Method for pre-processing substrate in carbon-based semiconductor device manufacturing technology

A preparation process and semiconductor technology, applied in the field of nanoelectronics, can solve the problems of carbon-based material carrier mobility decline, device performance degradation, etc., and achieve the effect of good repeatability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

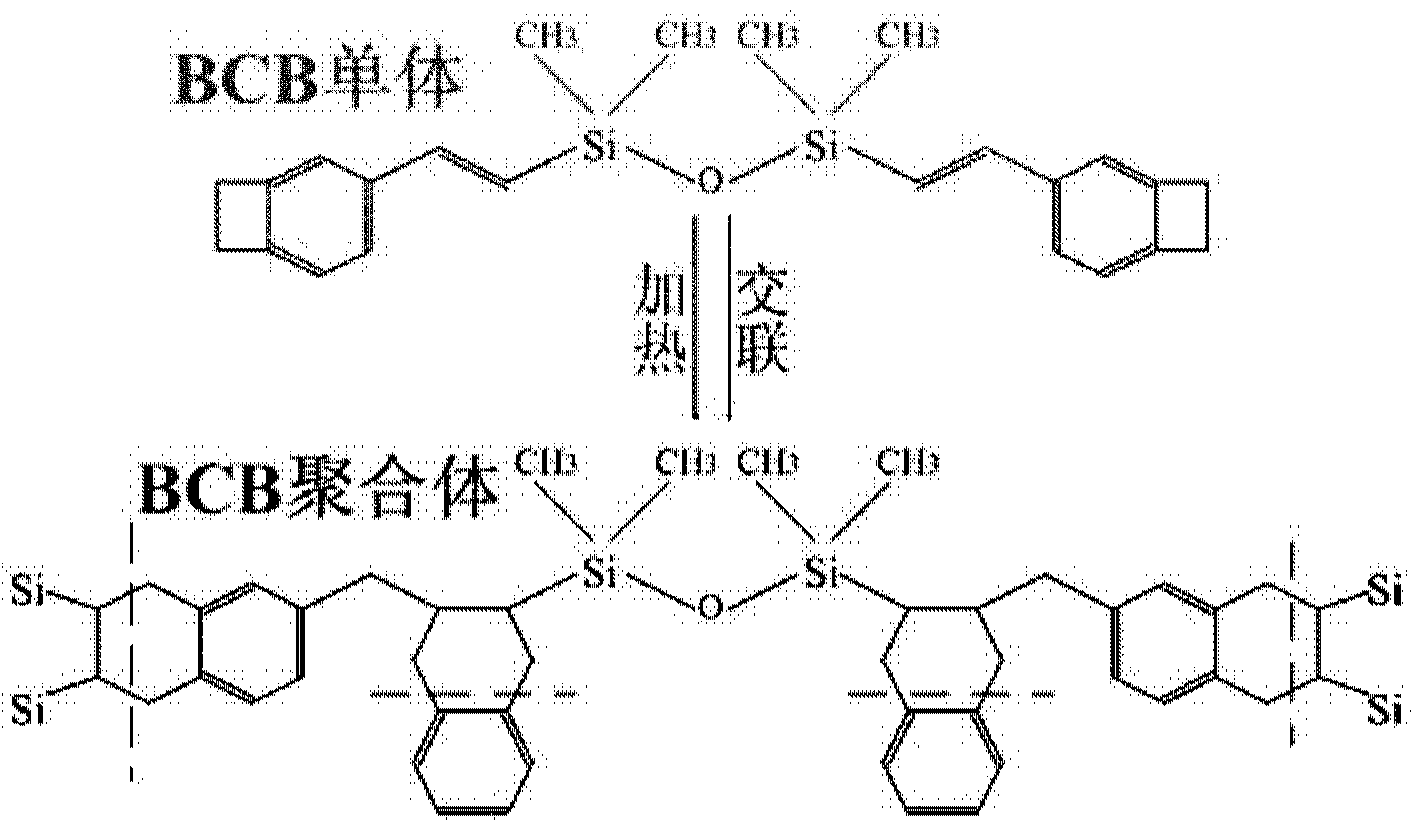

Method used

Image

Examples

Embodiment 1

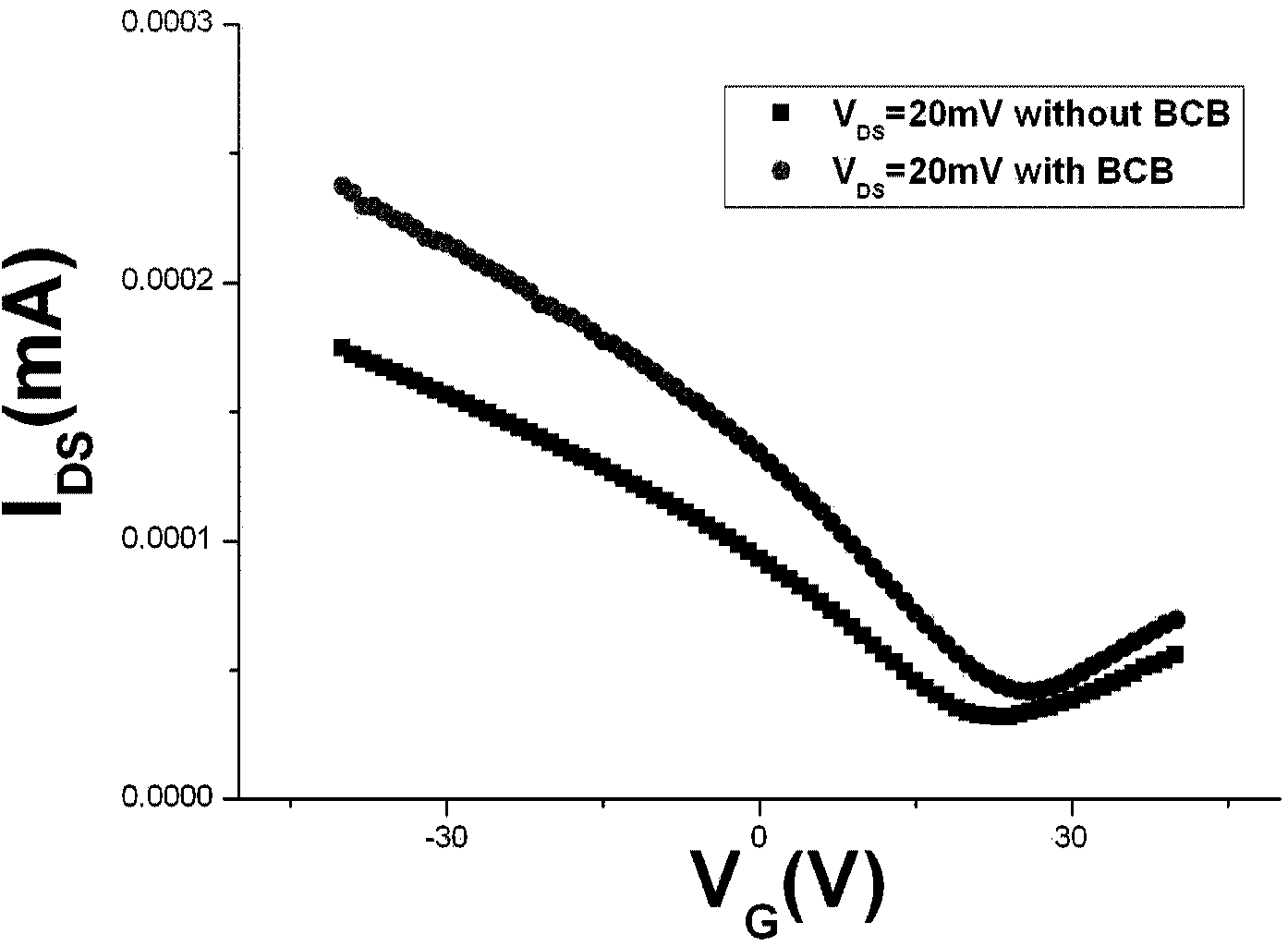

[0029] Embodiment 1: Graphene material is grown by CVD, and a graphene field effect transistor is realized on a silicon dioxide / silicon substrate pretreated by a BCB organic film layer.

