A treatment method for carbonation and desulfurization of steelmaking refining slag

A treatment method and carbonation technology, applied in the direction of process efficiency improvement, recycling technology, etc., can solve the problems of low reactivity of calcium silicate, impact on slag utilization, high treatment cost, etc., to improve carbonation efficiency and reaction degree , the effect of increasing the reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

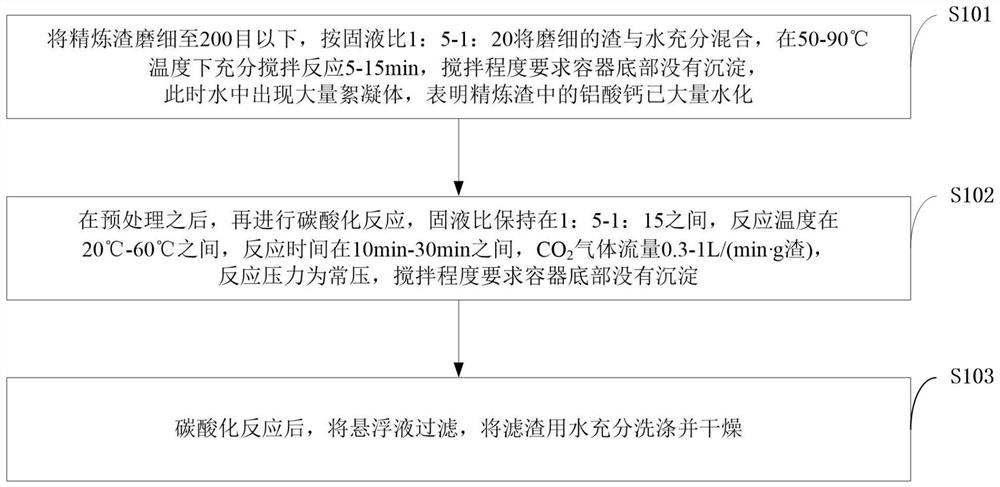

Method used

Image

Examples

Embodiment 1

[0037] A sample of refining slag was obtained from a steel plant, and its chemical composition is shown in Table 1. Grind the slag finely, pass through a 200 mesh sieve, fully mix the finely ground slag with water at a solid-liquid ratio of 1:10, react at 80°C for 15 minutes, add a small amount of water to keep the solid-liquid ratio at 1:10, While stirring, CO 2 , CO 2 The flow rate is 0.5L / (min·g slag), the reaction temperature is 40°C, and the reaction pressure is normal pressure. After 20 minutes of reaction, the ventilation is stopped, the suspension is filtered, and the filter residue is fully washed with water and dried. Compared with the S content of 0.98% in the original slag, the S content reduction rate is 67.3%.

