Patents

Literature

32results about How to "Prevent sticky residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

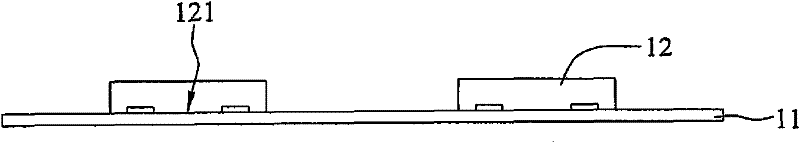

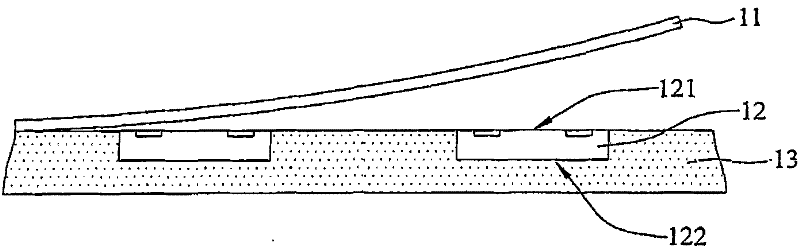

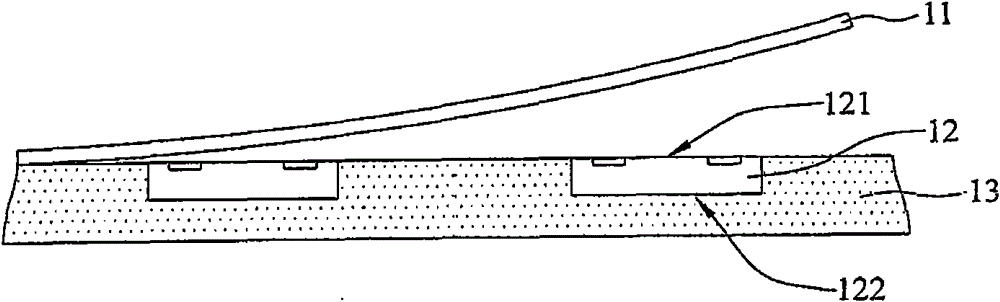

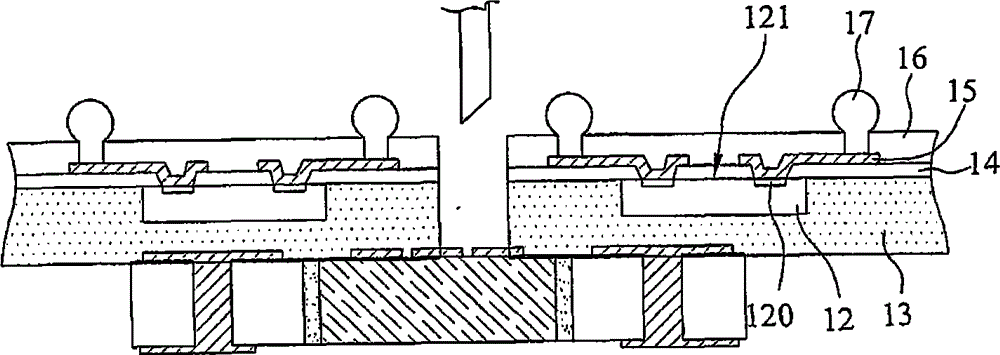

Package of embedded chip and manufacturing method thereof

ActiveCN102456636AAvoid offsetAvoid pollutionSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringChip-scale package

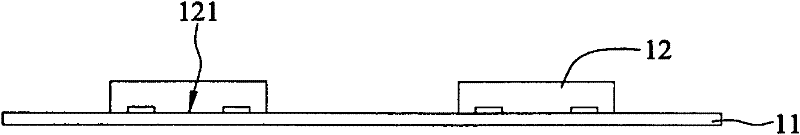

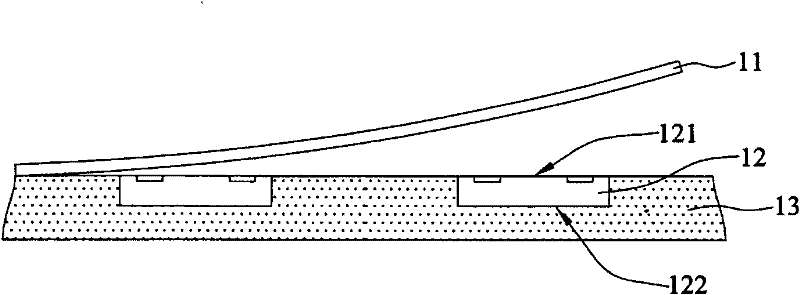

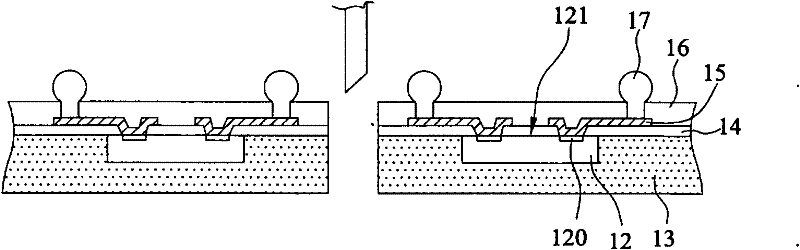

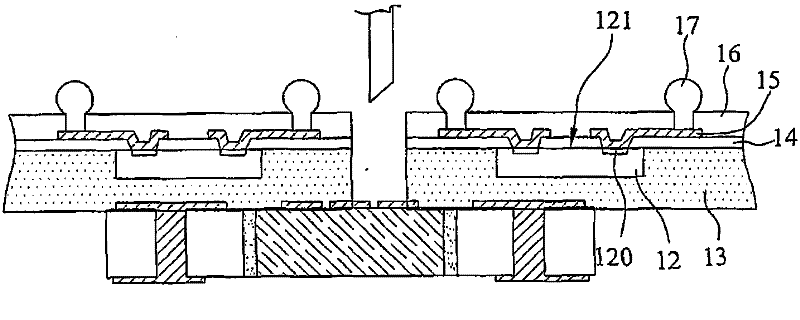

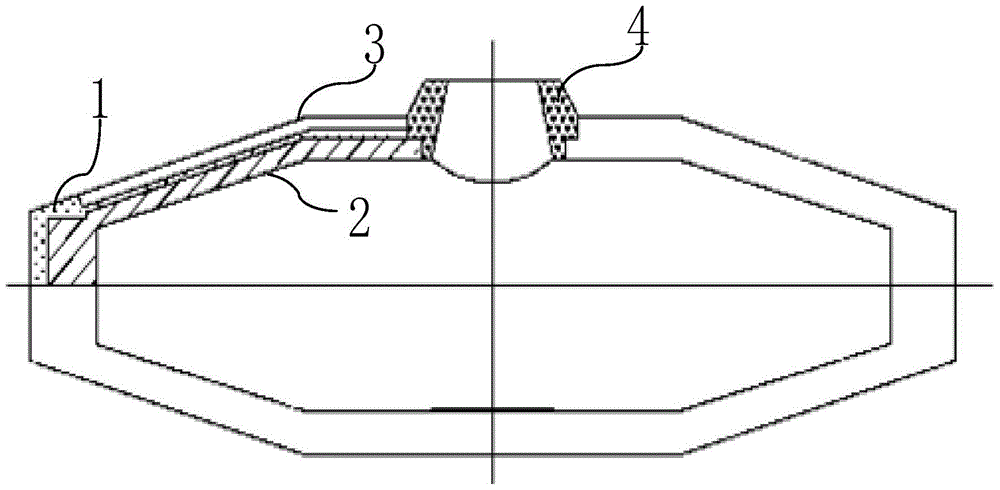

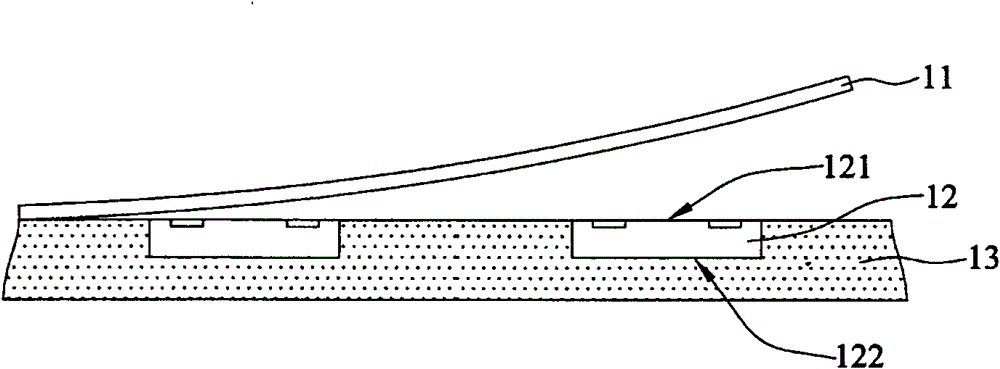

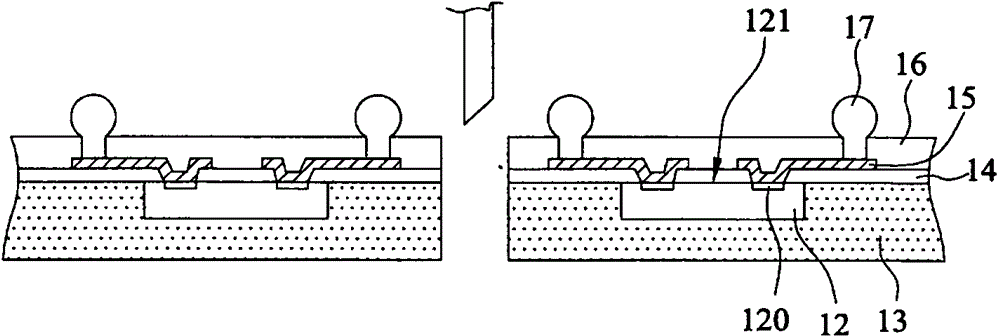

The invention relates to a package of an embedded chip and a manufacturing method thereof. The package comprises: a dielectric layer, which has a first surface and a second surface that is opposite to the first surface; conductive projections, which are arranged in the dielectric layer and are exposed outside the dielectric layer; a chip, which is embedded in the dielectric layer; a line layer, which is arranged on the first surface of the dielectric layer; conductive blind holes, which are arranged in the dielectric layer and are electrically connected with the line layer, the chip and the conductive projection; and a first welding-resistant layer, which is arranged on the first surface of the dielectric layer and the line layer. Therefore, other electronic apparatuses can be externally connected by the conductive projections, so that a stacked structure is formed; and the technology is effectively simplified. In addition, the invention also provides a manufacturing method of a chip scale package.

Owner:SILICONWARE PRECISION IND CO LTD

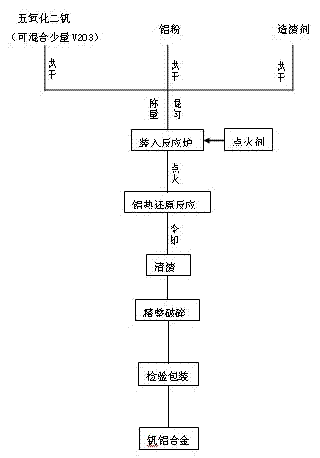

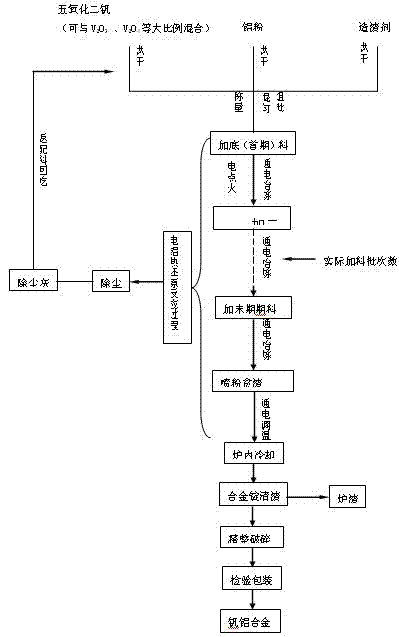

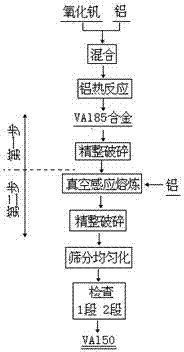

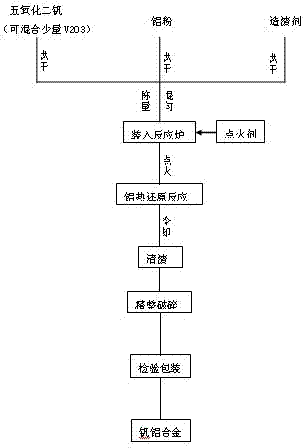

Method for smelting vanadium-aluminum alloy by electro-aluminothermic process

Owner:HEBEI IRON AND STEEL

Slag binding agent for preventing slag ladle as well as production process thereof

The invention provides a slag binding agent for preventing a slag ladle as well as a production process thereof. The production process comprises the following steps: cooling an aluminum-silicon carbide-carbon brick used by a torpedo ladle to 0.1-29.5 DEG C; placing the brick in a PC0606 jaw crusher to be crush to 5-50mm particles; then, adding the particles into a 4R3216 Raymond mill to be processed to powder which is below 3mm; mixing the powder with steel slag micropowder which is below 3mm in mass percent ratio of 15:85; and placing the mixture in a VI type forced stirring mixer to be uniformly stirred and mixed to obtain the slag binding agent, wherein the control time of adding 1 ton of materials is 15 minutes, and the stirring time is 15-20 minutes. When the slag binding agent is used, water is added into the inner wall of an empty slag ladle through a spray gun of a PB type semidry method gunning machine to spray, and the coating thickness is 0.5-2cm. The water addition of water added to spray accounts for 8-12% of total weight of the slag binding agent used.