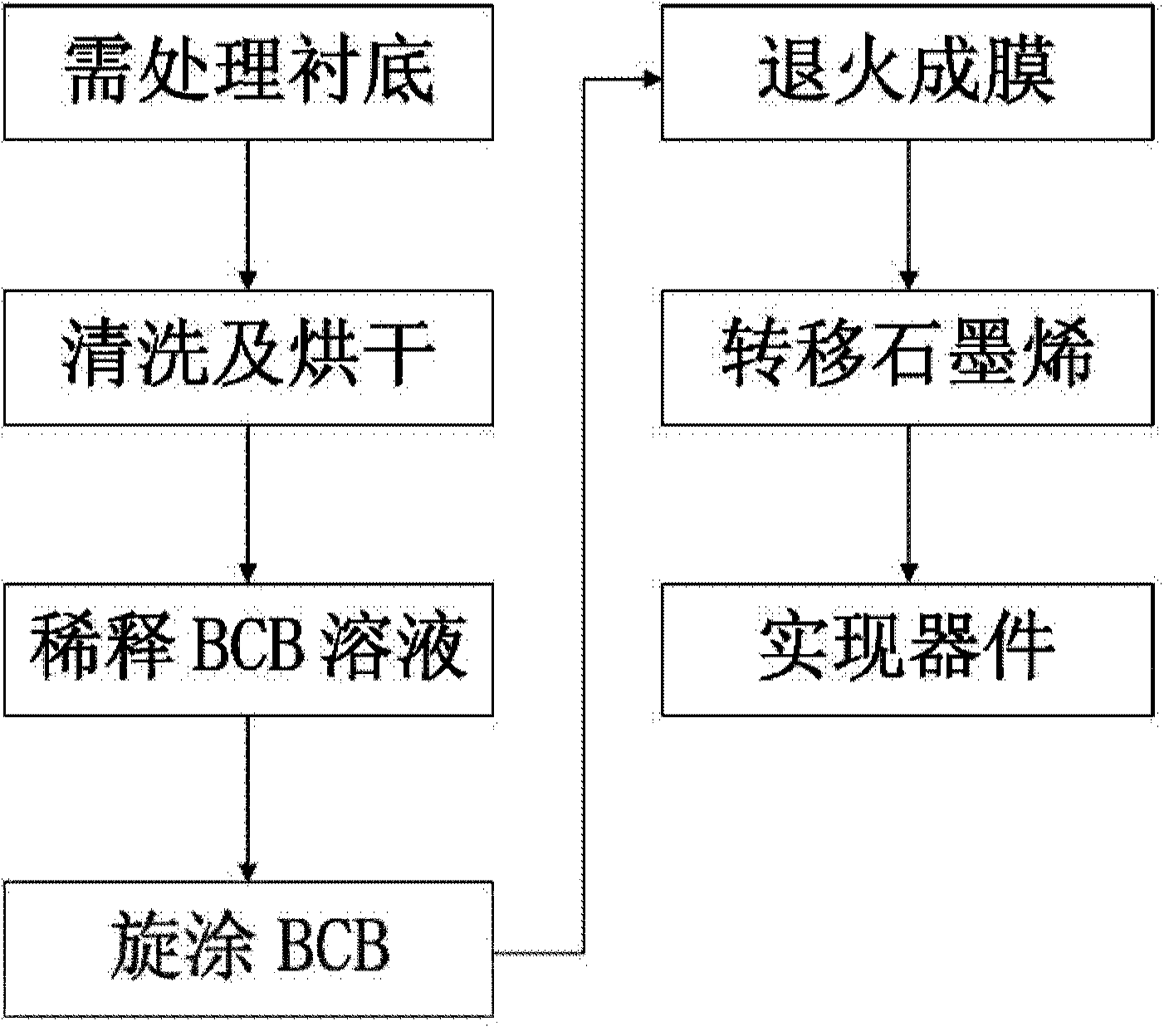

[0030] figure 2 Use BCB organic film layer to carry out the flowchart of surface pretreatment to substrate for the present invention, comprise the following steps:

[0031] Step 1: Put the cleaned silicon dioxide / silicon substrate with a thickness of 100nm into an oven at 80°C to 200°C for drying treatment for 5 minutes to 60 minutes;

[0032] Step 2: Prepare a benzocyclobutene (BCB) solution, dilute the BCB solution with an organic solution, and spin-coat the diluted BCB solution on the surface of the substrate through a homogenizer;

[0033] In this example, BCB (Cyclotene 3022-46, purchased from Dow Chemical Company of the United States) and 1,3,5-trimethylbenzene solution are diluted at a volume ratio of 1:27. Spin coating on the surface of the substrate, the speed of the homogenizer i...

Embodiment 2

[0039]Embodiment 2: Graphene material is grown by CVD, and a graphene field effect transistor is realized on a silicon dioxide / silicon substrate pretreated by rapid thermal annealing BCB.

[0040] The specific steps are similar to those in Example 1, but step 3 uses rapid thermal annealing (RTA) to treat the BCB. The BCB is subjected to rapid thermal annealing at 290 degrees Celsius for 15 seconds to form an organic dielectric layer with a thickness of 10 nm.

Embodiment 3

[0041] Embodiment 3: Use micromachines to exfoliate graphene materials, and realize graphene field effect transistors on silicon dioxide / silicon substrates pretreated by BCB.

[0042] The specific steps are similar to those in Example 1, but in Step 4, the micromechanically exfoliated graphene film is transferred to a silicon dioxide / silicon substrate pretreated by BCB, and then a field effect transistor device is implemented.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com