Patents

Literature

32results about How to "Excellent sound absorption and noise reduction performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

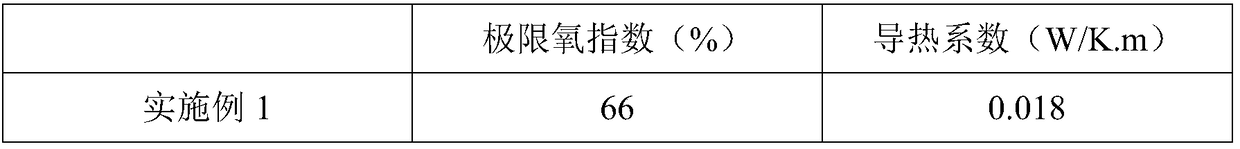

Sound-absorbing composite and preparation method thereof

ActiveCN102967042ALow densityExcellent sound absorption and noise reduction performanceNoise suppressionLaminationThermal insulationAdhesive

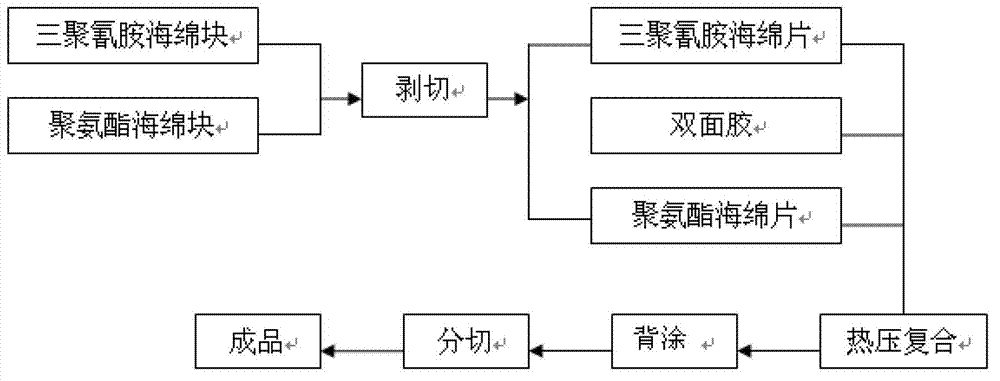

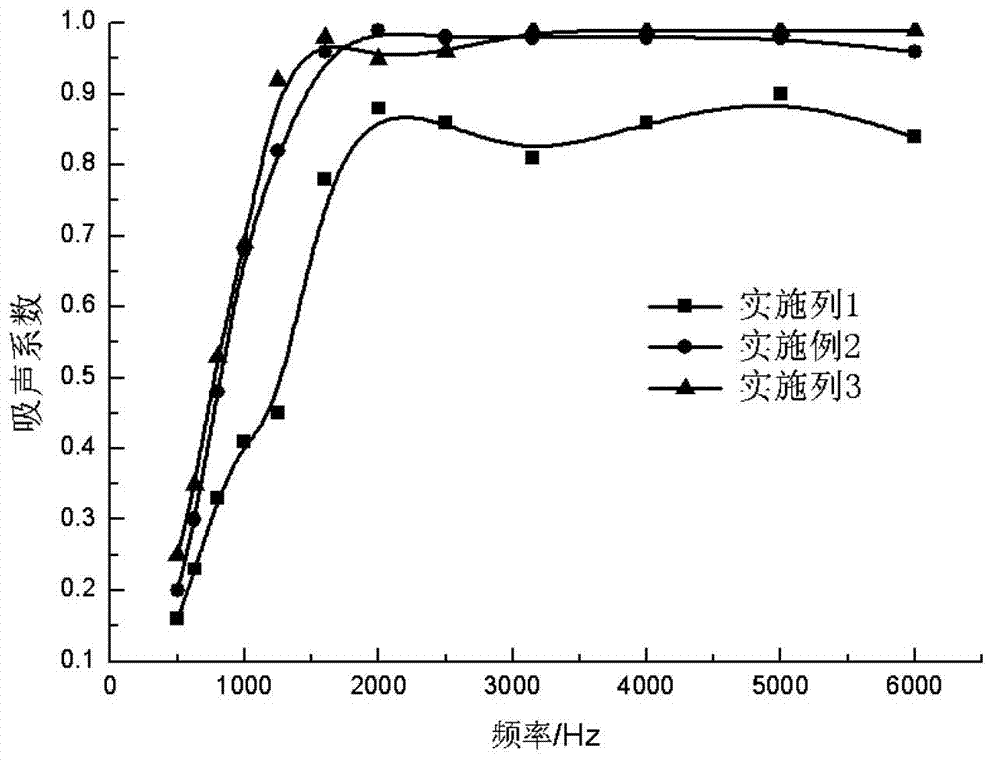

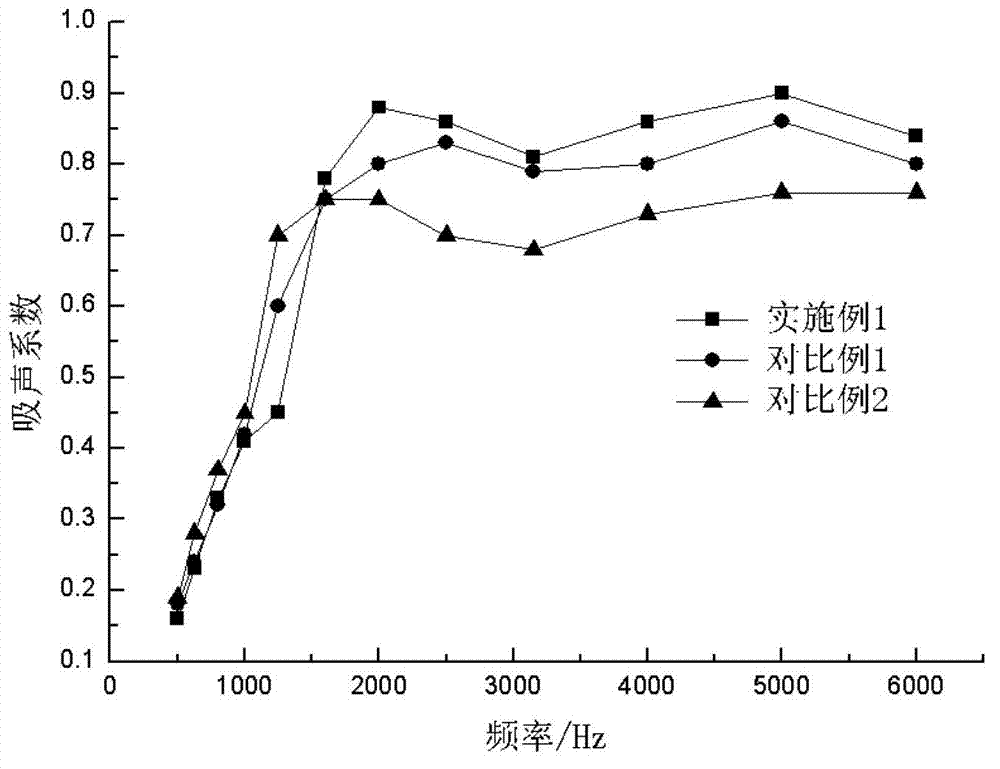

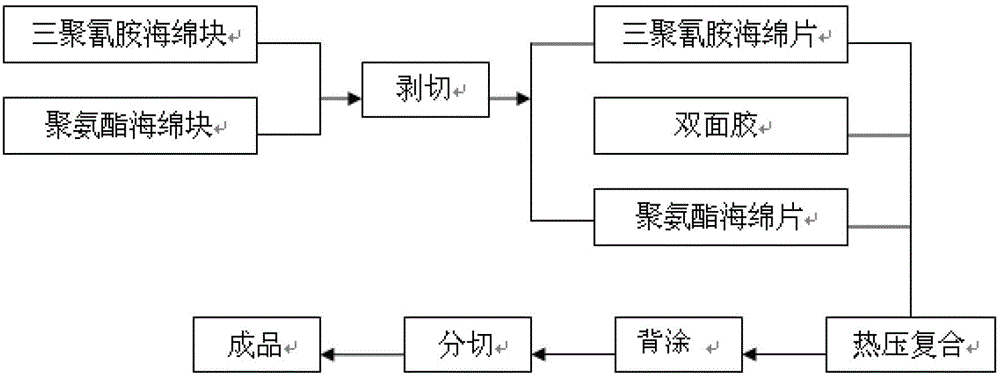

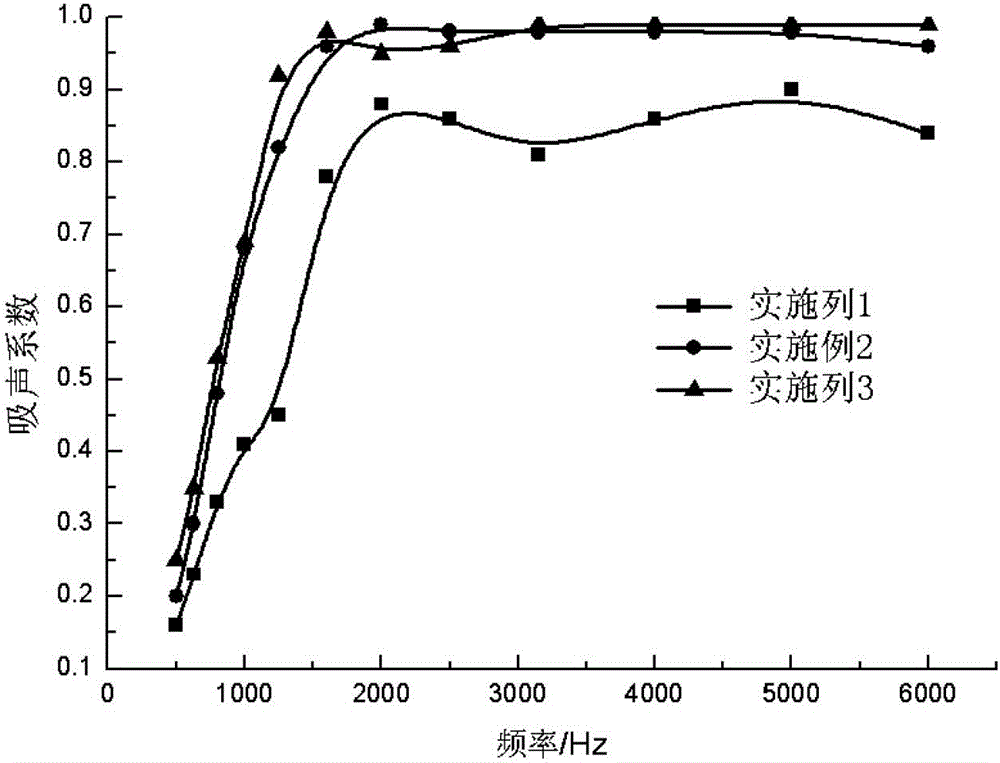

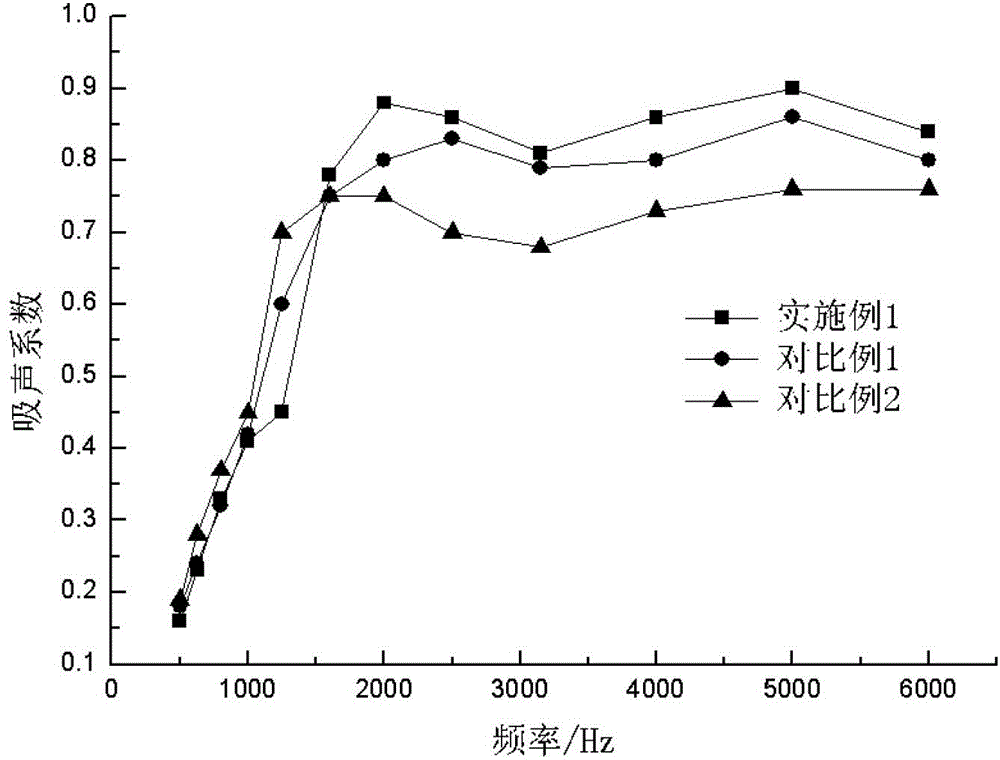

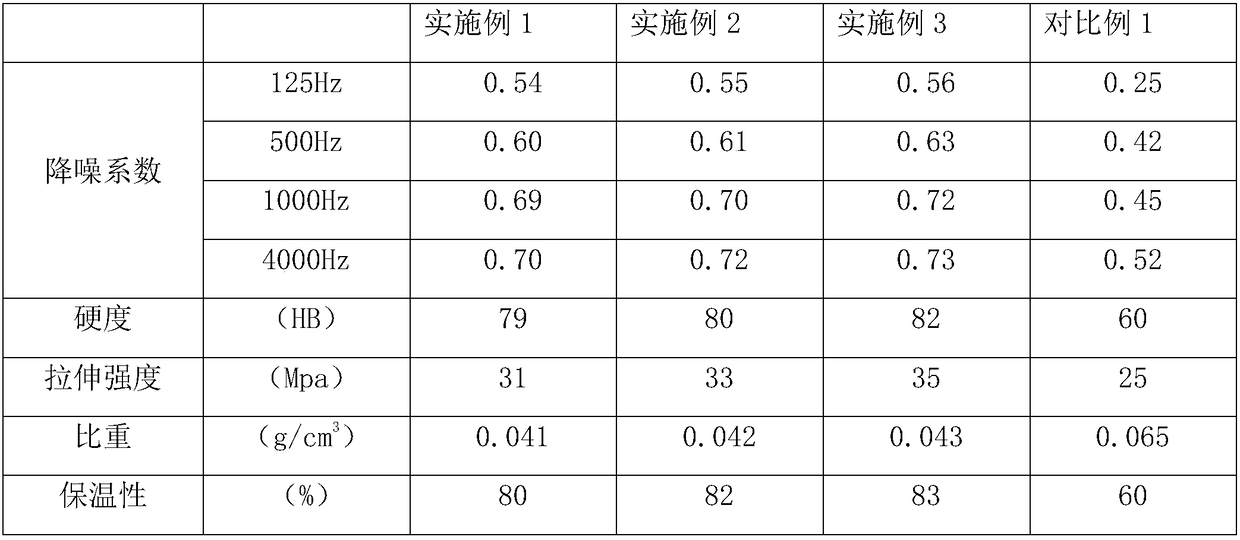

The invention provides a sound-absorbing composite and a preparation method of the sound-absorbing composite. The method comprises the steps of placing a double-faced adhesive tape between a polyurethane sponge and a melamine sponge, conducting hot pressing composition, obtaining a semifinished sound-absorbing composite, coating an adhesive on the melamine sponge of the semifinished sound-absorbing composite, and obtaining the sound-absorbing composite after an adhesive layer is formed, wherein the thickness ratio of the melamine sponge to the polyurethane sponge is 1:1.5-1:5. The sound-absorbing composite is prepared by hot pressing composition with the polyurethane sponge and the melamine sponge, so that the sound-absorbing composite has a smaller density and an excellent sound absorption reduction performance, and the effective noise reduction treatment can be conducted relative to the noise spectrum characteristic by adjusting the thickness ratio of the melamine sponge to the polyurethane sponge. In addition, the sound-absorbing composite is small in heat conductivity and has an excellent thermal insulation property, and the effective utilization ratio of energy sources can be increased when the sound-absorbing composite is used for vehicle-mounted air conditioners and air duct systems.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Preparation method of building thermal insulation material

InactiveCN108358544AImprove insulation effectGood heat insulationCeramicware2-methylbutaneThermal insulation

