Gasoline and diesel oil combined hydrogenation method

A diesel and gasoline technology, which is applied in the fields of dearomatization, hydrodesulfurization, and deolefination of gasoline and diesel. The effect of easing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

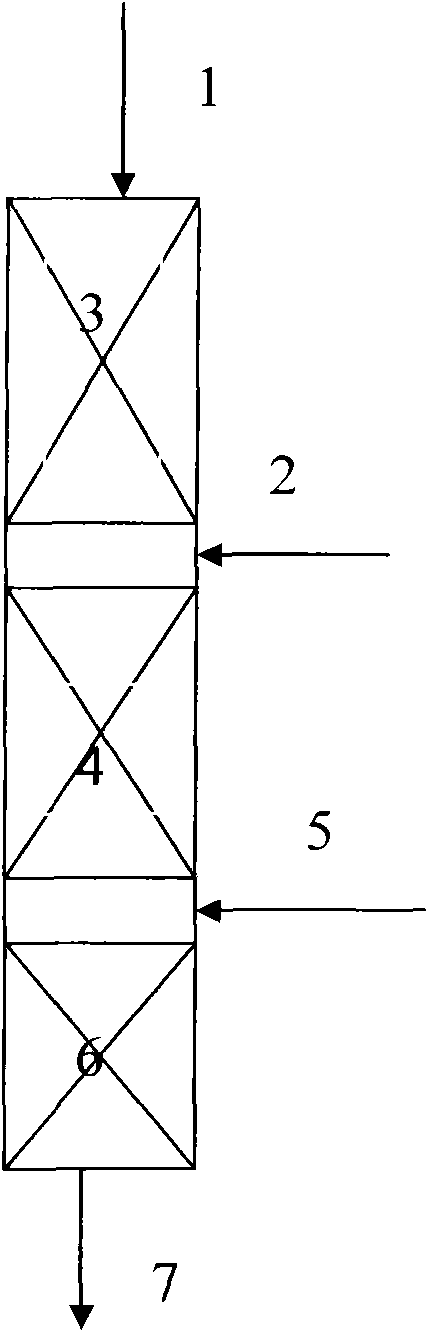

Image

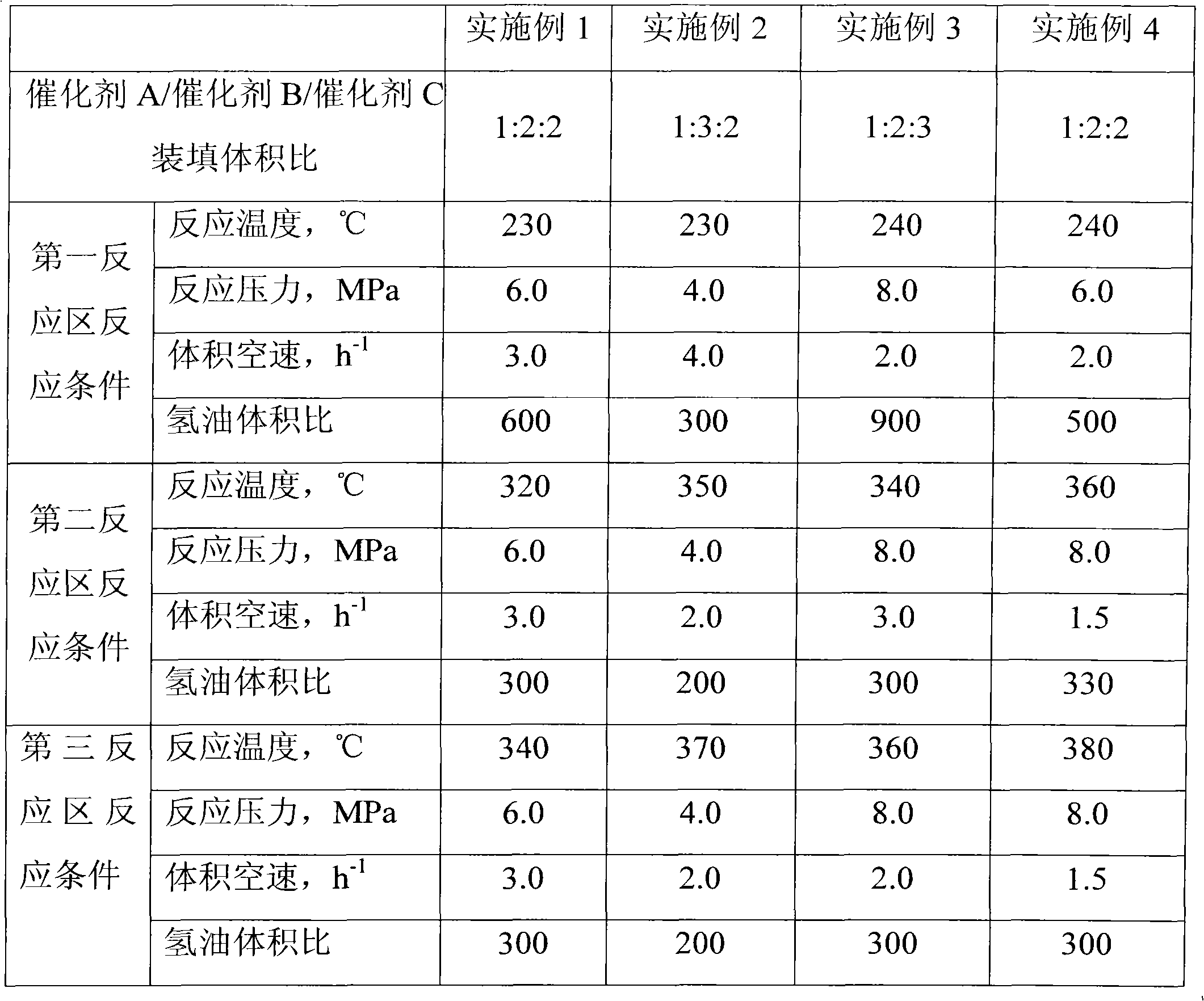

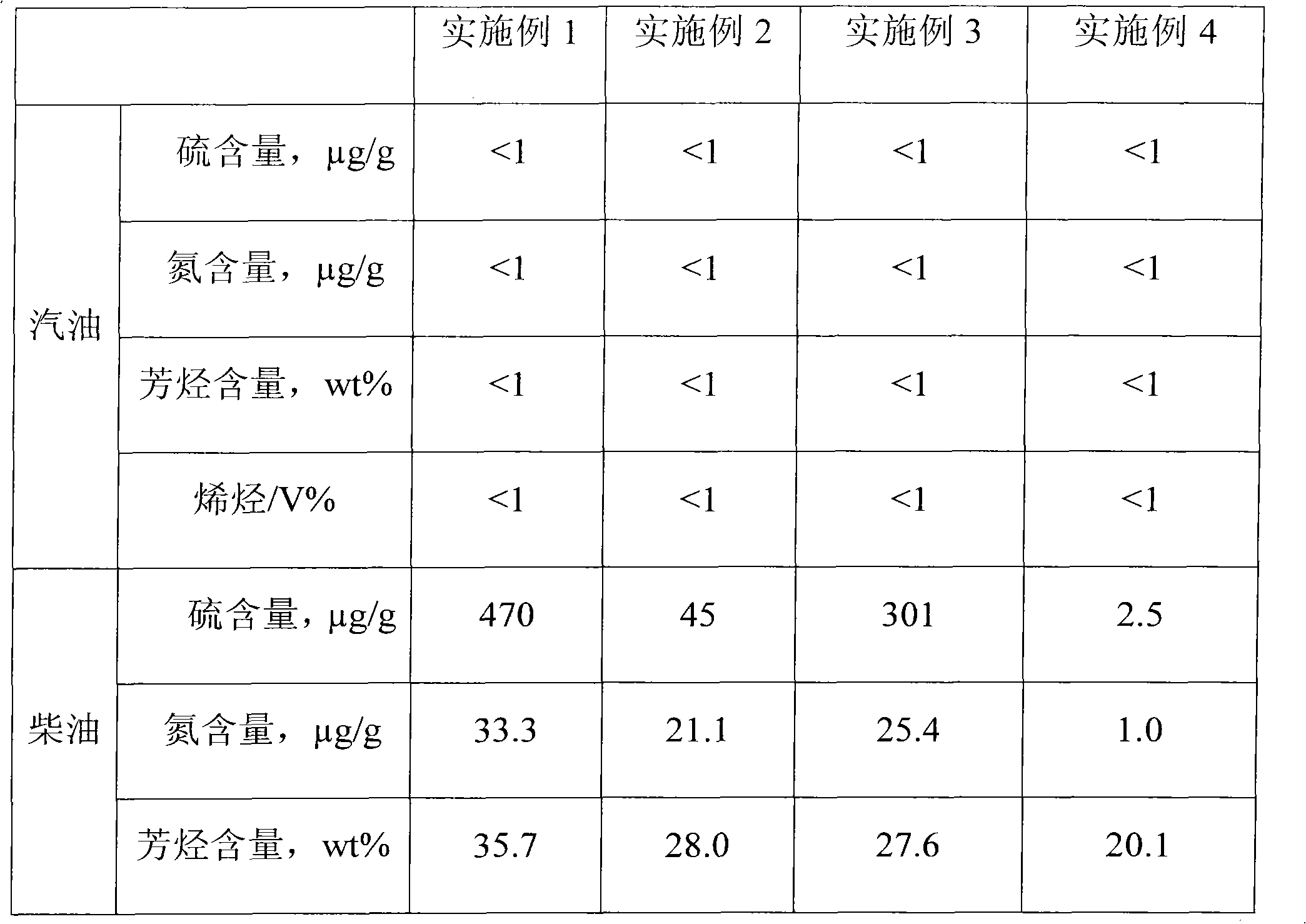

Examples

Embodiment Construction

[0019] In the gasoline and diesel combined hydrogenation method of the present invention, the catalysts described in step (1), step (2) and step (3) refer to non-noble metal hydrogenation with functions of hydrodesulfurization, olefin hydrogenation, and aromatic hydrogenation saturation. Catalyst, the function of the catalyst can focus on certain aspects. The non-noble metal catalyst generally exists in an oxidized state before use, and needs to be pre-sulfided to convert the non-noble metal oxide into a sulfide to have reactivity. Therefore, the non-noble metal catalyst must maintain the sulfided state during use. The hydrogenation catalyst used in the present invention can be a conventional gasoline hydrorefining catalyst or diesel hydrorefining catalyst. Generally, the metal of group VIB and / or group VIII is the active component, and the alumina or silicon-containing alumina is the carrier. Group VIB metals are generally Mo and / or W, and Group VIII metals are generally Co an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com