Owner:XINJIANG ZHONGHE DAZHENG COMMERCE & TRADE

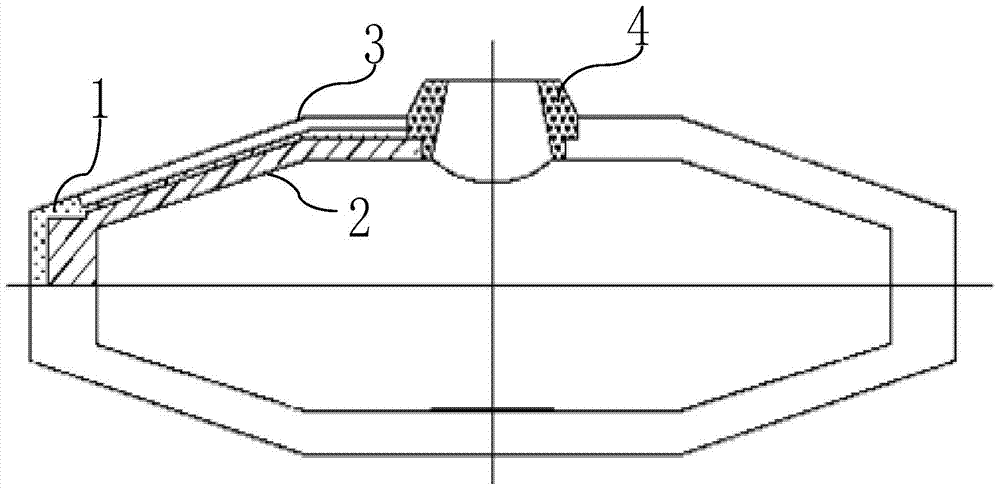

Chip-scale package and fabrication method thereof

ActiveCN102412208AAvoid poor contact and lead to waste problemsAvoid heat softeningSemiconductor/solid-state device detailsSolid-state devicesEngineeringColloid

The invention discloses a chip-scale package and a fabrication method thereof. The chip-scale package comprises a packaging colloid, conductive bumps, a chip, a dielectric layer, a circuit layer, conductive blind holes and a soldering-resistant layer, the packaging colloid is provided with a first surface and a second surface which are opposite from each other, the conductive bumps are arranged in the packaging colloid and exposed out of the first and the second surfaces of the packaging colloid, the chip is embedded in the packaging colloid and exposed out of the first surface of the packaging colloid, the dielectric layer is arranged on the first surface of the packaging colloid, the conductive bumps and the chip, the circuit layer is arranged on the dielectric layer, the conductive blind holes are arranged in the dielectric layer and electrically connected with the circuit layer, electrode pads and the conductive bumps, and the soldering-resistant layer is arranged on the dielectric layer and the circuit layer. Consequently, the conductive bumps can be directly connected with other external electronic devices, so that a stack structure can be formed, and the fabrication process is effectively simplified.

Owner:SILICONWARE PRECISION IND CO LTD

Casting powder for continuous casting crystallizer and preparation method of casting powder

The invention discloses casting powder for a continuous casting crystallizer. The casting powder comprises raw materials in parts by weight as follows: 3.5-15 parts of fluorite, 35-55 parts of aedelforsite, 5-15 parts of alkali, 0-2 parts of lithium carbonate, 0-10 parts of diaspore, 0-6 parts of a cement clinker, 1-5 parts of magnesia powder, 2-5 parts of pyrolusite, 0-8 parts of sodium fluoride, 0-5 parts of barium carbonate, 0-5 parts of bentonite, 1-4 parts of coke, 0-8 parts of a carburant, 1-3 parts of carbon black and 1-2 parts of a binder. According to the casting powder, the preparation cost is low; the recovery rate of the casting powder is larger than or equal to 98.5%; the color of the casting powder is uniform; the granularity is uniform; the granulation rate is high; dust is reduced; the melting point of the casting powder is low; the viscosity is low; after the casting powder is added into the crystallizer, the casting powder is melted uniformly and shows excellent spreadability, heat retaining property and adsorptive property; heat is transferred uniformly all around the crystallizer, and the lubrication is excellent; and defects such as concave pits, impurities and the like don't exist on the surface of a casting blank, the internal quality is excellent, and the qualified rate of the casting blank is equal to or larger than 99.8%.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Torpedo ladle slag line zone repair material

The invention relates to the technical field of metallurgy, in particular to a torpedo ladle slag line zone repair material. The repair material comprises the following components in percentage by mass: 40 to 80 percent of aluminum silicon carbide carbon brick waste, 10 to 40 percent of third-grade brown aluminum oxide, 1 to 6 percent of calcium aluminate cement, 2 to 8 percent of clay, 1 to 8 percent of silicon carbide material, 0.01 to 0.04 percent of polypropylene fiber and balance of inevitable impurity. The torpedo ladle slag line zone repair material provided by the embodiment of the invention has the advantages that the calcium aluminate cement can improve the normal temperature physical strength of the repair material; the clay can improve the viscosity of the repair material and the construction is facilitated; the silicon carbide can further improve the slag corrosion resistance of the repair material, the repair material is enabled to not stick slag and the times of use are improved; the polypropylene fiber can reduce the drying time of the repair material after construction, improve the volumetric stability during baking or use and prevent burst. The torpedo ladle slag line zone provided by the embodiment of the invention improves the slag corrosion resistance of the torpedo ladle slag line zone repair material; since a great amount of aluminum silicon carbide carbon brick waste is adopted, the use cost of the repair material is reduced.

Owner:WUGANG REFRACTORY CO LTD

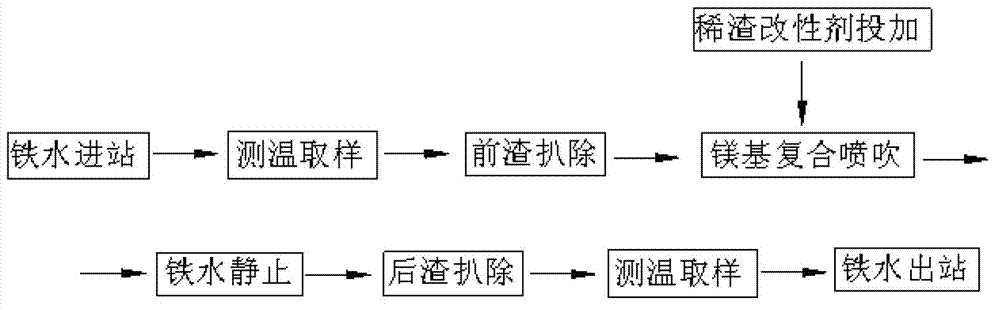

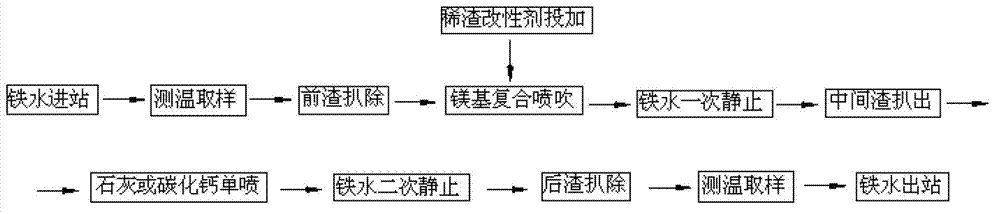

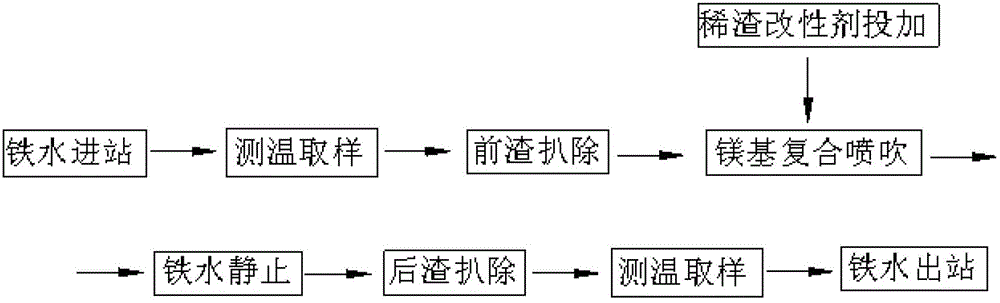

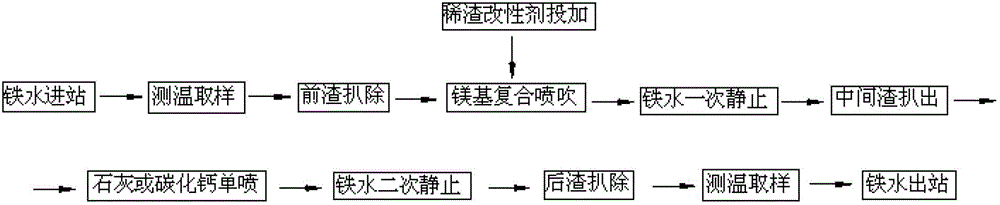

Deep desulfuration method for magnesium-based composite jetted molten iron

The invention discloses a deep desulfuration method for magnesium-based composite jetted molten iron. The deep desulphurization method comprises the following steps of: after the molten iron is fed and subjected to temperature measurement and sampling, scrabbling primary slag before a slag scrabbling station; subsequently desulfurating the molten iron in a magnesium-based composite jetting mode at a jetting and desulfuration station, adding a lean slag modifier in the jetting process and modifying the lean slag of the solid or semi-molten desulfurated slag; subsequently transferring to the slag scrabbling station to carry out primary standing on the molten iron and accomplish middle slag scrabbling; separately jetting lime or calcium carbide at the jetting and desulfuration station so as to carry out deep desulfuration on the molten iron and coagulate and modify residual liquid slag; after the separate jetting, transferring the molten iron tank to the slag scrabbling station to carry out secondary standing on the molten iron and accomplish later slag scrabbling; and after the later slag scrabbling, measuring the temperature, sampling and discharging the molten iron so as to meet the requirements on a molten iron material of a low-sulfur steel. The deep desulfuration method adopts a mode that desulfurated slag of different properties is respectively modified and scrabbled, and has the advantages of simplicity in operation, convenience in application and sufficiency in desulfurated slag modification.

Owner:武汉钢铁有限公司

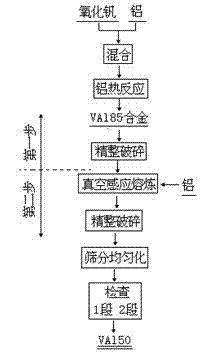

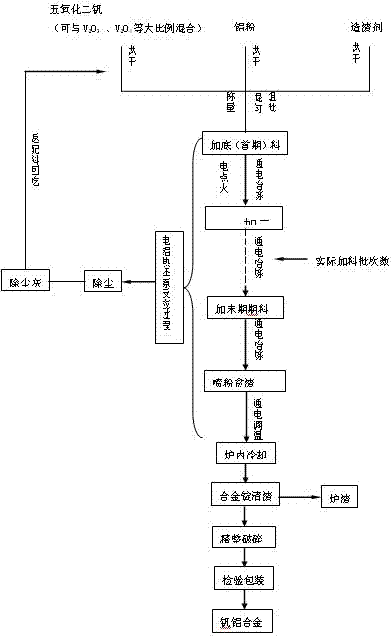

Method for smelting vanadium-aluminum alloy by electro-aluminothermic process

The invention discloses a method for smelting a vanadium-aluminum alloy by an electro-aluminothermic process. The method comprises the following steps of adding mixture into an electric arc furnace by stages after uniformly mixing vanadium oxide, an aluminum reducing agent and a slag forming constituent, and smelting by sequentially carrying out an aluminothermic reduction; and removing slag, finishing and crushing after completing the smelting, and thus obtaining the vanadium-aluminum alloy. According to the method disclosed by the invention, the electro-aluminothermic process is adopted for smelting at stages, the concentrated releasing of reaction heat can be effectively avoided, the splashing situation during a reaction process can be effectively relieved, the phenomenon that alloy exists in slag can be reduced to a large extent, the reaction process is controllable, and the method is particularly suitable for large-scale industrial production.