The invention provides a preparation method of a building thermal insulation material. The method comprises the following steps: a, adding hydrophobic expanded perlite to polymer emulsion, performingstirring, adding a cementing material, n-pentane and isopentane, and performing heating and stirring to obtain a mixture I; b, mixing blast furnace slag and filler for ball milling for 2-3 h, adding fly ash, desulfurized gypsum, hydrogen peroxide and a foaming agent, and performing stirring to obtain mixed slurry; c, adding expandable resin to the mixed slurry, performing stirring, injecting aluminum hydroxide and a hydrophobic agent, performing heating for a period of time, and performing dehydrating to obtain a mixture II; d, introducing the mixture I and the mixture II into a twin-screw extruder, adding modified environment-friendly glue, glass fiber and a flame retardant, and performing extrusion molding. The prepared thermal insulation material has excellent thermal insulation performance, low thermal conductivity coefficient and excellent sound absorption and noise reduction performance, the technological process of the method is simple, and manufacturing cost is low.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

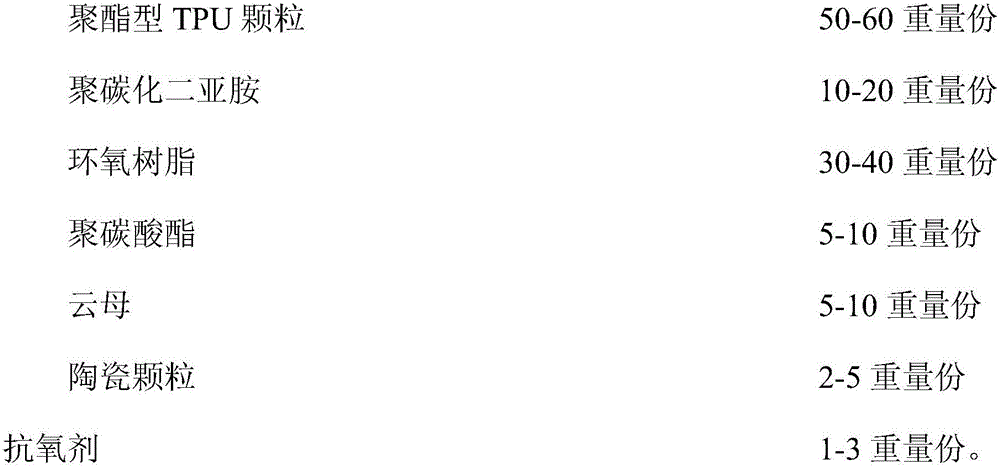

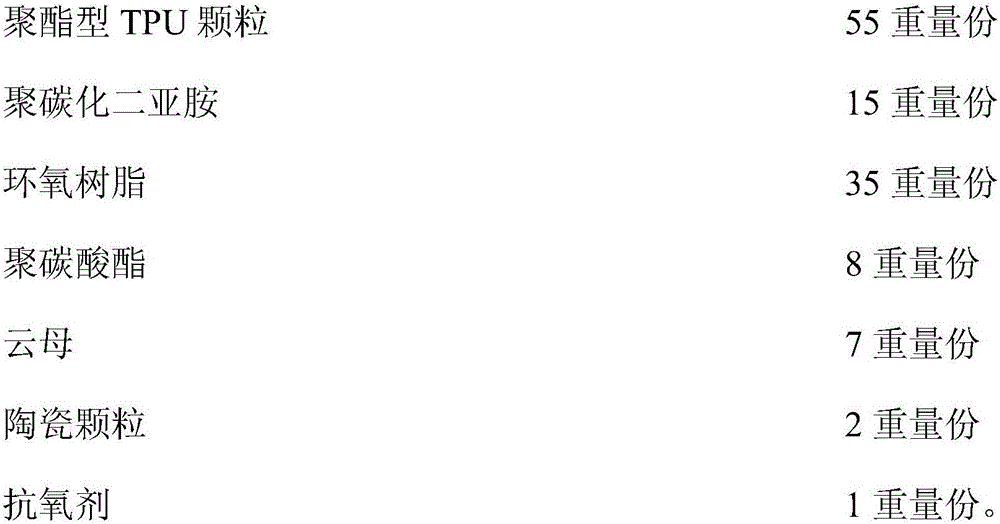

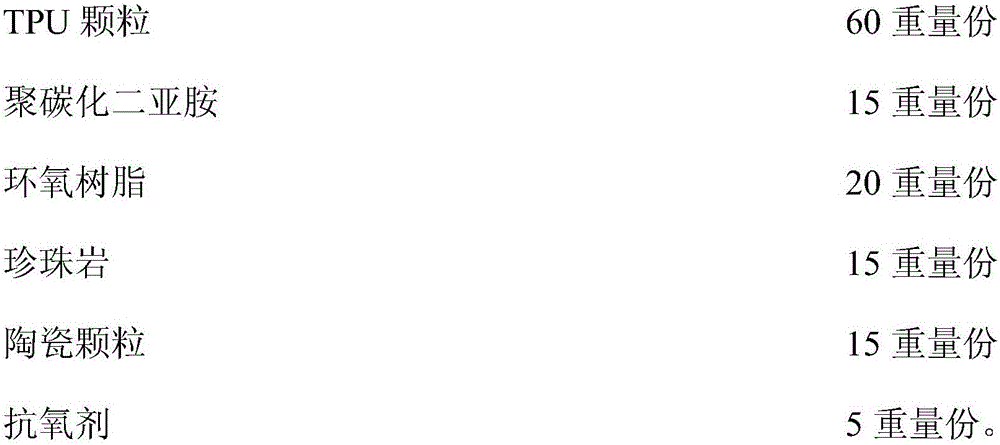

Heat insulation, sound absorption and noise reduction TPU film and production method thereof

InactiveCN106519648AExcellent sound absorption and noise reduction performanceImprove insulation effectPolyesterEpoxy

The invention provides a heat insulation, sound absorption and noise reduction TPU film and a production method thereof. The TPU film is produced from, by weight, 50-60 parts of polyester TPU particles, 10-20 parts of polycarbodiimide, 30-40 parts of epoxy resin, 5-10 parts of polycarbonate, 5-10 parts of mica, 2-5 parts of ceramic particles and 1-3 parts of an antioxidant. The sound absorption coefficient of the TPU film is 0.96-0.99, so the TPU film has good sound absorption and noise reduction performances; the heat conduction coefficient is 0.03-0.05 W / m.k, so the TPU film has very good heat insulation property; and the tensile strength of the TPU film is 62-68 MPa, the elongation at break is 598-632%, and the tear strength is 140-145 MPa, so the TPU film has good mechanical performances. The TPU film produced in the invention is a heat insulation, sound absorption and noise reduction TPU film with good comprehensive performances, and has wide application prospect.

