Lime slurry jetting circulating fluid bed semi-dry process desulfurizer

A circulating fluidized bed, semi-dry desulfurization technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problem of long time for material bed formation and stabilization process, slow system startup and adjustment response, dust removal and separation efficiency reduction and other problems, to achieve the effect of improving the desulfurization reaction efficiency, prolonging the contact reaction time, and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

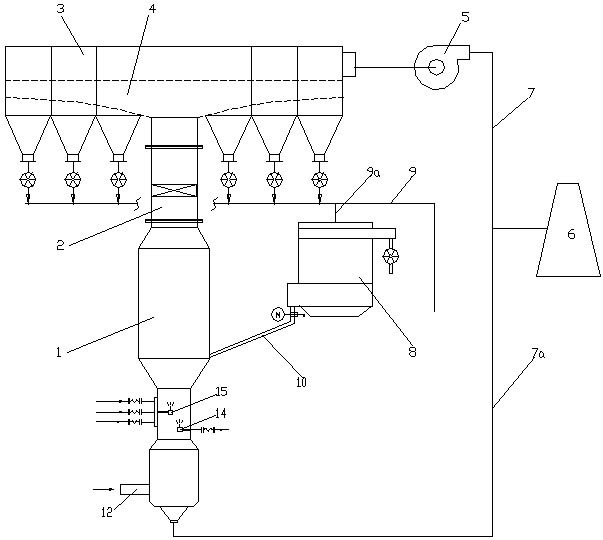

[0019] figure 1 It is a schematic flow chart of the present invention, figure 2 It is a schematic diagram of one of the arrangements of spoiler baffles, as shown in the figure: the semi-dry desulfurization device of the sprayed lime slurry circulating fluidized bed in this embodiment includes desulfurization reaction towers 1, gas-solid separation device 3 and induced draft fan 5, the lime slurry nozzle 15 and flue gas inlet 12 at the lower part of the desulfurization reaction tower 1, the upper part of the desulfurization reaction tower 1 is provided with a post-reaction gas outlet, and the post-reaction gas outlet of the desulfurization reaction tower 1 is separated from gas-solid The devices 3 communicate with each other through the spoiler 2, and the spoiler 2 is located at the upper part of the post-reaction gas outlet of the desulfurization reaction tower 1.

[0020] In this embodiment, the gas-solid separator 3 is a bag filter group located on the upper part of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com