Dual mode dephosphorization method carrying out in hot-metal ladle

A hot metal tank and dual-mode technology, applied in the field of dual-mode dephosphorization, can solve the problems of increased production costs, uncontrolled slag alkalinity, high price, etc., and achieve the effects of reduced production costs, reduced splashing, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below through embodiment.

[0022] In the embodiment, the dual-mode dephosphorization method implemented in the molten iron tank, the specific steps are as follows:

[0023] (1) Determine the amount of soot sprayed

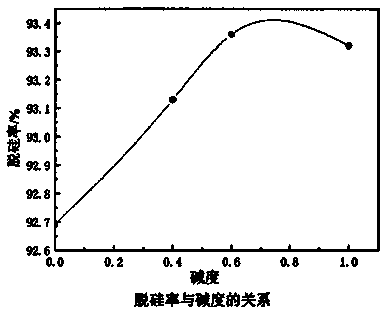

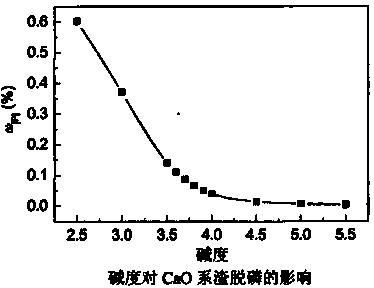

[0024] According to the composition of the original molten iron, the planned amount of lime with a particle size of 5-30mm, the expected basicity of the slag, the CaO content of the lime with a particle size of 5-30mm, and the CaO content of the passivation lime, the amount of passivation ash to be sprayed is calculated;

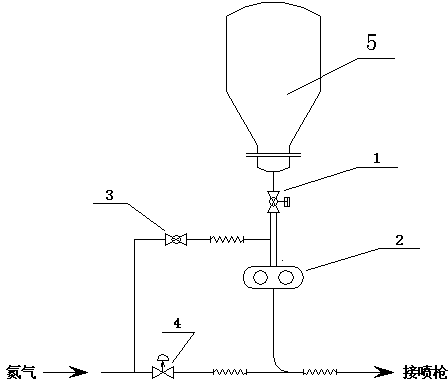

[0025] (2) Injection control system process

[0026] ①On the screen of the control computer, two buttons of "dust spray" and "air blow" are added to the spray control screen.

[0027] ② From the "dust spraying mode" to the "blowing mode", click the "blowing" button, the powder spraying quick cut valve 1 is closed, and the flow rate of the carrier gas regulating valve 4 is changed from 1.5N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com