Flue gas desulphurization system and method for flue gas desulfurization by means of same

A desulfurization system and flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of complex structure, large space occupation and high maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

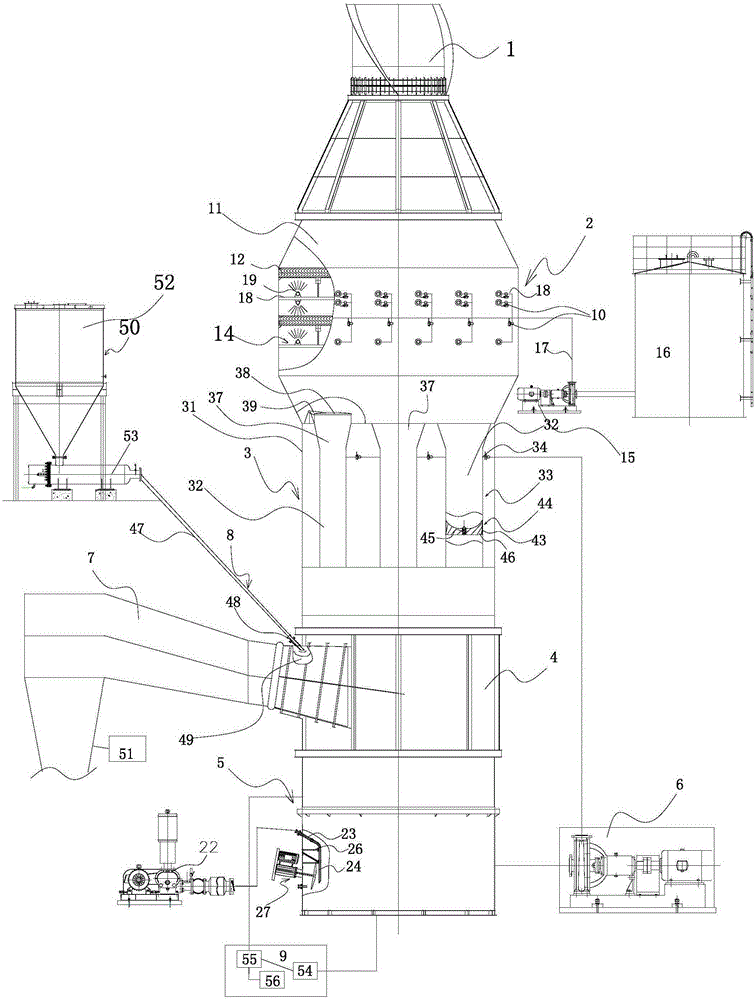

[0056] The following with attached Figure 2 to Figure 18 A flue gas desulfurization system of the present invention and a flue gas desulfurization method using it are further described in detail.

