Catalyst for deep desulfuration and octane number increase for gasoline and preparation and application methods thereof

A deep desulfurization and application method technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of short reaction cycle, difficult to achieve sulfur content, low cracking desulfurization activity, etc., and reach aromatics content Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

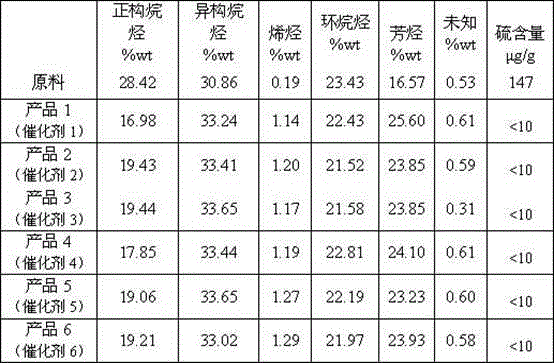

Examples

Embodiment 1

[0021]Embodiment 1, this invention is used for the catalyst of deep desulfurization of gasoline and raising octane number, namely the composition of the functional catalyst of coupling reaction adsorption desulfurization reaction and aromatization reaction is Ni-M / ZnO-ZSM-5, wherein M= One of Pb and Co, add a little alumina dry glue as a binder during the catalyst molding process. In the composition of the catalyst, the content of ZSM-5 is 25-40% (wt), the content of ZnO is 30-50% (wt), the content of Ni is 1-10% (wt), and the content of alumina dry glue is 10-15 % (wt), the balance is M. In addition, the molecular sieve ZSM-5 in the functional catalyst of the coupling reaction adsorption desulfurization reaction and aromatization reaction is a step-pore molecular sieve with micropores-mesopores-macropores. obtained through solid-phase crystallization transformation.

Embodiment 2

[0022] Embodiment 2, the method embodiment of preparing catalyst of the present invention is as follows:

[0023] Step 1: Weigh 200 grams of dried diatomaceous earth in a beaker, and first supplement it with aluminum. The specific process is to add 51.64 grams of NaAlO 2 , 4.348 grams of template agent triisopropylammonium hydroxide and 21.74 grams of sodium hydroxide were dissolved in 1000 milliliters of distilled water to prepare a solution. Stir and mix the diatomite with the solution evenly, dry at 80°C to obtain modified diatomite; then place the obtained modified diatomite in a crystallization tank, and crystallize at 170°C for 24 hours. The product after exiting the kettle was centrifuged and washed several times until the supernatant was neutral, then filtered and dried to obtain the raw molecular sieve powder, which was exchanged with ammonium nitrate according to the conventional method to obtain the hydrogen-form ZSM-5. The analysis results show that the pore struc...

Embodiment 3

[0026] Example 3, based on the premise of step 1 and step 2 in Example 2, accurately weigh 7 grams of nickel nitrate and 4 grams of lead nitrate and dissolve them in 30 ml of aqueous solution to prepare an impregnation solution, and use the impregnation method to prepare the impregnation solution. Liquid impregnated onto 40 grams of nano-zinc oxide synthesized in step two, then added 35 grams of ZSM-5 molecular sieve in step one, 15 grams of alumina dry glue and a small amount of 1% nitric acid, mixed evenly, extruded, dried and roasted After that, catalyst 2 (Ni-Pb / ZnO-ZSM-5) was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| macropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com