Desulfurizing agent for RH furnace

A desulfurizer and furnace technology, applied in the field of iron and steel smelting, can solve the problems of low CaO content, poor desulfurization effect, low basicity, etc., and achieve the effects of low TC content, low cost and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with some specific embodiments.

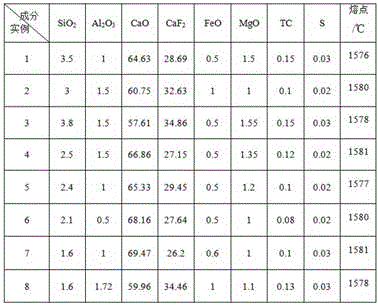

[0026] See Table 1 for the chemical composition and weight percentage of the desulfurizers for RH furnaces in Examples 1-8 of the present invention.

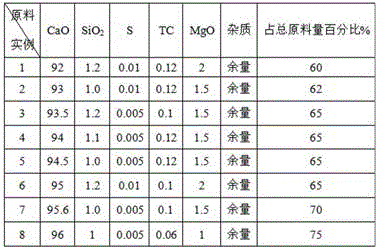

[0027] See Table 2 for the lime and its weight percentage of the desulfurizer for RH furnaces in Examples 1-8 of the present invention.

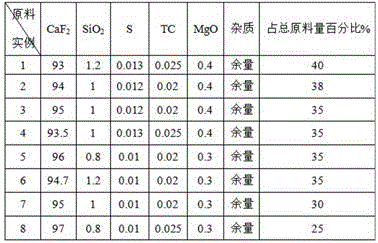

[0028] See Table 3 for the fluorite and its weight percentage of the desulfurizer for RH furnaces in Examples 1-8 of the present invention.

[0029] The preparation method of the limestone in Example 1-8 of the present invention includes the following steps: calcining the limestone with gas, then pulverizing it to 3-15mm, then heating to 110-130°C, then evenly spraying silicone oil on the surface of the limestone, and finally letting it cool to room temperature , that is.

[0030] The preparation method of the desulfurizer for RH furnace of the embodiment of the present invention 1-8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com