Owner:WUXI MINGSHENG TEXTILE MACHINERY

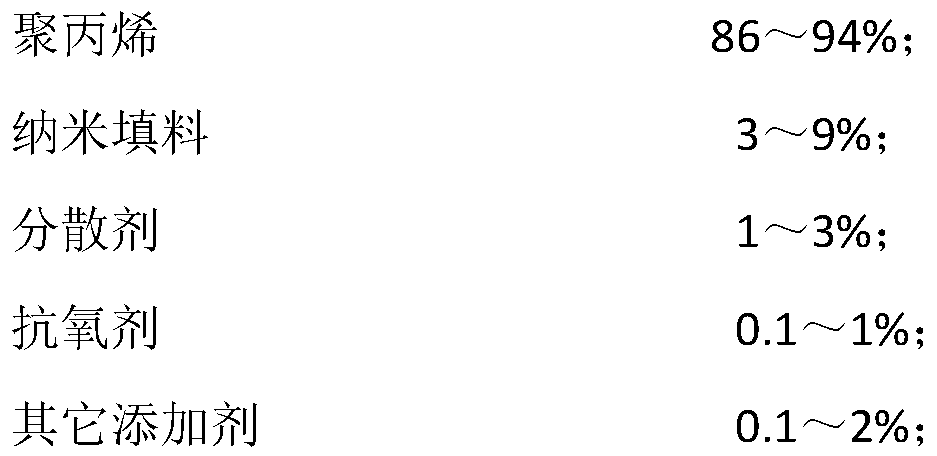

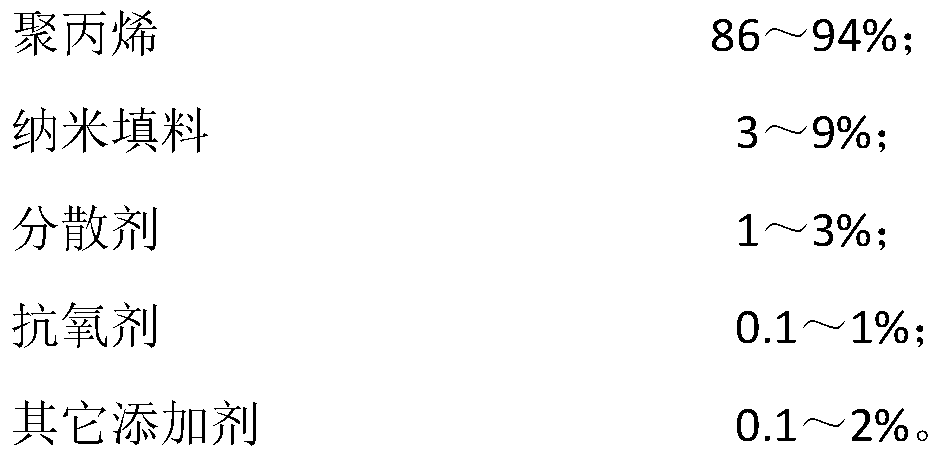

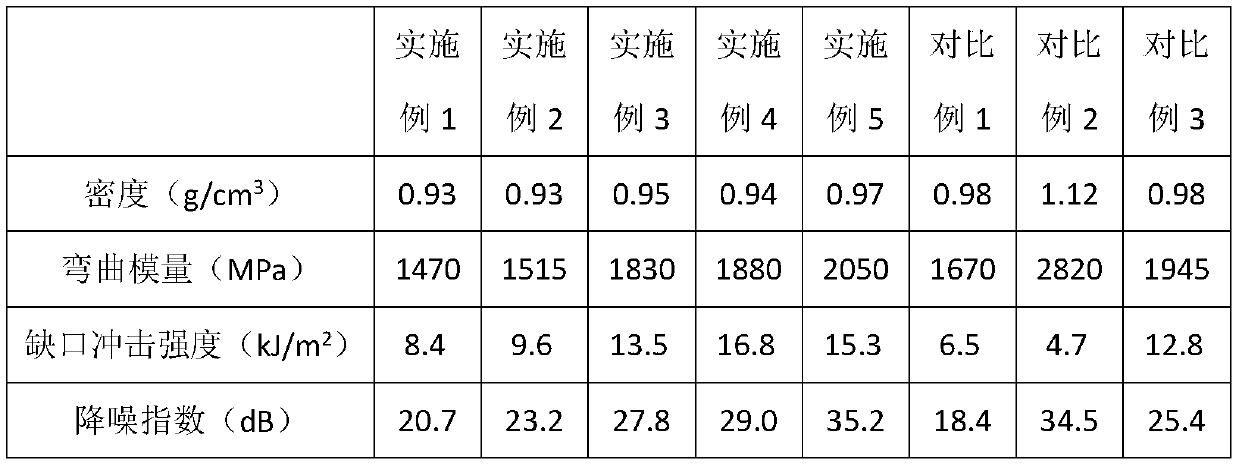

Low-density high-noise-reducing polypropylene nano-composite material and preparation method thereof

InactiveCN109867864AEnhance reflexesExcellent sound absorption and noise reduction performancePolypropylene compositesAntioxidant

A low-density high-noise-reducing polypropylene nano-composite material and a preparation method thereof are disclosed. The low-density high-noise-reducing polypropylene nano-composite material comprises the following raw materials in percentage by weight: 86-94% of polypropylene, 3-9% of nano-filler, 1-3% of dispersant, 0.1-1% of antioxidant and 0.1-2% of other additives, wherein the nano-filleris a mixture of organic modified montmorillonite and carbon nanotubes, and the weight ratio of the nano-filler to the carbon nanotubes is 2:1. The preparation method comprises the follow steps: weighing raw materials according to a weight ratio, uniformly mixing polypropylene, the dispersant, the antioxidant and other additives in a high-speed mixer, adding the mixture into a twin-screw extruder,adding nano-fillers in the second half of the extruder through side feeding, and granulating by melting extrusion and cooling. As that organic modified montmorillonite and the carbon nanotube are added, the polypropylene composite material has excellent noise reduction performance and low density at the same time, and can be widely applied in the field of automobile interior and exterior ornamentsand the like, thereby meeting the application requirements of automobile lightweight.

Owner:CHONGQNG PRET NEW MATERIAL +4

Sound-absorbing composite and preparation method thereof

ActiveCN102967042BLow densityExcellent sound absorption and noise reduction performanceNoise suppressionLaminationThermal insulationAdhesive

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Heat-insulation-preservation and sound-absorption-noise-reduction TPU film and preparing method thereof

InactiveCN105924933AExcellent sound absorption and noise reduction performanceImprove performanceEpoxyAntioxidant

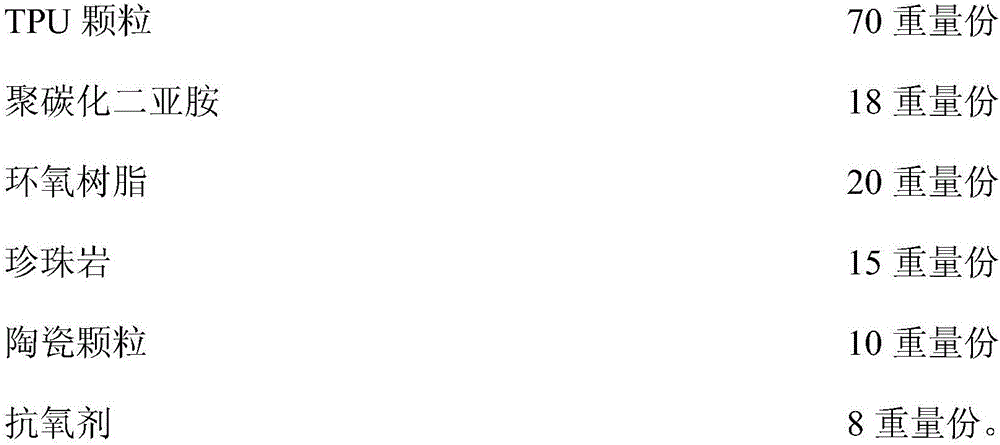

The invention provides a heat-insulation-preservation and sound-absorption-noise-reduction TPU film and a preparing method thereof. The TPU film is prepared from, by weight, 60-70 parts of TPU particles, 15-20 parts of polycarbodiimide, 10-30 parts of epoxy resin, 10-15 parts of perlite, 10-20 parts of ceramic particles and 5-10 parts of antioxidant. The TPU film has good heat-insulation-preservation and sound-absorption-noise-reduction performance and good mechanical performance, and application prospects are quite broad.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

Method for manufacturing flocking stainless steel spraying decoration plate

InactiveCN103510672AWith heat insulationExcellent sound absorption and noise reduction performanceCovering/liningsMetal layered productsWeather resistanceFireproofing

The invention relates to a method for manufacturing a building plate which has corrosion resistance and weather resistance, prevents dew from dropping and has certain heat insulation performance, in particular to a method for manufacturing a flocking stainless steel spraying decoration plate. The manufacturing method comprises the following steps of material selecting, plate surface pretreatment, drying treatment, tackiness agent coating, electrostatic flocking, pattern spraying, process drying, checking, and putting in storage. The method for manufacturing the flocking stainless steel spraying decoration plate is characterized in that the flocking of electrostatic flocking is polypropylene fiber flocking. A plate surface treatment agent is FD90 passivant. A product obtained through the method has good fireproof performance, and passes China building material fireproofing grade B-1 certification after detection, complete environmental protection is achieved, pollution is avoided, environmental certification is passed, the product can be directly used indoors, and the effects that the upright flocking sense is strong, colors are bright and attractive, hand feeling is soft, sound absorption and light absorption performance is good, and light diffusion reflection is excellent are achieved.

Owner:WUXI XINDAZHONG STEEL SHEET

Preparation method of ceramic fibers

The invention provides a preparation method of ceramic fibers. A formula of the ceramic fibers comprises the following components in parts by weight: 45 to 55 parts of silicon dioxide, 40 to 50 partsof aluminum oxide, 0.8 to 1 part of iron oxide, 0.1 to 0.25 part of sodium oxide and 0.1 to 0.25 part of potassium oxide; the preparation method comprises the following steps: a, weighing the materials and putting the materials into a melting furnace with the temperature of 2000 to 2500 DEG C and melting; b, carrying out thread throwing and fiber forming on the molten mixture through a thread throwing machine, wherein a thread throwing speed is 8000 to 10000r / min; c, conveying obtained fibers into a bulk material; forming a layer spreading structure through a conveyor belt; d, carrying out double-faced needling on bulk cotton with the layer spreading structure, so as to form original ceramic fibers with a certain tensile force; e, determining the nature of the original ceramic fibers through a high-temperature box with the height of more than ten meters; f, cutting and packaging the ceramic fibers with the determined nature. The preparation method of the ceramic fibers has the advantages that the prepared ceramic fibers have light weight and the whole quality of an industrial kiln furnace can be effectively reduced; the chemical stability is good and the chemical corrosion resisting capability is relatively strong.

Owner:CHUZHOU SANHE FIBER MFG

Method for manufacturing flocking cold-rolled printing steel plate

InactiveCN103722855AExcellent sound absorption and noise reduction performanceReduce wind and other noiseLamination ancillary operationsLaminationSteel platesDew

The invention relates to a method for manufacturing a building plate which resists corrosion and weathering, prevents dew from dropping, and has a certain heat-preservation performance, in particular to a method for manufacturing a flocking cold-rolled printing steel plate. The manufacturing method comprises the following steps of material selection, plate surface pretreatment, drying treatment, printing, adhesive and epoxy zinc-rich paint mixture coating, electrostatic flocking, drying program and inspection and storage. The method is characterized in that villi for electrostatic flocking are aramid villi, and a plate surface treating agent is a HAS656 passivator. The product obtained through the method has good fireproofing properties. After testing, the product is certified by the fireproofing grade B-1 of national building materials, is completely environment-friendly and no-pollution, and is also certified by environmental-friendliness. The product can be directly used in a room, has strong upright pile feeling, is bright in color and gentle in hand feel, and has sound-absorbing and light-absorbing performances and a good light diffuse reflection effect.