Owner:HEBEI IRON AND STEEL

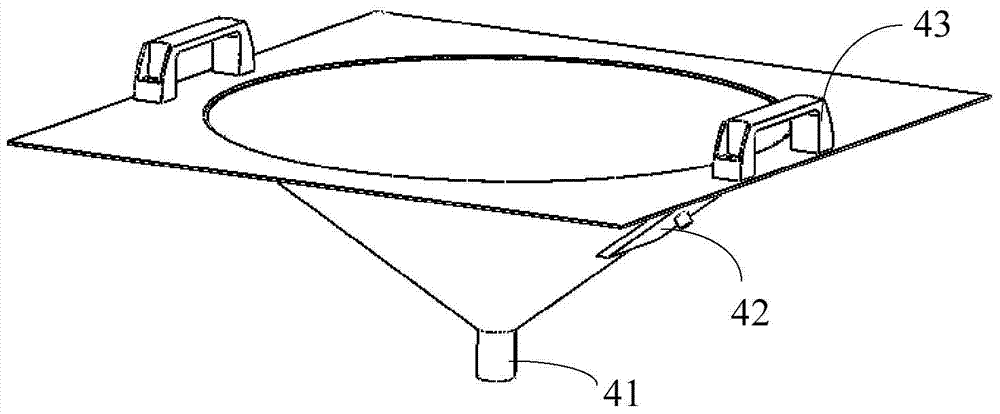

Slag adhesion preventing separant for stirring head and preparation method thereof

The invention discloses a slag adhesion preventing separant for a stirring head and a preparation method thereof and solves the problem of slag adhesion of the stirring head. The slag adhesion preventing separant for the stirring head is prepared from the following raw materials in parts by weight: 55 to 75 parts of quartz powder, 5 to 15 parts of amorphous graphite, 5 to 15 parts of silicon carbide, 3 to 8 parts of clay, 0.5 to 2 parts of sodium carboxymethylcellulose, 1 to 3.5 parts of paper fiber and 0.03 to 0.15 parts of organic fiber. The prepared separant disclosed by the invention has the characteristics of good adhesion under a normal temperature, high low-temperature bonding strength, reduction or loss of high-temperature bonding strength and benefit to automatic falling off; theseparant can generate larger volume expansion or contraction along with temperature rise and fall, so that the separant is favorable for self crack generating and has an automatic structure collapsingeffect. When being applied to the surface of a refractory material of the KR stirring head, the separant has an effect of preventing slag adhesion; thus, labor intensity is reduced, and service lifeof the stirring head is improved.

Owner:北京利尔高温材料股份有限公司

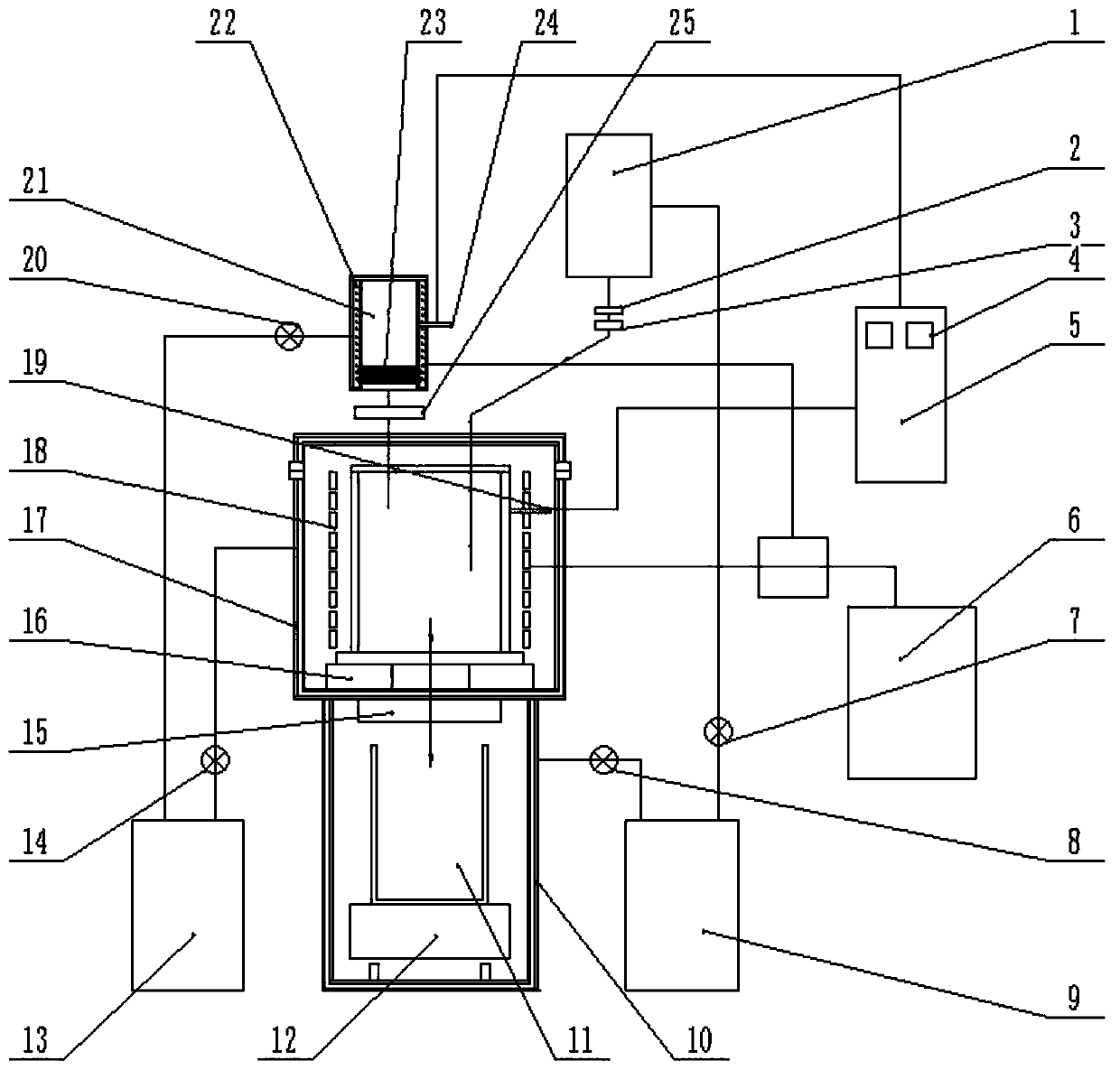

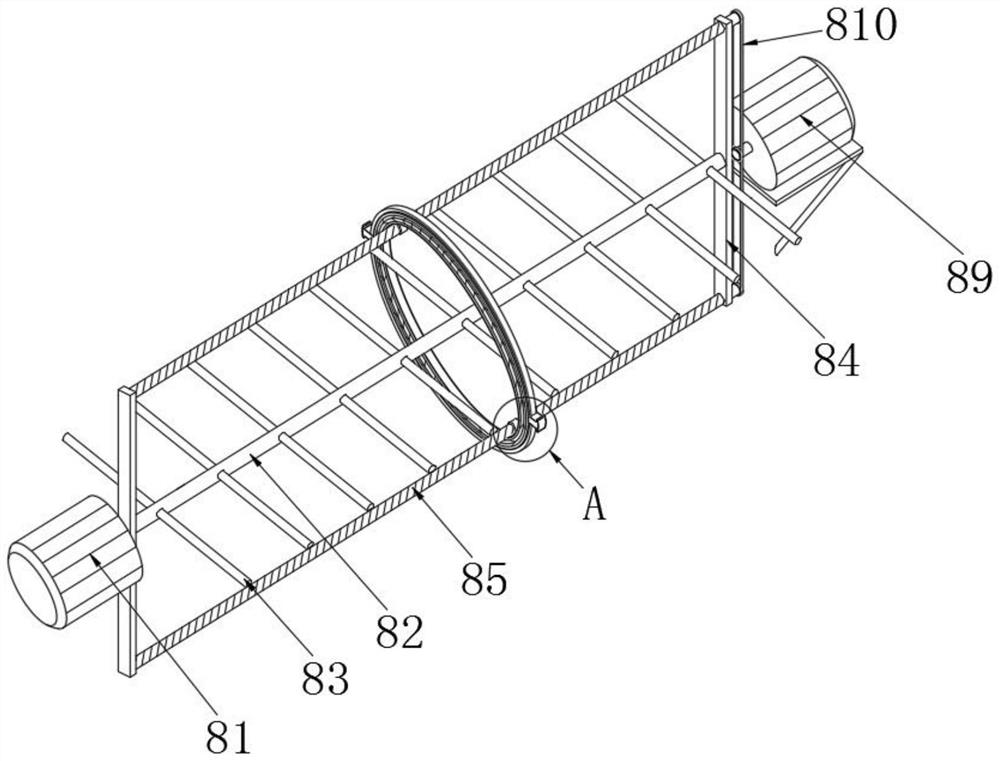

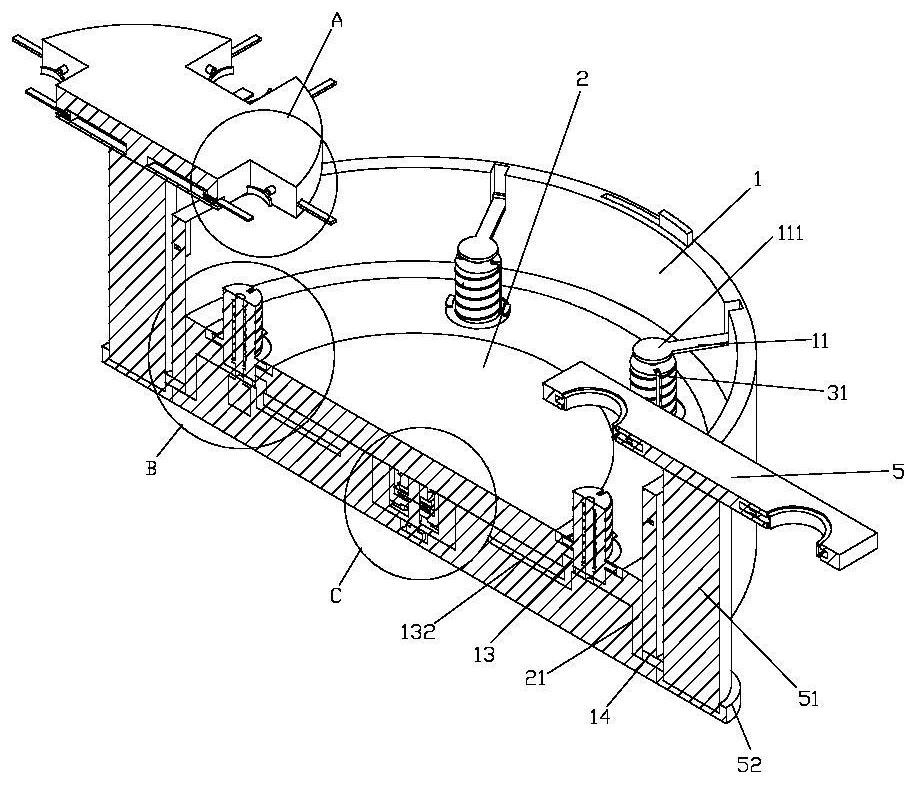

Continuous production equipment and continuous production method for magnesium metal

The invention discloses continuous production equipment and a continuous production method for a magnesium metal. The continuous production equipment comprises a charging device, a reduction room, a crystallizer and a deslagging room. The charging device, the reduction room, the crystallizer and the deslagging room are provided with vacuum detectors and communicate to a vacuum device. The chargingdevice is located above the reduction room and communicates to the reduction room, a material isolating valve is arranged between the charging device and the reduction room, the deslagging room is arranged right below the reduction room, the reduction room communicates to the deslagging room and a deslagging isolating valve is arranged between the reduction room and the deslagging room, and the crystallizer communicates to the upper side of the reduction room; the inner wall of the reduction room is a graphite crucible, titanium boride is plasma sprayed to the surface of the graphite crucible, and an electromagnetic induction heating device is arranged in the reduction room, so that no other heating devices are available in the reduction room, and therefore, the equipment is large in space and quick and uniform to head, the reaction time can be saved obviously and a slag adhesion phenomenon can be also avoided.

Owner:BEIJING OUFEI JINTAI TECH CO LTD

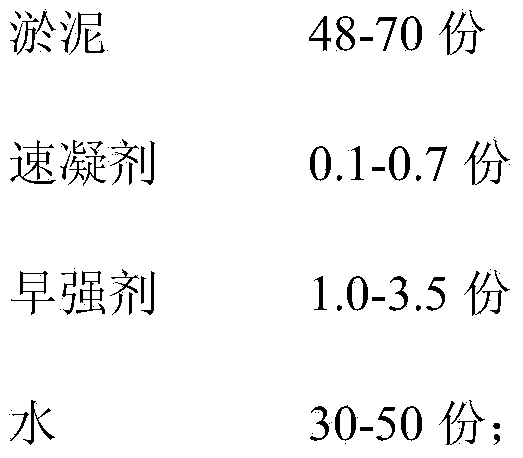

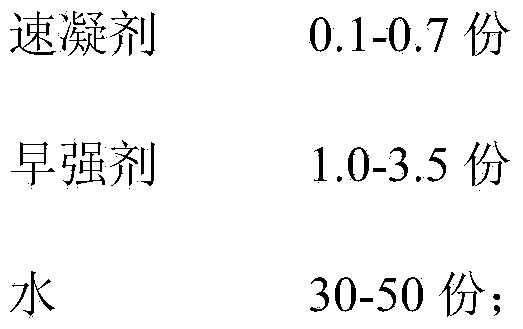

Short-flow recycling process of drum-method circulating water sludge

The invention provides a short-flow recycling process of drum-method circulating water sludge, and discloses a sludge body taking sludge as a main material of a gunning slag ladle. The sludge body of the gunning slag ladle comprises the following components in parts by weight: 48-70 parts of sludge, 1.1-5.6 parts of additive, and 30-50 parts of water, wherein the sludge is precipitated sludge generated in three-stage precipitation in a drum-method circulating water treatment process; in total mass of the sludge, the remained amount is less than or equal to 5 percent by weight after sludge is screened through a sieve screen of 40 mu m; the additive comprises 0.1-0.7 part of accelerator by weight and 1.0-3.5 parts of early strength agent. The slurry can be used for gunning slag ladles, so that the drum slag treatment process is improved, and the sludge can be recycled.

