Environmental-protection comprehensive treatment system and environmental-protection comprehensive treatment process for high-pollution-factor low-temperature flue gas

A low-temperature flue gas and comprehensive treatment technology, applied in the direction of dispersed particle separation, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of inability to meet the new requirements of environmental protection, complex treatment system, low desulfurization efficiency, etc., to ensure stability and high efficiency Operation, reduce process, improve the effect of desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

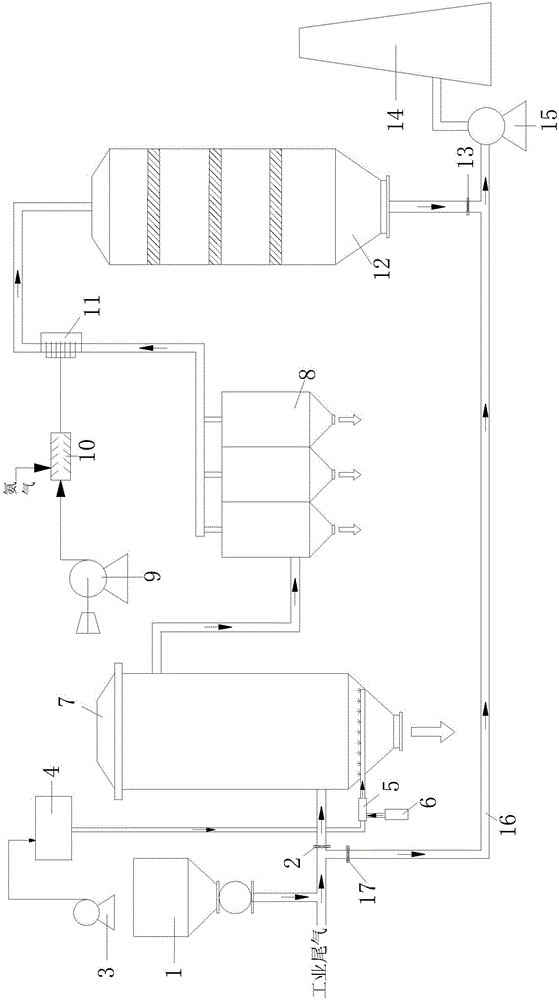

[0027] In the embodiment of the present invention, a high-pollution factor low-temperature flue gas environmental protection comprehensive treatment system includes a fully automatic desulfurizer delivery device 1, a water pump 3, a water tank 4, a two-fluid spray gun 5, an air compressor 6, a desulfurization tower 7, a bag type Dust removal unit 8, dilution fan 9, ammonia-air mixer 10, ammonia injection grid 11, medium and low temperature SCR reactor 12, chimney 14, induced draft fan 15 and bypass 16; the fully automatic desulfurizer delivery device 1 passes The flue gas pipeline is connected to the air inlet of the desulfurization tower 7, and an industrial exhaust gas inlet is provided on the flue gas pipeline between the automatic desulfurizing agent delivery device 1 and the desulfurization tower 7, and one end of the water tank 4 is connected to the water pump 3, and the The other end of the water tank 4 is connected to the desulfurization tower 7 through the double-fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com