Owner:WUXI XINDAZHONG STEEL SHEET

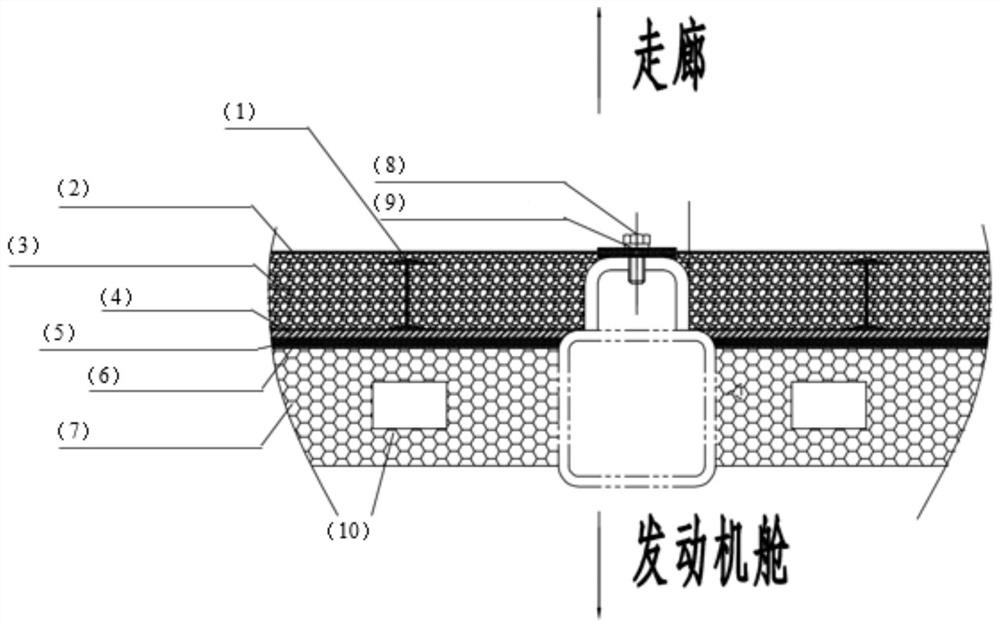

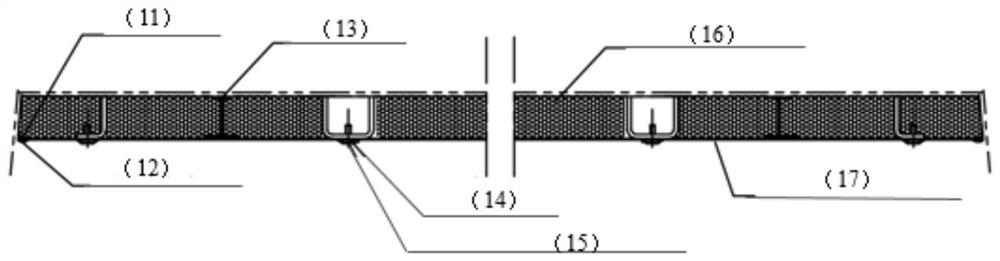

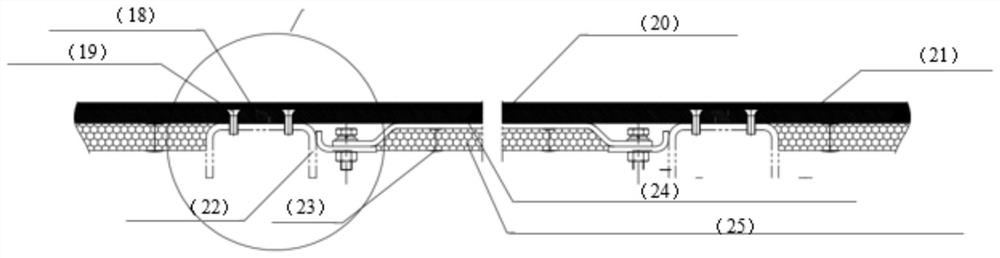

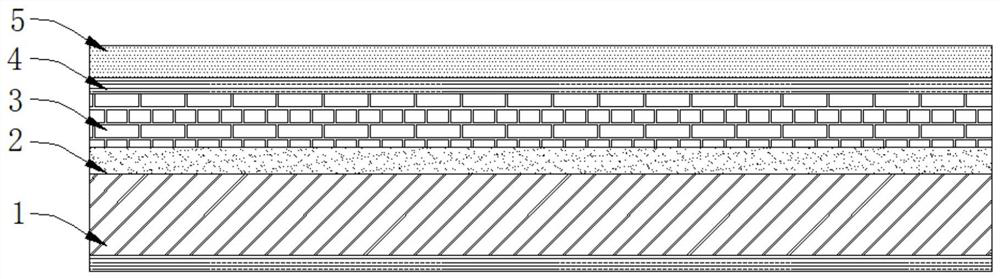

Noise reduction interior trim system for special vehicle cab

PendingCN112550180AIncrease the amount of noise reductionImprove reliabilitySuperstructure subunitsEngineeringVehicle driving

The invention relates to a noise reduction interior system for a special vehicle cab. The system comprises any one or a combination of more of a sound absorption interior structure, a high-strength multi-layer composite floor structure and an engine compartment sound absorption and insulation structure. The roof sound absorption structure sequentially comprises a first sound absorption material and a first protective surface layer from inside to outside, and the first sound absorption material is attached to the roof. The high-strength multi-layer composite floor structure sequentially comprises floor leather, a damping composite sandwich structure and a second sound absorption material from top to bottom, and the second sound absorption material is attached to the ground. The engine compartment sound absorption and insulation structure sequentially comprises a third sound absorption material, a damping steel plate, a fourth sound absorption material and a second protective surface layer from inside to outside, the third sound absorption material is attached to the inner side of the compartment plate, and the fourth sound absorption material is attached to the outer side of the compartment plate. Compared with the prior art, the noise reduction frequency range is wide, and the application range is wide.

Owner:SHANGHAI UNIV OF ENG SCI

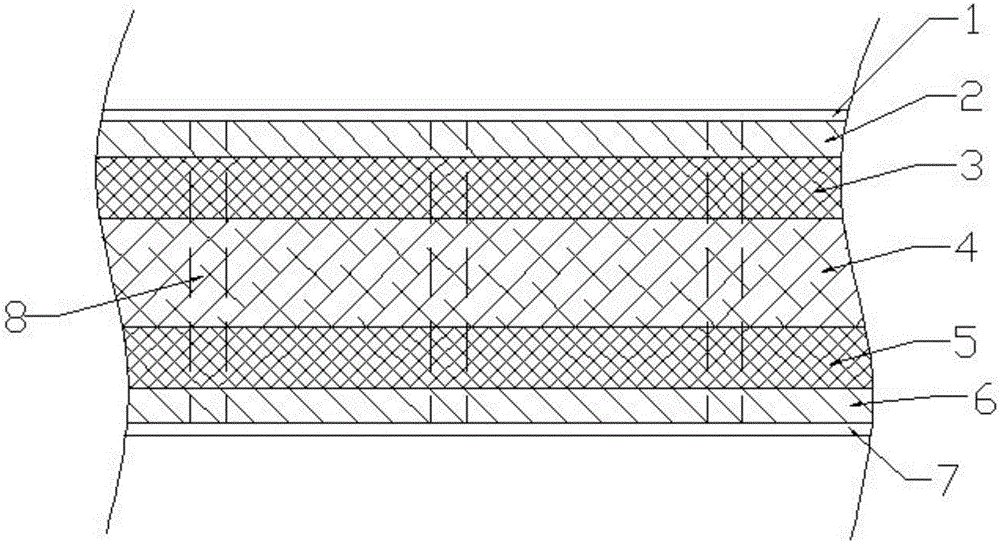

Sound-insulating aluminum plastic composite plate with high heat-dissipating property

InactiveCN106739287AWith compressive strengthExcellent sound absorption and noise reduction performanceCovering/liningsSynthetic resin layered productsHeat conductingAluminum silicate

The invention relates to building materials, in particular to a sound-insulating aluminum plastic composite plate with high heat-dissipating property. The section structure comprises an ETFE (ethylene-tetrafluoroethylene copolymer) coating, an aluminum alloy plate upper layer, a polyethylene (PE) plate upper layer, an aluminum silicate fiberboard layer, a PE plate lower layer, an aluminum alloy lower layer, and a PVDF (poly-vinylidene difluoride) coating sequentially from outside to inside, wherein the aluminum alloy upper layer, the PE plate upper layer, the aluminum silicate fiberboard layer, the PE plate lower layer and the aluminum alloy plate lower layer are bonded; an aluminum heat-conducting column is fixedly connected between the aluminum alloy plate upper layer and the aluminum alloy plate lower layer; the aluminum heat-conducting column runs through the PE plate upper layer, the aluminum silicate fiberboard layer and the PE plate lower layer. The sound-insulating aluminum plastic composite plate with high heat-dissipating property has excellent heat-conducting capability, has a certain sound-insulating and sound-absorbing function and is suitable for buildings such as machine rooms to use.

