Efficient slagging agent for semi-steel tank and preparation method of efficient slagging agent

A technology of slagging agent and steel tank, which is applied in the field of high-efficiency slagging agent for semi-steel tanks and its preparation, can solve the problems of resource waste and environmental pollution, reduce steelmaking costs, solve environmental pollution problems, and reduce tank capacity loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A high-efficiency slagging agent for semi-steel tanks, which is obtained by the following preparation method:

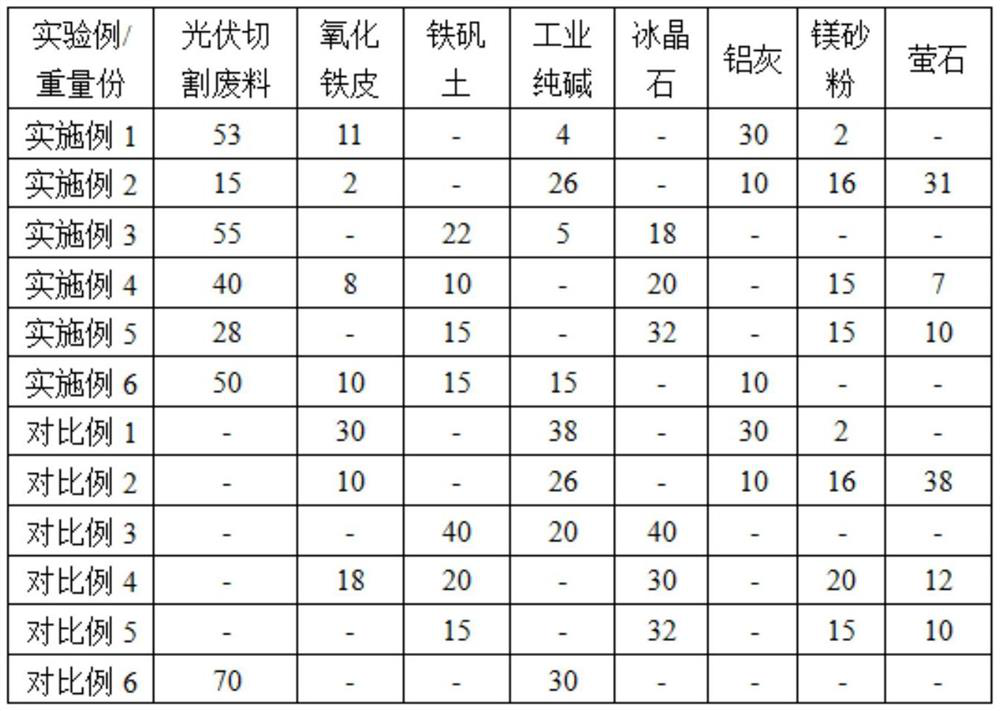

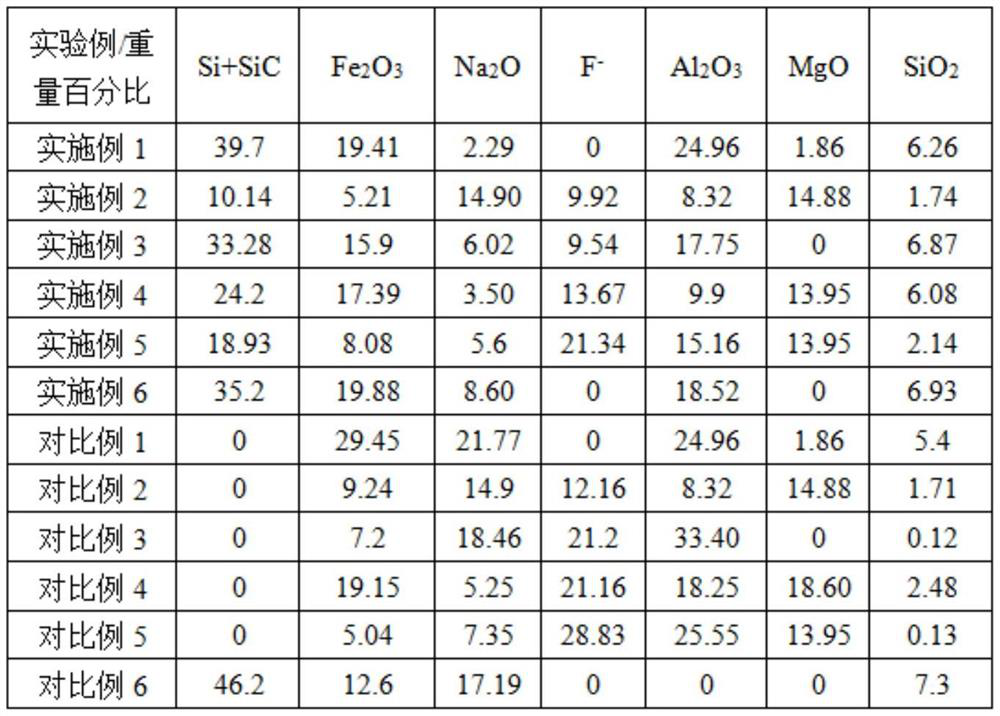

[0056] (1) Ingredients: According to the raw materials shown in Table 1, accurately measure, mix each raw material, add 2.0 parts by weight of binder, and mix and grind for 20 minutes to obtain a mixed material;

[0057] (2) Ball briquetting: transport the above-mentioned mixed materials to the double-roller briquetting machine, roll them into balls, and sieve them with a sieve, and control the ball diameter at 5-40mm;

[0058] (3) Drying: Put the qualified sieved pellets into a drying kiln for 30 minutes at 350° C., and cool, sieve, pack, and put into storage when the moisture content of the finished product is below 0.5%.

Embodiment 2

[0060] A high-efficiency slagging agent for semi-steel tanks, which is obtained by the following preparation method:

[0061] (1) Ingredients: According to the raw materials shown in Table 1, accurately measure, mix each raw material, add 0.3 parts by weight of binder, and mix and grind for 10 minutes to obtain a mixed material;

[0062] (2) Ball briquetting: transport the above-mentioned mixed materials to the double-roller briquetting machine, roll them into balls, and sieve them with a sieve, and control the ball diameter at 5-40mm;

[0063] (3) Drying: Put the qualified sieve pellets into a drying kiln for 100 minutes at 100°C, and cool, sieve, pack, and put into storage when the moisture content of the finished product is below 0.5%.

Embodiment 3

[0065] A high-efficiency slagging agent for semi-steel tanks, which is obtained by the following preparation method:

[0066] (1) Ingredients: According to the raw materials shown in Table 1, accurately measure, mix each raw material, add 1.3 parts by weight of binder, and mix and grind for 15 minutes to obtain a mixed material;

[0067] (2) Ball briquetting: transport the above-mentioned mixed materials to the double-roller briquetting machine, roll them into balls, and sieve them with a sieve, and control the ball diameter at 5-40mm;

[0068] (3) Drying: put the qualified sieved balls into a drying kiln for 60 minutes at 220°C, and cool, sieve, pack and put into storage when the moisture content of the finished product is below 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com