Owner:MCC BAOSTEEL TECH SERVICE

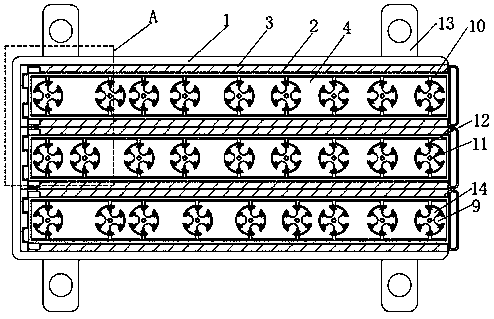

Mixing device for lithium battery electrolyte

ActiveCN114146608ALarge flow areaEvenly blendedShaking/oscillating/vibrating mixersTransportation and packagingElectrolytic agentElectrolyte

The stirring device comprises a second servo motor and a third servo motor, stirring blades are symmetrically and fixedly connected to the surface of a rotating rod, the two ends of the rotating rod are symmetrically and rotationally sleeved with rotating sleeve plates, and the opposite faces of the rotating sleeve plates are symmetrically and rotationally sleeved with rotating lead screws; the surface of the rotating screw rod is symmetrically sleeved with rotating sleeve rings in a threaded mode, flow guide mechanisms are fixedly connected to the opposite surfaces of the rotating sleeve rings, sliding blocks are symmetrically connected to the surfaces of the flow guide mechanisms, and one end of the rotating screw rod extends out of one side of the right rotating sleeve plate and is movably sleeved with a belt pulley. According to the mixing device for the lithium battery electrolyte, the problems that when a conventional stirring mechanism is used for stirring, the flowing area of liquid in an inner cavity is not changed, so that lithium salt, a solvent and an additive are not uniformly fused again, and residual materials of the lithium salt, the solvent and the additive appear in the liquid are solved.

Owner:湖北诺邦科技股份有限公司

Slag binding agent for preventing slag ladle as well as production process thereof

The invention provides a slag binding agent for preventing a slag ladle as well as a production process thereof. The production process comprises the following steps: cooling an aluminum-silicon carbide-carbon brick used by a torpedo ladle to 0.1-29.5 DEG C; placing the brick in a PC0606 jaw crusher to be crush to 5-50mm particles; then, adding the particles into a 4R3216 Raymond mill to be processed to powder which is below 3mm; mixing the powder with steel slag micropowder which is below 3mm in mass percent ratio of 15:85; and placing the mixture in a VI type forced stirring mixer to be uniformly stirred and mixed to obtain the slag binding agent, wherein the control time of adding 1 ton of materials is 15 minutes, and the stirring time is 15-20 minutes. When the slag binding agent is used, water is added into the inner wall of an empty slag ladle through a spray gun of a PB type semidry method gunning machine to spray, and the coating thickness is 0.5-2cm. The water addition of water added to spray accounts for 8-12% of total weight of the slag binding agent used.

Owner:XINJIANG ZHONGHE DAZHENG COMMERCE & TRADE

A repairing material for torpedo slag line area

The invention relates to the technical field of metallurgy, in particular to a torpedo ladle slag line zone repair material. The repair material comprises the following components in percentage by mass: 40 to 80 percent of aluminum silicon carbide carbon brick waste, 10 to 40 percent of third-grade brown aluminum oxide, 1 to 6 percent of calcium aluminate cement, 2 to 8 percent of clay, 1 to 8 percent of silicon carbide material, 0.01 to 0.04 percent of polypropylene fiber and balance of inevitable impurity. The torpedo ladle slag line zone repair material provided by the embodiment of the invention has the advantages that the calcium aluminate cement can improve the normal temperature physical strength of the repair material; the clay can improve the viscosity of the repair material and the construction is facilitated; the silicon carbide can further improve the slag corrosion resistance of the repair material, the repair material is enabled to not stick slag and the times of use are improved; the polypropylene fiber can reduce the drying time of the repair material after construction, improve the volumetric stability during baking or use and prevent burst. The torpedo ladle slag line zone provided by the embodiment of the invention improves the slag corrosion resistance of the torpedo ladle slag line zone repair material; since a great amount of aluminum silicon carbide carbon brick waste is adopted, the use cost of the repair material is reduced.

Owner:WUGANG REFRACTORY CO LTD

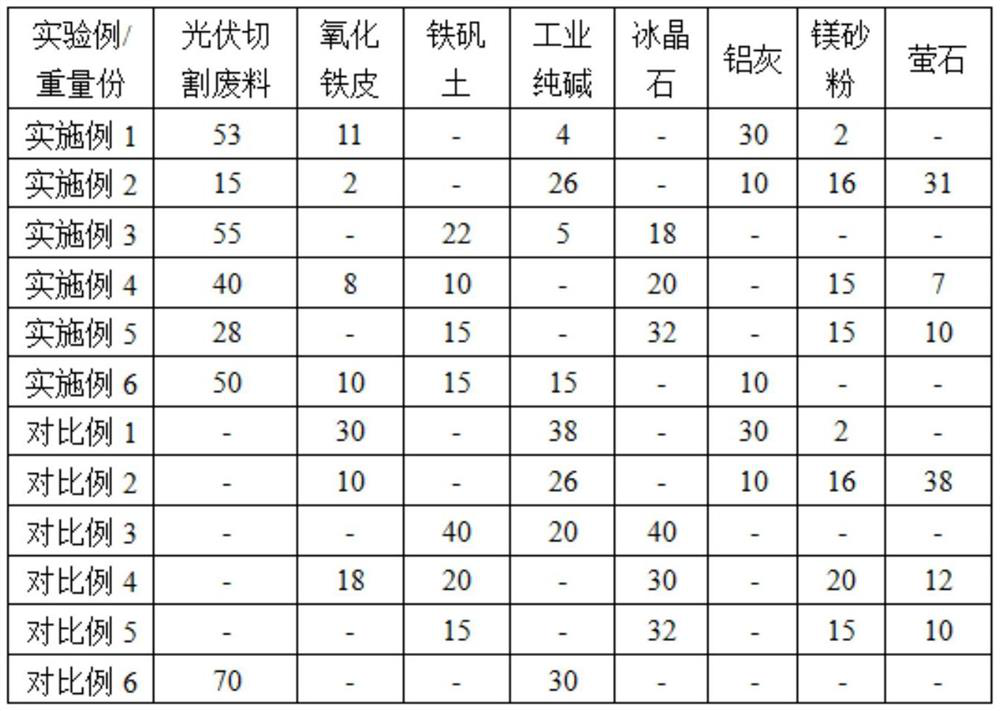

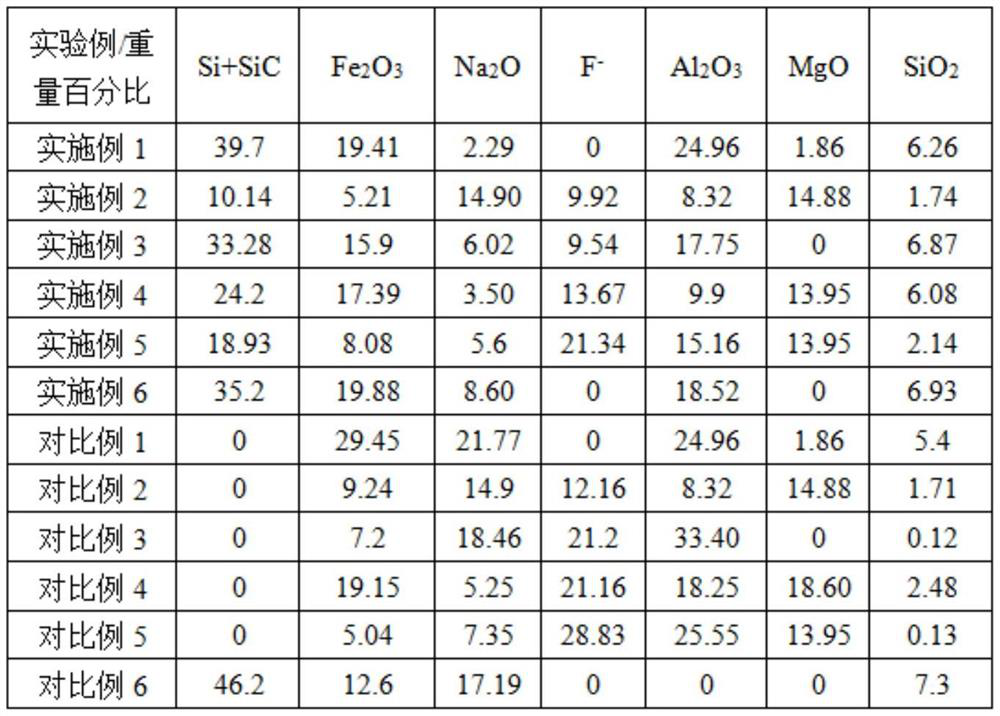

Efficient slagging agent for semi-steel tank and preparation method of efficient slagging agent

ActiveCN114131008AImproved thermodynamic environmentImprove slag removal effectCasting cleaning apparatusProcess efficiency improvementChemical compositionSemi-steel

The invention provides a high-efficiency slagging agent for a semi-steel tank, and belongs to the technical field of metallurgical auxiliary materials. The invention relates to a high-efficiency slag melting agent for a semi-steel tank. The high-efficiency slag melting agent comprises the following chemical components in percentage by weight: 10-40% of Si + SiC, 5-20% of Fe2O3, 2-15% of Na2O, 0-22% of F, 8-25% of Al2O3, 0-15% of MgO, 1-7% of SiO2 and the balance of impurities. According to the efficient slagging agent, through reasonable matching of the effective chemical components, reasonable utilization of medium-grade and low-grade photovoltaic cutting waste can be achieved, ladle wall bonded slag can be melted and diluted, and the problem that the slag is seriously bonded to a semi-steel tank in the processes of production, transfer and the like of semi-steel is thoroughly solved.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