Owner:重庆优优新材料有限公司

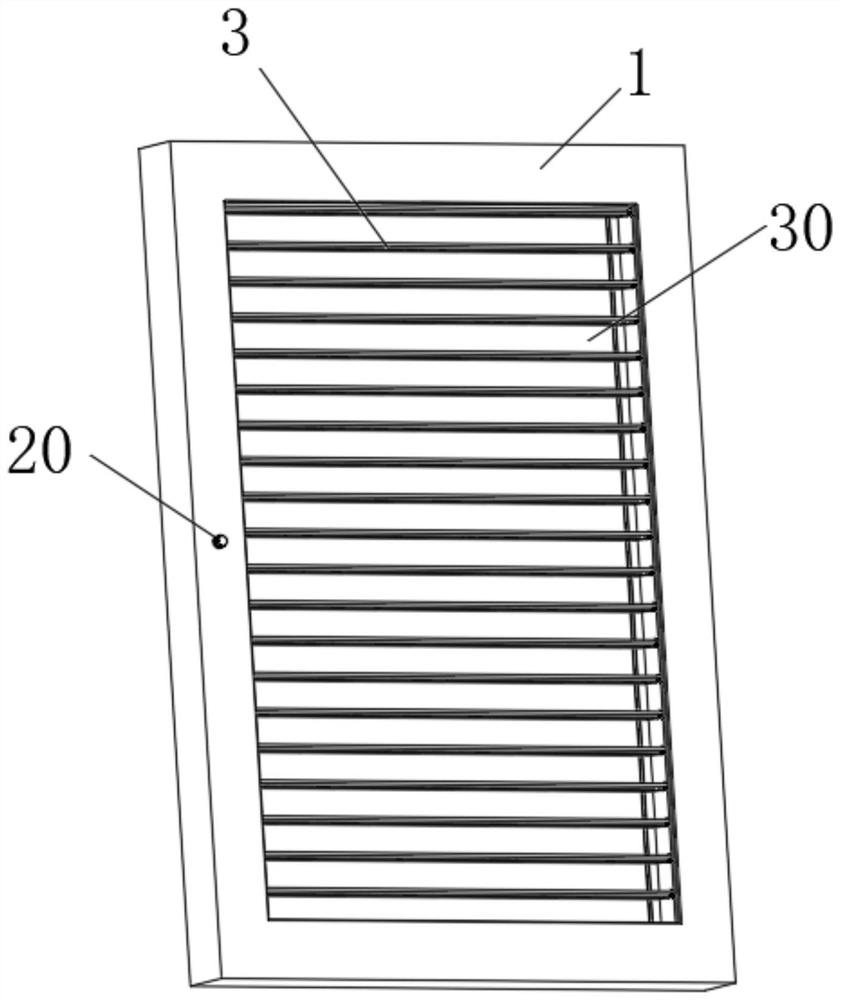

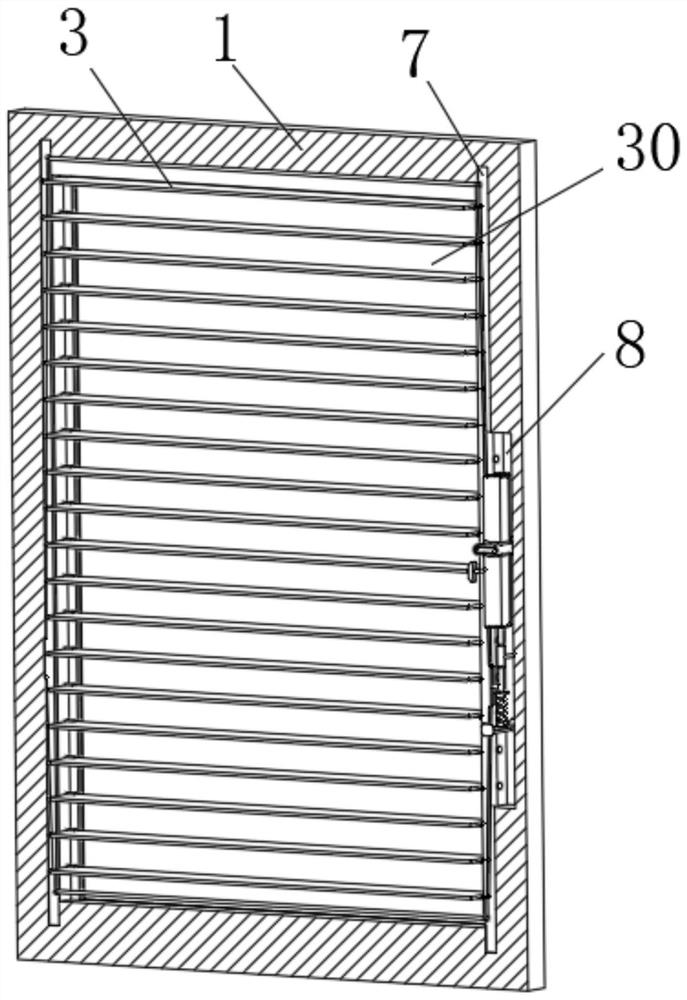

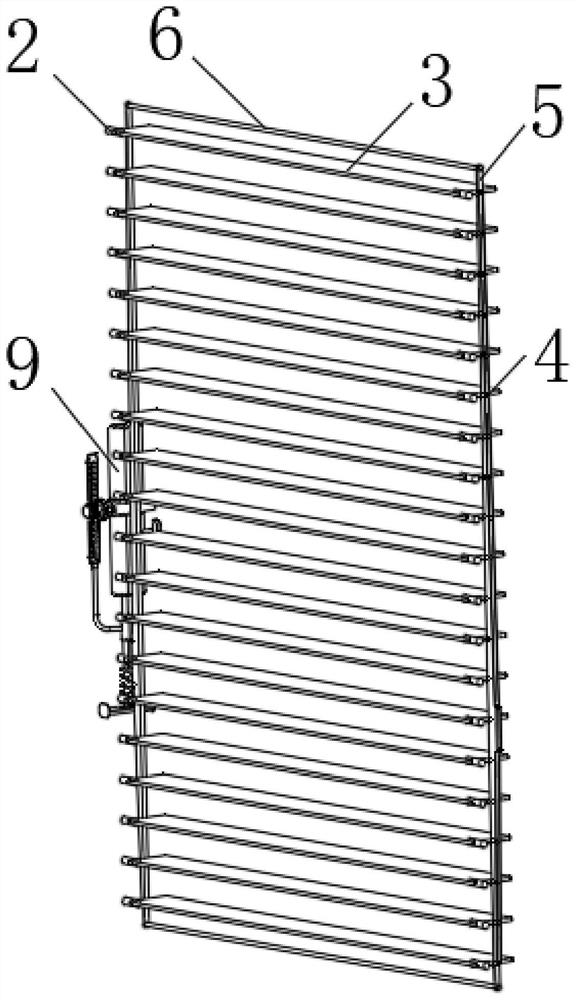

Energy-saving green building structure capable of preventing heat loss and use method of energy-saving green building structure

ActiveCN114809893AAvoid bendingImprove support strengthWallsLight protection screensElectrical energy consumptionHeat losses

The invention provides an energy-saving green building structure capable of preventing heat loss and a using method thereof, and belongs to the technical field of buildings. Comprising a curtain wall support, two pieces of glass are symmetrically and fixedly installed on the inner side of the curtain wall support with respect to the center of the curtain wall support, a shielding part, a first adjusting part, a second adjusting part and an automatic limiting part which are connected are installed in the curtain wall support, and the shielding part is located between the two pieces of glass. By arranging the first adjusting component and the shielding component, the indoor heat loss is reduced, the working load of an indoor air conditioner is reduced, the indoor electric energy consumption is saved, the adverse effect of external strong light on the indoor space is avoided, meanwhile, the adjusting mode is simple, no electric appliance element needs to be arranged, the manufacturing cost is reduced, and the practicability is high. And automatic adjustment can be carried out according to the outdoor temperature, the convenience in daily use is improved, and the adjustment convenience of the shielding component is further enhanced by arranging a second adjustment component.

Owner:深圳市雍钒浩建设有限公司

Preparation method of composite foamed building wall thermal-insulation material

The invention relates to a preparation method of a composite foamed building wall thermal-insulation material. The invention aims to provide a thermal-insulation material which has the advantages of excellent thermal-insulation property, favorable heat-insulating property (low heat conductivity coefficient) and favorable noise absorption and reduction properties. The method provided by the invention has the advantages of simple technical process and low manufacturing cost. The technical scheme is as follows: the manufacturing method comprises the following steps: 1) preparing hydrophobic expanded perlite; 2) preparing a wood liquefied expandable resin; and 3) preparing the composite foamed building wall thermal-insulation material.