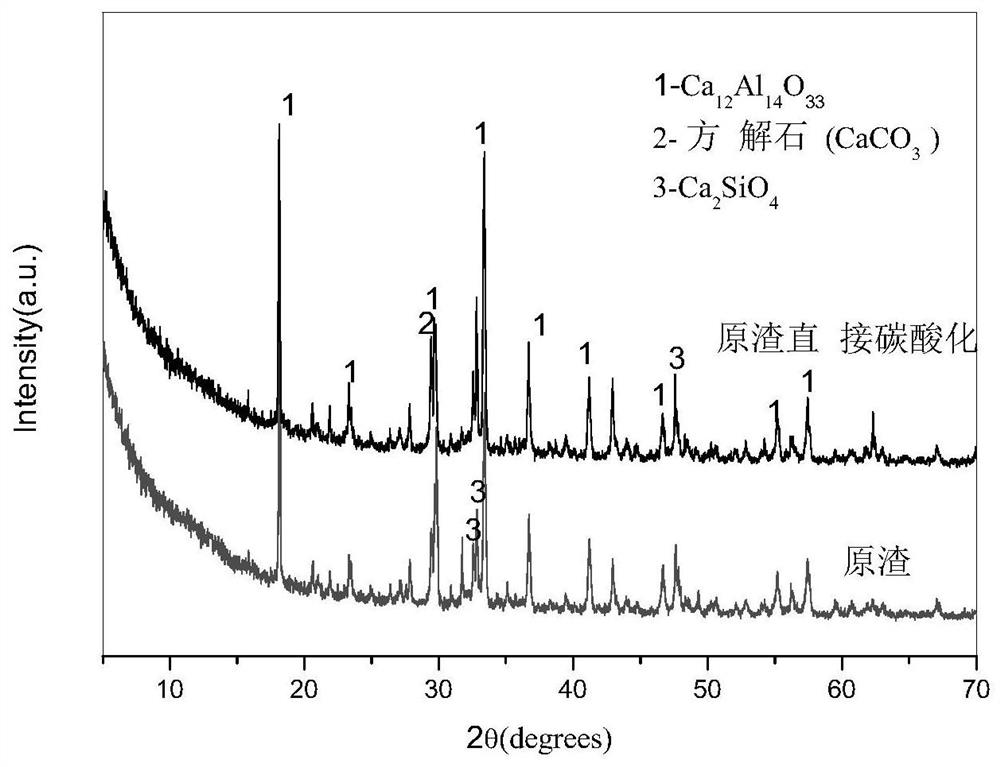

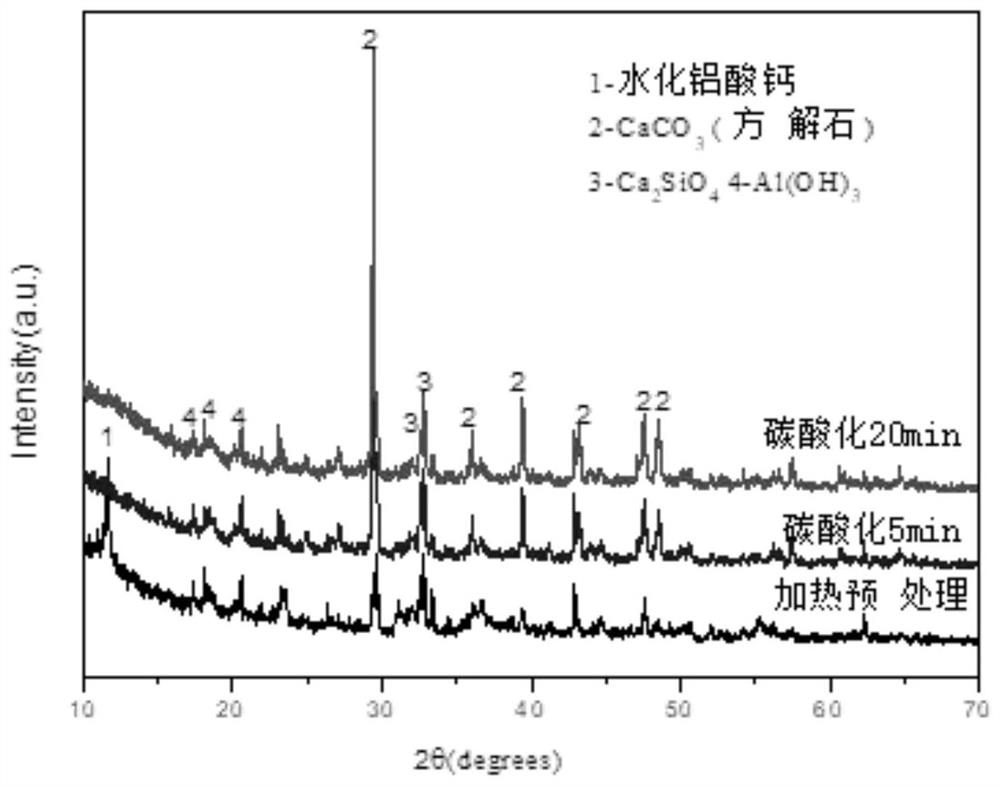

[0038] figure 2 Shown are the XRD patterns of the original slag and the direct carbonation slag of the original slag, image 3 Shown are the XRD patterns of hydrothermally pretreated slag and carbonated 5 and 20 min of pretreated slag. Depend on f...

Embodiment 2

[0043] A sample of refining slag was obtained from a steel plant, and its chemical composition is shown in Table 2. Grind the slag finely and pass it through a 200-mesh sieve. Fully mix the finely ground slag with water at a solid-liquid ratio of 1:15. Use an ultrasonic pulverizer to ultrasonically treat it for 10 minutes at a working frequency of 18kHZ. Supplement water to maintain the solid-liquid ratio. At 1:15, while stirring, blow CO 2 , CO 2 The flow rate is 0.8L / (min·g slag), the reaction temperature is 30°C, and the reaction pressure is normal pressure. After 20 minutes of reaction, the ventilation is stopped, the suspension is filtered, the filter residue is fully washed with water and dried, and the concentration of the residue after desulfurization reaction is determined. The S content of the slag is 0.44%, compared with the S content of 2.16% in the original slag, the S content reduction rate is 79.6%.

[0044] Figure 7 Shown are the XRD patterns of ultrasonic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com