves, but they do not limit the structure of the present invention.

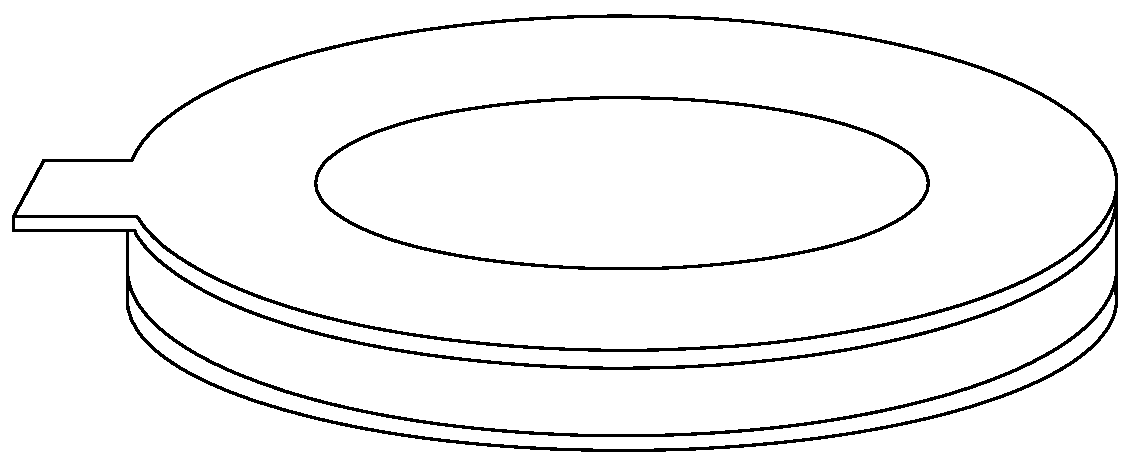

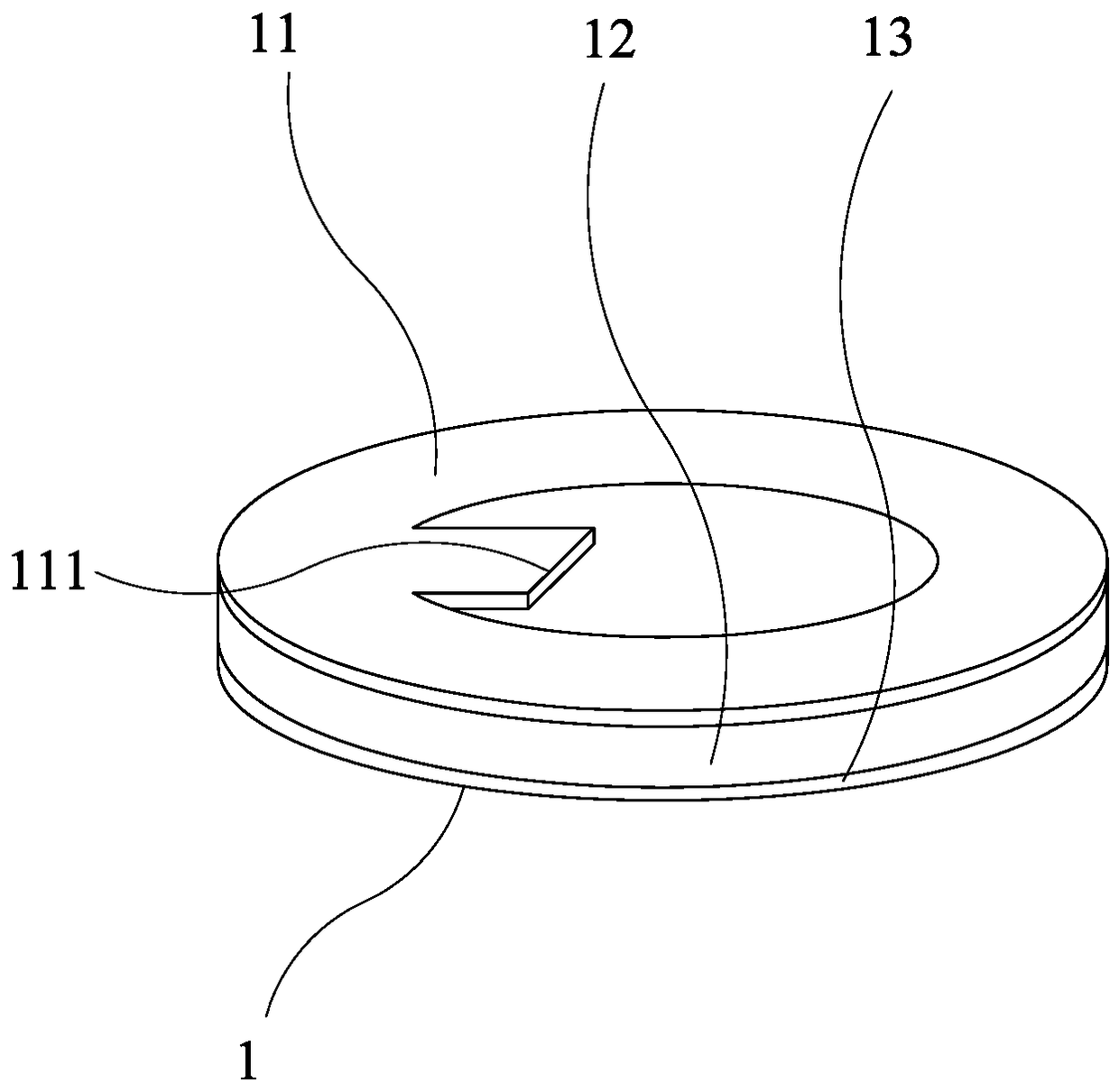

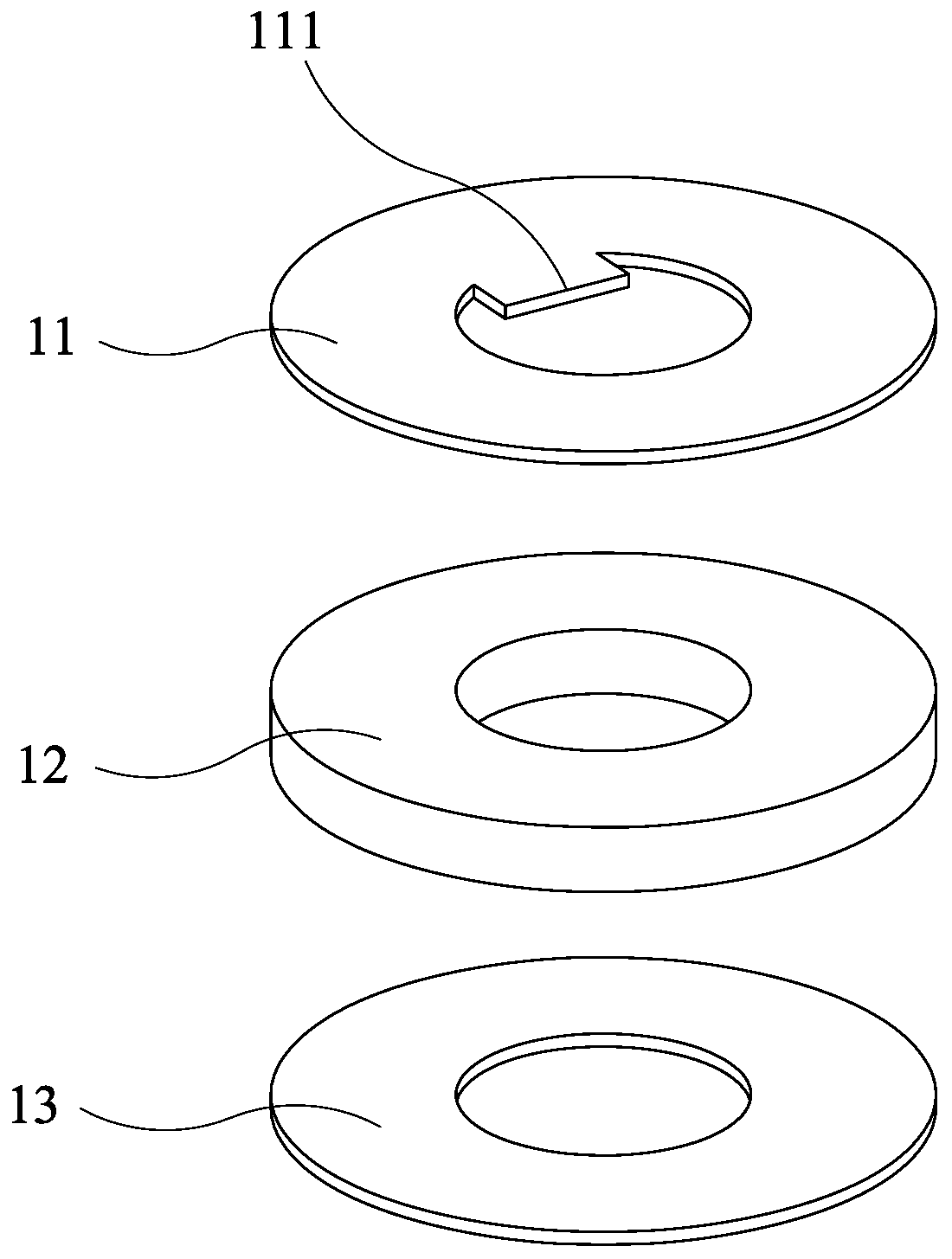

[0036] Such as figure 2 , image 3 As shown, a ring-shaped double-sided tape 1 includes a ring-shaped upper isolation film 11 , a double-sided adhesive body 12 and a lower isolation film 13 . The inner diameter and outer diameter of the upper isolation film 11, the double-sided adhesive body 12 and the lower isolation film 13 are the same. The upper isolation film 11 and the lower isolation film 13 are fitted on the upper and lower surfaces of the double-sided adhesive body 12 respectively to form a ring-shaped double-sided adhesive 1 . During use, the upper isolation fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com