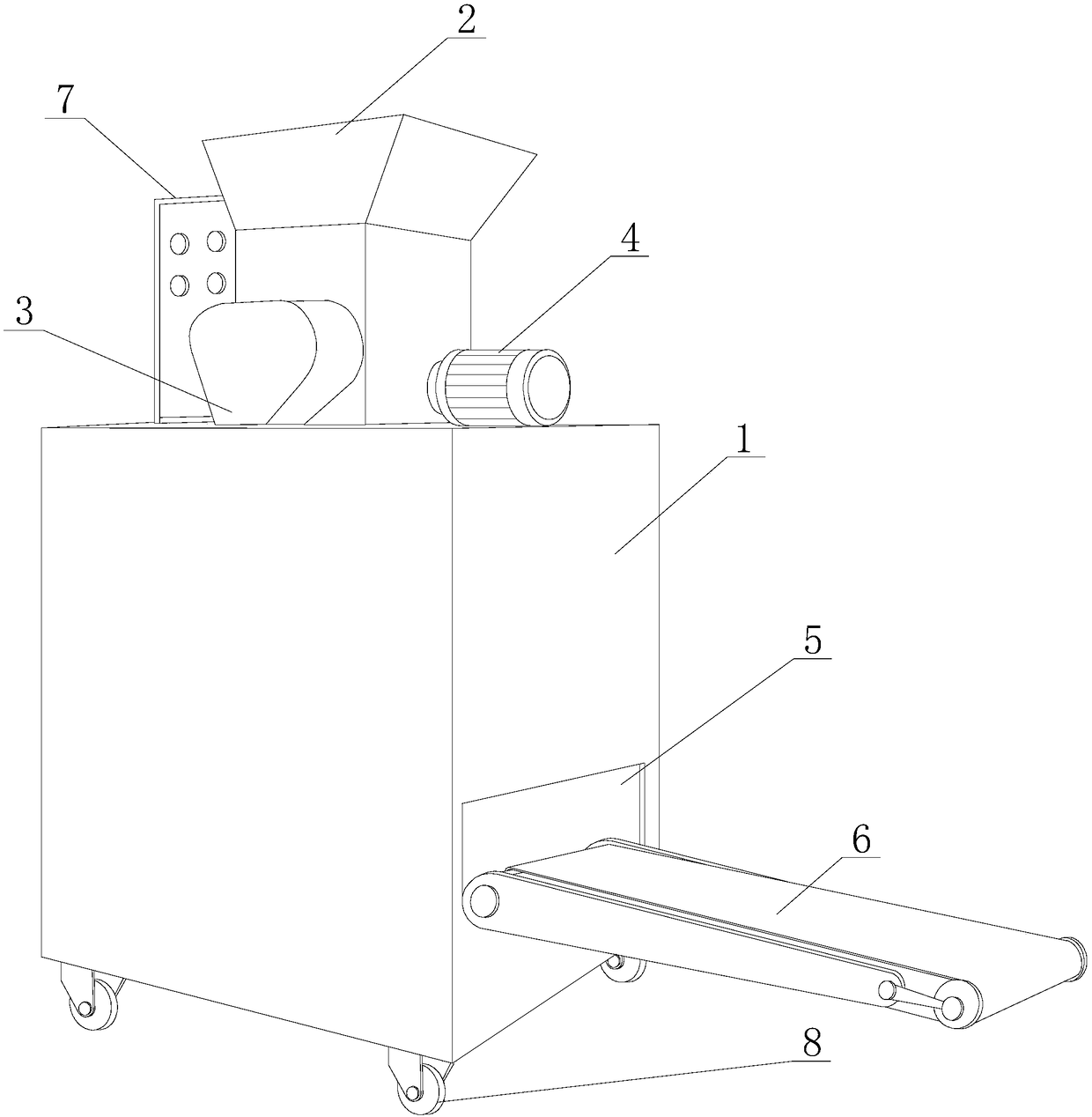

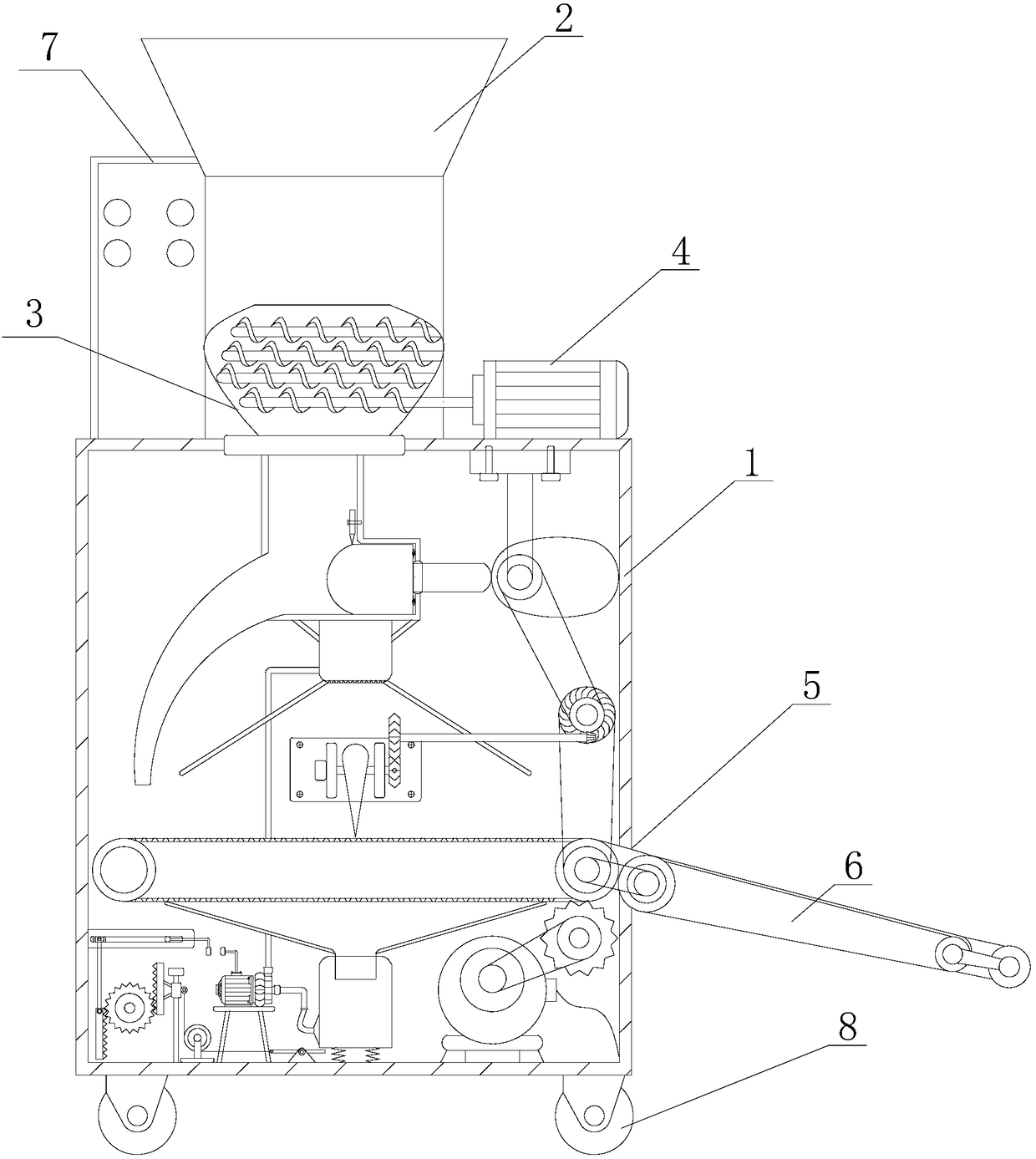

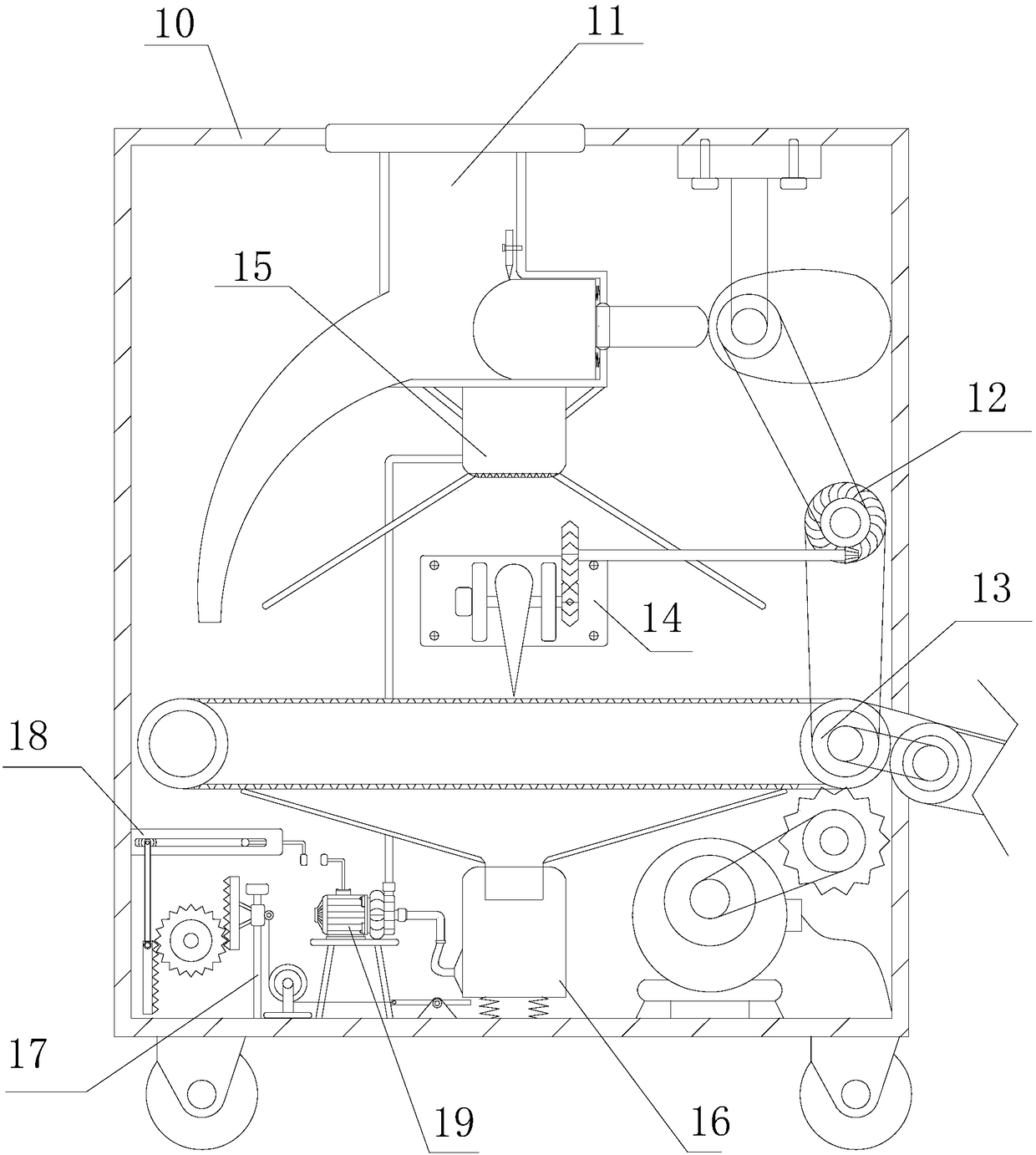

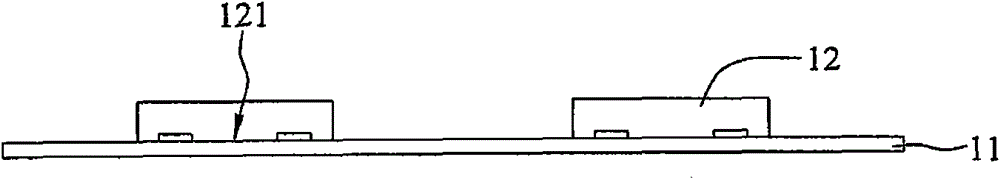

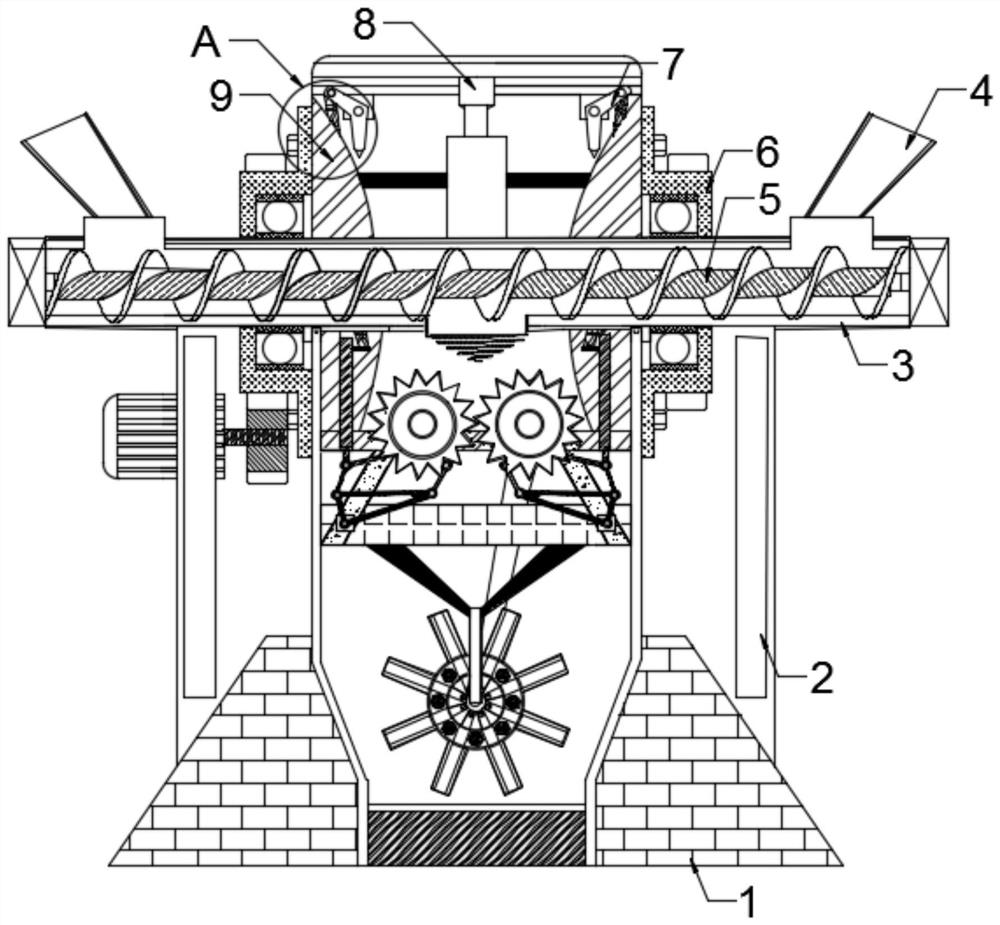

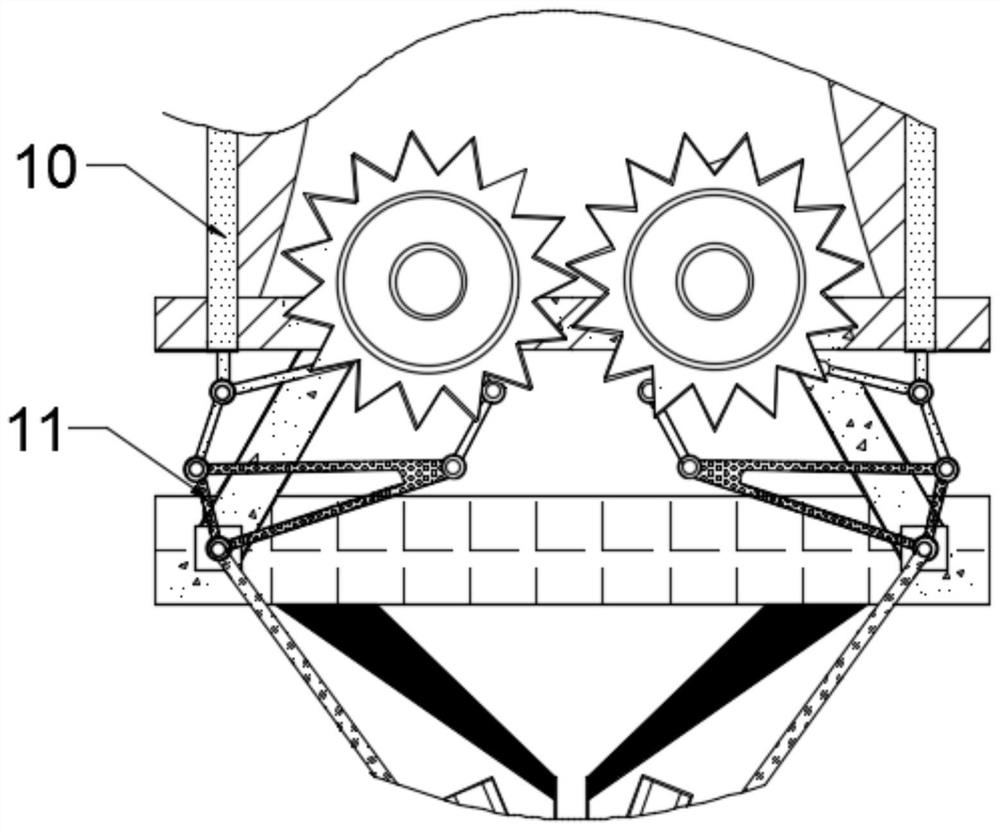

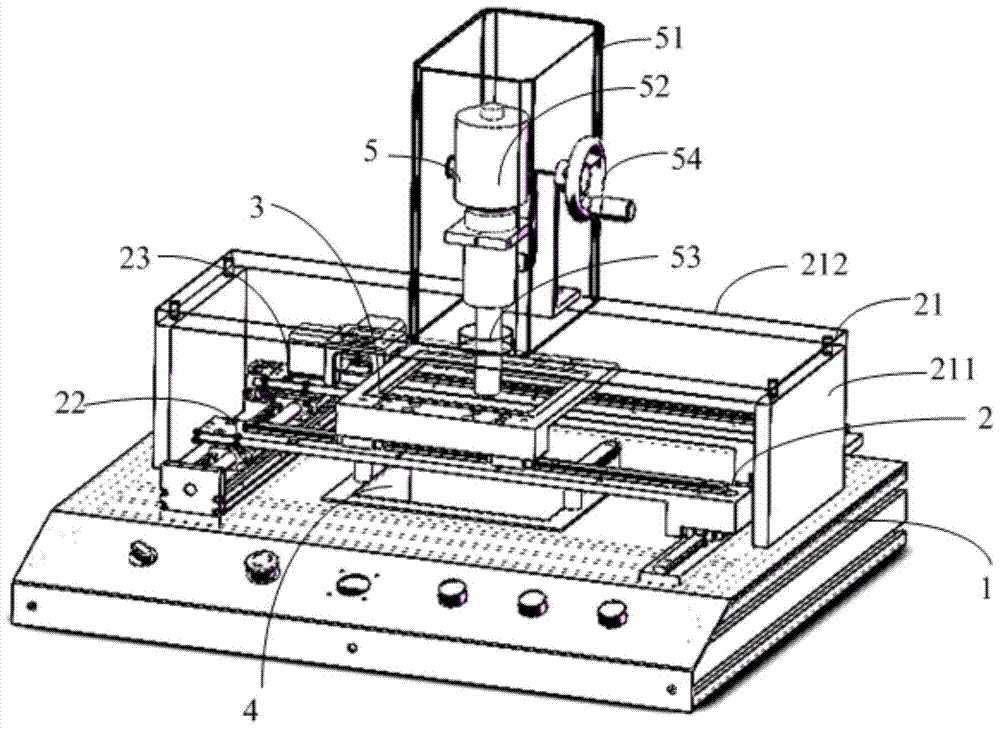

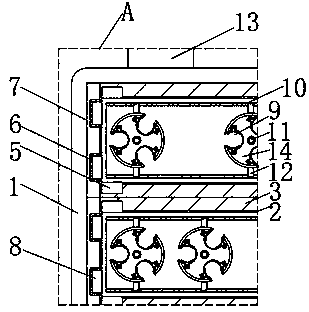

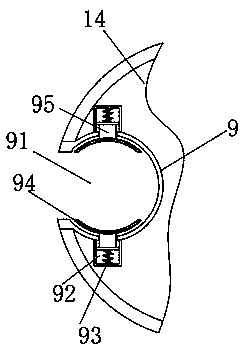

Cutting device of viscoelastic food

InactiveCN108338392APrevent food sticky residueEasy to cleanFood coatingFood shapingScattering functionCorrosion

The invention discloses a cutting device of viscoelastic food. The cutting device structurally comprises an anti-sticking thorough cutting device, a feeding hopper, a uniform mixing device, a mixing motor, a discharging port, a discharging conveying device, an electric cabinet and moving rollers. The anti-sticking thorough cutting device adopts a rectangular structure, the feeding hopper is arranged in the center of the upper side of the anti-sticking thorough cutting device and in vertical communication connection through electric welding, the uniform mixing device is arranged in the feedinghopper, and the mixing motor is arranged on the upper right side of the anti-sticking thorough cutting device and penetrates through the right side wall of the feeding hopper to be connected with theuniform mixing device through electric welding. By the aid of the anti-sticking thorough cutting device, viscoelastic food can be cut thoroughly by use of a rotary cutter, meanwhile, the device has apowder scattering function, food sticking can be prevented, cleaning is facilitated, device corrosion is prevented, the practicality of the cutting device for the viscoelastic food is effectively enhanced, and the service life of the device is prolonged.

Owner:南安富诚阁工业设计有限公司

Steel separating agent for rotary platform and furnace cover of ladle refining furnace and method for preventing steel bonding of rotary platform and furnace cover of ladle refining furnace

ActiveCN102557694ASolve the problem of sticking steelSafe cleanupMelt-holding vesselsPhosphateGraphite

The invention provides a steel separating agent for a rotary platform and a furnace cover of a ladle refining furnace and a method for preventing the steel bonding of the rotary platform and the furnace cover of the ladle refining furnace, wherein the steel separating agent comprises the following components in percent by weight: 8-15 percent of high-alumina aggregate powder, 5-8 percent of quartz sand powder, 4-6 percent of silica micropowder, 25-35 percent of phosphorus-sheet graphite powder, 5-10 percent of zircon sand powder, 4-8 percent of organic bentonite, 10-18 percent of aluminium dihydrogen phosphate liquid and 15-25 percent of water. After the steel separating agent provided by the scheme is adopted, the difficult problem of steel bonding at all parts of the ladle refining furnace is effectively solved, the normal refining production time is greatly saved, the steel refining environment is effectively improved, the original fussy working for repeatedly bedding asbestos plates is eliminated, the production cost and the production time are greatly saved, and the economic value is higher.