Owner:刘方成

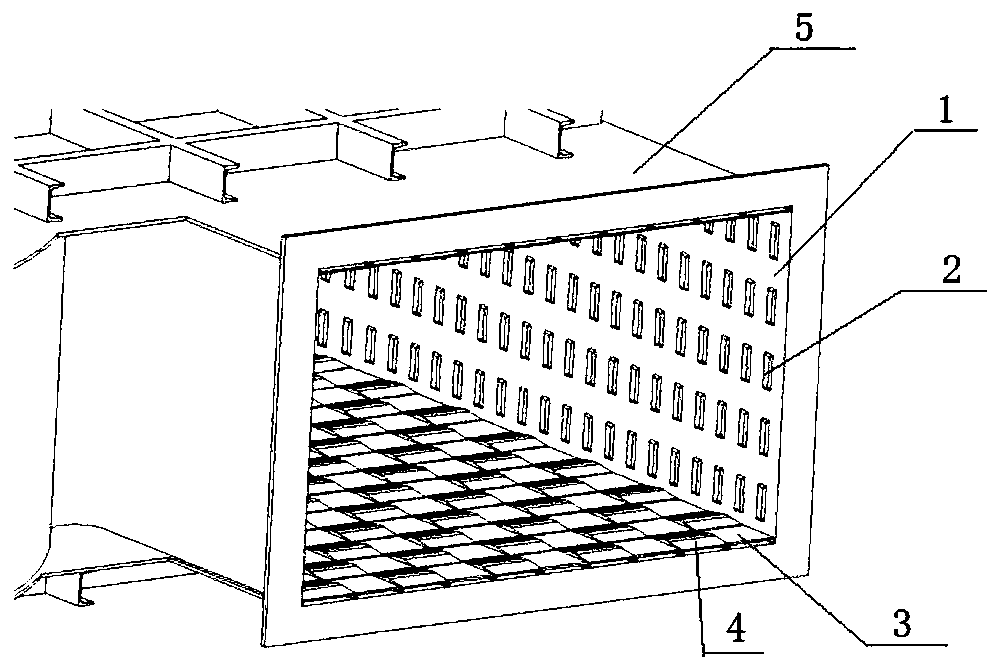

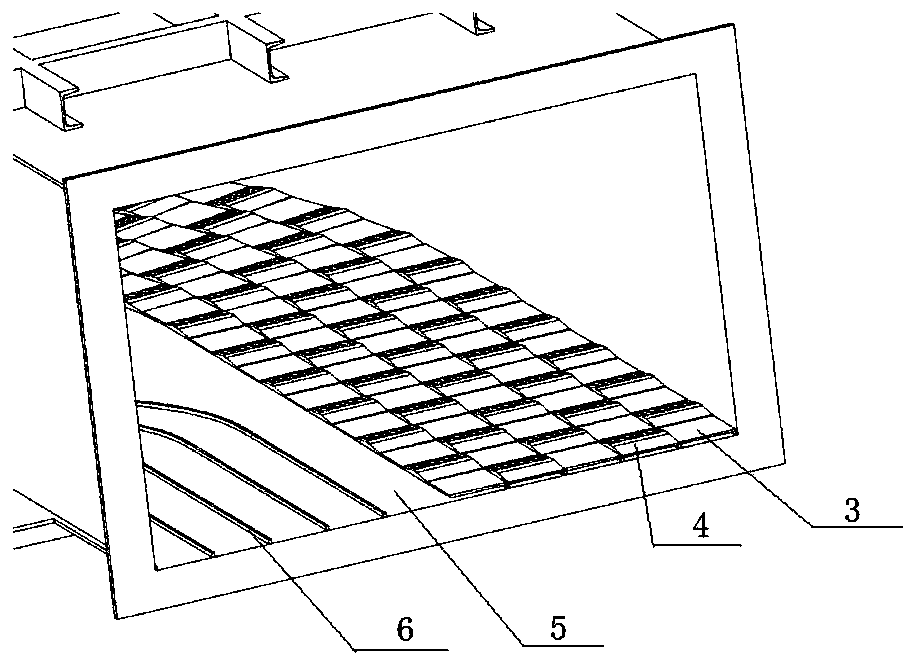

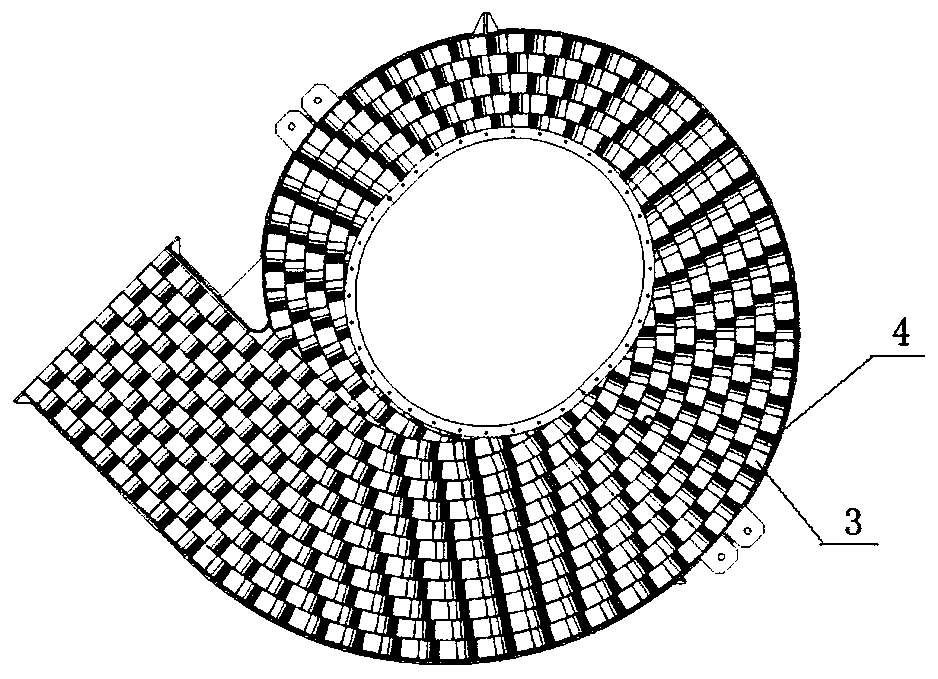

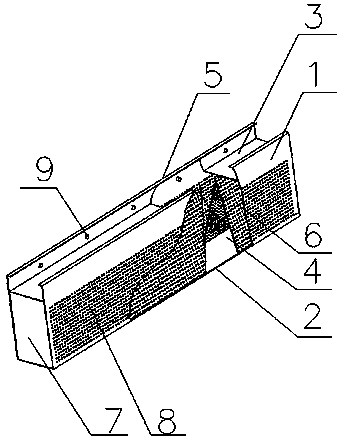

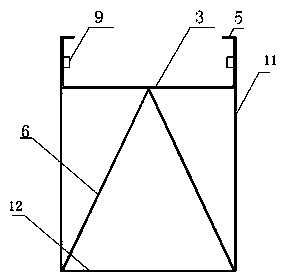

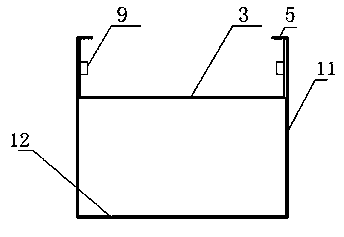

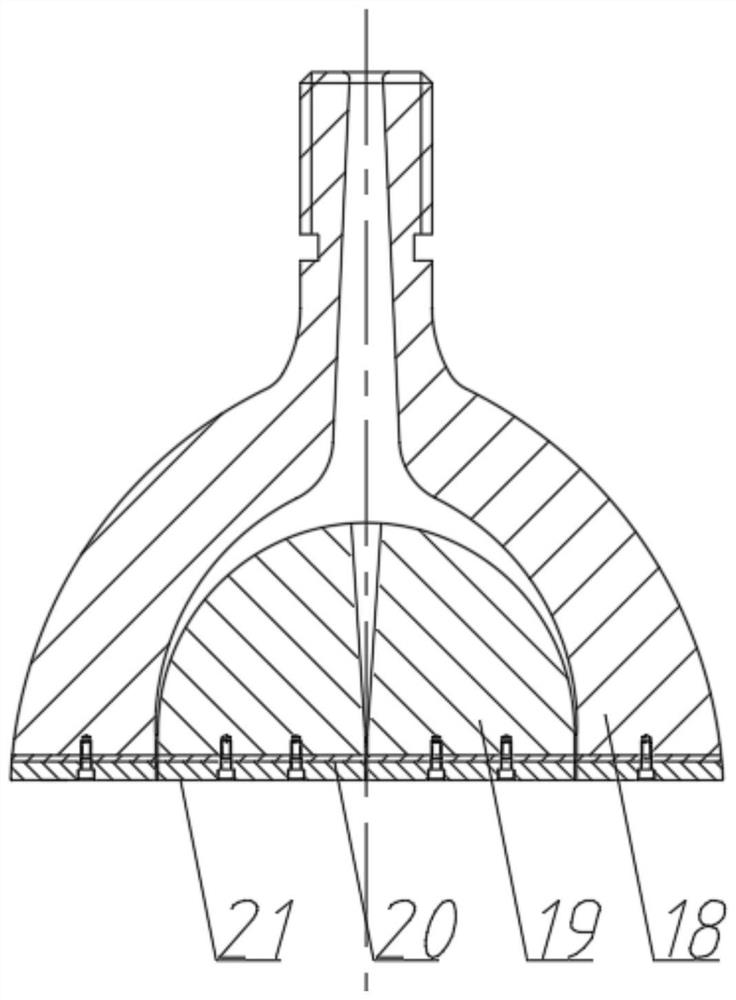

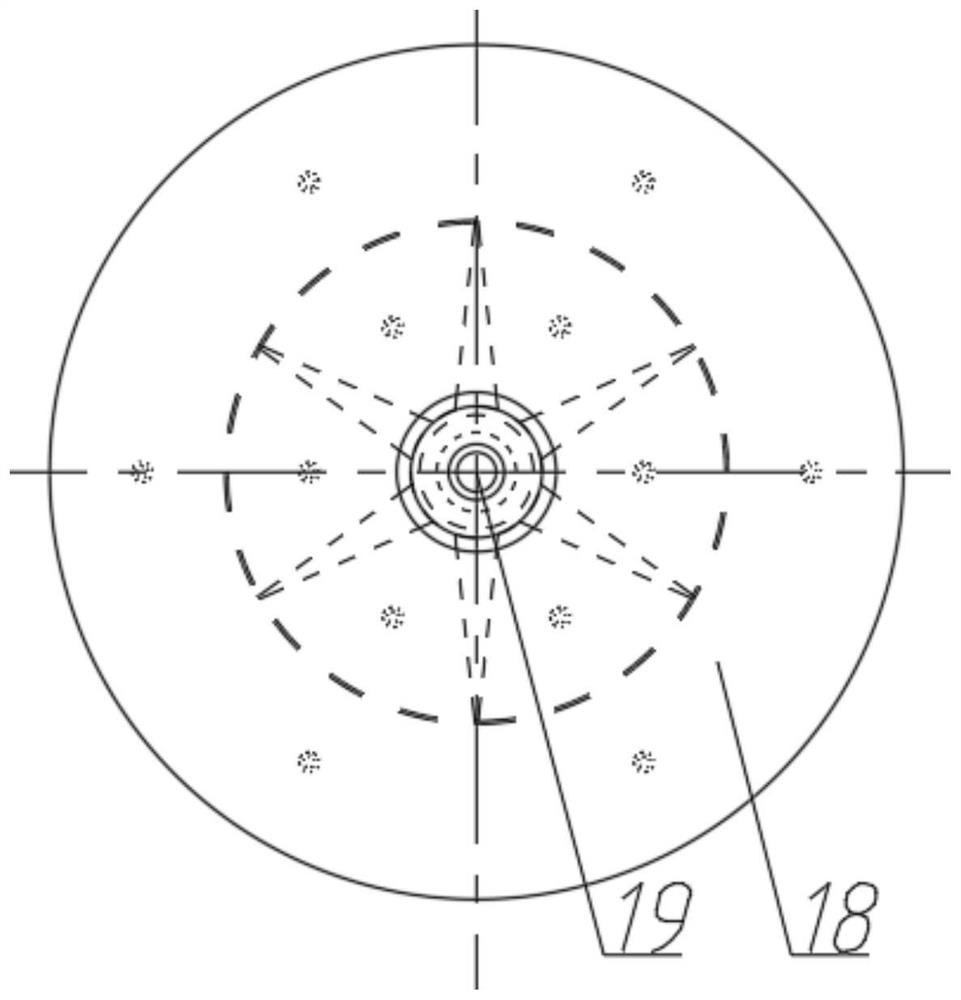

Sound absorption structure of volute and volute air inlet of noise reduction centrifugal fan

PendingCN111188795AIt has the function of vibration reduction and sound insulationImprove sound absorptionPump componentsPumpsLow noiseEngineering

The invention relates to a sound absorption structure of a volute and volute air inlet of a noise reduction centrifugal fan. According to the sound absorption structure, a sound absorption plate is fixed to a volute side plate through a mounting plate, and a silencing cavity is formed between the sound absorption plate and the volute side plate; a plurality of web sound absorption plates are uniformly arranged on a volute web in the transverse and longitudinal directions; and a plurality of arc-shaped flow guide blocks which are obliquely arranged are arranged on the arc-shaped side wall of avolute air inlet. Compared with the prior art, the sound absorption structure has the following beneficial effects that the design of a spatial sound absorption structure is adopted, so that the effective sound absorption area is greatly increased, and the noise reduction effect is good; the structure is safe and reliable, and repeated maintenance and replacement are not needed in the service cycle; a sound absorption material has small influence on the performance of the fan, and the influence on the fan efficiency is less than 1%; and the sound absorption structure can be widely applied to ventilation and air supply industries with higher requirements on environmental comfort (low noise).

Owner:ANSHAN GANGFENG FAN

Heat-insulating carbon fiber soft felt and preparation method thereof

ActiveCN108773123AHomogeneous properties in all directionsExtended service lifeSynthetic resin layered productsLaminationFiberPolyester

The invention specifically relates to a heat-insulating carbon fiber soft felt and a preparation method thereof, belonging to the field of novel materials. The heat-insulating carbon fiber soft felt comprises a surface layer and a composite web layer, wherein a ratio of the thickness of the surface layer to the thickness of the composite web layer is 1: (1.8-3), and the composite web layer is prepared from 15 to 25 parts by weight of polyester fibers and 30 to 45 parts by weight of carbon fibers.

Owner:江苏庞捷实业发展有限公司

Metal ultramicropore sound absorption tab

InactiveCN103643747ASound absorption frequency bandwidthImprove noise reductionCovering/liningsSound proofingEngineeringMetal

The invention discloses a metal ultramicropore sound absorption tab. The sound absorption tab comprises side panels and a top support plate, wherein ultramicropores are formed in the side panels; an inner cavity is formed by the side panels and the top support plate; partition boards are arranged in the inner cavity; clamping edges are formed on the side panels, and sealing cover plates are arranged at two ends of the inner cavity; the appearance shape of the section of the sound absorption tab can be rectangular, semi-circular-arc or wedged; and the partition boards with different shapes are arranged in the cavity as required, and the sealing cover plates are arranged at two ends of each sound absorption tab. The metal ultramicropore sound absorption tab is an acoustical decorative material, has excellent acoustic performance and good decorative effect and can meet the sound absorption, noise reducing and decoration requirements of various buildings.

Owner:NANJING CHANGRONG ACOUSTIC INC

Sound-absorption and noise-reduction material and preparation method thereof

InactiveCN109135018APromote degradationImprove low temperature performanceFoaming agentThermal insulation

The invention relates to a sound-absorption and noise-reduction material and a preparation method thereof. The sound-absorption and noise-reduction material comprises, by weight, 50-60 parts of PE resin, 6-10 parts of graphene, 12-16 parts of polypropylene fibers, 1-3 parts of stabilizer and 5-9 parts of foaming agent. The sound-absorption and noise-reduction material is prepared by sequentially subjecting the materials above to ball mill, foaming, extrusion granulation and the like. The sound-absorption and noise-reduction material and the preparation method thereof have the advantages that the PE resin can increase the elasticity of the sound-absorption and noise-reduction material to a certain degree, and the polypropylene fibers increase the hardness, wear resistance, corrosion resistance, tensile strength and ductility of the sound-absorption and noise-reduction material and allow the sound-absorption and noise-reduction material to be easily applied to construction; the sound-absorption and noise-reduction material is good in sound absorption and noise reduction performance and good in thermal insulation performance, and the whole wall face after construction is light and less prone to scaling; the preparation method is simple, easy to operate and low in cost.