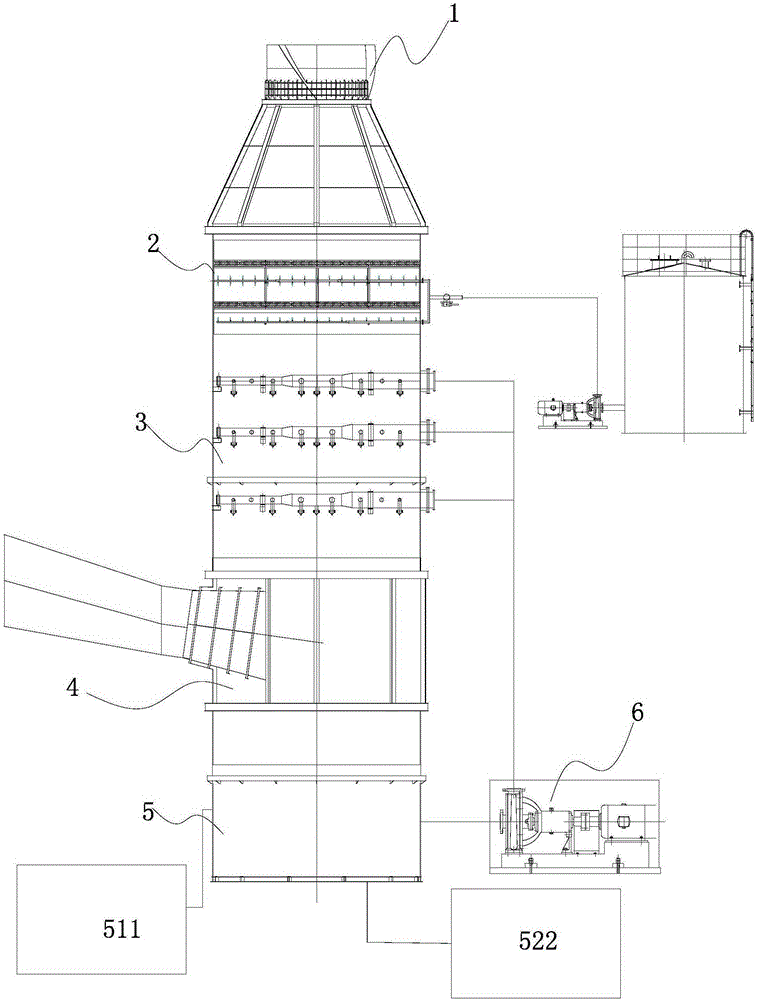

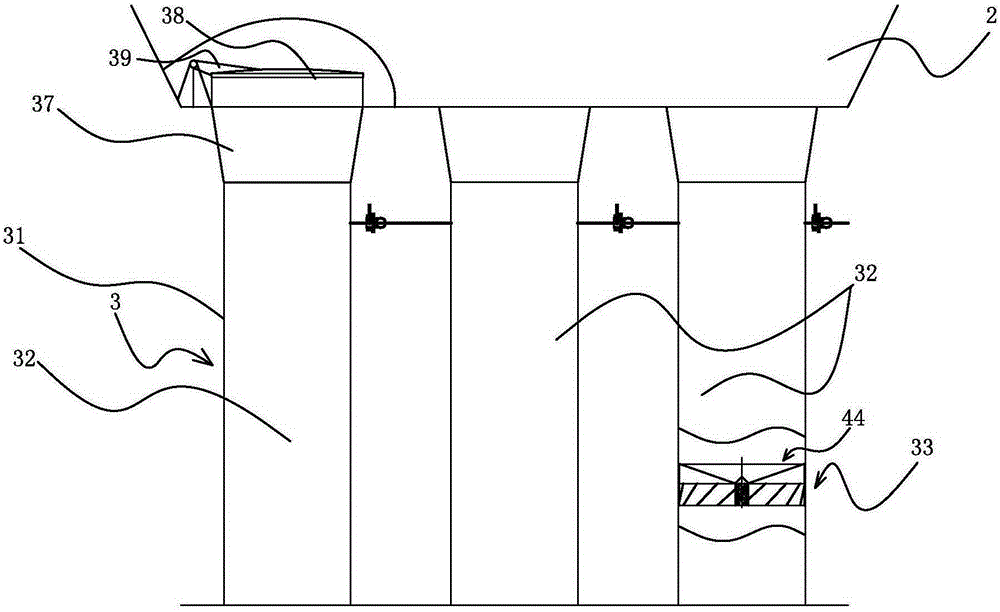

[0057] A flue gas desulfurization system of the present invention, please refer to Figure 2 to Figure 18, including a flue gas desulfurization tower, an ash storage device 50, a gypsum preparation device 9 and an air induction device 51, the ash storage device 50, an induction air device 51 and a gypsum preparation device 9 are all connected to the flue gas desulfurization tower, and the flue gas The desulfurization tower includes a tower body and a smoke exhaust device 1, a mist removal device 2, a swirl reaction device 3, a gas equalization device 4 and a multifunctional liquid collection pool 5 arranged from top to bottom along the tower body. The liquid pool 5 communicates with the cyclone reaction device 3 through the slurry circulation system 6 for pumping the reaction slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com