Owner:湖南省涟源市合成耐火材料厂

Chip-scale package and fabrication method thereof

ActiveCN102412208BSolve warpingPrevent sticky residueSemiconductor/solid-state device detailsSolid-state devicesChip sizeEngineering

The invention discloses a chip-size package and a manufacturing method thereof. The chip-size package comprises: an encapsulation compound having opposite first and second surfaces, a first encapsulation compound disposed in the encapsulation compound and exposed to the encapsulation compound. and the conductive bump on the second surface, the chip embedded in the encapsulant and exposed on the first surface of the encapsulant, the dielectric layer provided on the first surface of the encapsulant, the conductive bump and the chip, The circuit layer arranged on the dielectric layer, the conductive blind holes arranged in the dielectric layer to electrically connect the circuit layer, electrode pads and conductive bumps, and the barriers arranged on the dielectric layer and the circuit layer solder layer. Therefore, other electronic devices can be directly externally connected through the conductive bump to form a stack structure, which effectively simplifies the manufacturing process.

Owner:SILICONWARE PRECISION IND CO LTD

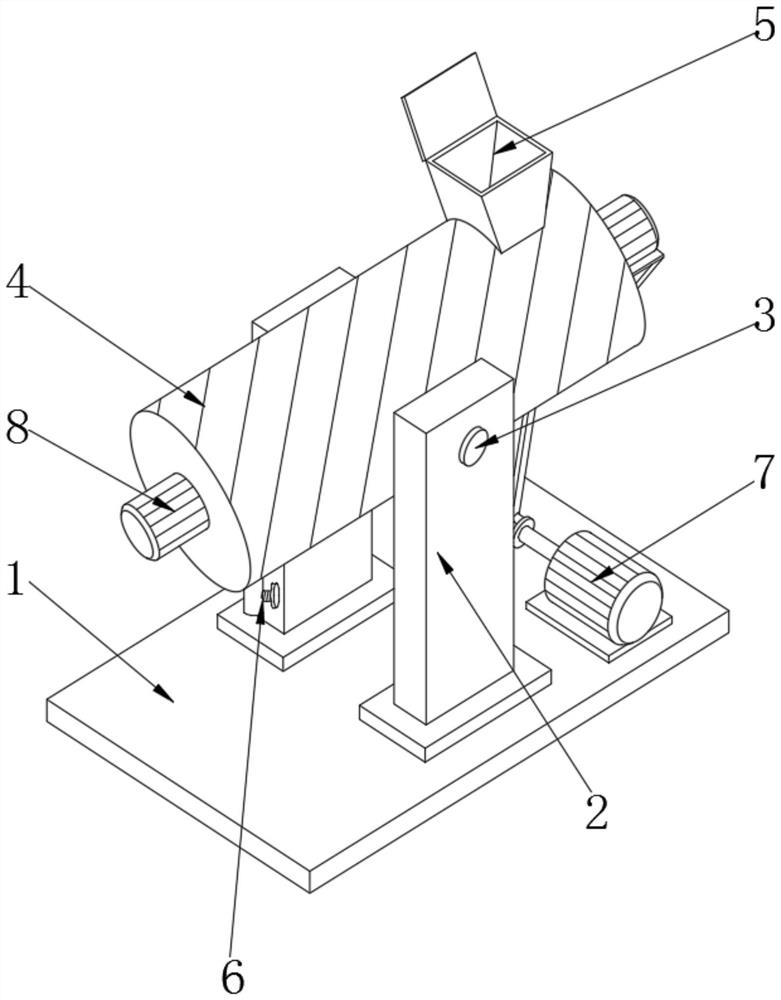

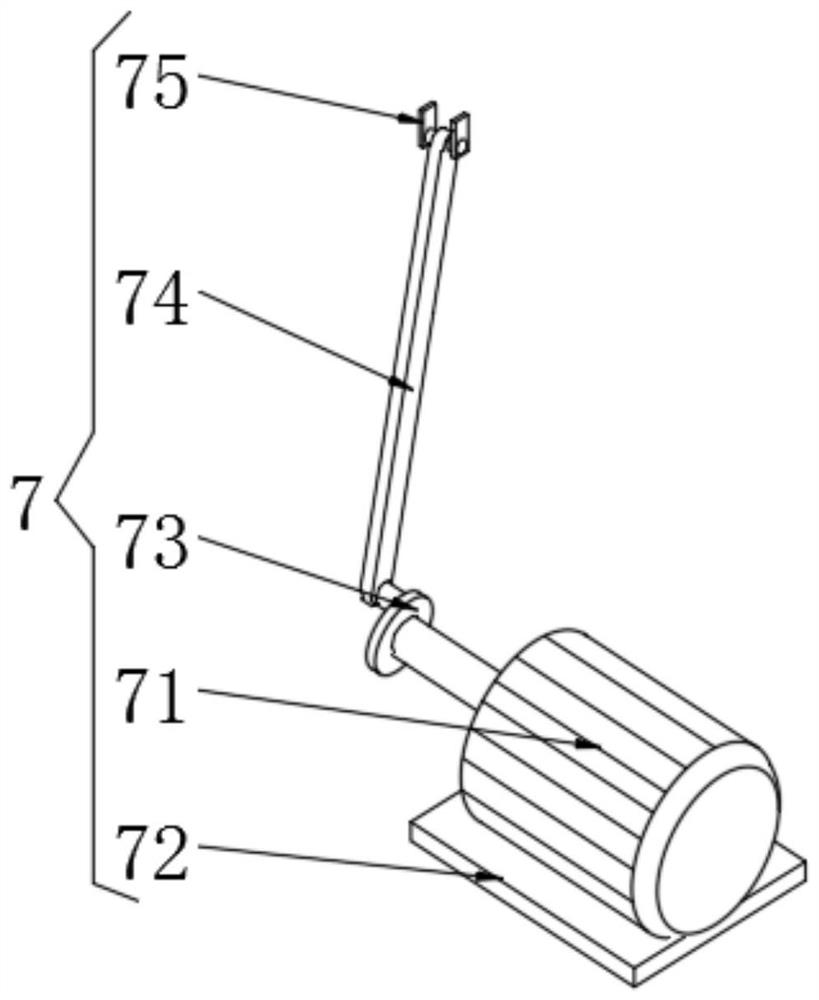

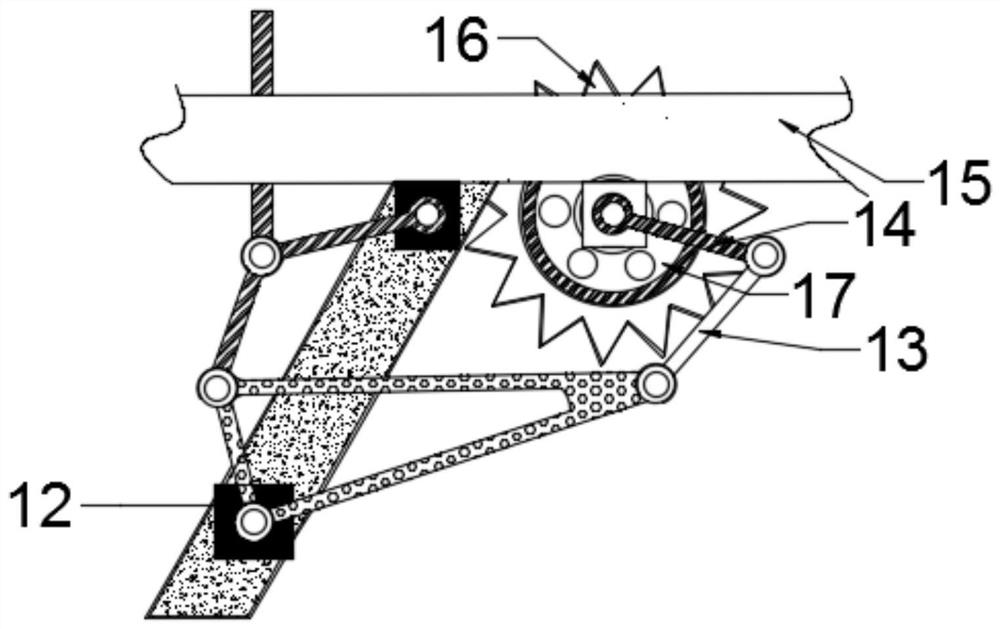

Plastic granulator equipment for detecting granule weight by utilizing water cooling

InactiveCN112372873ASolve the problem of easy adhesionPrevent sticky residueWeighing apparatus using fluid action balancingEngineeringWater cooling

The invention relates to the technical field of plastic granulators, and discloses plastic granulator equipment for detecting a granule weight by utilizing water cooling. The equipment comprises a base, wherein the left end and the right end of the base are movably connected to a support frame, the top end of the support frame is fixedly connected to a hopper, a right arm of the top end of the hopper is movably connected to a feed port, and the inner side of the feed port is movably connected to a rotating rod. According to the plastic granulator equipment for detecting the granule weight by utilizing water cooling, a round rotating wheel rotates to drive a driven rod to start to operate, the driven rod drives a linkage rod to do circular motion around the round rotating wheel, an action rod drives a knocking part to knock the hopper, a pushing rod inclines along with rotation of the linkage rod by a certain angle, water inside a solvent part is dried in the sun at a uniform speed, rawmaterials are subjected to water cooling, under the dual effects of knocking and spraying, raw material residues are effectively prevented from adhering to the inner side of the equipment, and the problem that granules produced by a plastic granulator are prone to adhering together is solved.

