Dry flue gas desulfurizing process with independent feeding, back-returning and water-spraying devices

A dry flue gas desulfurization and process technology is applied in the field of dry desulfurization system and dry flue gas desulfurization technology, which can solve the problems of failing to meet the technical requirements of desulfurization, difficult to meet the desulfurization efficiency of low calcium and sulfur, and large water consumption. Achieve the effect of improving utilization rate and reaction efficiency, improving desulfurization reaction efficiency, and reducing flue gas flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

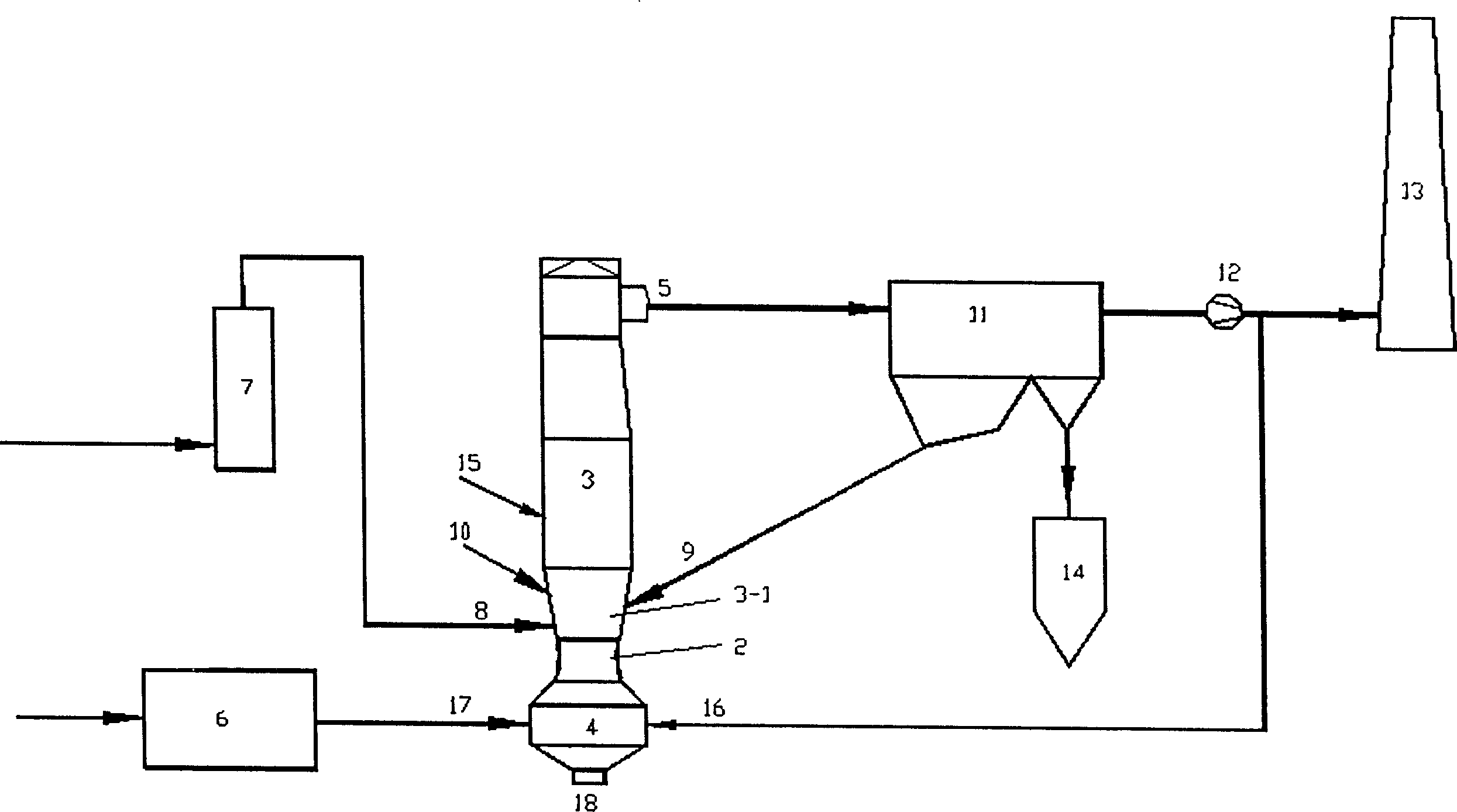

[0033] First of all, the flue gas discharged from the combustion equipment first passes through a flue gas pre-dust removal device 6 (which can be electrostatic, cloth bag, inertial or other types of dust collectors or a combination of multiples) device 6, and the flue gas after pre-dust removal passes through the main flue gas inlet The pipe 17 is sent into the flue gas mixing chamber 4, and enters the flue gas ejection device 2 at the bottom of the desulfurization tower, maintains the exit velocity range of the flue gas jet flow at 20-55m / s, and accelerates into the area 3-1 at the bottom of the desulfurization tower.

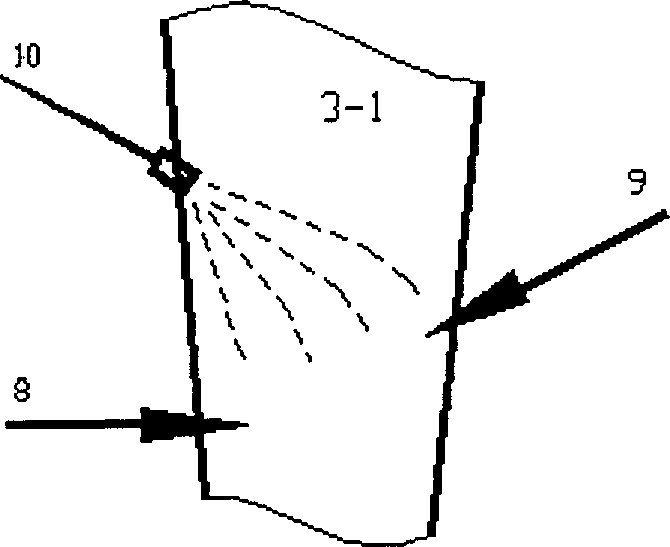

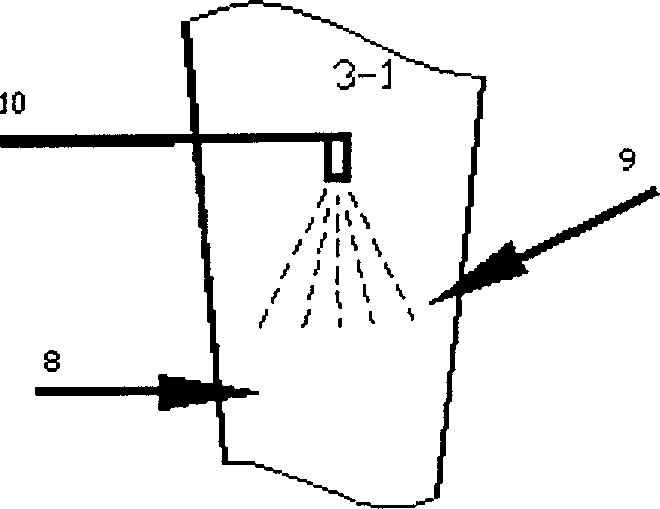

[0034]At the same time, the desulfurizer raw material (such as CaO powder) is sent into the digestive system 7, and highly active desulfurizer particles are generated through digestion reaction, and the desulfurizer (such as Ca(OH) 2 ) particles are sprayed into the fluidized area 3-1 at the lower part of the desulfurization reaction tower through the desulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com