Novel ecological water permeation concrete pavement

A technology of permeable concrete and concrete, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of fly ash waste pollution and other problems, and achieve good water permeability and water retention performance, low bulk density, and porosity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

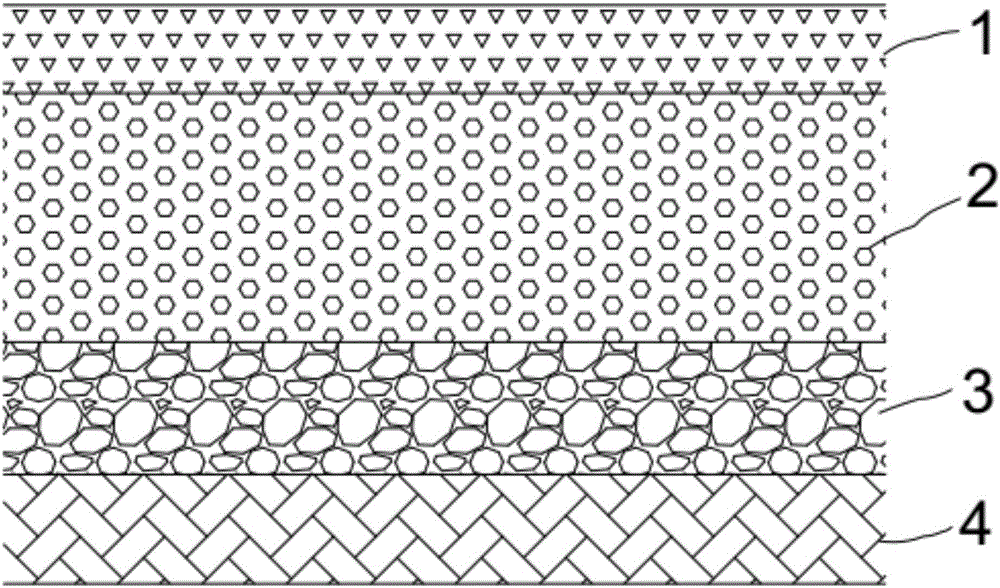

[0028] Such as figure 1 As shown, in this embodiment, the new ecological permeable concrete pavement includes a permeable surface layer, a permeable structure layer, a recycled aggregate base layer and a rammed soil base layer arranged in sequence. Among them, the permeable surface layer is cement permeable mortar (or colored permeable finish) with a weight ratio of cement and sand of 1:4 and a thickness of 30mm; the permeable structure layer is 150mm and a compressive strength of 21.5Mpa. Granular permeable concrete; the thickness of the base layer of recycled aggregate is 100 mm, which is the aggregate with a particle size of 5 mm after crushing, screening, and impurity removal processes for concrete construction waste; the base layer is plain soil rammed soil foundation.

[0029] Fly ash ceramsite permeable concrete includes cement, fly ash ceramsite, recycled building coarse aggregate, water reducing agent and water. The weight ratio of cement, fly ash ceramsite, recycled...

Embodiment 2

[0034] In this embodiment, the novel ecological permeable concrete pavement includes a permeable surface layer, a permeable structure layer, a recycled aggregate base layer and a rammed soil base layer arranged in sequence. The permeable surface layer is a cement permeable sand surface layer (or colored permeable finish) with a weight ratio of cement and sand of 1:4 and a thickness of 30mm; the permeable structure layer is a permeable fly ash ceramsite with a compressive strength of 150mm and a compressive strength of 23.2Mpa. Concrete; the thickness of the base layer of recycled aggregate is 100 mm, which is the aggregate with a particle size of 15 mm after crushing, screening, and impurity removal processes of concrete construction waste; the base layer is plain soil rammed soil foundation.

[0035] Fly ash ceramsite permeable concrete includes cement, fly ash ceramsite, recycled building coarse aggregate, water reducing agent and water. The weight ratio of cement, fly ash c...

Embodiment 3

[0040] In this embodiment, the novel ecological permeable concrete pavement includes a permeable surface layer, a permeable structure layer, a recycled aggregate base layer and a rammed soil base layer arranged in sequence. The permeable surface layer is a cement permeable sand surface layer (or colored permeable finish) with a weight ratio of cement and sand of 1:4 and a thickness of 30mm; the permeable structure layer is a permeable fly ash ceramsite with a compressive strength of 150mm and a compressive strength of 22.6Mpa. Concrete; the thickness of the base layer of recycled aggregate is 100 mm, which is the aggregate with a particle size of 20 mm after crushing, screening, and impurity removal processes of concrete construction waste; the base layer is plain soil rammed soil foundation.

[0041] Fly ash ceramsite permeable concrete includes cement, fly ash ceramsite, recycled building coarse aggregate, water reducing agent and water. The weight ratio of cement, fly ash c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com