Deep desulfuration method for magnesium-based composite jetted molten iron

A deep desulfurization and molten iron technology, applied in the field of molten iron injection desulfurization, can solve the problems that affect the development and popularization of magnesium-based composite injection desulfurization technology, affect the application effect, and cannot realize the overall modification of desulfurization slag, so as to reduce the liquid slag Residual amount, avoiding adverse effects, reducing the effect of entrainment amount and iron loss of slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

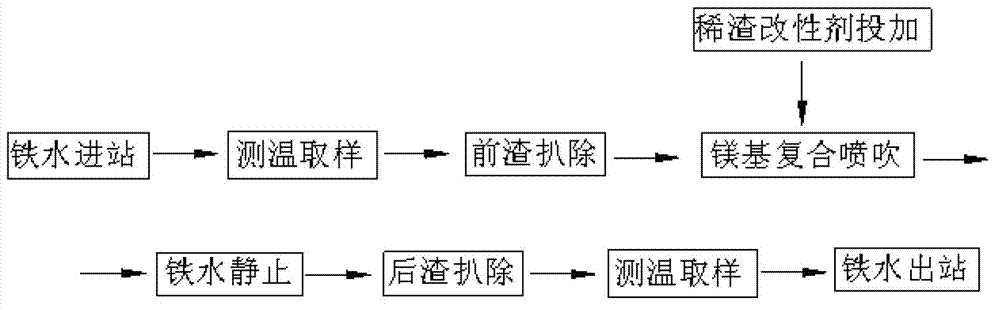

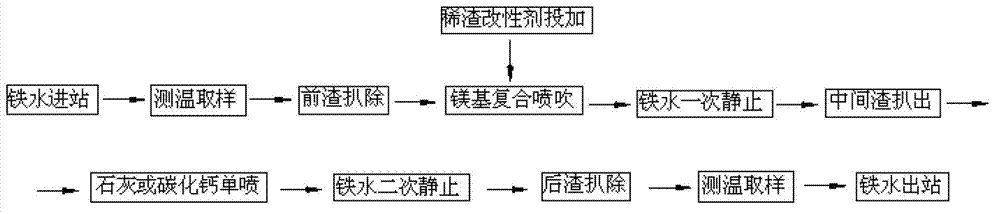

[0035] The magnesium-based composite injection molten iron deep desulfurization method of the present invention, the technological process is as follows figure 2 shown.

[0036] After the molten iron enters the station and takes temperature measurement and sampling, the front slag is removed at the slag removal station. The weight of the front slag removed is 1 / 2 of the weight of the slag in the molten iron tank.

[0037] Then in the blowing desulfurization station, magnesium-based composite (magnesium metal and lime) is used to blow hot metal to desulfurize. The injection time is selected according to the actual production, the injection time for deep desulfurization is 8~9min, and the injection time for ultra-deep desulfurization is about 13~14min;

[0038] After that, turn to the slag removal station to carry out the first resting of the molten iron, the resting time is 4 minutes, and complete the removal of the intermediate slag, the weight of the slag removal is 2 / 3 of ...

Embodiment 2

[0043] The magnesium-based composite injection molten iron deep desulfurization method of the present invention, the technological process is as follows figure 2 shown.

[0044] After the molten iron enters the station and takes temperature measurement and sampling, the front slag is removed at the slag removal station. The weight of the front slag removed is 2 / 3 of the weight of the slag in the molten iron tank.

[0045] Then in the blowing desulfurization station, magnesium-based composite (magnesium metal and lime) is used to blow hot metal to desulfurize. According to the actual production, select the injection time, and inject until the sulfur content is 0% to 0.002% higher than the target sulfur content;

[0046] Afterwards, turn to the slag removal station to carry out the first resting of the molten iron, the resting time is 6 minutes, and complete the removal of the middle slag, the weight of the slag removal is 2 / 3 of the weight of the slag in the molten iron tank;...

Embodiment 3

[0051] The magnesium-based composite injection molten iron deep desulfurization method of the present invention, the technological process is as follows figure 2 shown.

[0052] After the molten iron enters the station and takes temperature measurement and sampling, the front slag is removed at the slag removal station. The weight of the front slag removed is 2 / 3 of the weight of the slag in the molten iron tank.

[0053] Then in the blowing desulfurization station, the magnesium-based composite (metal magnesium and calcium carbide) is used to blow the molten iron to desulfurize. Modification, choose the injection time according to the actual production, and inject until the sulfur content is 0% to 0.002% higher than the target sulfur content;

[0054] Afterwards, turn to the slag removal station to carry out the first resting of the molten iron, the resting time is 6 minutes, and complete the removal of the middle slag, the weight of the slag removal is 2 / 3 of the weight of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com