Comprehensive deoxidizing and desulfurizing process for smelting stainless steel by using small-capacity AOD (Argon Oxygen Decarburization) furnace

A desulfurization process, small capacity technology, used in the field of metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

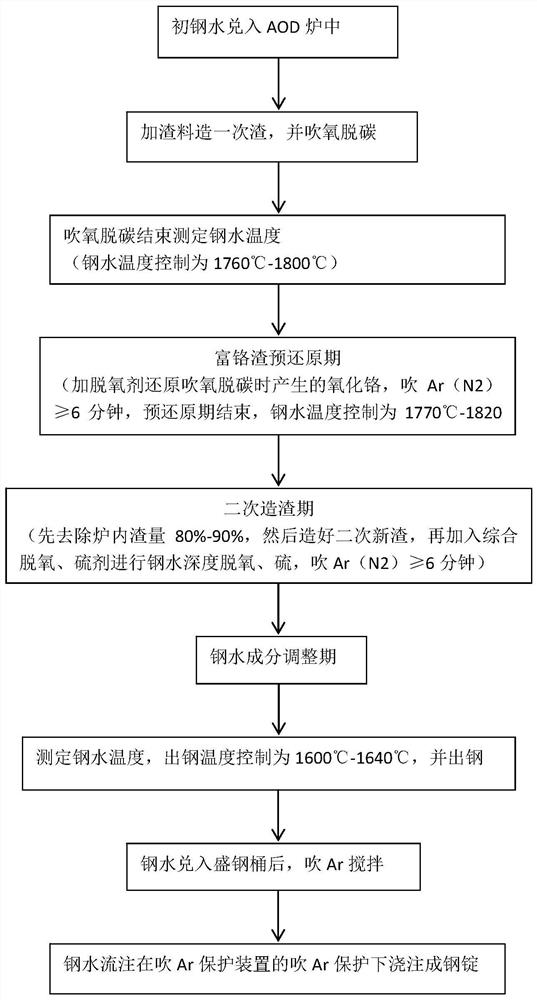

Method used

Image

Examples

Embodiment 1

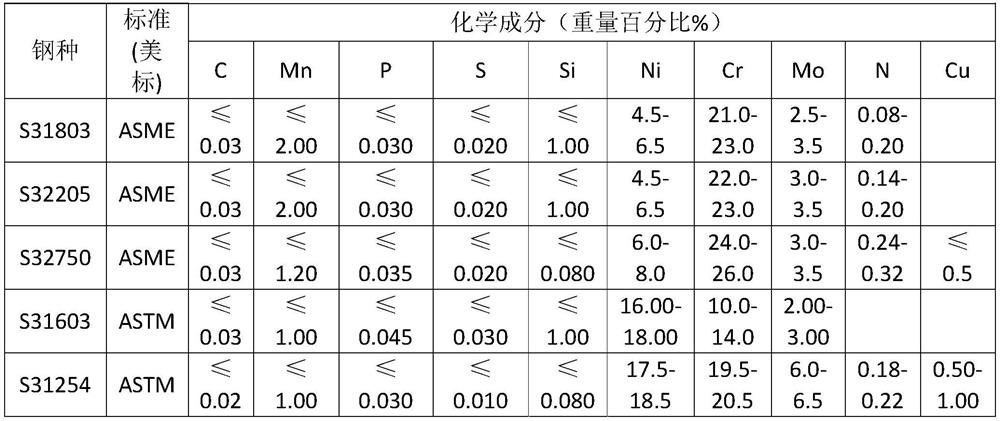

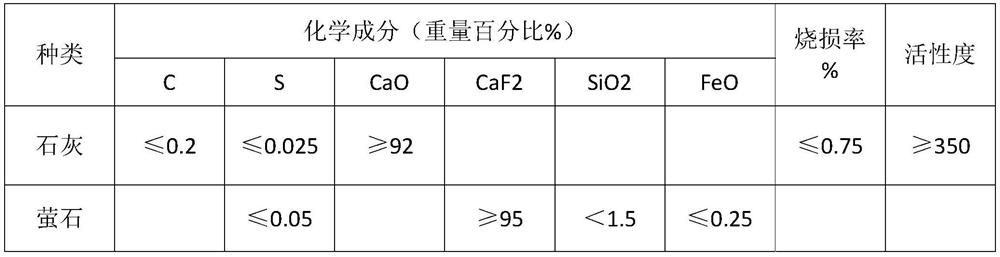

[0122] Smelting standard duplex stainless steel S31803, AOD furnace capacity 6 tons.

[0123] The primary molten steel used in the AOD furnace is smelted by an intermediate frequency furnace, the C content is controlled to 1.5%, the metal element composition is controlled according to the lower limit of the composition of S31803 (American Standard ASME) in Table 1, the tapping temperature of the primary molten steel is controlled at 1600 ° C, and the steel slag is fully discharged. The molten steel is poured into the steel ladle, and then mixed into the AOD furnace. In the AOD furnace, after the oxygen blowing decarburization is completed, the temperature of the molten steel is controlled at 1760°C. Oxidized chromium oxide, blown Ar(N 2 ) stirring time for 6 minutes. After the reduction, the molten steel temperature is 1770°C. After entering the secondary slagging period, part of the slag is removed to remove 80% of the slag in the furnace, leaving a layer of thin slag layer t...

Embodiment 2

[0128] Smelting standard duplex stainless steel S32205, AOD furnace capacity, 6 tons.

[0129] The primary molten steel used in the AOD furnace is smelted by an intermediate frequency furnace. The C content is controlled at 1.3%. The metal element composition is controlled according to the lower limit of the composition of S32205 (American Standard ASME) in Table 1. The tapping temperature of the primary molten steel is controlled at 1620°C. Pour it into a steel ladle, and then mix it into the AOD furnace. In the AOD furnace, after the oxygen blowing decarburization is completed, the temperature of the molten steel is controlled at 1780°C. When Al blocks and Si-Fe blocks are added to reduce the oxygen blowing decarburization, Chromium oxide, blowing Ar(N 2 ) stirring time for 7 minutes, the temperature of molten steel after reduction is 1790°C, after entering the second slagging period, part of the slag is removed, and after removing 85% of the slag in the furnace, a thin slag...

Embodiment 3

[0134] Smelting super duplex stainless steel S32750, the capacity of AOD furnace is 6 tons.

[0135] The primary molten steel used in the AOD furnace is smelted by an intermediate frequency furnace. The C content is controlled at 1.7%. The metal element composition is controlled according to the lower limit of the composition of S32750 (American Standard ASME) in Table 1. The tapping temperature of the primary molten steel is controlled at 1610°C, and the steel slag is fully discharged. The molten steel is poured into the steel ladle, and then mixed into the AOD furnace. In the AOD furnace, after the oxygen blowing decarburization is completed, the temperature of the molten steel is controlled at 1790°C. Oxidized chromium oxide, blown Ar(N 2 ) stirring time for 7 minutes, the temperature of molten steel after reduction is 1800°C, after entering the secondary slagging period, part of the slag is removed, and after removing 90% of the slag in the furnace, a thin slag layer that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com