Owner:安徽微威环保科技有限公司

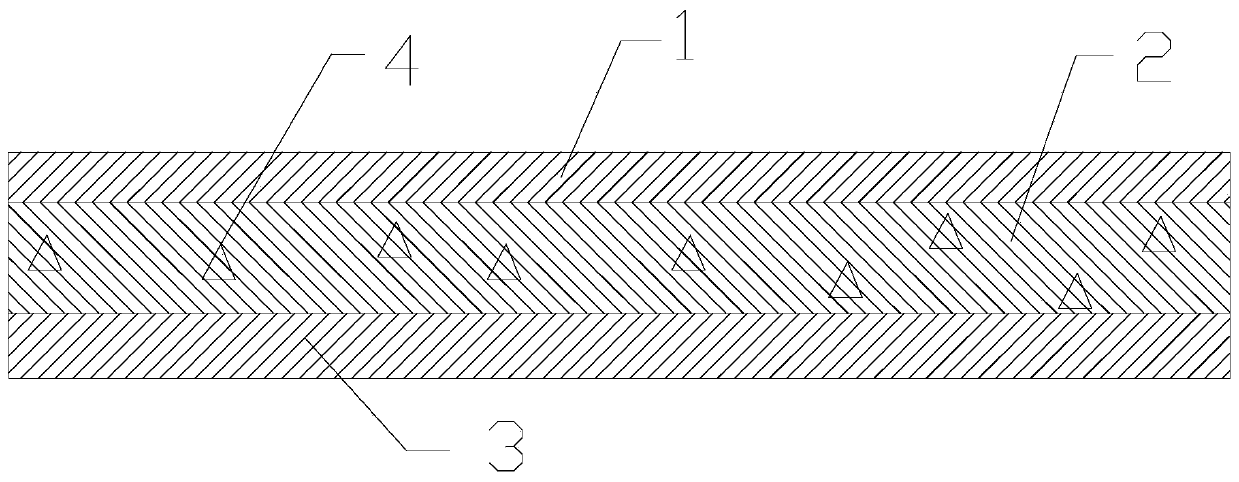

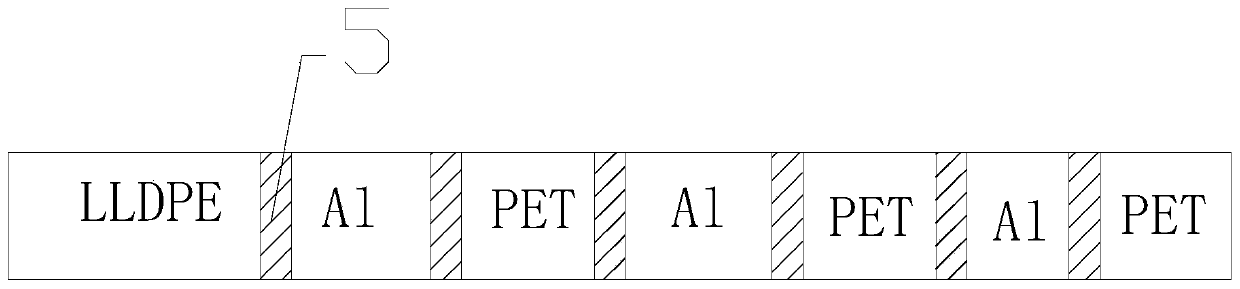

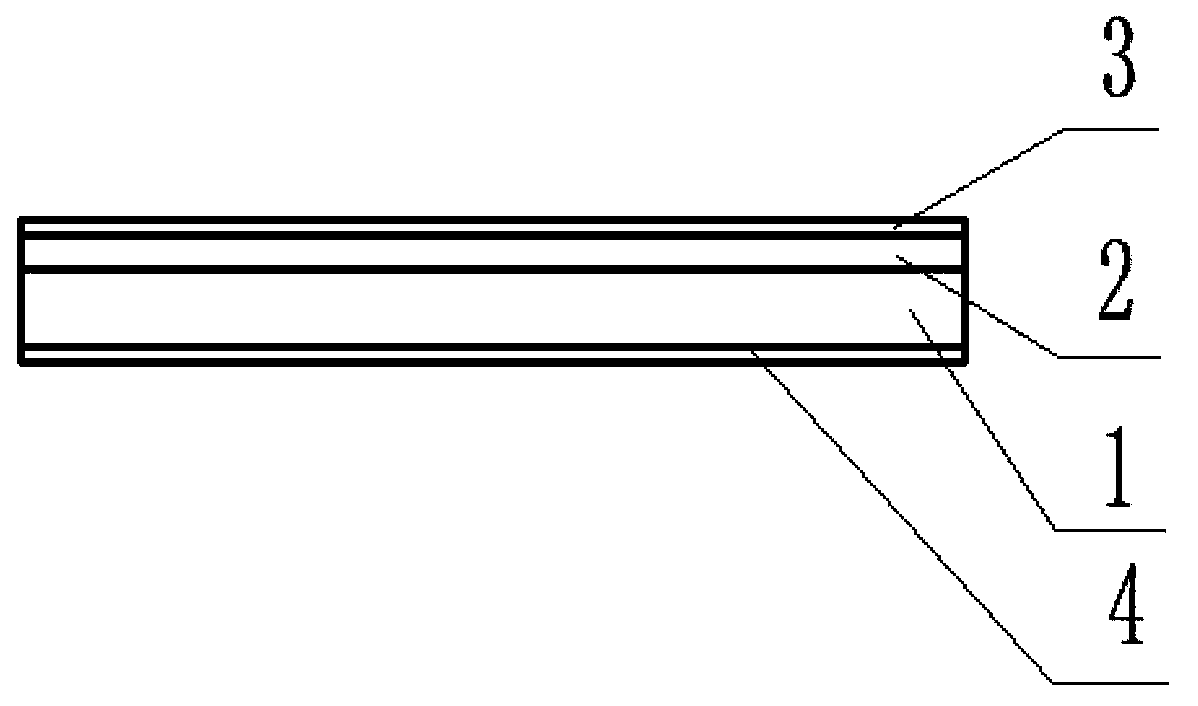

Nanometer flame-retardant soundproof adiabatic material used for aerospace

ActiveCN110744889AGuaranteed long-term useNot oxidizedSynthetic resin layered productsGlass/slag layered productsAviationMultilayer membrane

The invention provides a nanometer flame-retardant soundproof adiabatic material used for aerospace. The nanometer flame-retardant soundproof adiabatic material used for aerospace comprises a surfacelayer, a middle layer and a bottom layer, wherein the middle layer is porous material fibers, the surface layer is a mirror aluminium foil covered with nanometer SiO2, and the bottom layer is an aluminium-plastic compound material. The middle of the adiabatic material is of a porous material fiber structure, and glass fibers used for aerospace and astronavigation are adopted, so that gas convection is effectively reduced, and the nanometer flame-retardant soundproof adiabatic material used for aerospace has excellent thermal-insulation performance and sound-absorption noise-reduction performance; the bottom layer is the aluminium-plastic compound material, is formed by compounding multiple layers of films, and has an excellent thermal-insulation effect; and the surface layer is the mirroraluminium foil covered with the nanometer SiO2, so that the anti-oxidation capability and the corrosion-resistant capability of the aluminium foil are improved, the reflectivity of the aluminium foilis not affected, and the fact that the material is used in a severe environment for a long term, and is not oxidized or corroded can be guaranteed.

Owner:SUZHOU JUNYUE NEW MATERIAL TECH

Method for manufacturing flocking aluminium alloy spraying decoration plate

InactiveCN103510673AExcellent sound absorption and noise reduction performanceReduce wind and other noiseCovering/liningsMetal layered productsWeather resistanceBuilding material

The invention relates to a method for manufacturing a building plate which has corrosion resistance and weather resistance, prevents dew from dropping, has certain heat insulation performance, in particular to a method for manufacturing a flocking aluminium alloy spraying decoration plate. The manufacturing method comprises the following steps of material selecting, plate surface pretreatment, drying treatment, tackiness agent coating, electrostatic flocking, pattern spraying, process drying, checking and putting in storage. The method for manufacturing the flocking aluminium alloy spraying decoration plate is characterized in that the flocking of the electrostatic flocking is Dacron flocking, and a plate surface treatment agent is GR934 passivant. A product obtained through the method has good fireproof performance and passes the China building material fireproofing grade B-1 certification after detection, complete environmental protection is achieved, pollution is avoided, environmental certification is passed, the product can be directly used indoors, and the effects that strong upright flocking sense is achieved, colors are bright and attractive, hand feeling is soft, and the sound absorption and light absorption performance are excellent are achieved.

Owner:WUXI XINDAZHONG STEEL SHEET

Thermal insulation sound-absorption and noise-reduction TPU (Thermoplastic polyurethanes) thin film and preparation method thereof

InactiveCN106497013AExcellent sound absorption and noise reduction performanceImprove insulation effectEpoxyAntioxidant

The invention provides a thermal insulation sound-absorption and noise-reduction TPU (Thermoplastic polyurethanes) thin film and a preparation method thereof. The TPU thin film is prepared from the following raw materials in parts by weight: 60 to 70 parts of TPU particles, 15 to 20 parts of polycarbodiimide, 10 to 30 parts of epoxy resin, 10 to 15 parts of perlite, 10 to 20 parts of ceramic particles and 5 to 10 parts of antioxidant. The prepared TPU thin film is good in thermal insulation performance, sound-absorption and noise-reduction performance and mechanical performance and wide in application prospect.

Owner:WUXI MINGSHENG TEXTILE MACHINERY

Sound insulation construction steel plate

InactiveCN103866901AImprove sound insulationColorfulCovering/liningsBuilding componentsFiberPolyester

The invention provides a sound insulation construction steel plate, belongs to the technical field of construction or decoration materials, and solves the problems of poor sound insulation effect and the like of stainless steel sheet plates in the prior art. The sound insulation construction stainless steel plate comprises a substrate made of a stainless steel material, one side of the substrate is sequentially provided with a sound insulation layer and a resin coating layer, the other side of the substrate is provided with a polyester fiber sound-absorbing decorative board. The sound insulation construction stainless steel plate can not only regulate the indoor sound mixing effect to obtain clear and full audio experience, but also has good sound absorption and noise reduction performances, and can effectively prevent the spread of sound, and on the other hand, the resin coating layer and the polyester fiber sound-absorbing decorative board can make the stainless steel plate color rich and diverse.

Owner:TIANJIN BINHAI NEW DISTRICT DAGANG TIANCHENG METAL DECORATION

A kind of preparation method of composite foam building wall insulation material

The invention relates to a preparation method of a composite foamed building wall thermal-insulation material. The invention aims to provide a thermal-insulation material which has the advantages of excellent thermal-insulation property, favorable heat-insulating property (low heat conductivity coefficient) and favorable noise absorption and reduction properties. The method provided by the invention has the advantages of simple technical process and low manufacturing cost. The technical scheme is as follows: the manufacturing method comprises the following steps: 1) preparing hydrophobic expanded perlite; 2) preparing a wood liquefied expandable resin; and 3) preparing the composite foamed building wall thermal-insulation material.

Owner:刘方成

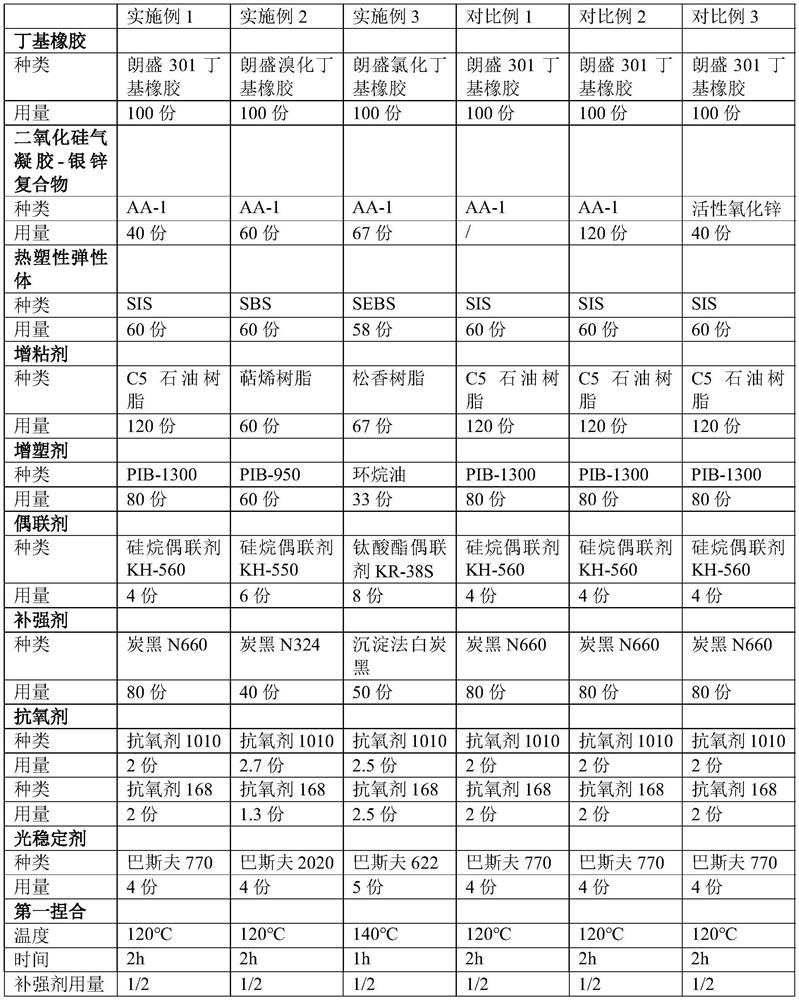

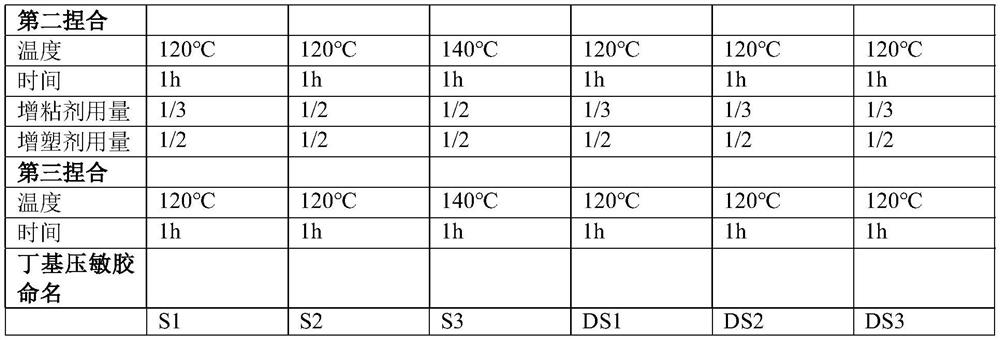

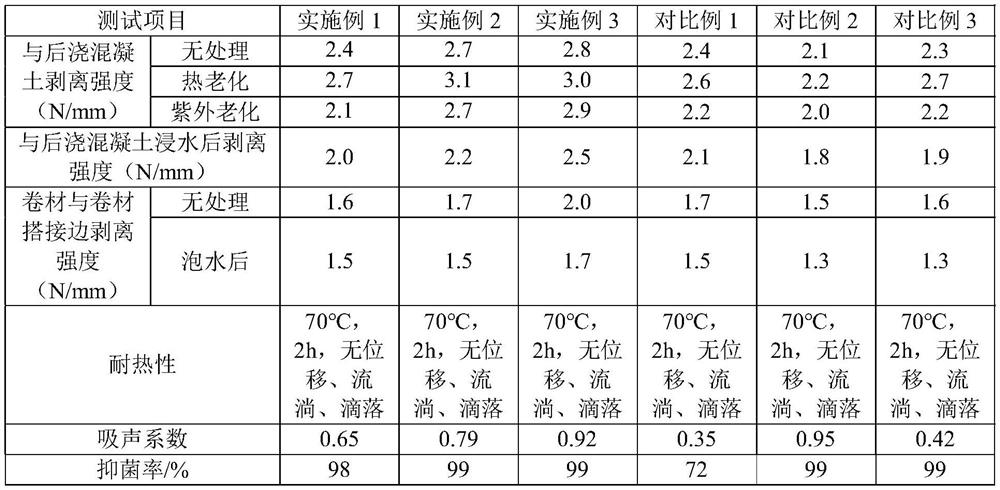

Butyl pressure-sensitive adhesive as well as preparation method and application thereof

ActiveCN114250046AExcellent sound absorption and noise reduction performanceImprove mildew resistanceNon-macromolecular adhesive additivesInsulation improvementElastomerPolymer science

The invention relates to the field of building waterproof materials, in particular to a butyl pressure-sensitive adhesive and a preparation method and application thereof.The method comprises the steps that 1, butyl rubber, a silicon dioxide aerogel-silver zinc compound, a thermoplastic elastomer, an antioxidant, a light stabilizer and a part of a reinforcing agent are subjected to a first contact reaction, and a product I is obtained; (2) carrying out a second contact reaction on the product I, a part of a tackifier, a part of a plasticizer and the rest of a reinforcing agent to obtain a product II; and (3) carrying out third contact reaction on the product II, a coupling agent, the rest tackifier and the rest plasticizer to obtain the butyl pressure-sensitive adhesive. The butyl pressure-sensitive adhesive provided by the invention has relatively high mildew-proof and noise-reducing properties, and meanwhile, can keep relatively good cohesive strength.

