Polytropic-process desulfurization device

A desulfurization device and process technology, applied in the field of desulfurization, can solve the problems of slow desulfurization speed and low efficiency, and achieve the effects of saving time, convenient and simple device operation, and accelerating desulfurization reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

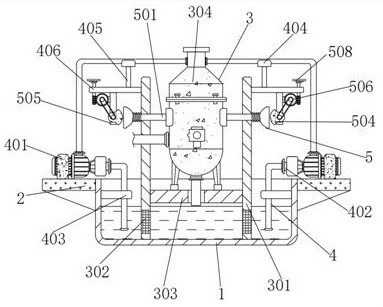

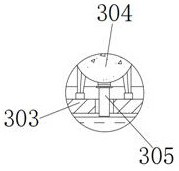

Embodiment 1

[0032] A variable process desulfurization device, including a box body 1 and a sloping plate 2, the upper and lower outer walls of the left and right sides of the box body 1 are fixed with a sloping plate 2, and a desulfurization device 3 is installed inside the box body 1, and the desulfurization device 3 includes a first Vertical plate 301, screen plate 302, first horizontal plate 303, desulfurization tower 304 and discharge pipe 305, the outer walls of the left and right first vertical plates 301 are fixedly connected with the inner wall of the box body 1, and the lower part of the first vertical plate 301 is fixed inside There is a screen plate 302, through which the filter residue after the desulfurization reaction can be blocked, so as to facilitate its cleaning. A first horizontal plate 303 is arranged on the inner side of the left and right screen plates 302, and the middle of the first horizontal plate 303 is processed with Opening, the outer walls of the left and righ...

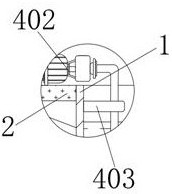

Embodiment 2

[0034] As an option, see figure 1 , 3 , 4 and 6, variable flow desulfurization device, a circulation device 4 is installed above the inclined plate 2, and the circulation device 4 includes a second vertical plate 401, a water pump 402, a second horizontal plate 403, a concave plate 404, and a third vertical plate 405 and the third horizontal plate 406, the lower surface of the left and right second vertical plates 401 is fixedly connected with the upper surface of the slant plate 2, the inside of the second vertical plate 401 is fixedly connected with a water pump 402, the model of the water pump 402 is 0510A, and the water pump 402 The outer wall of the water suction pipe is fixedly connected with the second horizontal plate 403, the outer outer wall of the second horizontal plate 403 is fixedly connected with the inner wall of the box body 1, the outlet pipe of the water pump 402 is fixedly connected with the top of the desulfurization tower 304, and the outlet pipe of the w...

Embodiment 3

[0037] As an option, see figure 1 , 4, 5 and 6, variable flow desulfurization device, a fixing device 5 is installed on the upper outside of the first vertical plate 301, and the fixing device 5 includes a baffle 501, an arc block 502, a spring 503, a cam 504, a T-shaped plate 505, a worm gear 506, the worm 507 and the turntable 508, the outer walls of the left and right baffles 501 are in clearance with the inner wall of the through hole of the first vertical plate 301; An arc block 502 is connected, and a spring 503 is installed on the inner side of the arc block 502. The inner wall of the spring 503 fits with the outer wall of the baffle plate 501, and the outer walls on both sides of the spring 503 are respectively fixed with the arc block 502 and the first vertical plate 301. Connected, when the arc block 502 moves to the inside, the spring 503 is in a compressed state, and a cam 504 is installed on the outside of the arc block 502, and the outer wall of the cam 504 fits...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com