Wet desulphurization device and process for sulfur-containing process gas

A technology of wet desulfurization and process gas, which is applied in the chemical industry, can solve the problems of economic rationality and comprehensive cost performance, and achieve the effects of improving gas-liquid mass transfer reaction speed, reducing equipment size, and reducing land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

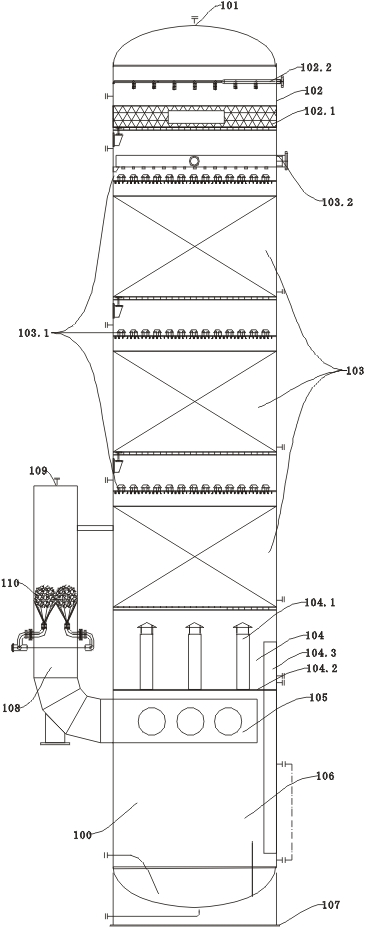

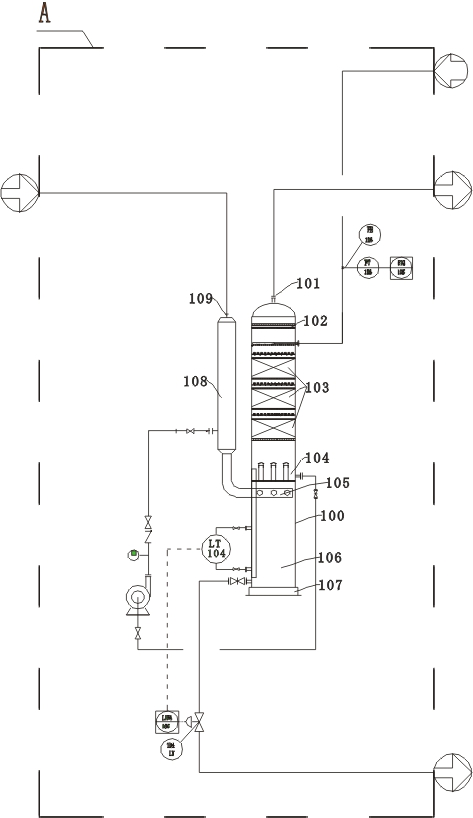

[0068] The device only includes the first desulfurization equipment A, and its structure diagram is as follows figure 1 shown.

[0069] A sulfur-containing process gas wet desulfurization device A, comprising:

[0070] Desulfurization tower assembly 100, the desulfurization tower assembly is sequentially provided with: process purification gas outlet 101; first demister section 102, including first demister 102.1 and demister flushing device 102.2, the tower contains After the sulfur process gas is desulfurized and purified, it exits the desulfurization tower assembly from the top of the tower;

[0071] Packed tower 103: Contains 3 packing absorption sections, the packing is standard structured packing or granular packing (materials are stainless steel, carbon steel, plastic, light porcelain or ceramics, porcelain plastic, etc.); and in each packing absorption section A gas-liquid redistributor 103.1 is provided at the top, and a top liquid distributor 103.2 is provided at t...

Embodiment 2

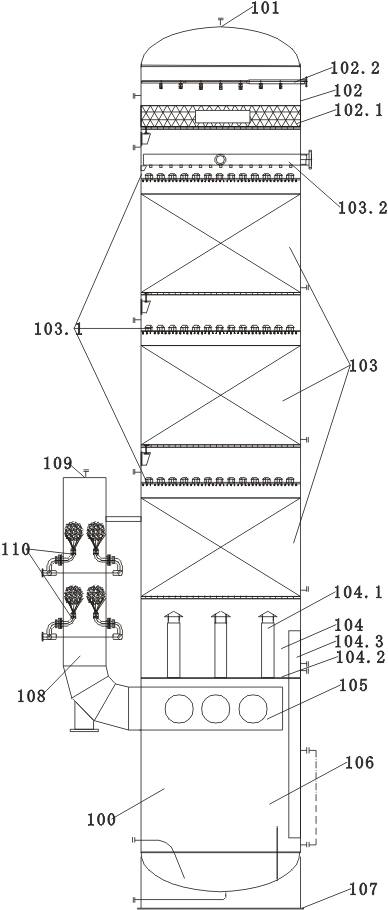

[0081] Compared with Example 1, the second desulfurization device 200 is added, which includes the first desulfurization device A and the second desulfurization device 200 (DGX type reactor), and the first high-efficiency reactor 108 of the first desulfurization device A Installed with 2 layers of liquid high-efficiency atomizing nozzles. The schematic diagrams of the first desulfurization equipment A and the second desulfurization equipment 200 are as follows image 3 , 4 shown.

[0082] The second desulfurization device 200 is connected to the first desulfurization device A through pipelines, including:

[0083] The high-efficiency reaction section 201 has two layers of second atomizing nozzles 201.1 inside, which are liquid high-efficiency atomizing nozzles, and the desulfurization liquid sprayed out is in countercurrent contact with the process gas to cause desulfurization absorption reaction; the top is equipped with a sulfur-containing process gas inlet 201.2 ;

[00...

Embodiment 3

[0093] Compared with Embodiment 2, the second desulfurization equipment is replaced by the third desulfurization equipment 300, that is, the device includes the first desulfurization equipment and the third desulfurization equipment, and the schematic diagram of the third desulfurization equipment is as follows Image 6 shown.

[0094] The third desulfurization equipment 300 includes: a first dedicated reactor 301 and a gas-liquid separation equipment 302, which are connected to the first desulfurization equipment through pipelines. The bottom of the first dedicated reactor 301 is provided with a gas-liquid inlet mixer 301.1, and the gas-liquid inlet mixer 301.1 is a general-purpose dendritic branch pipe distributor type; the height-to-diameter ratio of the first dedicated reactor 301 is 6:1, There are 450Y stainless steel regular orifice corrugated fillers 301.2 arranged inside to strengthen gas-liquid mass transfer and reaction; the gas-liquid separation equipment 302 is a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com