Owner:KESHUN WATERPROOF TECH CO LTD

Method for manufacturing flocked hot-dip galvanized printed board

InactiveCN103721914AWith heat insulationExcellent sound absorption and noise reduction performanceLamination ancillary operationsPretreated surfacesThermal insulationFireproofing

The invention relates to a method for manufacturing a building board which has corrosion resistance and weather resistance, can prevent dew from dripping and has certain thermal insulation performance, in particular to a method for manufacturing a flocked hot-dip galvanized printed board. The method includes the following steps: material selection, board surface pretreatment, drying treatment, printing, spreading of an adhesive and epoxy zinc-rich paint mixture, electrostatic flocking, drying, checking and warehousing; the method is characterized in that dacron flock is adopted in the electrostatic flocking step, and the GR934 passivator is adopted as a board surface treating agent. The board obtained through the method has excellent fire resistance; as is shown in detection, the board passes the National Building Material Fireproofing Grade B-1 Certification and is environmentally friendly and free of pollution; the board also passes the Environmental Certification, can be directly used indoors and has the advantages of being strong in upright-flock sense, bright in color, capable of achieving comfortable touch and good in sound absorption performance, light absorption performance and light diffuse reflection effect.

Owner:WUXI XINDAZHONG STEEL SHEET

Inorganic fibre fireproof insulation board

The invention discloses an inorganic fibre fireproof insulation board which is prepared by the following steps: preparing a wet blank by using water and the following raw materials according to weight part ratio: an inorganic fibre, an organic binding agent and a moisture repellent with weight part ratio of 100: 2-10: 0.1-1; and then uniformly coating an interface treatment agent on the wet blank, wherein the interface treatment agent is formed by modulating water with the following materials: a cement, a styrene-acrylic emulsion, an alkali-swelling thickening agent and a water repellent in the weight part ratio of 30-60: 40-70: 0.05-0.15: 2-5, and finally drying the wet blank to obtain the finished product. The inorganic fibre fireproof insulation board is has the characteristics of low thermal conductivity, non-rigid material, good toughness, low water absorbing rate, low thermal capacity, excellent thermal stability and hot shock resistance, high compression strength, high tensile strength, long service life, excellent toughness, wind erosion resisting capability, excellent machining property and excellent sound-absorbing and noise-reducing properties.

Owner:重庆龙者伯尔高新材料有限公司

Preparation method of building heat insulation material

InactiveCN109354479AExcellent sound absorption and noise reduction performanceHigh porosityCeramicwareCross-linkChemistry

The invention provides a preparation method of a building heat insulation material. The method includes the following steps that S1, Kiryu sand, vermiculite, kieselguhr and medical stone are mixed evenly, calcined and cooled to obtain a mixture, and aqueous ammonia, ethanol, ethyl orthosilicate and the mixture are mixed and stirred evenly to obtain a hydrophobically modified mixture; S2, straw powder, a phenolic compound and a catalyst are mixed by weight part and react to obtain a straw liquefaction liquid; S3, a starch solution, water, sodium polyacrylate and sodium formaldehyde sulfoxylateare mixed to obtain a first mixed material; S4, acrylic acid, N,N,N',N',N''-pentamethyldiethylenetriamine, polyvinyl alcohol, the hydrophobically modified mixture and the first mixed material are mixed evenly to obtain a second mixed material; S5, the straw liquefaction liquid, the second mixed material, a cross-linking agent, a curing agent, a foaming agent and an emulsifying agent react to obtain the heat insulation material. The heat insulation material can achieve an excellent heat insulation and sound insulation effect.

Owner:刘兴海

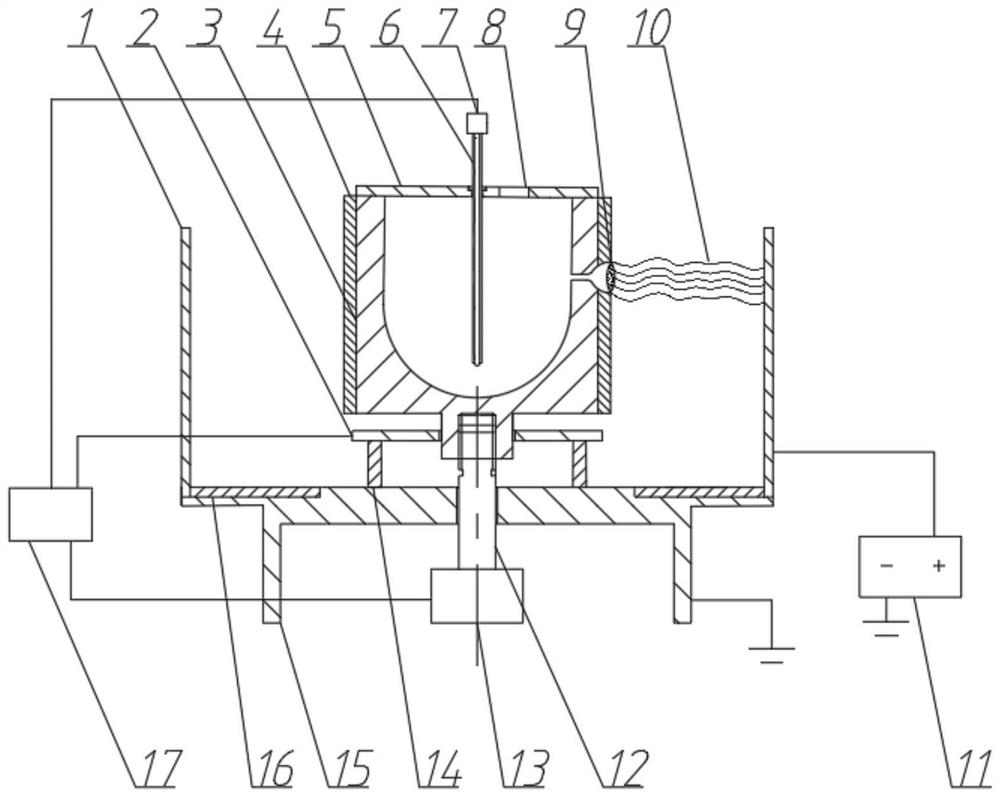

Method for preparing metal micro-nano fibers through centrifugal melt electrostatic spinning

ActiveCN114850422ANot easy to stickGood electromagnetic induction abilityTextile/flexible product manufactureMetal fiberSpinning

The invention belongs to the field of electrostatic spinning, and particularly relates to a novel method for preparing metal micro-nanofibers through centrifugal melt electrostatic spinning. The method comprises the following steps: 1) putting a pure metal block with a certain mass into a customized crucible, covering an end cover, installing a thermocouple, starting a power supply of a comprehensive console, turning on an electromagnetic induction coil heating switch, and heating the customized crucible until the metal block is completely melted; (2) starting a high-voltage power supply and a high-speed motor, driving the customized crucible to rotate under the action of a rotating shaft so as to provide centrifugal force, and enabling the metal melt in the customized crucible to uniformly fall on a collecting plate in a fiber form through a porous spray head under the dual action of the centrifugal force and high-voltage electrostatic force, and the obtained long metal fiber has the advantages of small fiber diameter, wide application range and the like. According to the method, metal fiber preparation is simple and convenient, the production cost is low, the spinning efficiency is high, and thinner and longer micro-nano-scale metal fibers can be produced.

Owner:BEIJING UNIV OF CHEM TECH

TPU (thermoplastic polyurethane) film with thermal insulation, sound insulation and noise reduction properties and preparation method of TPU film

InactiveCN106433097AExcellent sound absorption and noise reduction performanceImprove performanceFlat articlesEpoxyThermal insulation

The invention provides a TPU (thermoplastic polyurethane) film with thermal insulation, sound insulation and noise reduction properties and a preparation method of the TPU film. The TPU film is prepared from, in parts by weight, 70-80 parts of TPU particles, 10-20 parts of polycarbodiimide, 20-30 parts of epoxy resin, 10-20 parts of polycarbonate, 10-15 parts of mica, 5-10 parts of ceramic particles and 1-5 parts of an antioxidant. The TPU film has good thermal insulation, sound insulation and noise reduction properties and good mechanical properties and has very broad application prospect.

Owner:WUXI MINGSHENG STRONG BLOWER

Method for manufacturing flocking hot galvanizing spraying decoration plate

InactiveCN103510674AExcellent sound absorption and noise reduction performanceReduce wind and other noiseLiquid surface applicatorsCovering/liningsBuilding materialWeather resistance

The invention relates to a method for manufacturing a building plate which has corrosion resistance and weather resistance, prevents dew from dropping, and has certain heat insulation performance, in particular to a method for manufacturing a flocking hot galvanizing spraying decoration plate. The manufacturing method comprises the following steps of material selecting, plate surface pretreatment, drying treatment, tackiness agent coating, electrostatic flocking, pattern spraying, process drying, checking and putting in storage. The method for manufacturing the flocking hot galvanizing spraying decoration plate is characterized in that the flocking of electrostatic flocking is acrylic fiber flocking. A plate surface treatment agent is SD986 passivant. A product obtained through the method has good fireproof performance and passes China building material fireproof grade B-1 certification after detection, complete environmental protection is achieved, pollution is avoided, environmental certification is also passed, the product can be directly used indoors, and the effects that upright flocking sense is strong, colors are bright and attractive, the hand feeling is soft, the sound absorption and light absorption performance is good, and light diffusion reflection is excellent are achieved.

Owner:WUXI XINDAZHONG STEEL SHEET

High-heat-insulation ultralow-heat-conductivity-coefficient composite heat preservation material with fireproof function

ActiveCN113719697AWith fire protection functionWith heat insulationThermal insulationPipe protection by thermal insulationFiberInsulation layer

The invention discloses a high-heat-insulation ultralow-heat-conductivity-coefficient composite heat preservation material with a fireproof function, and relates to the technical field of heat insulation composite heat preservation materials. The high-heat-insulation ultralow-heat-conductivity-coefficient composite heat preservation material comprises an aluminum silicate fiber base layer and a waterproof coating, a blocking layer is arranged on one side of the aluminum silicate fiber base layer, a heat insulation layer is arranged on the other side of the blocking layer, the waterproof coating is arranged on the other side of the heat insulation layer, and a fireproof layer is arranged on the other side of the waterproof coating. The high-heat-insulation ultralow-heat-conductivity-coefficient composite heat preservation material with the fireproof function has excellent chemical stability, heat stability, tensile strength, low heat capacity and low heat conductivity, and the situation that the overall heat insulation and fireproof effect is affected due to breakage and pull-apart of the composite heat preservation material caused by pulling of external force in the actual use process is avoided; and meanwhile, due to the excellent sound absorption and noise reduction performance, the actual use range of the composite thermal insulation material is greatly widened, and the composite thermal insulation material has the fireproof performance and the good waterproof performance.

Owner:无锡海跃船舶新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com