Slag ladle protective agent using steel slag as main raw material, and preparation method and spray repair method thereof

A technology of main raw material and protective agent, applied in the field of metallurgy, can solve problems such as increased content of free calcium oxide, difficulty in comprehensive utilization of steel slag, poor stability of steel slag, etc., to achieve the effects of improving stability, promoting a virtuous cycle, and increasing tank life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Prepare 1 ton of slag irrigation protective agent with steel slag as the main raw material:

[0039] The slag pot protective agent with steel slag as the main raw material of this embodiment, its raw material components and its proportioning ratio are shown in Table 1; the performance parameters of the steel slag powder used in its raw materials are shown in Table 2; the specific components of its raw materials as shown in Table 3.

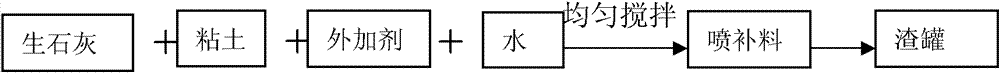

[0040] Its preparation method (process flow chart as figure 2 shown) is:

[0041] After weighing steel slag powder, coagulant, plasticizer and curing agent according to the ratio of raw materials, put the weighed raw materials in a forced mixer, add water according to the ratio and stir evenly for 10 minutes to form a slurry material, which is A slag tank protective agent with steel slag as the main raw material.

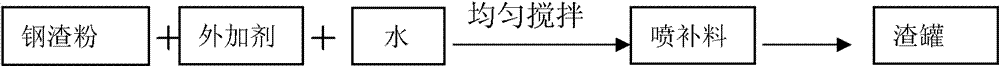

[0042] The method (such as image 3 (shown) is: the obtained slag tank protective agent with steel slag as the main raw ma...

Embodiment 2

[0045] Prepare 1 ton of slag irrigation protective agent with steel slag as the main raw material:

[0046] The slag pot protective agent with steel slag as the main raw material of this embodiment, its raw material components and its proportioning ratio are shown in Table 1; the performance parameters of the steel slag powder used in its raw materials are shown in Table 2; the specific components of its raw materials as shown in Table 3.

[0047] Its preparation method is:

[0048] After weighing steel slag powder, coagulant, plasticizer and curing agent according to the ratio of raw materials, put the weighed raw materials in a forced mixer, add water according to the ratio and stir evenly for 10 minutes to form a slurry material, which is A slag tank protective agent with steel slag as the main raw material.

[0049] The method of repairing the slag tank with the slag tank protective agent with steel slag as the main raw material is: spray the obtained slag tank protectiv...

Embodiment 3

[0052] Prepare 1 ton of slag irrigation protective agent with steel slag as the main raw material:

[0053] The slag pot protective agent with steel slag as the main raw material of this embodiment, its raw material components and its proportioning ratio are shown in Table 1; the performance parameters of the steel slag powder used in its raw materials are shown in Table 2; the specific components of its raw materials as shown in Table 3.

[0054] Its preparation method is:

[0055]After weighing steel slag powder, coagulant, plasticizer and curing agent according to the ratio of raw materials, put the weighed raw materials in a forced mixer, add water according to the ratio and stir evenly for 10 minutes to form a slurry material, which is A slag tank protective agent with steel slag as the main raw material.

[0056] The method of repairing the slag tank with the slag tank protective agent with steel slag as the main raw material is: spray the obtained slag tank protective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com