Owner:邓建芳

Casting material and method for fusible mold

The invention provides a material for casting a fusible mold. The material for casting the fusible mold is composed of the following raw materials of, by weight, 60-100 parts of ductile cast iron, 10-30 parts of silicon iron, 10-30 parts of scrap tin products, 15-30 parts of scrap aluminium products, 25-35 parts of ethylene copolymer elastomer, 23-38 parts of nano calcium carbonate, 18-35 parts ofethylene-acrylate, 30-40 parts of crystalline flake graphite, 16-27 parts of a carburant, 4-8 parts of hollow glass microsphere, 3-8 parts of bentonite, 5-13 parts of wood fiber with the mesh being 100-230, 6-14 parts of kieselguhr with the mesh being 100-200, 8-11 parts of open hole expanded perlite with the mesh being 60-150, 5-9 parts of light paint plaster, 5-9 parts of a casting nucleating agent and 3-7 parts of a slag removal agent. The fusible mold is cast by performing heating melting, slagging-off, slag gathering, keeping warm and pouring on the raw materials in sequence. The castingmaterial and method for the fusible mold have the beneficial effects that (1), the casting material flows evenly, the phenomenon of sticky slag existing on a final cast blank is avoided, the acceptedproduct rate is increased, and the production efficiency is improved at the same time; (2), the casting method is simple, the cost is low, and meanwhile the service life of the final fusible mold ismade to be prolonged.

Owner:东风精密铸造安徽有限公司

Deep desulfuration method for magnesium-based composite jetted molten iron

The invention discloses a deep desulfuration method for magnesium-based composite jetted molten iron. The deep desulphurization method comprises the following steps of: after the molten iron is fed and subjected to temperature measurement and sampling, scrabbling primary slag before a slag scrabbling station; subsequently desulfurating the molten iron in a magnesium-based composite jetting mode at a jetting and desulfuration station, adding a lean slag modifier in the jetting process and modifying the lean slag of the solid or semi-molten desulfurated slag; subsequently transferring to the slag scrabbling station to carry out primary standing on the molten iron and accomplish middle slag scrabbling; separately jetting lime or calcium carbide at the jetting and desulfuration station so as to carry out deep desulfuration on the molten iron and coagulate and modify residual liquid slag; after the separate jetting, transferring the molten iron tank to the slag scrabbling station to carry out secondary standing on the molten iron and accomplish later slag scrabbling; and after the later slag scrabbling, measuring the temperature, sampling and discharging the molten iron so as to meet the requirements on a molten iron material of a low-sulfur steel. The deep desulfuration method adopts a mode that desulfurated slag of different properties is respectively modified and scrabbled, and has the advantages of simplicity in operation, convenience in application and sufficiency in desulfurated slag modification.

Owner:武汉钢铁有限公司

Manufacturing method of package with embedded chip

ActiveCN102456636BAvoid offsetAvoid pollutionSemiconductor/solid-state device detailsSolid-state devicesDielectric layerChip-scale package

Owner:SILICONWARE PRECISION IND CO LTD

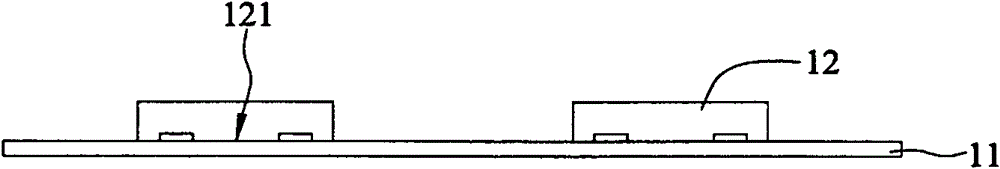

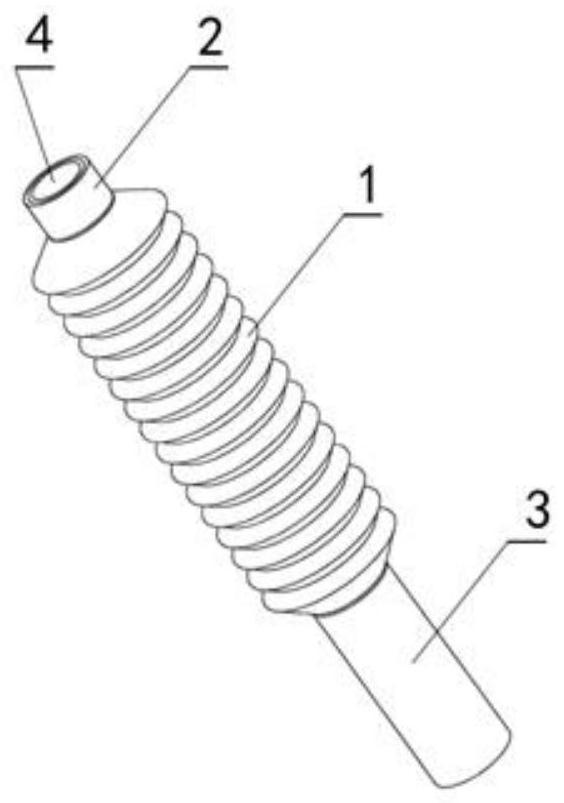

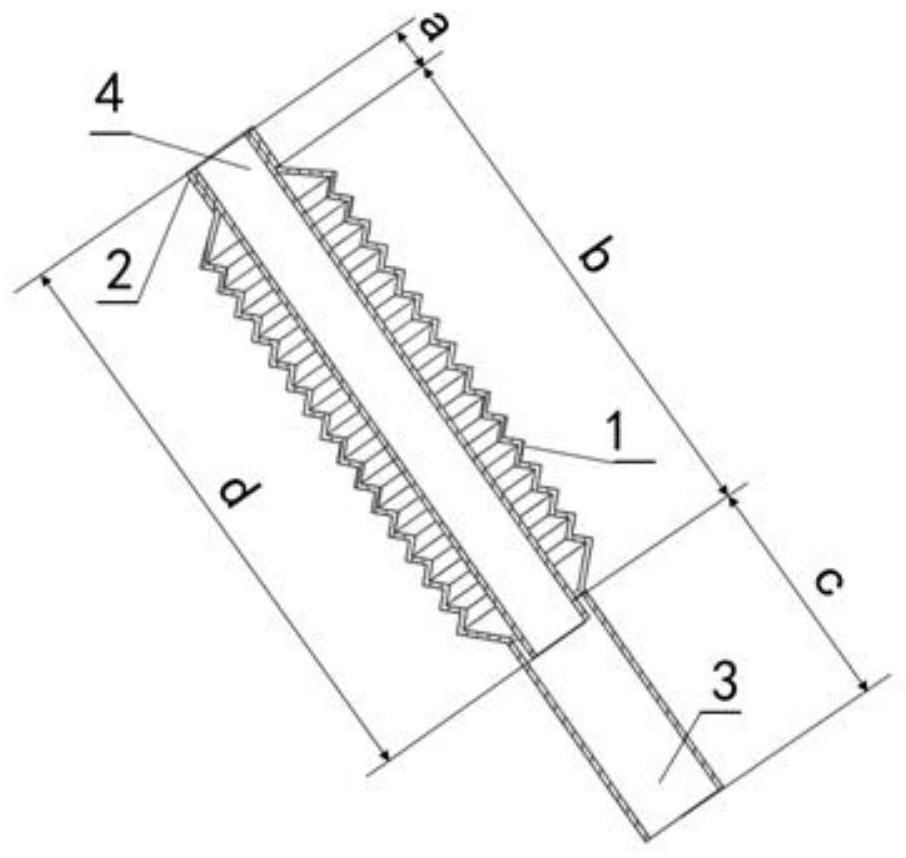

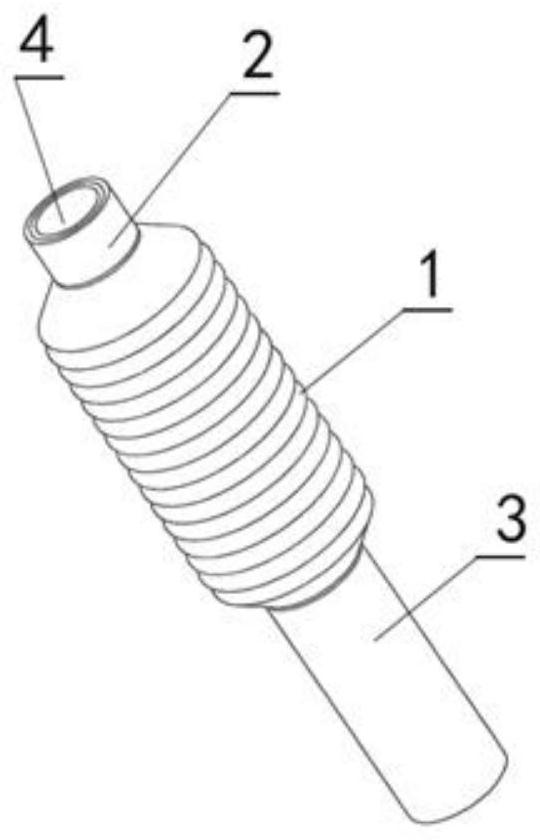

Seed metering pipe capable of preventing seed residues

PendingCN113711739AGuaranteed uniformityGuarantee the quality of sowingSeed depositing seeder partsSeederAgricultural engineering

The invention discloses a seed metering pipe capable of preventing seed residues. The seed metering pipe comprises a rubber corrugated pipe, and further comprises a rubber pipe I, a rubber pipe II and a rubber polish pipe, the inner walls of the rubber pipe I, the rubber pipe II and the rubber polish pipe are smooth surfaces, an opening at one end of the rubber pipe I is in butt joint with an opening at one end of the rubber corrugated pipe, an opening at one end of the rubber pipe II is in butt joint with an opening at the other end of the rubber corrugated pipe, the rubber polish pipe sequentially penetrates through the rubber pipe I and the rubber corrugated pipe and is tightly attached to the inner side face of the rubber pipe I. When the rubber corrugated pipe stretches out and draws back, the rubber pipe II moves along the outer side face of the rubber polish pipe. During seeding, the external rubber corrugated pipe is stretched out and drawn back along with the fluctuation of the ground, the rubber pipe II moves along the outer side face of the rubber polish pipe, at the moment, seeds slide down along the inner wall of the rubber polish pipe all the time, the problems of blockage and the like do not exist, and the seed metering uniformity and the seed metering quality of a seeding machine are guaranteed.

