Multifunctional integrated wet desulphurization device and process

A wet desulfurization and multi-functional technology, applied in the field of desulfurization, can solve the problems of large desulfurization liquid regeneration cycle, low mass transfer efficiency of the absorption tower, and large floor area, so as to save rich liquid pumps, save materials, and occupy a large area. to reduce the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

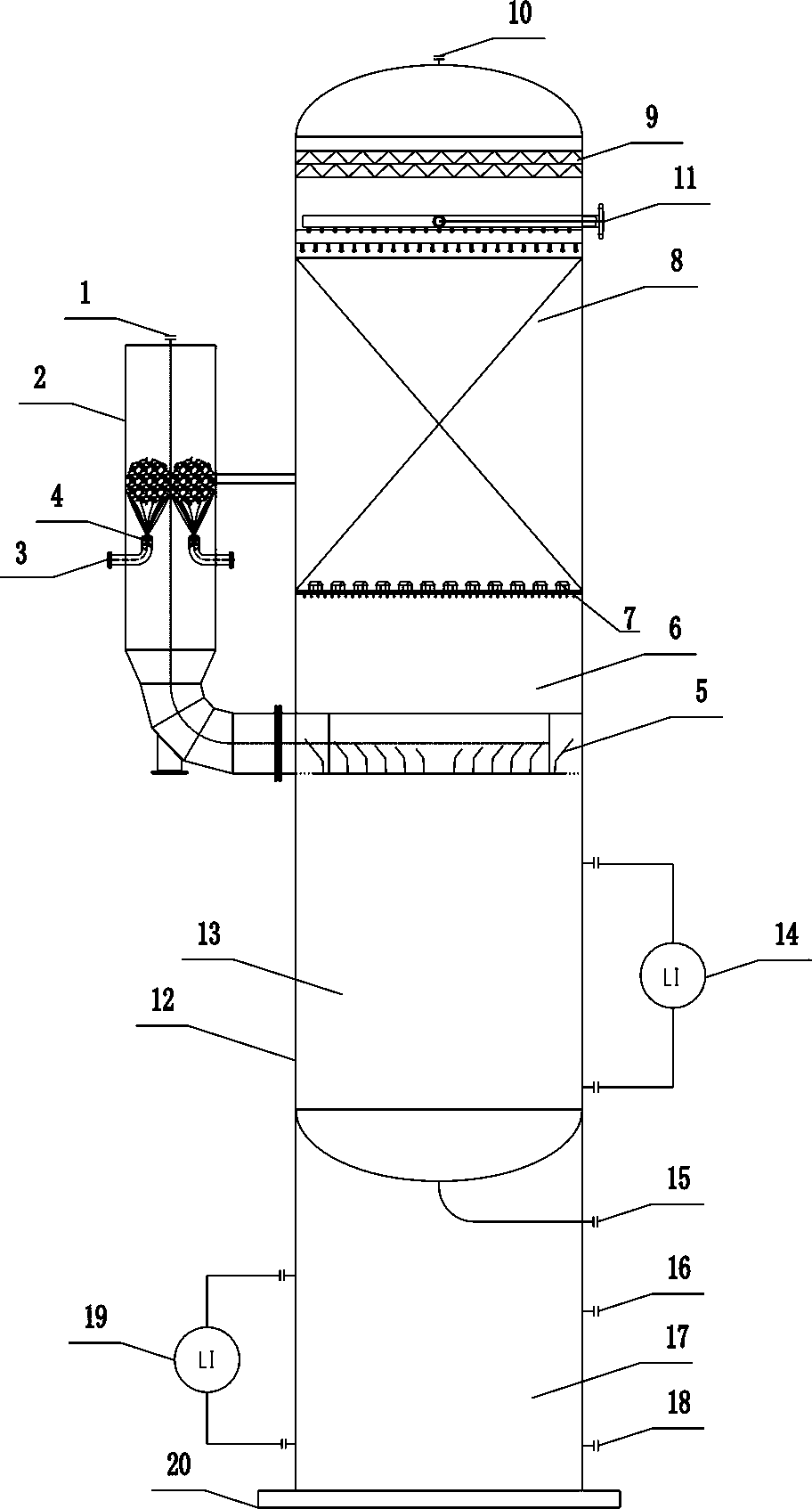

[0034] refer to figure 1 , a multifunctional integrated wet desulfurization device, including a high-efficiency reactor 2, a desulfurization tower 12 and a base 20, the desulfurization tower 12 is fixedly installed above the base 20, and the high-efficiency reactor 2 is installed externally on the desulfurization tower 12 On the side wall of the air inlet end, and at the connection between the high-efficiency reactor 2 and the desulfurization tower, an inlet gas-liquid separator 5 located in the tower is provided. The top of the high-efficiency reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com