Owner:HUHHOT BRANCH OF CHINESE ACAD OF AGRI MECHANIZATION SCI

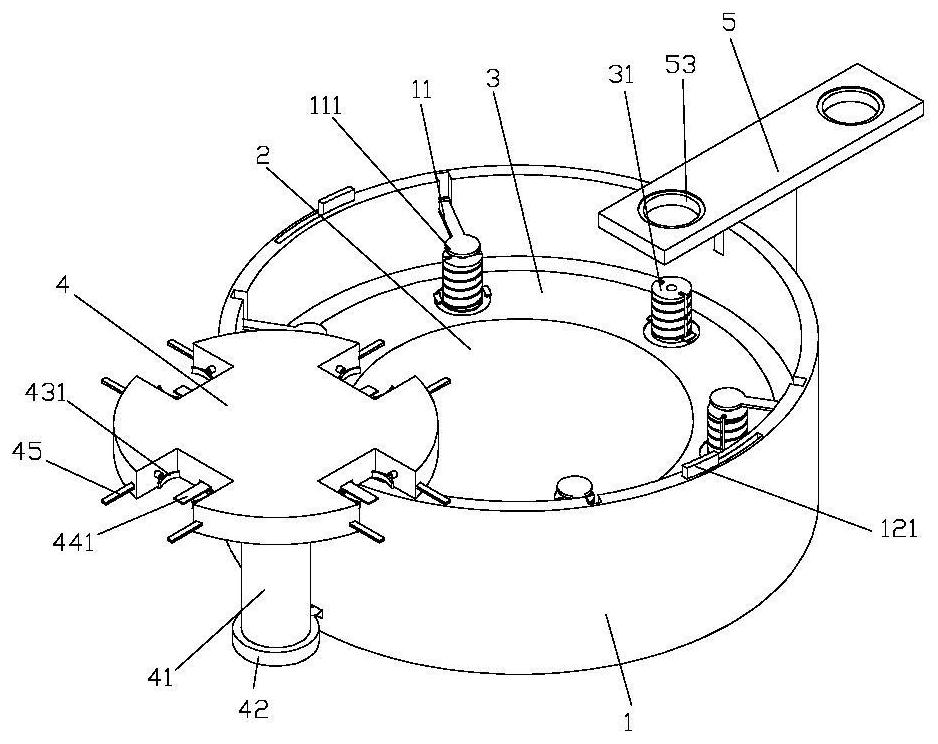

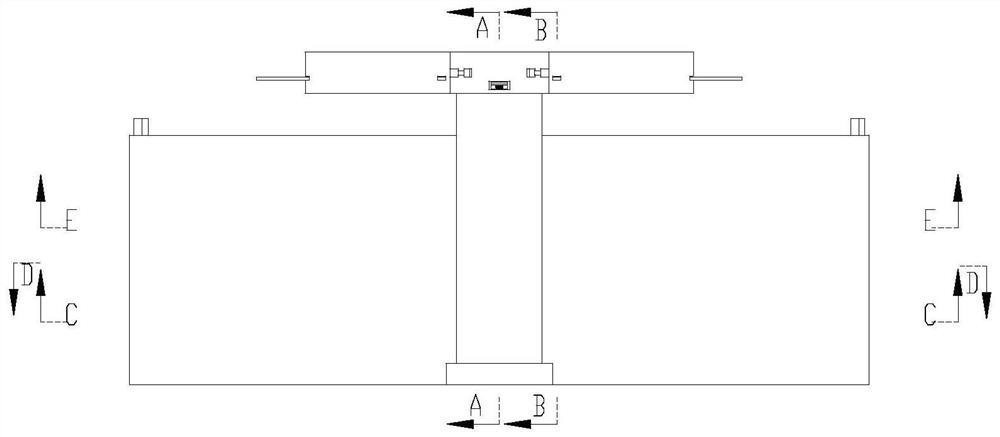

Stripping and collecting equipment based on high-frequency vibration

ActiveCN104600008BReduce work intensityImprove work efficiencySemiconductor/solid-state device manufacturingAdhesiveEngineering

The invention discloses a high-frequency vibration based material stripping and collecting device. The material stripping and collecting device comprises a base, an operating platform located above the base, a fixing plate fixed to the operating platform, a material collecting device located under the operating platform and used for collecting striped components and parts and a high-frequency vibration device located above the fixing plate, wherein a support is fixed to the fixing plate and used for fixing components and parts to be striped. The high-frequency vibration based material stripping and collecting device can reduced strength and working strength of an operator, remarkably improves working efficiency and is simple in structure, high in automation degree and operating accuracy and capable of effectively avoiding damage of the components and parts and residual adhesive and meanwhile avoiding edge water material collection.

Owner:苏州微赛智能科技有限公司

Fixing frame for thermocouple

InactiveCN111076834AFixing made easyFlexible adjustment of fixed positionThermometer detailsThermometers using electric/magnetic elementsFixed frameEngineering

The invention discloses a fixing frame for a thermocouple. The fixing frame comprises a main frame body, a built-in frame plate, fixing lugs and a circular frame plate. The fixing lugs are welded to the surfaces of the outer side of the main frame body, a fixing notch is formed in the main frame body, the built-in frame plate is transversely inserted into the fixing notch, mounting blocks are welded to the two sides of one end of the built-in frame plate, and mounting grooves matching the mounting blocks are formed in the two sides of the inner wall of the fixing notch. According to the invention, an e adjusting block transversely slides in an adjusting groove, so that the fixing position of the thermocouple can be flexibly adjusted; the thermocouples with different diameters can be easilyfixed by utilizing the fixing mode of the elastic force of the reset spring, so that the situation that the surfaces of the thermocouples are abraded due to surface friction in the thermocouple fixing process is reduced and the situation that mucilage glue remains after the thermocouples are disassembled is also avoided.

Owner:西安西派测控技术有限公司

A kind of determination method of yellow brown esterification liquid

ActiveCN113290002BPrevent sticky residueAvoid it happening againChemical analysis using titrationHollow article cleaningSodium acetateP-Nitroaniline

The invention discloses a method for measuring yellow brown esterification liquid, which comprises: weighing about 0.4 g of a sample into a 400 mL beaker, adding 10 mL glacial acetic acid and 100 mL sodium acetate solution, and then adding 50 mL water to keep the solution temperature at 5 " Below C, add 50 mL of p-nitroaniline diazonium salt droplet, stir at (0-5) °C for 30 min, and perform coupling titration with 2,4-diaminotoluene standard titration solution. When the intersection of the coupling test solution on the medium-speed qualitative filter paper and the diluted p-nitroaniline diazonium salt solution (1:5), the intersection is yellow, and the intersection with the H acid solution is colorless, that is as the end point; record the volume V1 of the 2,4-diaminotoluene standard titration solution consumed. At the same time, do a blank test; after the test, put the beaker into the ultrasonic cleaner for cleaning.

Owner:浙江汇翔新材料科技股份有限公司

Steel separating agent for rotary platform and furnace cover of ladle refining furnace and method for preventing steel bonding of rotary platform and furnace cover of ladle refining furnace

ActiveCN102557694BSolve the problem of sticking steelSafe cleanupMelt-holding vesselsAsbestos sheetPhosphate

Owner:湖南省涟源市合成耐火材料厂

Short-flow recycling process of drum-method circulating water sludge

ActiveCN103496943BSolving the problem of Sinotrans stockpiling and landfillingSolve the landfill problemThree stageSlag

The invention provides a short-flow recycling process of drum-method circulating water sludge, and discloses a sludge body taking sludge as a main material of a gunning slag ladle. The sludge body of the gunning slag ladle comprises the following components in parts by weight: 48-70 parts of sludge, 1.1-5.6 parts of additive, and 30-50 parts of water, wherein the sludge is precipitated sludge generated in three-stage precipitation in a drum-method circulating water treatment process; in total mass of the sludge, the remained amount is less than or equal to 5 percent by weight after sludge is screened through a sieve screen of 40 mu m; the additive comprises 0.1-0.7 part of accelerator by weight and 1.0-3.5 parts of early strength agent. The slurry can be used for gunning slag ladles, so that the drum slag treatment process is improved, and the sludge can be recycled.

Owner:MCC BAOSTEEL TECH SERVICE

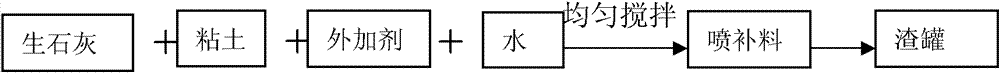

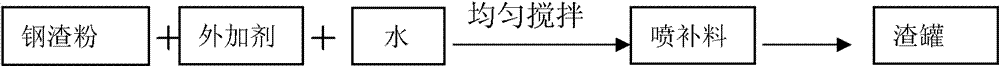

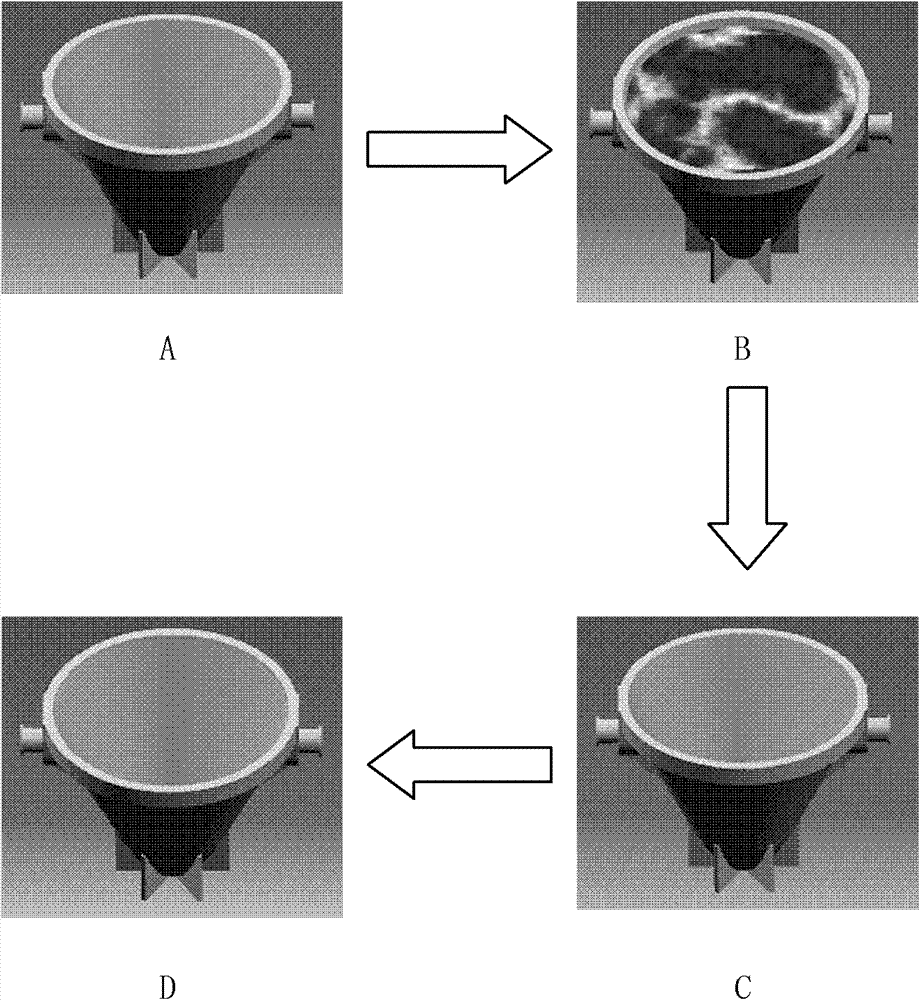

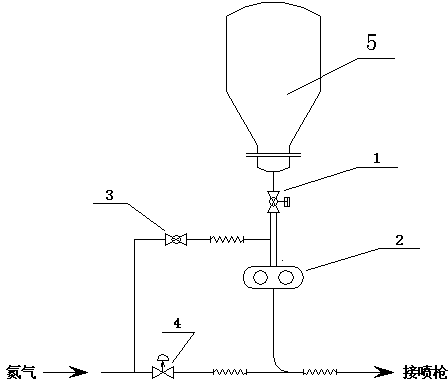

Slag ladle protective agent using steel slag as main raw material, and preparation method and spray repair method thereof

The invention belongs to the field of metallurgy, and relates to a slag ladle protective agent using steel slag as a main raw material, and a preparation method and a spray repair method thereof. The slag ladle protective agent which comprises the following main raw materials in parts by weight: 10-30 parts of steel slag powder and 70-90 parts of water. The slag ladle protective agent also comprises a coagulant, a plasticizer and a curing agent, wherein the coagulant accounts for 0.5-2.0 wt% of the steel slag powder, the plasticizer accounts for 0.3-5.0 wt% of the steel slag powder, and the curing agent accounts for 0.3-3.0 wt% of the steel slag powder. The spray repair protective agent is uniformly sprayed to the inner wall of the hot-state slag ladle to form a slag ladle protective filmlayer, thereby effectively preventing the slag ladle from adhesion, optimizing the quality of the steel slag, enhancing the stability of the steel slag, prolonging the service life of the ladle, lowering the production cost, being beneficial to equalizing and organizing production and promoting the benign circulation of production.

Owner:MCC BAOSTEEL TECH SERVICE +1

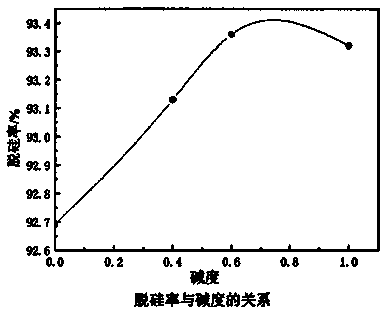

Dual mode dephosphorization method carrying out in hot-metal ladle

The invention relates to a dual mode dephosphorization method carrying out in hot-metal ladle and belongs to the technical field of hot metal pretreatment. According to the technical scheme, the method comprises the following steps of: setting two dephosphorization modes in the process of dephosphorization and switching between the two modes, particularly alternately using the dust-spraying mode and the gas-spraying mode for carrying out dephosphorization in the hot-metal ladle. According to the dust-spraying mode, a spray gun is used to spray passivating lime, surface oxygen and scale 1.5-2 meters deep into the hot-metal liquid level with the nitrogen as a carrier; according to the gas-spraying mode, the same spray gun is used to spray nitrogen, lime having a granularity of 5-30mm and transported by a belt, surface oxygen and surface oxygen and scale 1.5-2 meters deep into the hot-metal liquid level, the nitrogen is sprayed separately and just used for stirring. The method realizes flexible switching of the spray gun between the two spraying modes under the hot metal surface level according to pipeline diameter and dynamic conditions, thereby avoiding the hot metal from flowing backward and blocking the spray gun, stabilizing the injection, and shortening the process period and reducing the production cost.

Owner:XINGTAI IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com